Method for lowering gasoline sulphur content

A technology of sulfur content and gasoline, applied in the petroleum industry, processing hydrocarbon oil, hydrotreating process, etc., can solve problems such as large energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

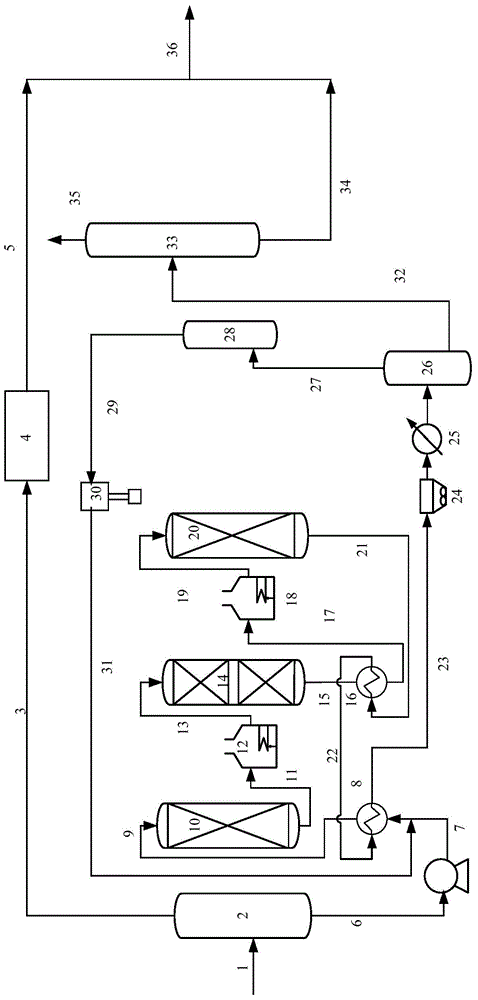

[0066] A catalytically cracked gasoline is used as feedstock F, and its feedstock properties are shown in Table 1. Raw oil F is first cut into light distillate gasoline (distillation range C 5 ~65°C) and heavy distillate gasoline (distillation range 65°C~190°C). Wherein the mass proportion of light distillate gasoline is 25%, and the mass proportion of heavy distillate gasoline is 75%. The light distillate gasoline is sweetened by alkali extraction; the heavy distillate gasoline is subjected to hydrodesulfurization treatment using the technological process in the accompanying drawings of the present invention. The light distillate gasoline after alkali extraction is mixed with the heavy distillate gasoline after hydrodesulfurization to obtain the whole distillate gasoline product.

[0067] The specific reaction conditions of the first reactor, the second reactor and the third reactor and the properties of the whole fraction gasoline product are shown in Table 3. It can be se...

Embodiment 2

[0070] A catalytically cracked gasoline is used as feedstock G, and its feedstock properties are shown in Table 1. Raw oil G is first cut into light distillate gasoline (distillation range C 5 ~58°C) and heavy distillate gasoline (distillation range 58°C~205°C). Among them, the proportion of light distillate gasoline is 25% by weight, and the proportion of heavy distillate gasoline is 75% by weight. The light distillate gasoline is sweetened by alkali extraction; the heavy distillate gasoline is subjected to hydrodesulfurization treatment using the technological process in the accompanying drawings of the present invention. The light distillate gasoline after alkali extraction is mixed with the heavy distillate gasoline after hydrodesulfurization in the product tank to obtain the whole distillate gasoline product.

[0071] The specific reaction conditions of the first reactor, the second reactor and the third reactor and the properties of the whole fraction gasoline product ...

Embodiment 3

[0073] A catalytically cracked gasoline is used as feedstock I, and its feedstock properties are shown in Table 1. Raw oil I is first cut into light distillate gasoline (distillation range C 5 ~60°C) and heavy distillate gasoline (distillation range 60°C~205°C). Among them, the proportion of light distillate gasoline is 24% by weight, and the proportion of heavy distillate gasoline is 76% by weight. The light distillate gasoline is sweetened by alkali extraction; the heavy distillate gasoline is subjected to hydrodesulfurization treatment using the technological process in the accompanying drawings of the present invention. The light distillate gasoline after alkali extraction is mixed with the heavy distillate gasoline after hydrodesulfurization in the product tank to obtain the whole distillate gasoline product.

[0074] The specific reaction conditions of the first reactor, the second reactor and the third reactor and the properties of the whole fraction gasoline product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com