Hydrogenation sweetening catalyst, preparing method and application thereof

A hydrodesulfurization and catalyst technology, which is applied in catalyst activation/preparation, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of unqualified mercaptan sulfur, high octane number loss, etc., and achieves high liquid yield, octane The effect of less loss of alkane number and high desulfanization activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Take by weighing 200g and synthesize nanometer NaZSM-5 molecular sieve by the method for embodiment 1 among CN1240193A, and 50g Al 2 o 3 powder, 5g sage powder mixed evenly, add 2.6gHNO 3 The aqueous solution, after kneading, is extruded into a cylindrical shape in an extruder, dried at 120°C overnight, and then calcined at 540°C for 4 hours. Mix the calcined catalyst with 0.4mol / L NH 4 NO 3 The aqueous solution is impregnated at room temperature for 1 to 6 hours according to the sieve liquid volume ratio of 1:3~10, poured off the exchange liquid, repeats the above operation, then washes with the same volume of deionized water until neutral, and dries at 120°C for 5 hours. Calcined at 540°C for 4 hours to obtain a nanometer HZSM-5 catalyst carrier, wherein the content of nanometer HZSM-5 is 76.9wt%, Al 2 o 3 The content is 23.1wt%. Then put the nanometer HZSM-5 in the constant temperature section of the hydrothermal treatment furnace, and treat it with ammonia con...

Embodiment 2

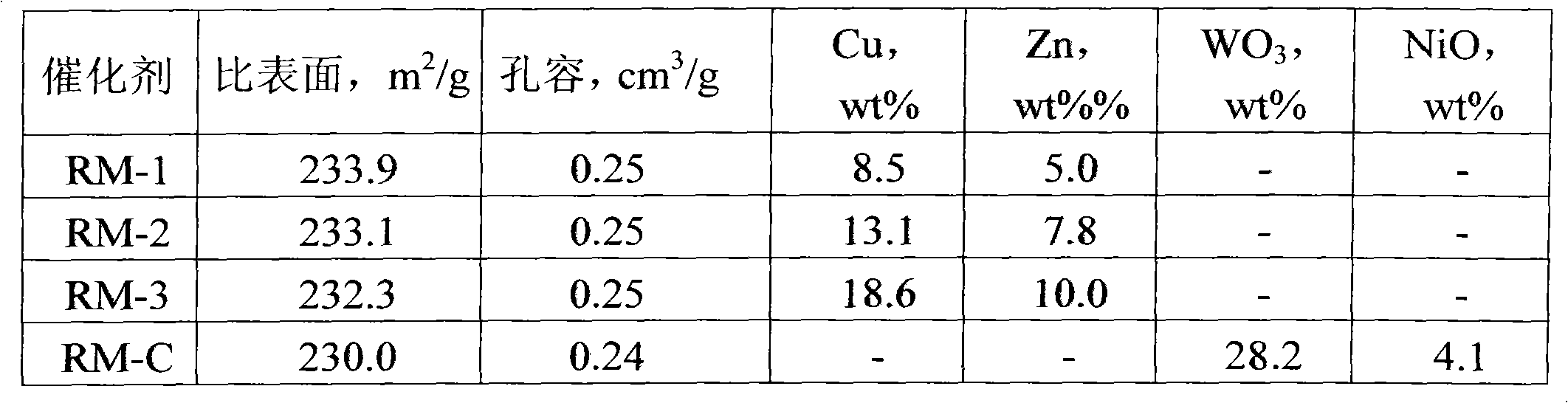

[0035] Weigh 30 grams of copper nitrate, 18 grams of zinc nitrate and 60 milliliters of deionized water, mix them, and dissolve them at 60° C. for 1 hour to obtain 65 milliliters of co-immersion solution containing copper and zinc. Take 100 grams of the water-treated HZSM-5 carrier prepared in Example 1 and put it into the co-immersion solution containing copper and zinc for 8 hours, then dry it at 120°C for 8 hours, and roast it at 500°C for 8 hours to obtain the catalyst RM- 1.

[0036] The physical properties of the RM-1 catalyst are listed in Table 1.

Embodiment 3

[0041] Weigh 45 grams of copper nitrate, 29 grams of zinc nitrate and 60 milliliters of deionized water and mix them at 60 ° C for 1 hour to obtain 65 milliliters of co-immersion solution containing copper and zinc. Take 100 grams of the water-treated HZSM prepared in Example 1 -5 Carrier, impregnated with the above impregnating solution at room temperature, dried at 120°C for 8 hours, and calcined at 500°C for 8 hours to obtain catalyst RM-2.

[0042] The physical properties of the RM-2 catalyst are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com