Preparation method of sulfur-free gasoline

A gasoline and low-quality gasoline technology, applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problems of small octane loss, large investment, complicated process, etc., and achieve low octane loss and high yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

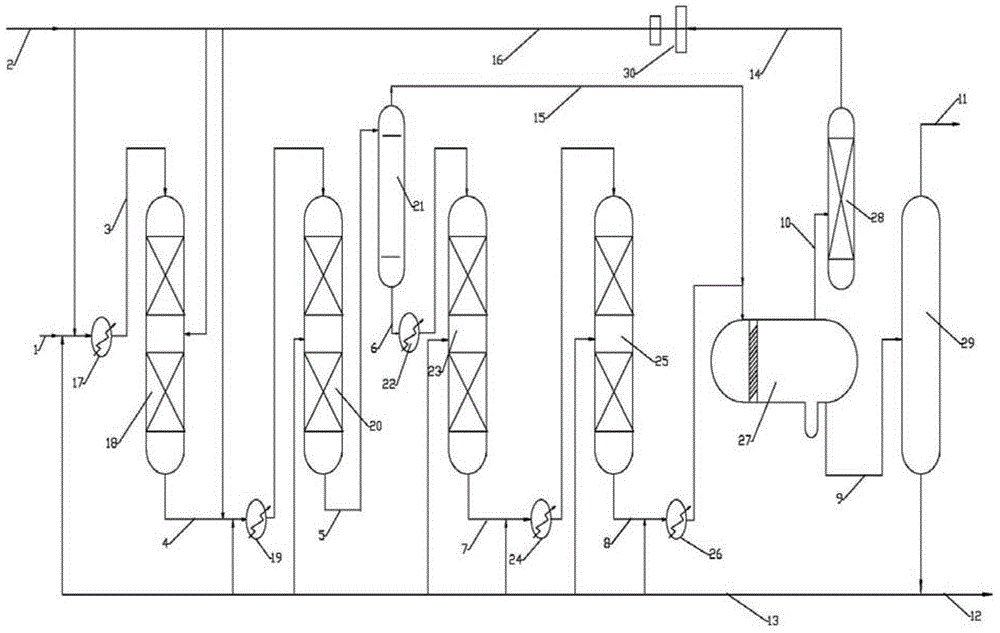

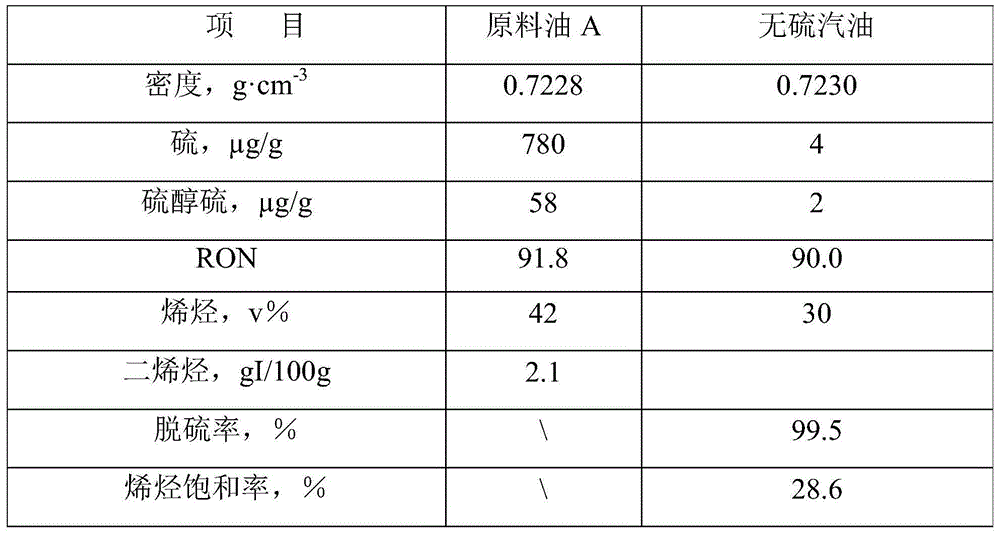

[0066] according to figure 1 The flow shown produces sulfur-free gasoline, and the selective hydrogenation catalyst HDDO-100, the first selective hydrodesulfurization catalyst HDOS-200, the second selective hydrogenation catalyst HDOS-200, and the second Two selective hydrodesulfurization catalysts HDOS-200 and hydrorefining catalyst HDMS-100, carry out selective hydrodesulfurization treatment on feedstock oil A (properties are shown in Table 1) to produce sulfur-free gasoline, properties are shown in Table 1, and equipped with H 2 S stripper.

[0067] The selective hydrogenation reaction conditions for HDDO-100 catalyst are as follows:

[0068] Temperature = 135°C

[0069] Pressure = 2.2MPa

[0070] Liquid hourly space velocity = 3h -1

[0071] Hydrogen oil volume ratio = 10v / v

[0072] The first selective hydrodesulfurization reaction conditions for the first selective hydrodesulfurization reactor HDOS-200 catalyst are as follows:

[0073] Temperature = 240°C

[007...

Embodiment 2

[0096] The selective hydrogenation catalyst HDDO-100, the first selective hydrodesulfurization catalyst HDOS-200, and the second selective hydrodesulfurization catalyst HDOS were installed in a 200ml small-scale hydrogenation evaluation device with four hydrogenation reactors in series -200 and hydrorefining catalyst HDMS-100, carry out selective hydrodesulfurization treatment on raw material oil B, and in the hydrogenation reactor equipped with the first selective hydrodesulfurization catalyst and the hydrogenation reactor equipped with the second selective hydrodesulfurization catalyst The hydrogenation reactor is provided with H 2 S stripper.

[0097] Among them, the reaction temperature in the selective hydrogenation reactor is 150°C, the reaction temperature in the second selective hydrodesulfurization reactor is 270°C, and the reaction temperature in the hydrofining reactor is 340°C. The same as Example 1, wherein the properties of feedstock oil B and sulfur-free gasoli...

Embodiment 3

[0103] Under the same conditions as in Example 2, recycle sulfur-free gasoline to the feed port of the device, the recycle amount is 0.3-2 times the amount of raw materials to be treated, and properly adjust the first selective hydrodesulfurization catalyst and the second The reaction temperature of the two-selective hydrodesulfurization catalyst makes the sulfur content of the obtained sulfur-free gasoline less than 5 μg / g, and the other reaction conditions are the same as in Example 2.

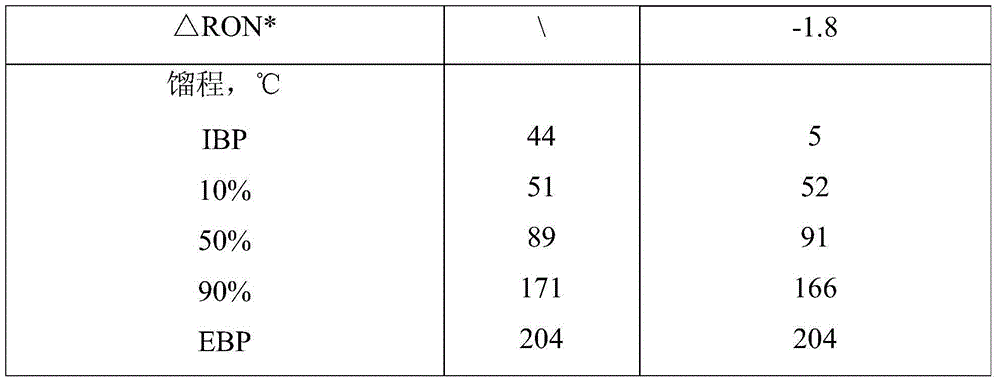

[0104] Table 3 shows the properties of the gasoline product obtained after hydrotreating the raw material oil B under the conditions of different recirculation ratios (recycling amount / the amount of raw material to be treated).

[0105] table 3

[0106] recirculation ratio

[0107] It can be seen from the data in Table 3 that under the condition of controlling the sulfur content of the product at 5 μg / g, operating the hydrogenation reactor by recycling a part of sulfur-free gasolin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com