Preparation method and use of lanthanum coordinated diamino-functionalized mesoporous silica film

A silicon dioxide membrane and diamino technology, which is used in the preparation of lanthanum-coordinated diamino functionalized mesoporous silica membranes and the field of adsorption and separation of phosphate ions in water, can solve the problems of cumbersome preparation process, poor selectivity, mechanical Poor performance and other problems, to achieve the effect of simple preparation process, low manufacturing cost and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

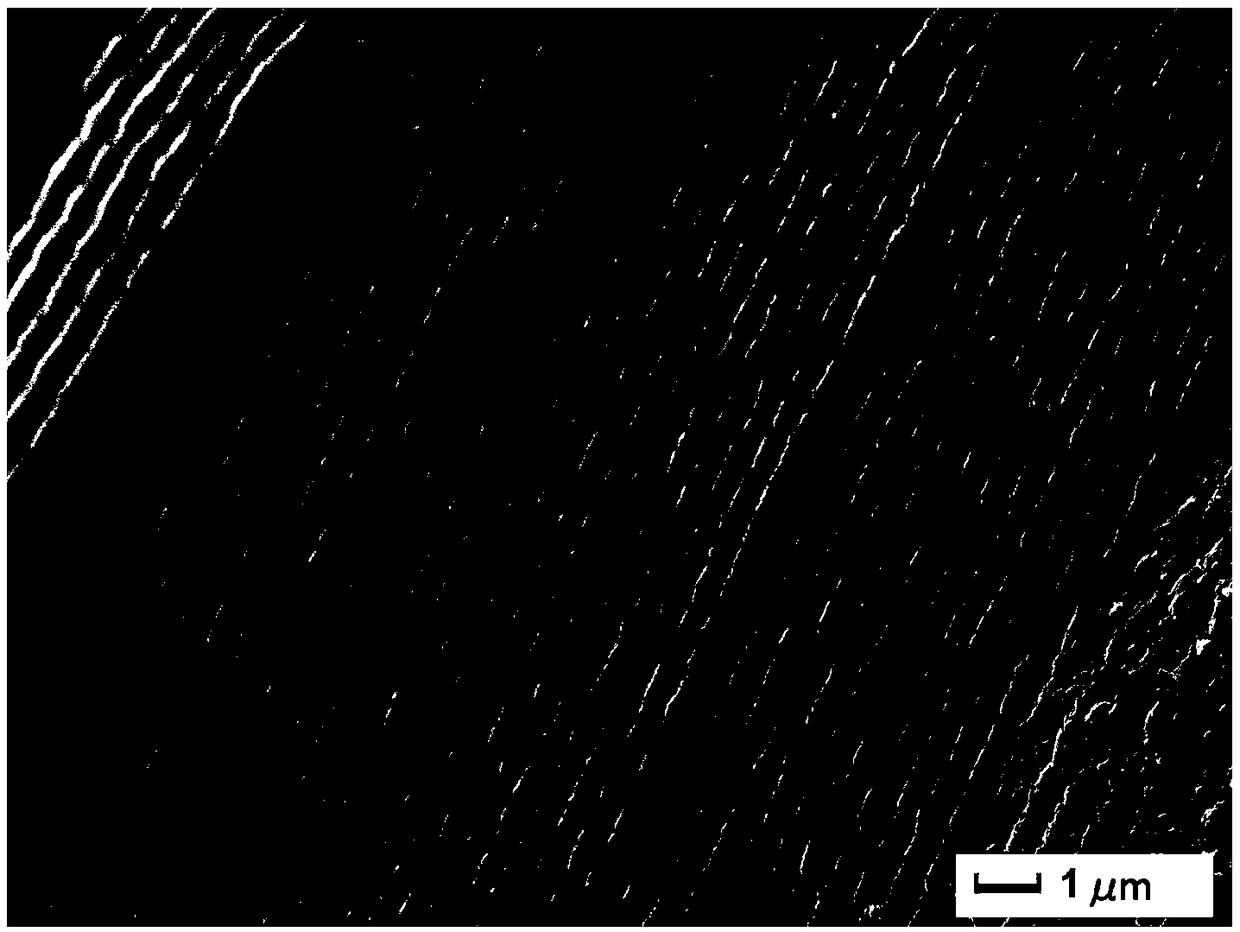

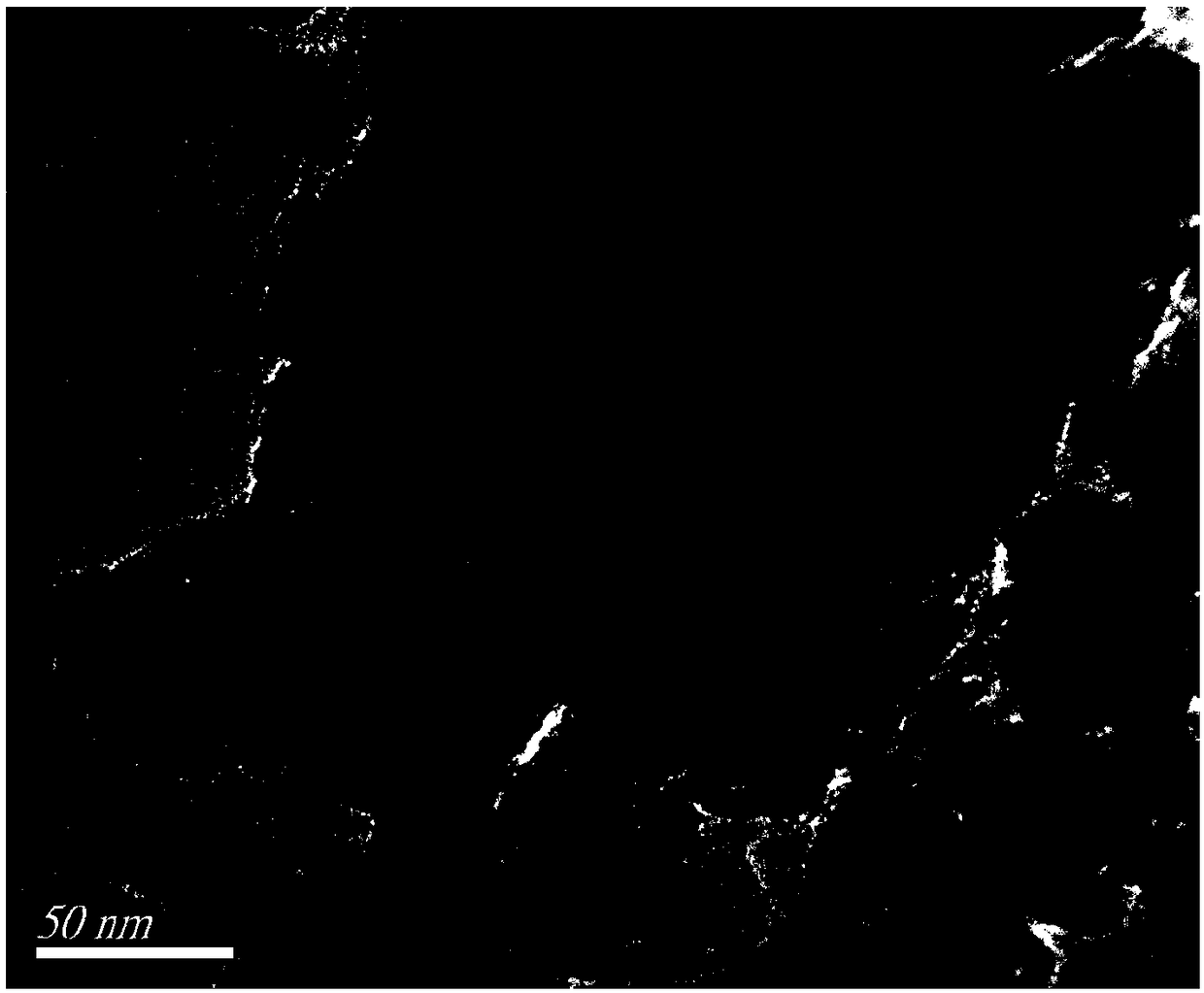

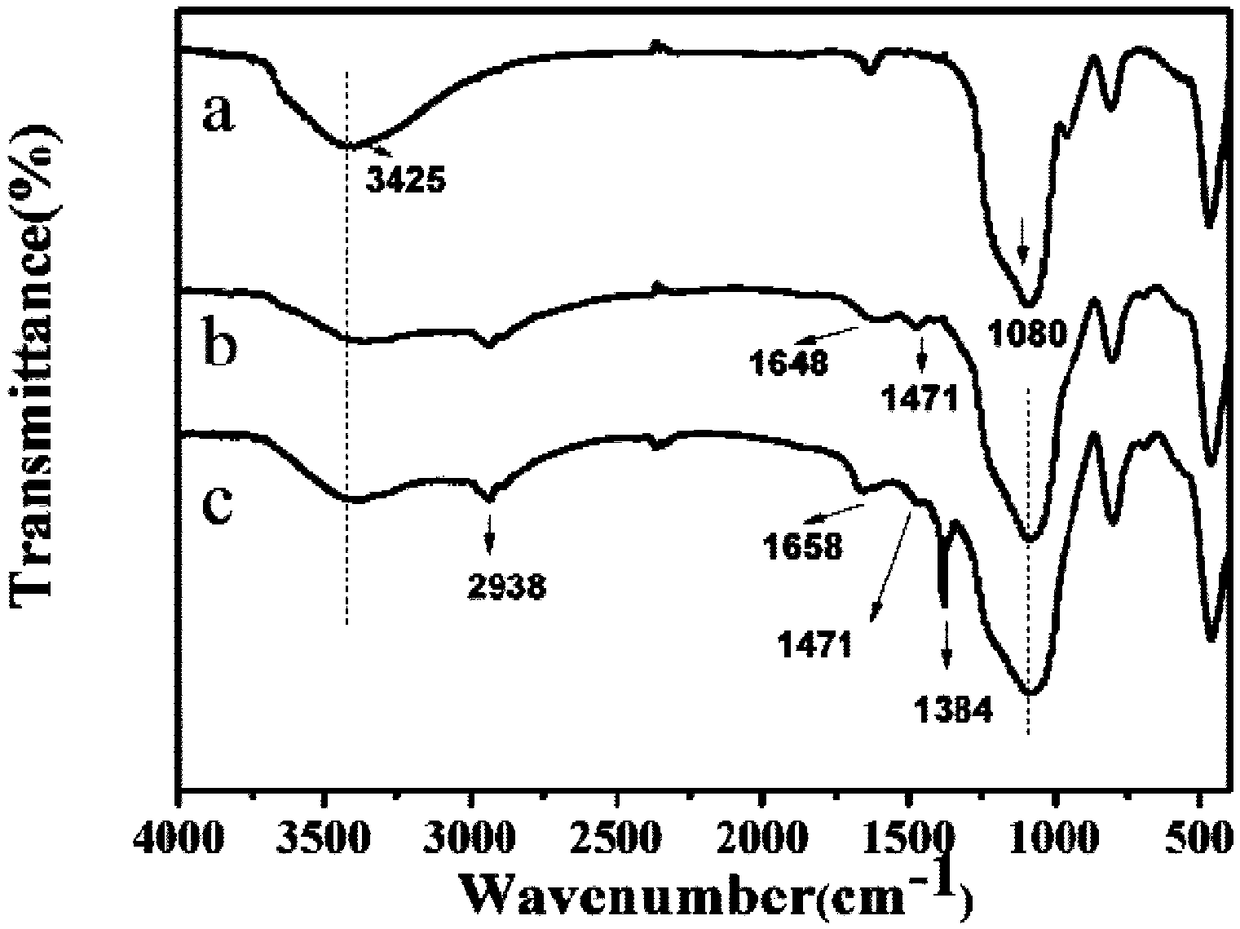

[0050] (1) Dissolve 10 g of medical absorbent cotton in 40 wt % sulfuric acid, and stir at 35° C. for 3 h. Afterwards, the hydrolysis process was terminated by diluting with 1500 ml of cold deionized water and allowed to stand overnight. The supernatant was discarded and the cellulose was centrifuged. Subsequently, the remaining white suspension was washed 3 times to remove soluble cellulosic material and placed in a dialysis bag (MWCO 11000-15000) for 2-5 days (up to pH = 2.4). The final solid product was diluted in water and dispersed by sonication for 10 minutes before use.

[0051] (2) 10 mL of the CNCs suspension (pH=2.4) obtained in step 1 was sonicated for 10 min. 100 mg of anhydrous glucose was added to the CNCs and stirred at 20 °C for 0.5 h, after which 400 μL of tetramethoxysilane (TMOS) was added to the mixture suspension. The mixture suspension was stirred at 25 °C for 2 h. Afterwards, the homogeneous mixture was poured into polystyrene Petri dishes (d=90mm) a...

Embodiment 2

[0069] (1) Dissolve 10 g of medical absorbent cotton in 50 wt % sulfuric acid, and stir at 45° C. for 2 h. Afterwards, the hydrolysis process was terminated by diluting with 1500 ml of cold deionized water and allowed to stand overnight. The supernatant was discarded and the cellulose was centrifuged. Subsequently, the remaining white suspension was washed 3 times to remove soluble cellulosic material, and then placed in a dialysis bag (molecular weight cut-off 11000-15000) for 2-5 days (until pH = 2.4). The final solid product was diluted in water and dispersed by sonication for 10 minutes before use.

[0070] (2) 15 mL of the CNCs suspension (pH=2.4) obtained in step 1 was sonicated for 20 min. 150 mg of anhydrous glucose was added to the CNCs and stirred at 25 °C for 1 h, after which 600 μL of tetramethoxysilane (TMOS) was added to the mixture suspension. The mixture suspension was stirred at 25 °C for 2.5 h. Afterwards, the homogeneous mixture was poured into polystyre...

Embodiment 3

[0088] (1) Dissolve 10 g of medical absorbent cotton in 60 wt % sulfuric acid, and stir at 55° C. for 1 h. Afterwards, the hydrolysis process was terminated by diluting with 1500 ml of cold deionized water and allowed to stand overnight. The supernatant was discarded and the cellulose was centrifuged. Subsequently, the remaining white suspension was washed 3 times to remove soluble cellulosic material, and then placed in a dialysis bag (molecular weight cut-off 11000-15000) for 2-5 days (until pH = 2.4). The final solid product was diluted in water and dispersed by sonication for 30 minutes before use.

[0089] (2) 20 mL of the CNCs suspension (pH=2.4) obtained in step 1 was sonicated for 10 min. 200 mg of anhydrous glucose was added to the CNCs and stirred at 30 °C for 1 h, after which 1000 μL of tetramethoxysilane (TMOS) was added to the mixture suspension. The mixture suspension was stirred at 30 °C for 3 h. Afterwards, the homogeneous mixture was poured into polystyren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com