Preparation method and application of COF-300/PPy/Au (G) nano-enzyme catalyst

A catalyst and nano-enzyme technology, which is applied in the field of preparation of COF-300/PPy/Au nano-enzyme catalysts to achieve the effects of improving dispersibility, increasing active centers, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

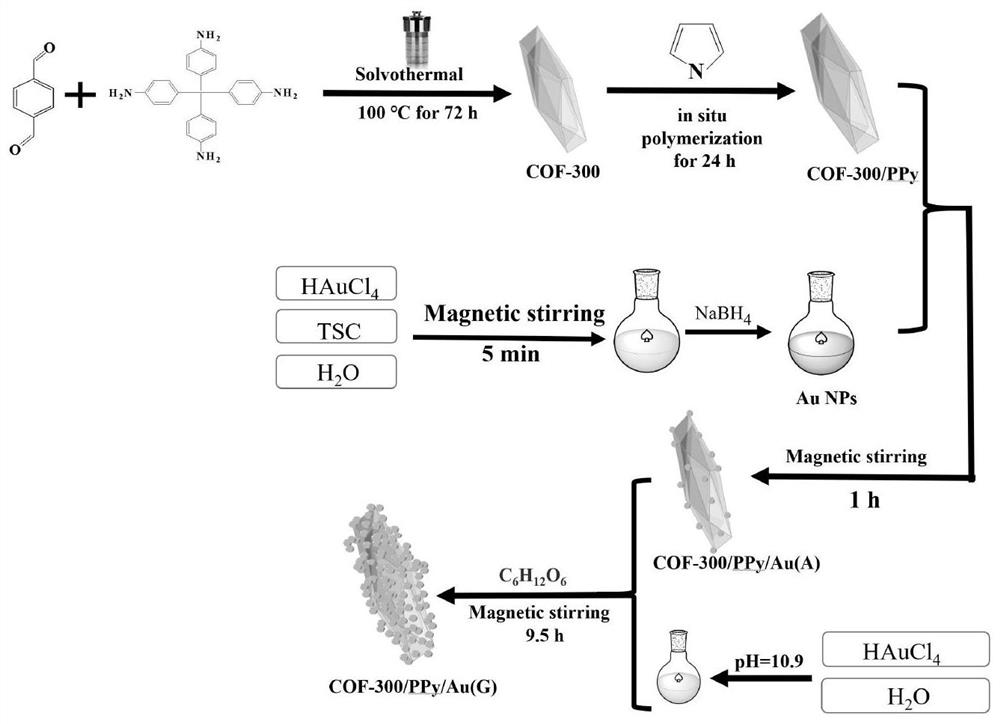

[0050] The preparation method of COF-300 / PPy / Au(G) nanozyme catalyst, the steps are as follows:

[0051] Preparation of COF-300

[0052] Accurately weigh 12mg of terephthalaldehyde and 20mg of tetrakis-(4-aminophenyl)-methane into a 10mL polytetrafluoroethylene reactor, then add 1mL of 1,4-dioxane, stir evenly with a glass rod, Add 0.2mL 3M acetic acid solution dropwise until the solution becomes transparent and bright yellow, and place it at room temperature for 2-5h; put the mixed solution in a 10mL autoclave, and react at 100°C for 72h; naturally cool to room temperature, and wash repeatedly with acetone for several times Afterwards, vacuum-dry at 60°C for 2-6 hours to obtain COF-300 light yellow powder.

[0053] Preparation of COF-300 / PPy

[0054] Under the condition of avoiding light, weigh 200mg COF-300 and add it into 20mL ultrapure water, ultrasonic 1-2h, and disperse evenly; then add 0.8mL pyrrole monomer to the above suspension, stir magnetically at 1500rpm for 2h,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com