Hydraulic punching and flanging mould used for interior high-pressure forming member

An internal high pressure forming and flanging mold technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problem of wasting cleaning time, difficult to remove the flanging inserts of the tube blank to be formed in the blanking area, reducing production efficiency, etc. problems, to achieve the effect of improving production efficiency, simple structure, and saving cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

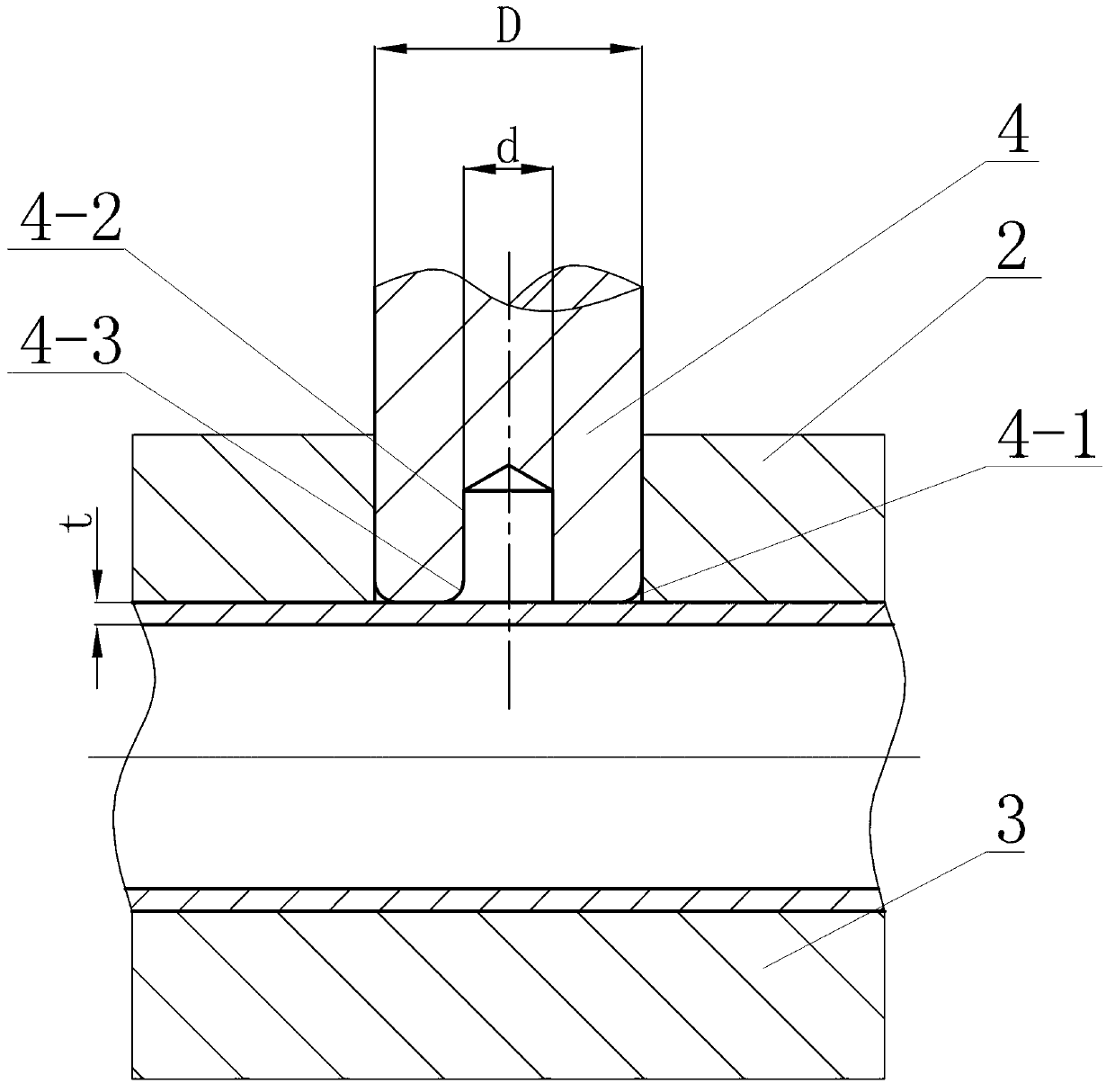

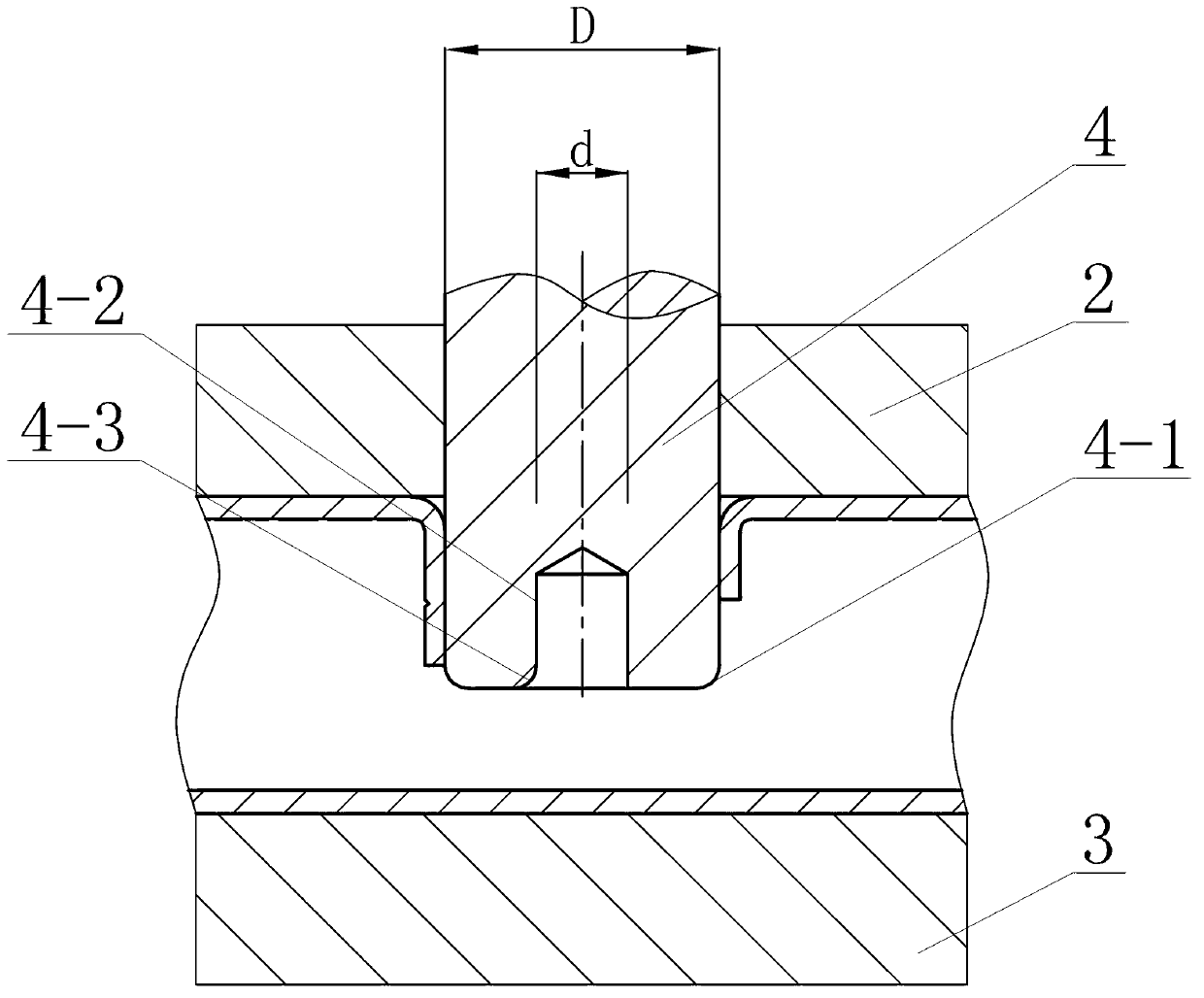

[0010] Specific implementation mode one: as Figure 1~3 As shown, the hydraulic punching-flange die for internal high-pressure formed parts of this embodiment includes an upper module 2, a lower module 3 and a punch 4, the upper module 2 is located on the upper end surface of the lower module 3, and the upper module 2 and The butt surface of the lower module 3 is machined along the length direction of the cavity of the tube blank to be formed. During internal high pressure forming, the tube blank to be formed is located in the cavity of the tube blank to be formed. Located in the punch hole, the outer edge of the lower end of the punch 4 has a first fillet 4-1, and the lower end of the punch 4 is processed with a central blind hole 4-2 along the axial direction, and the left half of the central blind hole 4-2 A second rounded corner 4-3 is processed, and the radii of the first rounded corner 4-1 and the second rounded corner 4-3 are both 0.8 to 2 times the wall thickness of th...

specific Embodiment approach 2

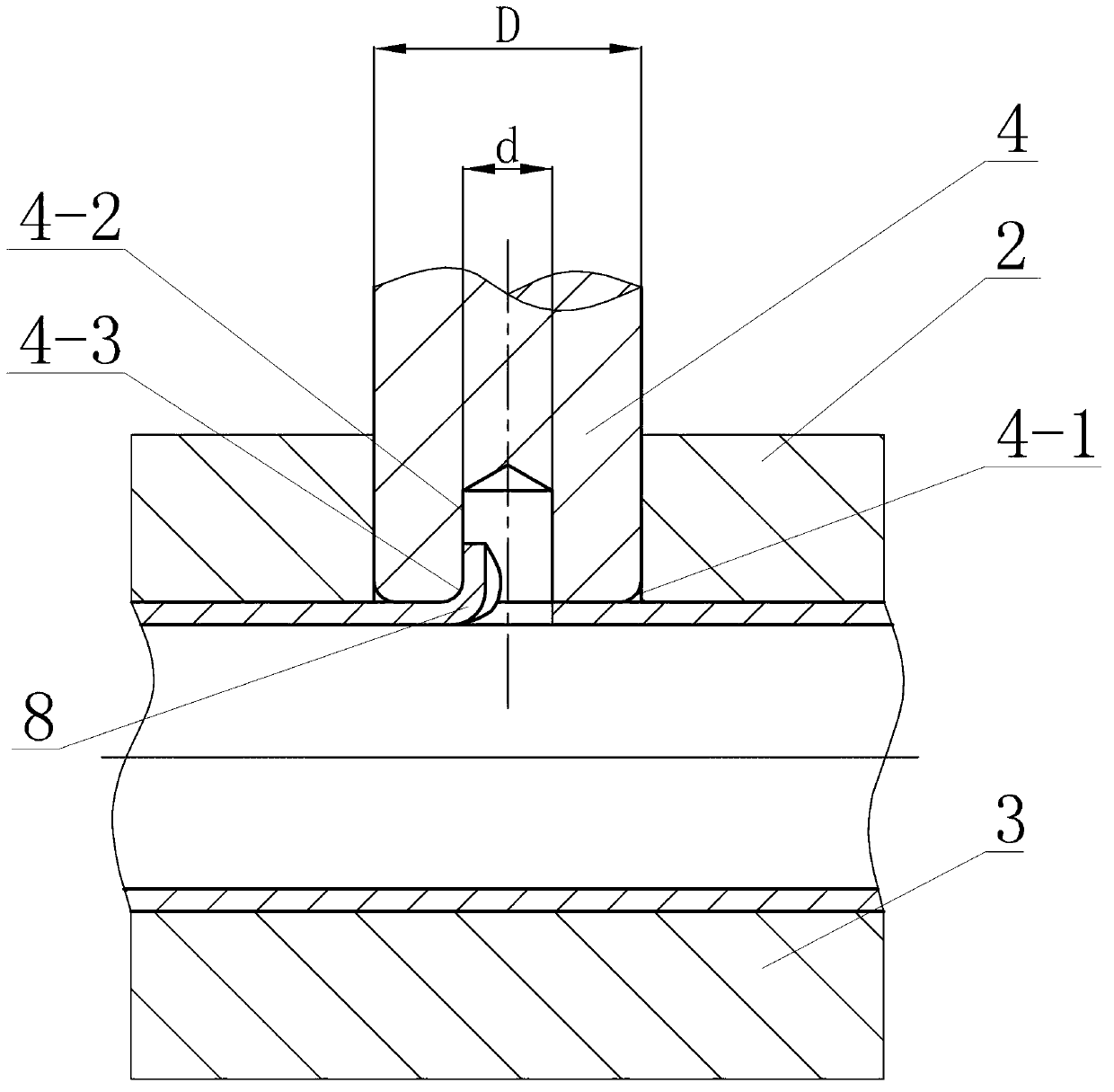

[0029] Specific implementation mode two: as Figure 4~6 As shown, the hydraulic punching-flange die described in this embodiment further includes a spring 14 and a mandrel 15, and the mandrel 15 is installed in the central blind hole 4-2 through the spring 14. In such a design, other components and connections are the same as those in the first embodiment.

[0030] When punching aperture , in order to ensure the forming of the transition fillet of the section of the internal high pressure forming part, the punch structure is designed as Figure 4~6 As shown, the outer diameter of the punch 4 is D, the inner diameter of the central blind hole 4-2 of the punch 4 is d, and the left half of the central blind hole 4-2 is processed with a second fillet 4-3. In order to prevent the internal pressure drop caused by the breakage of the blanking area 8 before the completion of the internal high pressure forming, a spring 14 and a mandrel 15 are installed in the central blind hole 4-2...

Embodiment 1

[0035] Embodiment 1: When punching hole diameter Time

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com