Method for mfg. isolation structure of poly imide film supercondeccting strip material and apparatus thereof

A technology of polyimide film and superconducting tape, which is applied in the usage of superconductor elements, inductance/transformer/magnet manufacturing, transformers, etc., can solve problems such as inadaptability, and achieve wide application, high efficiency, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

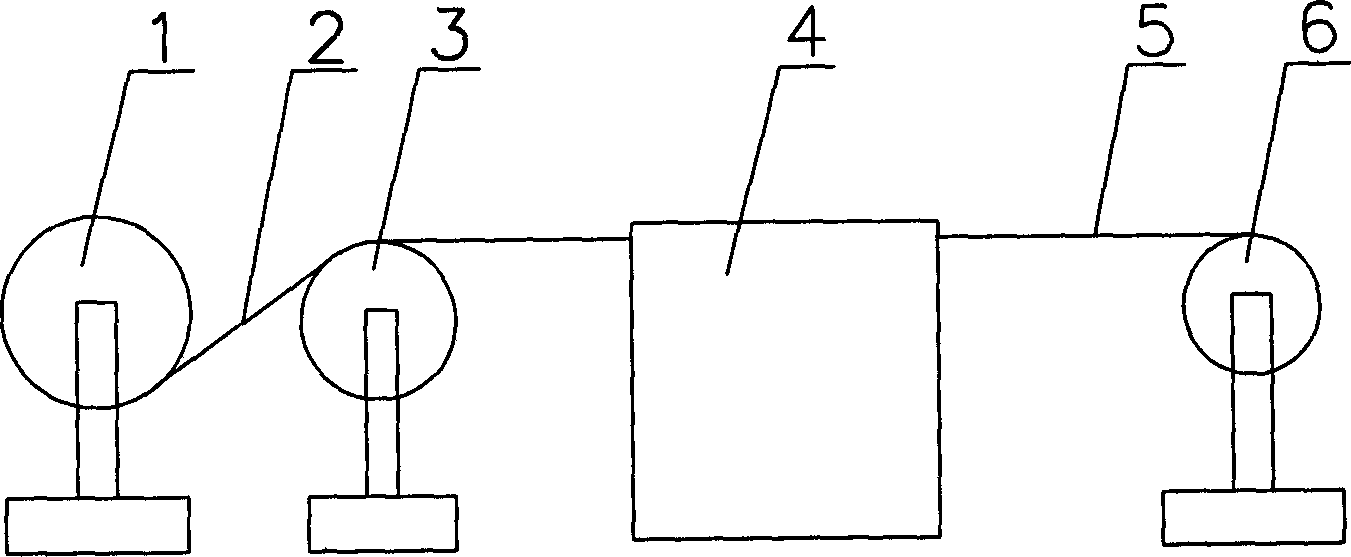

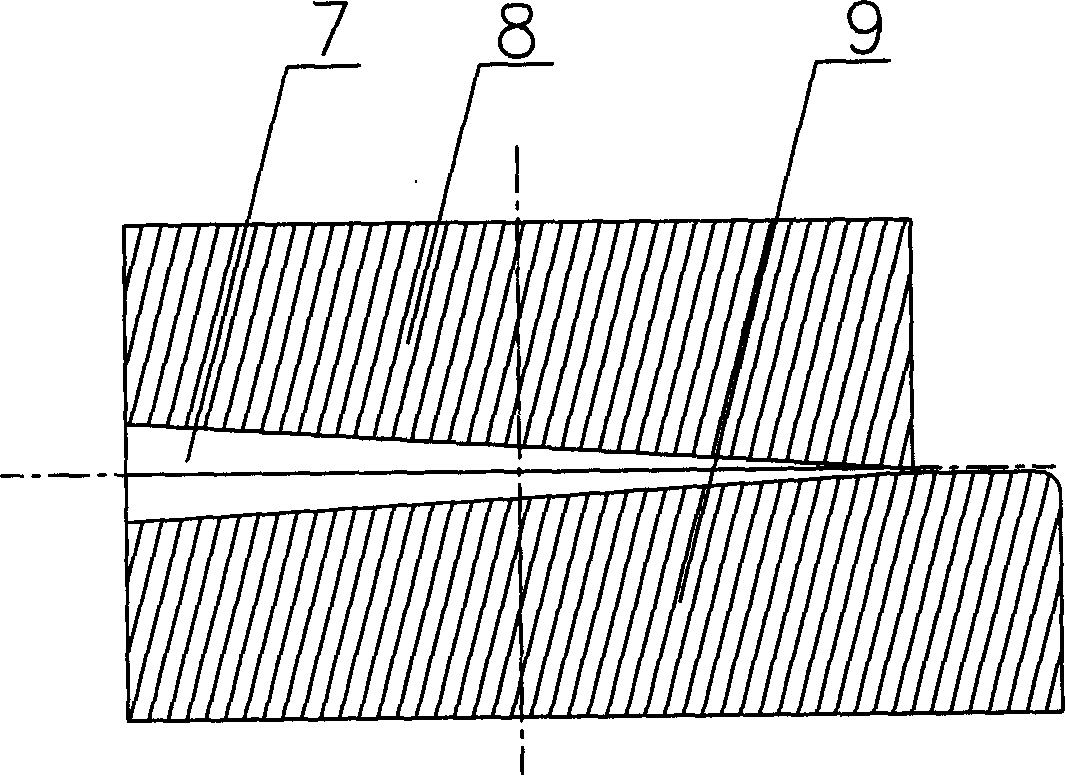

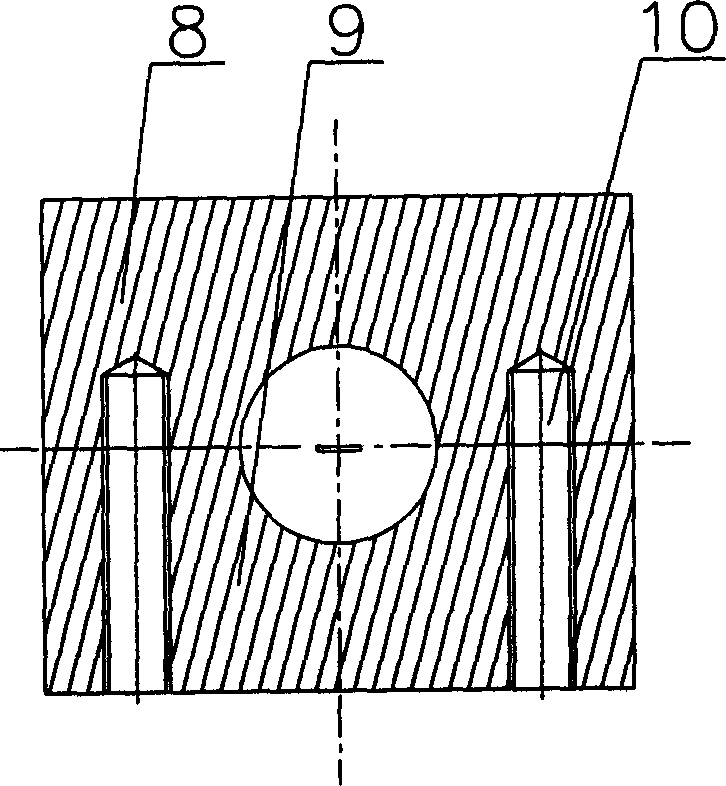

[0016] The accompanying drawing shows an embodiment of the present invention, and the present invention will be further described below in conjunction with the accompanying drawing and the embodiment.

[0017] It can be seen from the accompanying drawings that the present invention is a method for manufacturing a superconducting strip insulation layer of a high-temperature superconducting transformer and a manufacturing device thereof. A method of wrapping polyimide film tape along the longitudinal direction of the superconducting tape is adopted, through the self-adhesive polyimide film tape wrapping system, the superconducting tape is directly wrapped with a layer of self-adhesive polyimide film longitudinally along the wire axis The imide film tape makes the insulation strength between coil turns and cakes meet the requirements of 500V power frequency withstand voltage test. The size of the polyimide film is: width 8-12mm, thickness 0.1-0.2mm. The specific production metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com