Preparation method and application of lamellar manganese oxide catalyst used for eliminating VOCs (volatile organic compounds) gases at low temperature

A layered manganese oxide, catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve high and low temperature catalytic combustion elimination activity, low energy consumption, The effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

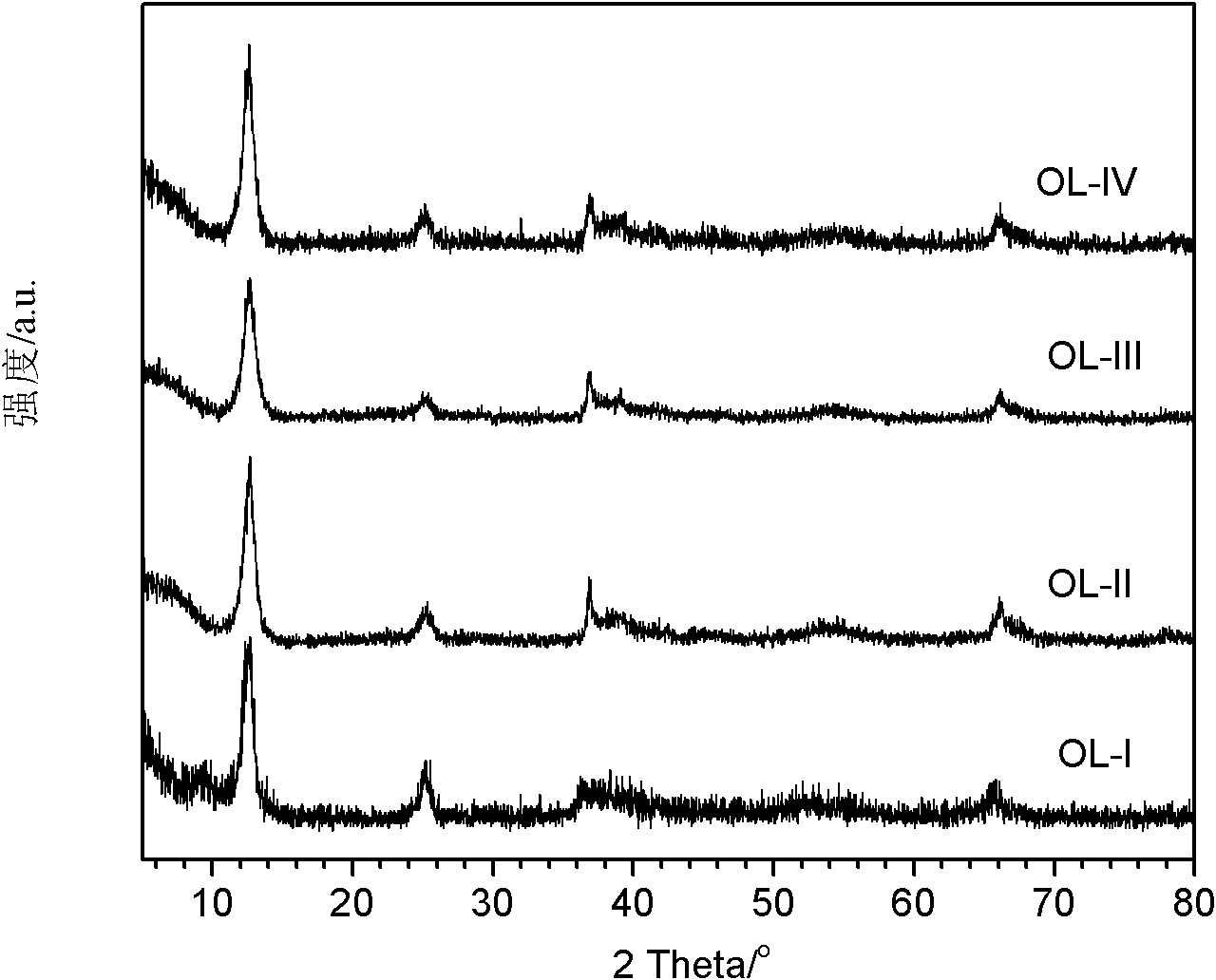

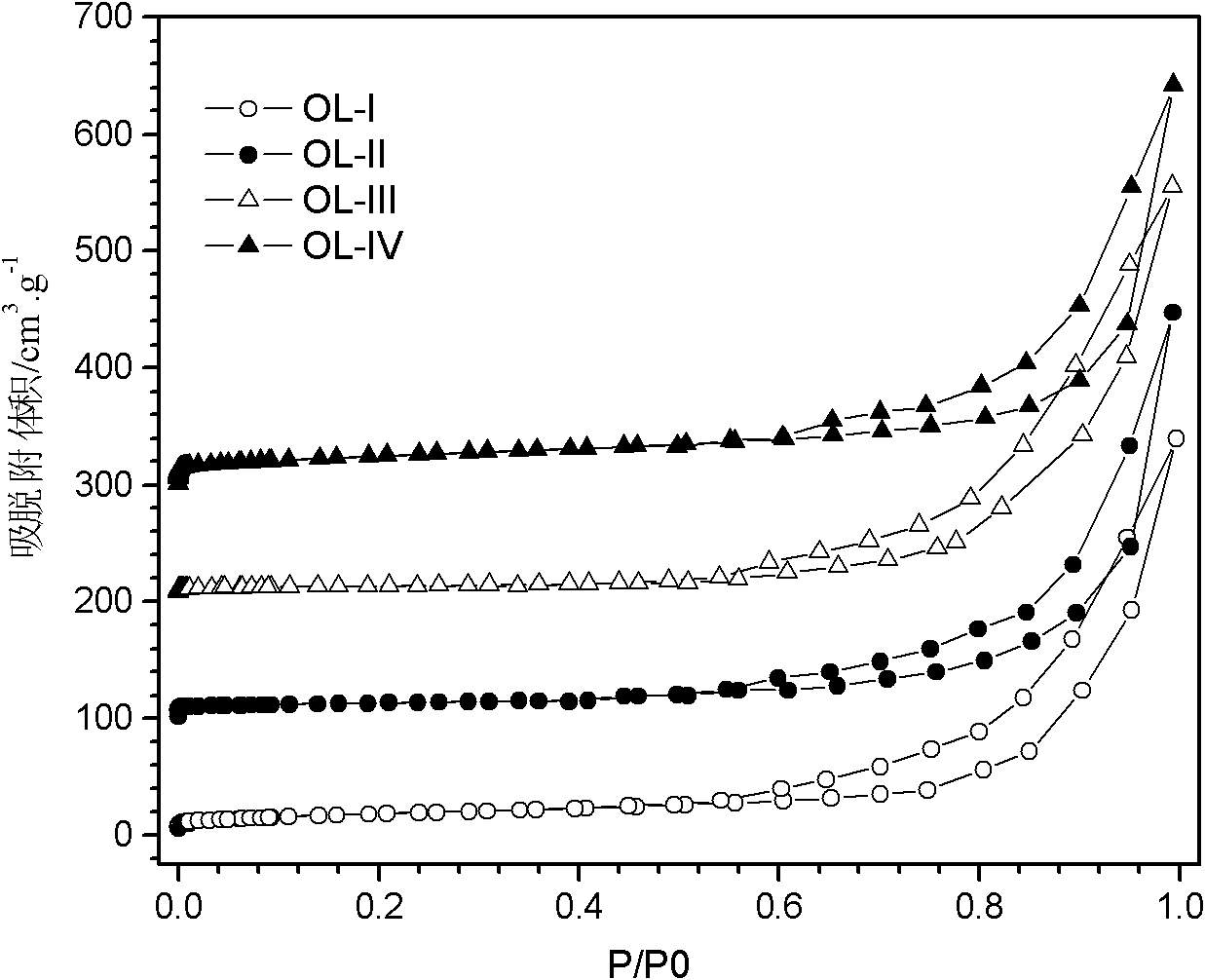

Embodiment 1

[0020] (1) the preparation method of above-mentioned catalyst provided by the present invention, comprises the steps:

[0021] Add methanol to 3mol.L -1 Mix in KOH solution (where methanol: KOH solution (volume ratio) = 1:1). Slowly add this mixture to 0.3mol.L -1 KMnO 4 Solution (wherein the mixture: KMnO 4 solution (volume ratio) = 1:1). The above mixed solution was continuously stirred for 10 hours, left to age for 4 hours, and the product was treated at 80° C. for 24 hours under a flowing air atmosphere of 20 ml / min. Finally, it was washed with distilled water until the pH value = 7, and dried at 120°C for 24 hours to obtain a black OL precursor, which was then placed in a muffle furnace and fired at 300°C at a rate of 1°C / min for 1 to 4 hours to obtain OL- I.

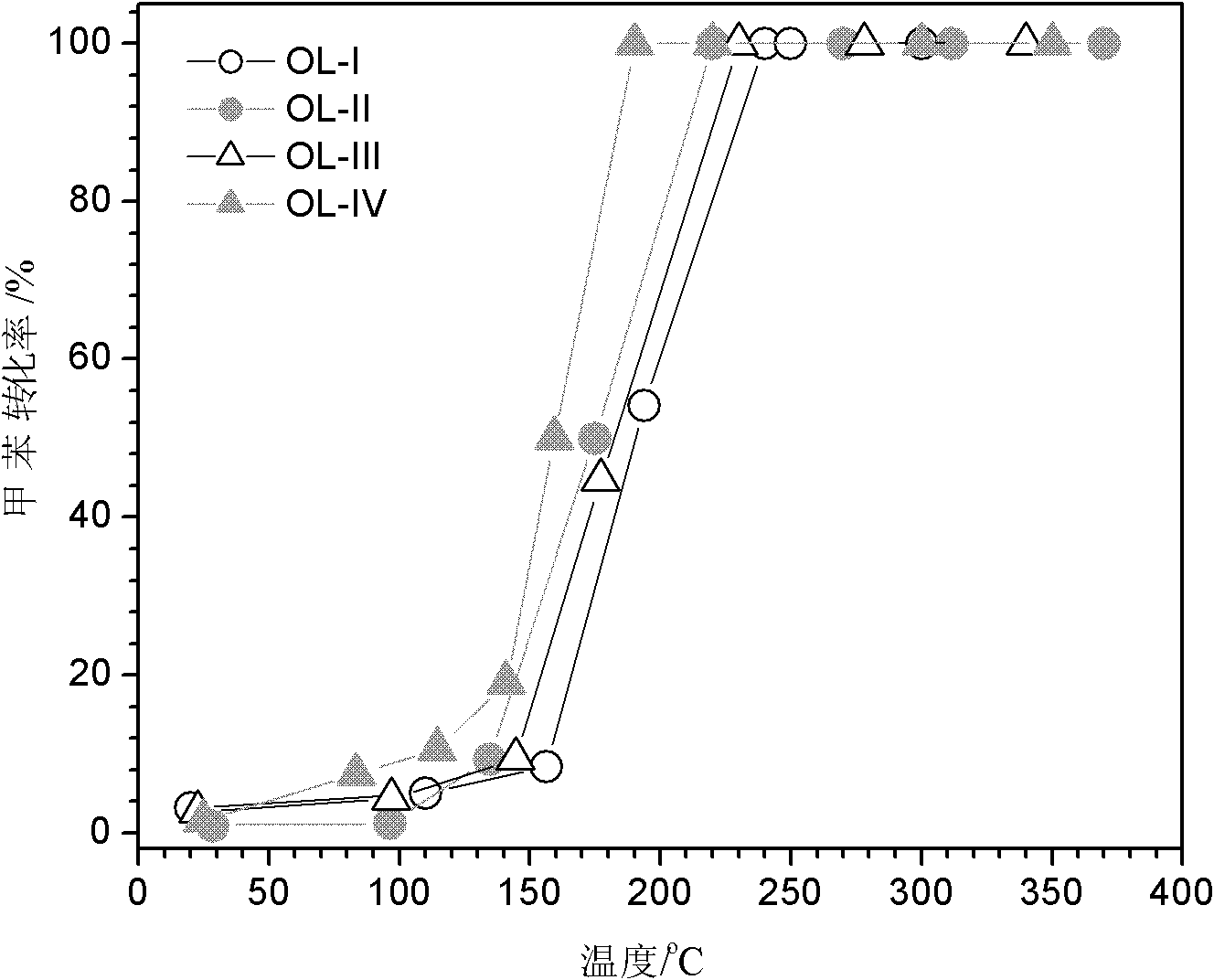

[0022] (2) Catalyst activity evaluation. The concentration of toluene is 500ppm, and the air velocity is 60,000h -1 . Gas chromatography TCD detection reaction tail gas CO 2 And CO, FID detects the conten...

Embodiment 2

[0024] (1) the preparation method of above-mentioned catalyst provided by the present invention, comprises the steps:

[0025] Add methanol to 6mol.L -1 Mix in KOH solution (where alcohol: KOH solution (volume ratio) = 1:3). Slowly add this mixture to 0.6mol.L -1 KMnO 4 Solution (wherein the mixture: KMnO 4 solution (volume ratio) = 3:1). With 2.0g of PVP (molecular formula (C 6 h 9 NO) n , molecular weight 1000) dissolved in the above mixture [among them, PVP: KMnO 4 (Number of moles)=0.004:1)], continued to stir for 12 hours, left to stand for aging for 7 hours, and the product was processed at 120°C for 48 hours under 40ml / min flowing air atmosphere. Finally, it was washed with distilled water until the pH value = 9, and dried at 120°C for 24 hours to obtain a black OL precursor, which was then placed in a muffle furnace and fired at 500°C at a rate of 1°C / min for 4 hours to obtain OL-II.

[0026](2) Catalyst activity evaluation. The concentration of toluene serie...

Embodiment 3

[0028] (1) the preparation method of above-mentioned catalyst provided by the present invention, comprises the steps:

[0029] Add ethanol to 3mol.L -1 Mix in KOH solution (where ethanol: KOH solution (volume ratio) = 1:1). Slowly add this mixture to 0.3mol.L -1 KMnO 4 Solution (wherein the mixture: KMnO 4 solution (volume ratio) = 1:1). The above mixed solution was continuously stirred for 10 hours, left to age for 4 hours, and the product was treated at 80° C. for 24 hours under a flowing air atmosphere of 20 ml / min. Finally, it was washed with distilled water until the pH value = 7, and dried at 120°C for 24 hours to obtain a black OL precursor, which was then placed in a muffle furnace and fired at 300°C at a rate of 1°C / min for 2 hours to obtain OL-III.

[0030] (2) Catalyst activity evaluation. The concentration of toluene series is 1000ppm, and the air velocity is 100,000h -1 . Gas chromatography TCD detection reaction tail gas CO 2 And CO, FID detects the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com