Precise vacuum oiling automation line

An automatic line and vacuum technology, applied in special distribution devices, packaging, distribution devices, etc., can solve the problems of inability to adapt to mass production, heavy workload, cumbersome operation, etc., and achieve friendly man-machine interface, high oil injection accuracy, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

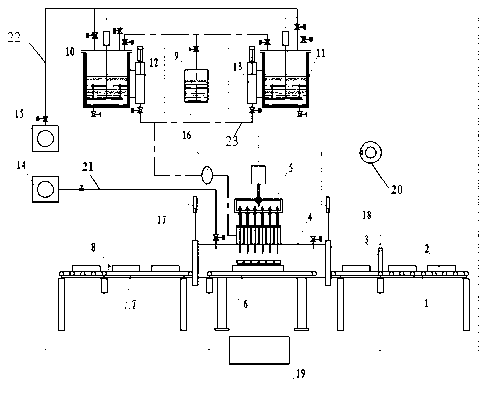

[0026] Below, the precision vacuum oiling automatic line of the present invention will be described in detail in conjunction with the accompanying drawings and embodiments:

[0027] Such as figure 1 As shown, a precision vacuum oiling automatic line includes a front belt unit 1, the front belt unit 1 is composed of a roller row device and a belt conveyor, a workpiece tray 2 is arranged on the front belt unit 1, and Equipped with a vacancy detector 3, when the workpiece pallet 2 passes under it, the vacancy detector 3 can automatically identify the working status of the workpiece pallet 2, and when the workpiece is empty, it will automatically alarm and the workpiece pallet 2 will automatically return to the original position, prompting the operation Those who make up the workpiece.

[0028] A vacuum oiling chamber 4 is arranged on one side of the front belt unit 1, a precision volume metering device 5 is arranged above the vacuum oiling chamber 4, a pallet transfer device 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com