Step air cylinder silicon oil injecting measuring device for fully-automatic silicon oil injecting machine

A technology of stepping cylinder and measuring device, applied in distribution device, special distribution device, liquid distribution, conveying or transfer device, etc., can solve the problems of inaccurate oil injection and continuous oil injection, and achieve high oil injection accuracy, The effect of strong work stability and improved oil injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific drawings and embodiments.

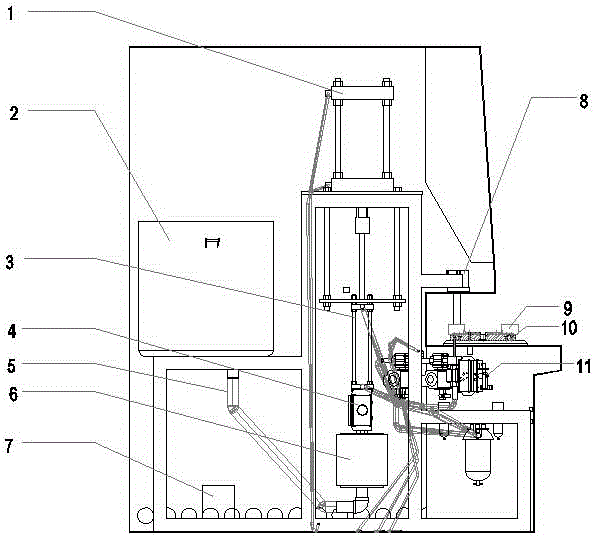

[0016] A stepping cylinder silicone oil filling measurement device for a fully automatic silicone oil filling machine, comprising an oiling machine housing, a stepping cylinder 1, an oil barrel 2, an oiling cylinder 3, an oiling pressure gauge 11, an oil inlet pneumatic integrated valve 4, and an oil delivery pipe 5. Heating tank 6, vacuum pump 7, support frame, coupling sleeve, oil nozzle, clamping cylinder 8, shock absorber 9, oiling fixture bottom plate 10 and work table, the oil delivery pipe 5, heating tank 6, oil inlet pneumatic The integrated valve 4 is connected to the oil injection cylinder 3 in sequence; the step cylinder 1 is arranged on the upper part of the oil injection cylinder 3, and is connected to the worktable through a support frame; an oil injection pressure gauge 11 is arranged under the bottom plate of the oil injection fixture, and the T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com