Grease filling machine and filling method

A technology of filling machine and butter, which is applied to the safety device of the filling device, packaging, bottle filling, etc., which can solve the problems of low precision and low filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

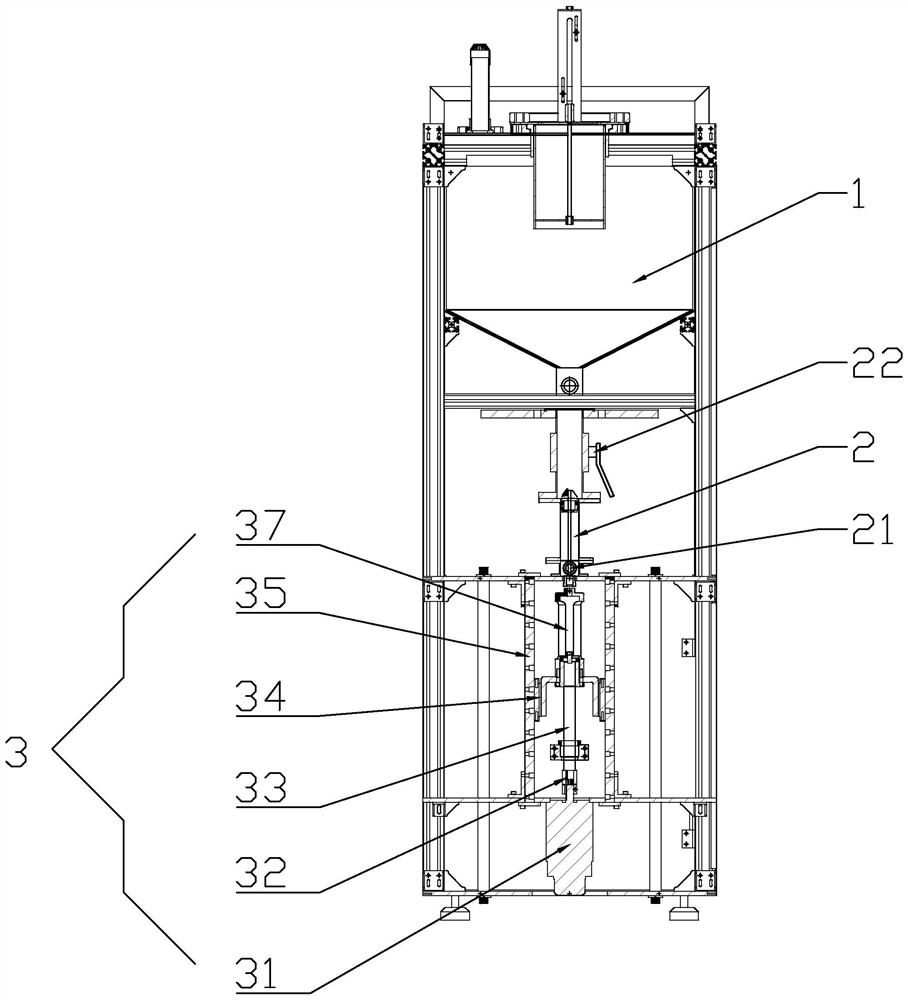

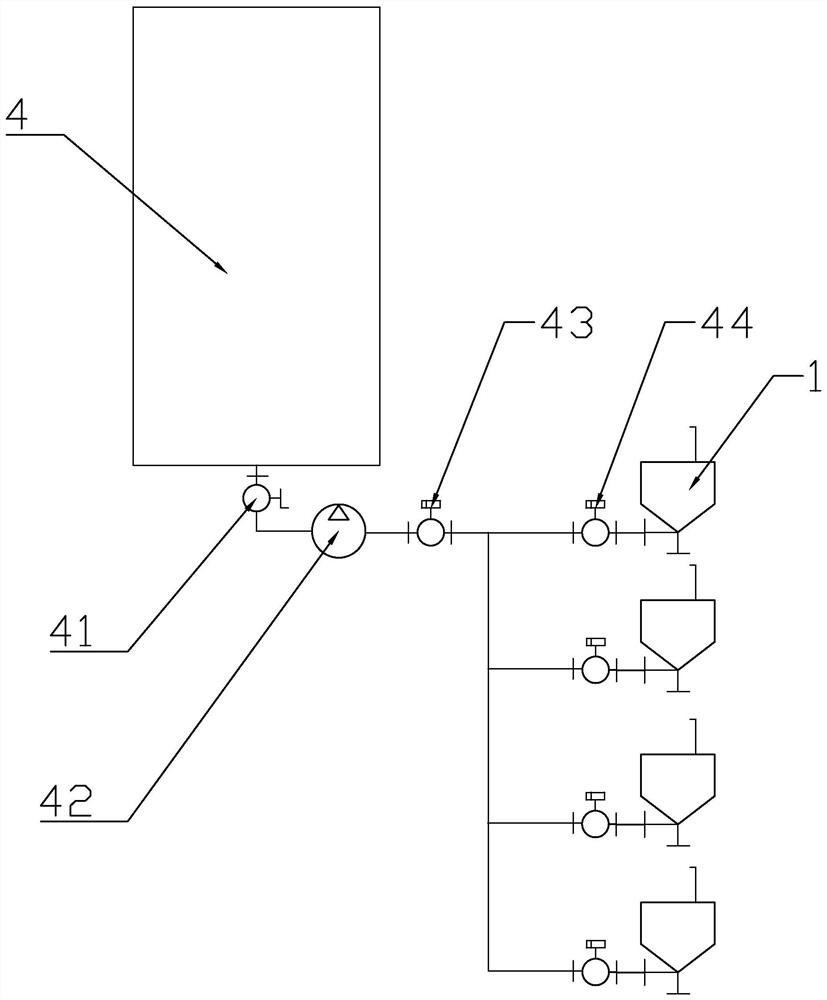

[0041] like figure 1 As shown, a tallow filling machine, comprising:

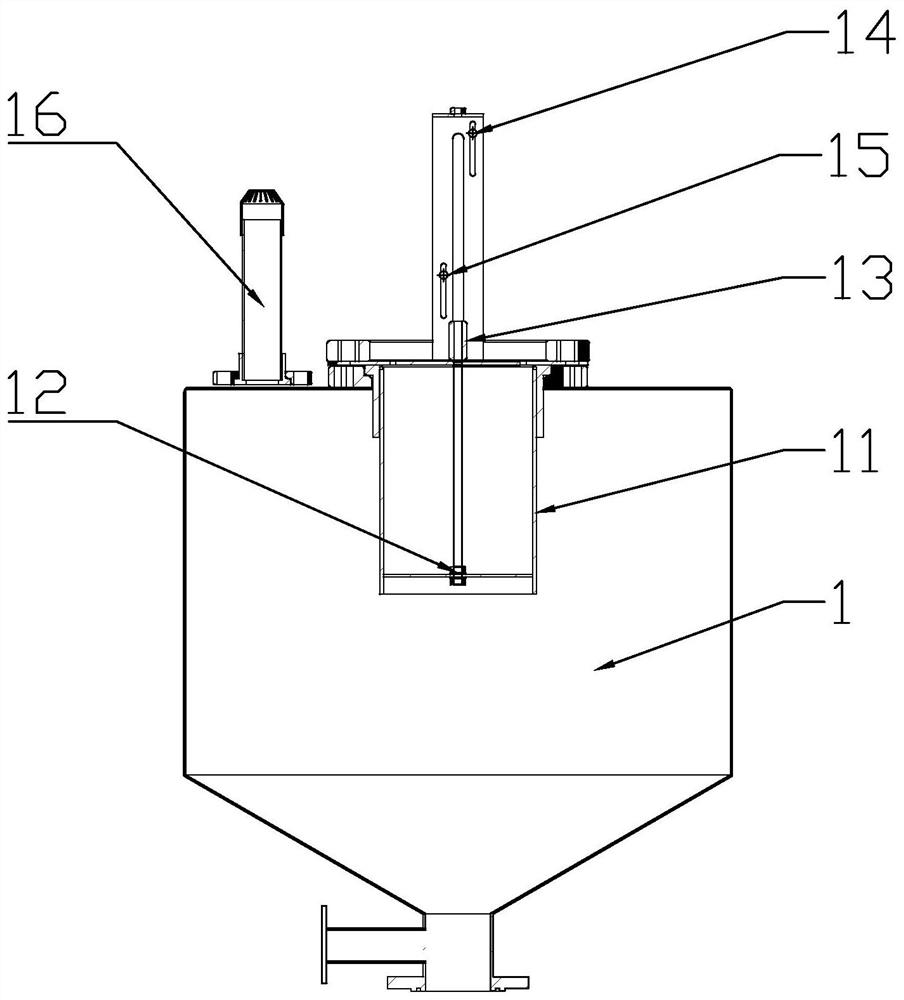

[0042] Butter tank 1, for storing butter, such as figure 2 As shown, the butter tank 1 has a funnel-shaped bottom barrel structure, the butter tank 1 is provided with an oil level control mechanism, and the oil level control mechanism includes an oil level monitoring cylinder 11 and a sliding device arranged in the oil level monitoring cylinder 11. An oil level control piston 12, an oil level monitoring cylinder 11 is vertically arranged in the butter tank 1, a sensing block 13 is arranged on the piston rod of the oil level control piston 12, the piston rod is an oil level indicator rod, and the center of the top of the butter tank 1 is provided with a sensing block 13. There is an induction switch mounting plate, an upper induction switch 14 and a lower induction switch 15 are arranged on the induction switch installation plate, and a breathing valve 16 is arranged on the top of the butter tank 1;

[0043...

Embodiment 2

[0057] A kind of tallow filling machine, its structure is roughly the same as embodiment 1, such as Figure 4 The difference is that it also includes a heating device. The heating device includes a sleeve 5 that is sleeved outside the quantitative oil cylinder 2. The outer wall of the quantitative oil cylinder 2 is provided with a friction surface with high roughness. The friction surface is made of alloy. 5. A brush 51 made of polymer material is arranged on the inner wall. The distal end of the brush 51 is attached to the outer wall of the quantitative oil cylinder 2. The driving device includes a servo motor 31, a connecting shaft 36 and a gear transmission mechanism.

[0058] The bottom of the servo motor 31 is provided with a lifting device, and the lifting device can be the prior art such as air cylinder, oil cylinder, etc. The output end of the servo motor 31 is connected with a connecting shaft 36, and the connecting shaft 36 includes a circular shaft segment 361 close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com