Busbar Heat Shrink Tube Hole Cutter

A heat-shrinkable tube and hole-cutting technology, used in metal processing and other directions, can solve the problems of slow efficiency and irregular incision, and achieve the effect of regular round holes and improved hole-cutting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments of the description:

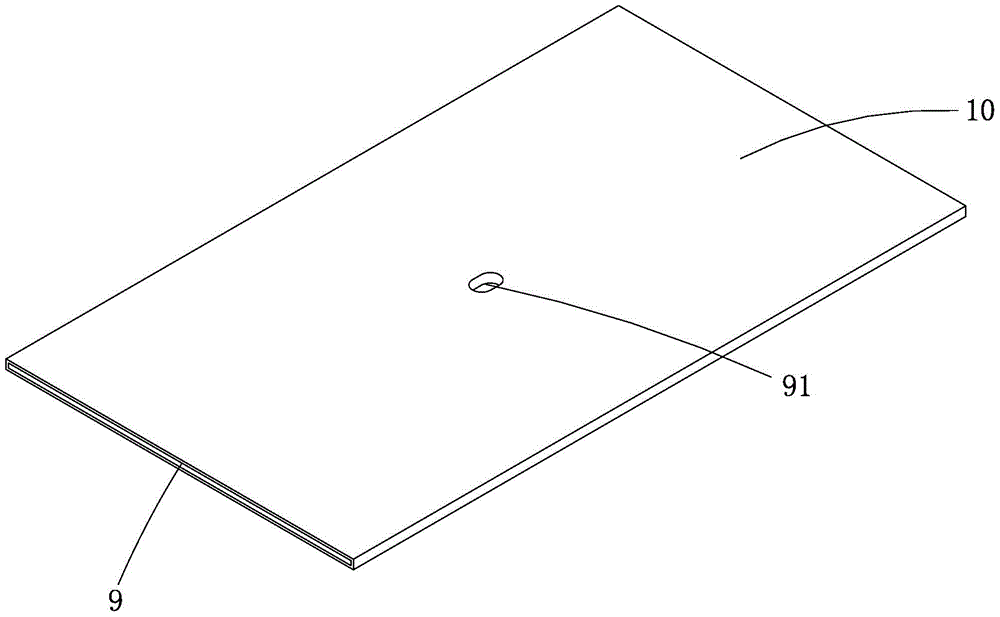

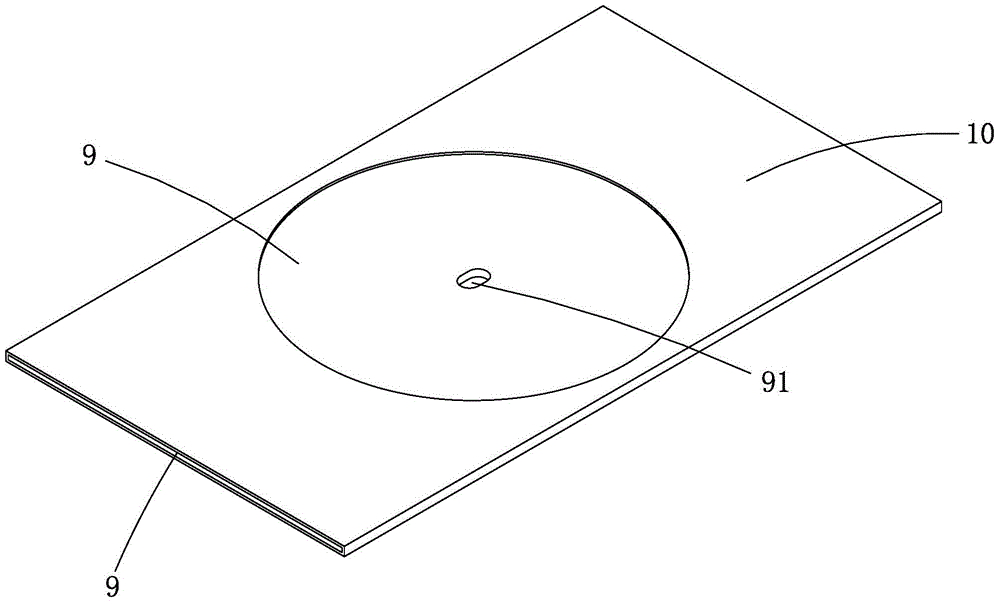

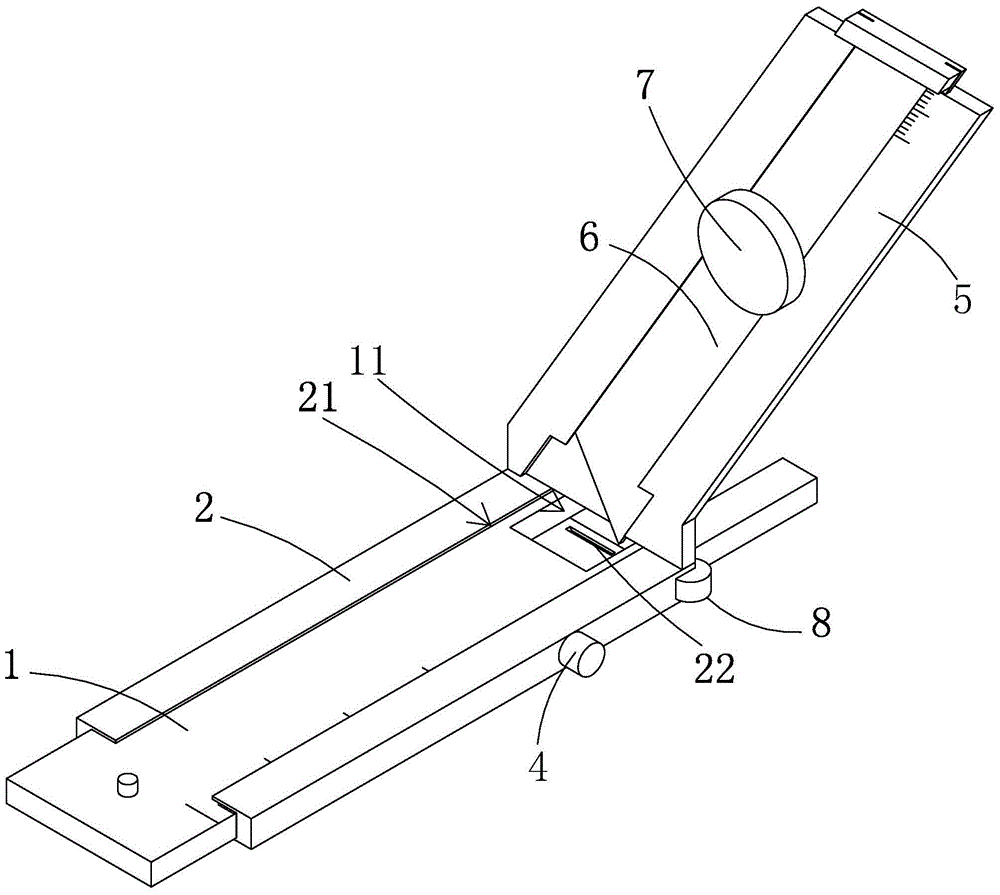

[0021] Such as Figure 3 to Figure 9 Shown is a schematic diagram of an embodiment of a busbar heat-shrinkable tube cutter provided by the present invention, which includes a telescopic rotating assembly and a knife assembly vertically arranged on the telescopic rotating assembly;

[0022] The telescopic rotating assembly includes a positioning plate 1, a sliding sleeve 2 slidingly sleeved on the positioning plate 1, a positioning block 3 hinged on the front bottom surface of the positioning plate 1, and a locking piece A4 for locking the sliding sleeve 2 and the positioning plate 1 The knife feed assembly includes a blade fixing slide rail 5 fixed on the rear end of the sliding sleeve 2, a blade feed 6 slidingly arranged on the blade fixing slide rail 5, and a tool for locking the blade fixing slide rail 5 and the bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com