Recoverable cable stripping equipment for safety explosion-proof cable for instrument

An explosion-proof cable and safety technology, applied in the field of recycling cable stripping equipment, can solve the problems of low practicability, cutter displacement, high maintenance cost, and achieve the effects of high practicability, avoidance of jamming, and strong functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

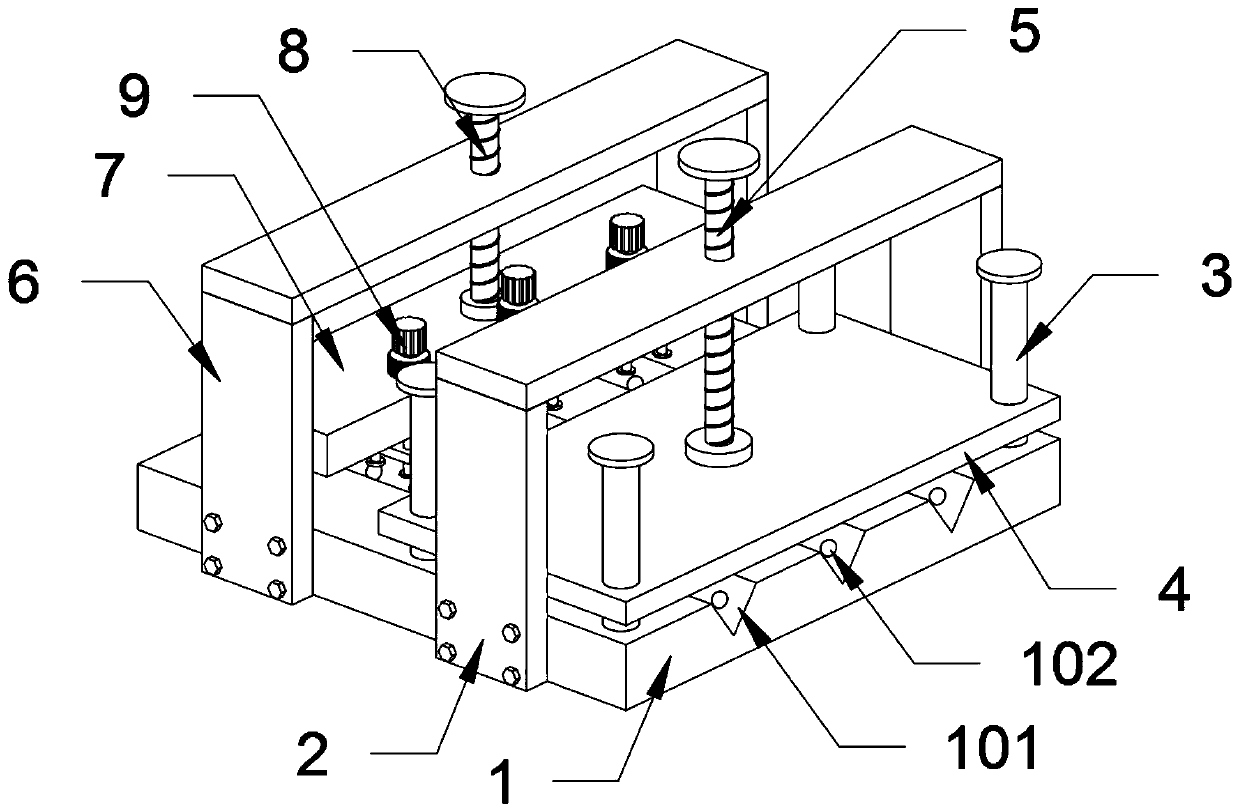

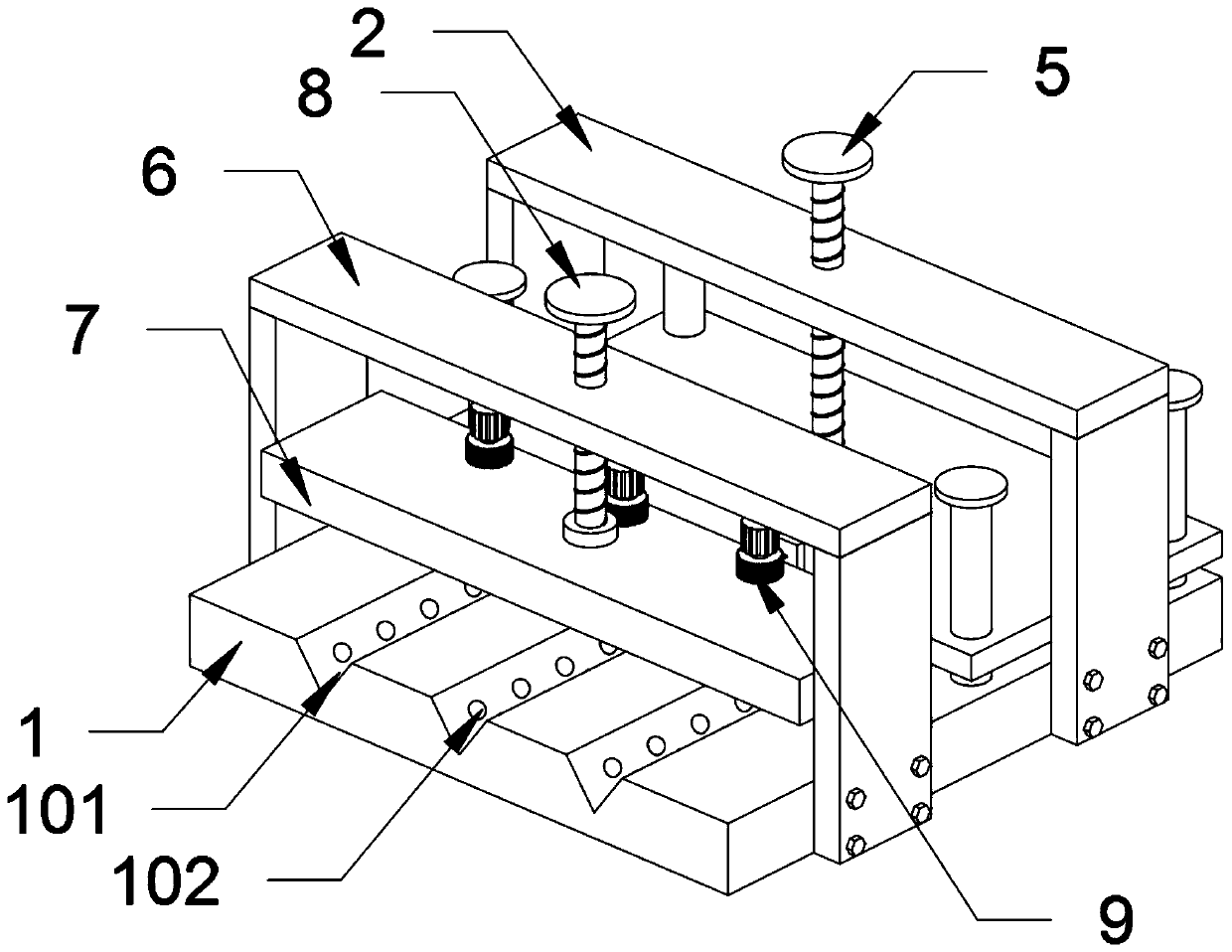

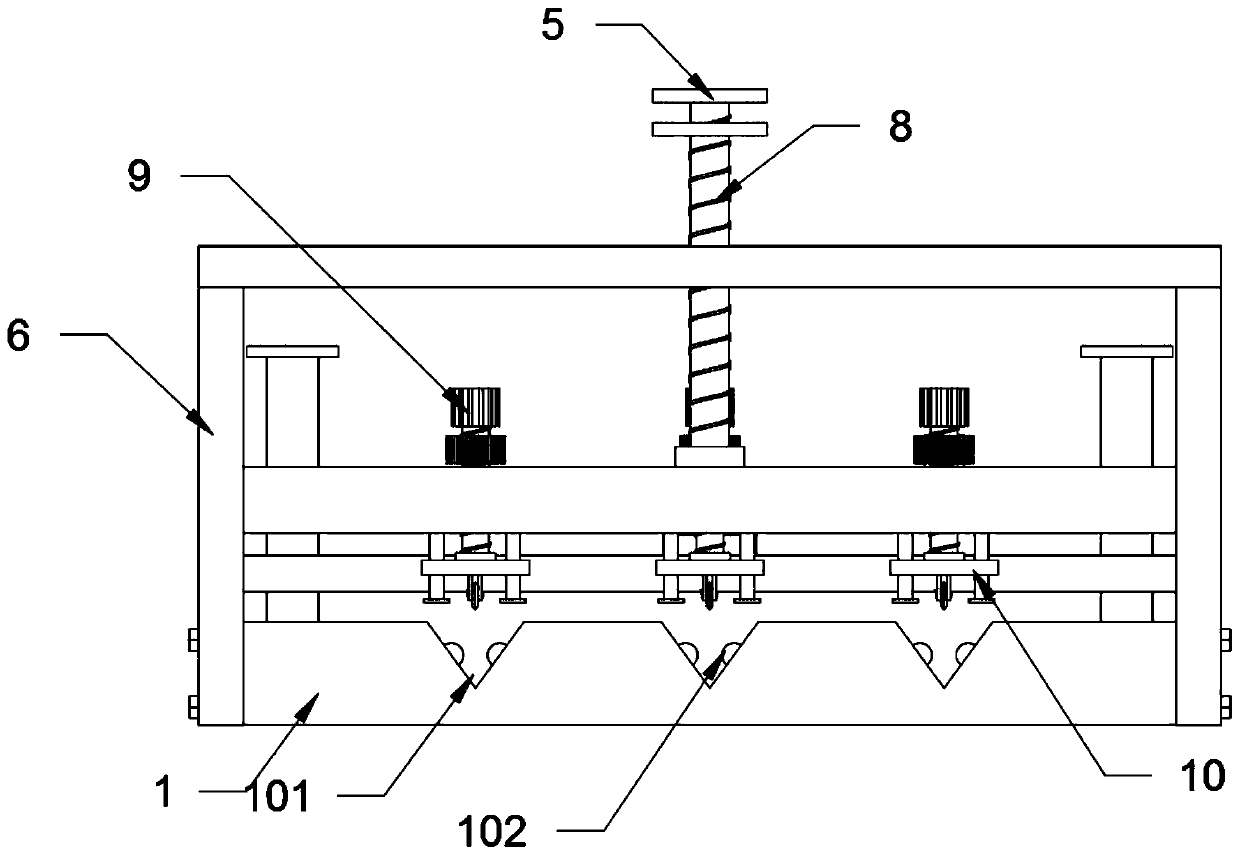

[0034] as attached figure 1 to attach Figure 8 Shown:

[0035]The present invention provides a recyclable cable peeling device for safety and explosion-proof cables for instruments, including a bottom plate 1, a guide groove 101, a ball 102, an adjustment frame A2, a guide shaft A3, a pressure plate 4, a threaded rod A5, an adjustment frame B6, a mounting plate 7, Threaded rod B8, adjusting rod structure 9, gear plate 901, peeling structure 10, rectangular plate 1001, guide shaft B1002, cutter seat 1003, cutter 1004, fixing bolt 1005, fixing structure 11, bolt fixing plate 1101, bolt 1102 and Spring 1103; the base plate 1 is a rectangular plate structure, and the top surface of the base plate 1 is provided with three guide grooves 101 in a rectangular array; the front side of the base plate 1 is fixedly connected with an adjustment frame A2 by bolts, and the The top surface of the base plate 1 is welded with four guide shafts A3 in a rectangular array, and a pressure plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com