Frame-hiding three-glass energy-saving sound insulating window and manufacture method thereof

A sound-proof window and hidden frame technology, applied in the direction of sound-proof doors/windows, sealing devices, etc., can solve problems such as heat preservation, energy saving, poor noise reduction performance, cost-effective noise reduction, insufficient performance, poor heat preservation, energy saving and noise reduction performance, etc., to achieve Excellent sound insulation performance, improved rainwater penetration performance, firm and durable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

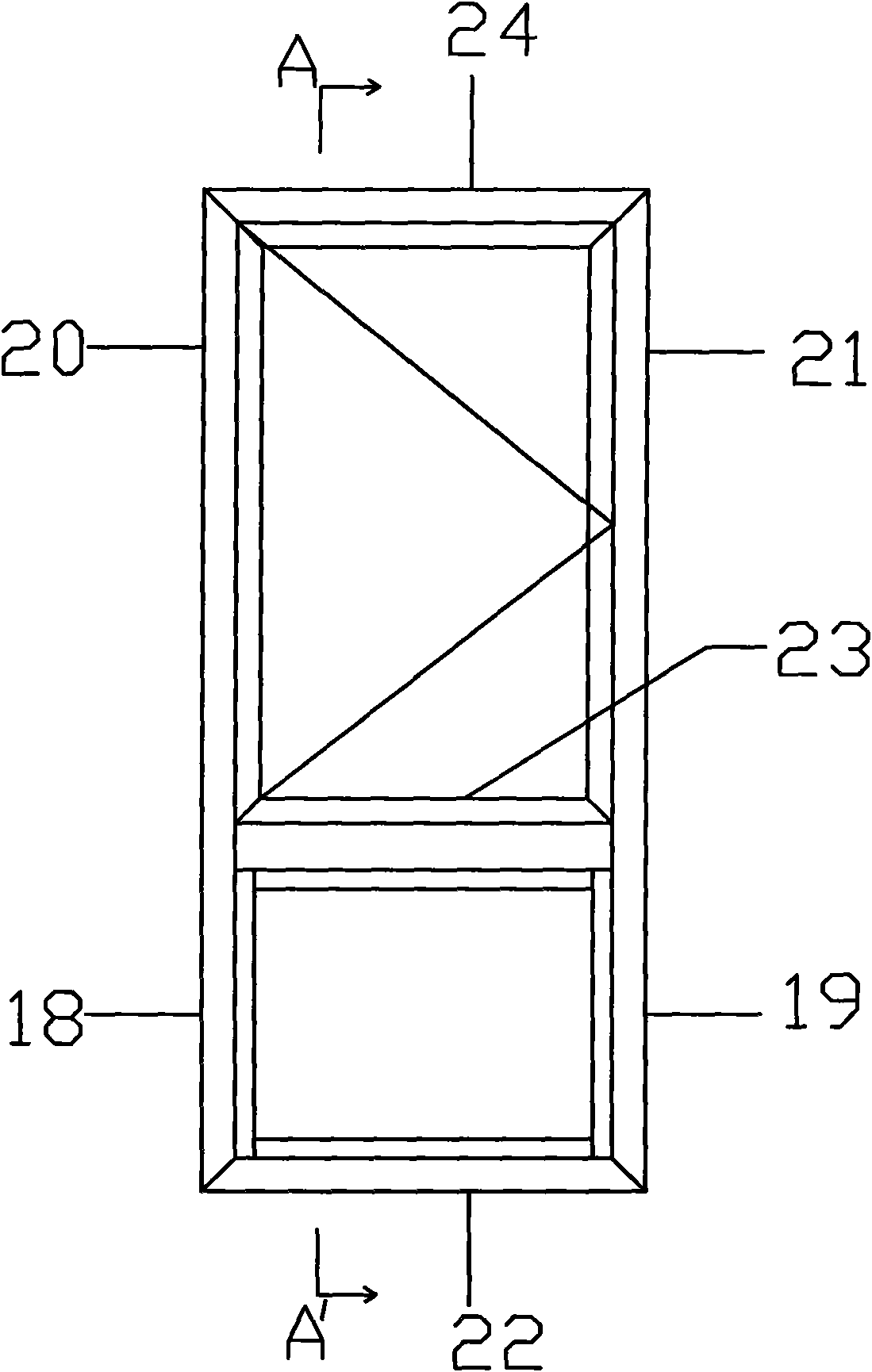

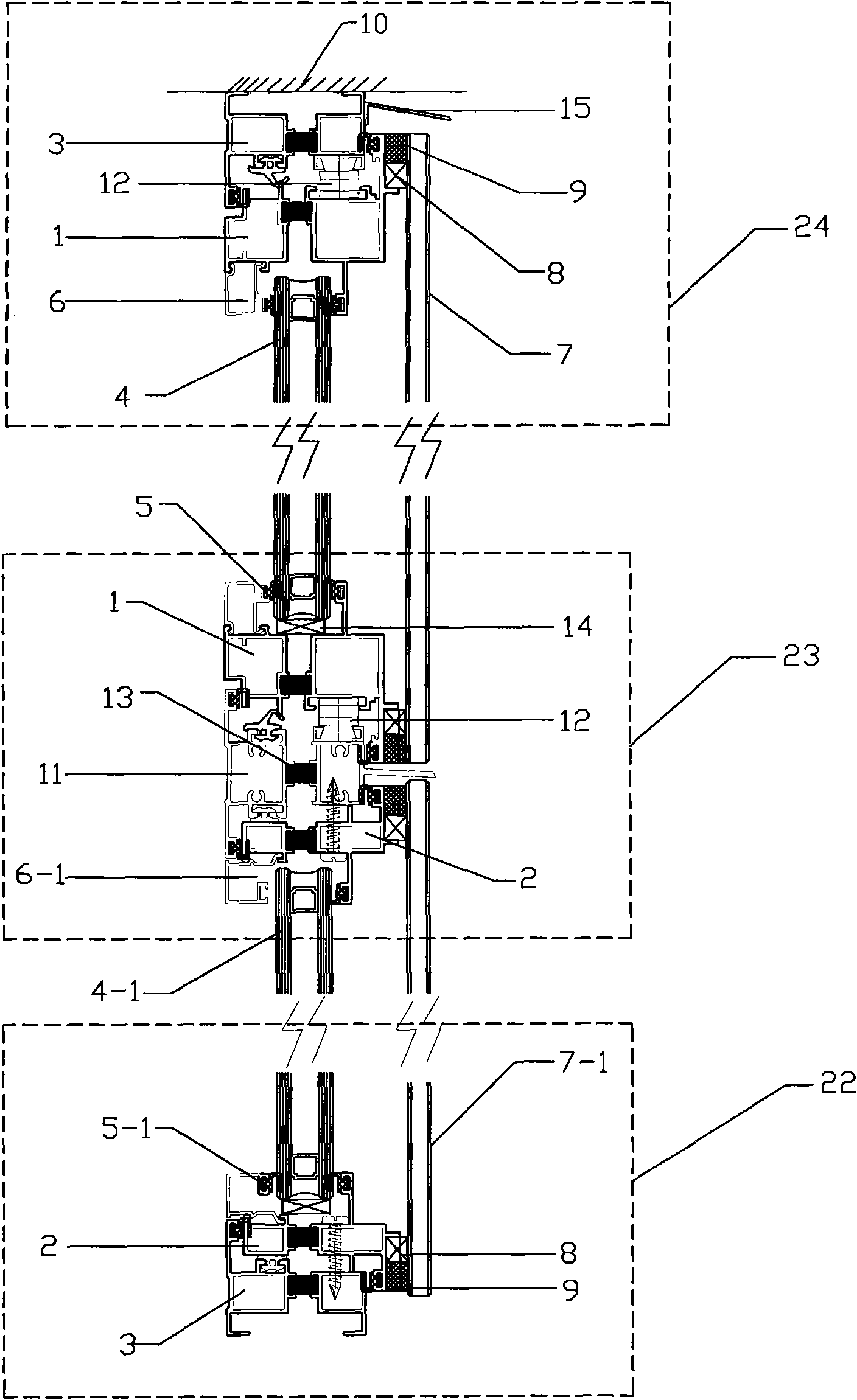

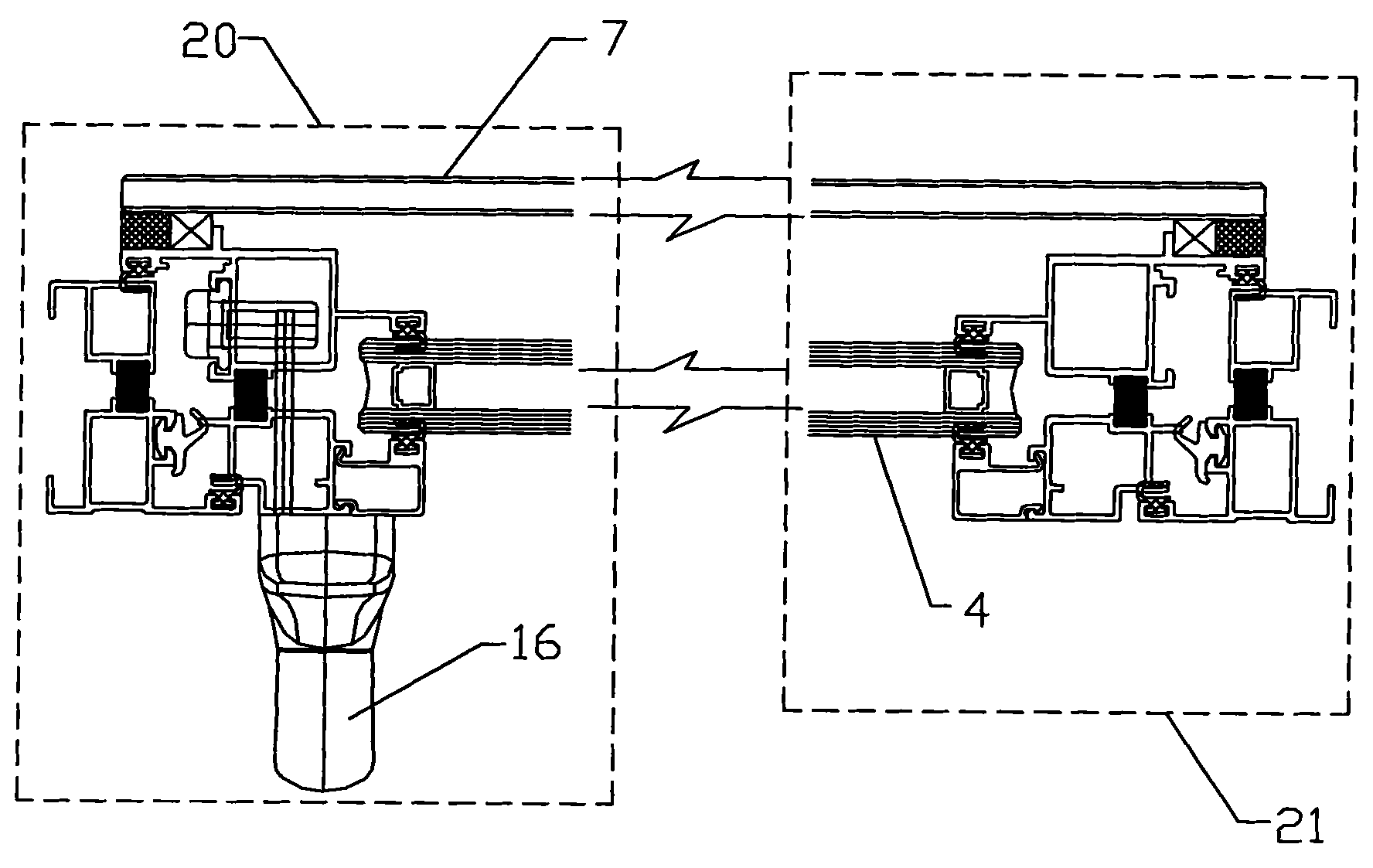

[0029] The present invention will be further described below in conjunction with accompanying drawing. figure 1 , 2 Among them, the soundproof window is composed of a casement fan 1 including a hollow glass inner layer and a single glass outer layer, a fixed fan 2 and a window frame 3; Stile 11, the hollow glass 4 is fixedly connected to the casement fan 1 through the sealing rubber strip 5 and the casement fan bead 6, and the single glass 7 is connected to the outside of the casement fan 1 through the double-sided adhesive strip 8 and the silicone structural adhesive 9 Fixedly connected, the top surface of the window outer frame 3 is flexibly fitted and sealed with the wall 10 through polyurethane foaming agent, and the top surface of the casement fan 1 is connected with the window frame through stainless steel sliding braces 12 .

[0030] The hollow glass 4-1 is fixedly connected to the fixed fan 2 through the sealing rubber strip 5-1 and the fixed fan bead 6-1, and the sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com