Spinning production process of super-fine polyester blended yarn

A technology of blended yarn and ultra-fine polyester, which is applied to spinning machines, yarns, combing machines, etc., can solve the problems of easy generation of coarse details, affecting yarn quality, and difficulty in spinning, so as to reduce wool particles and Generation of rough details, improvement of equipment and parameters, production of good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

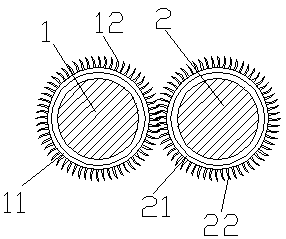

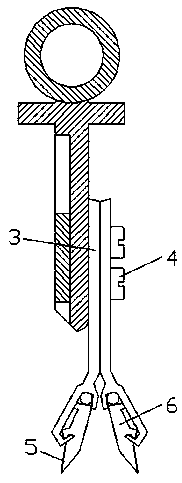

[0022] There are two types of needle plates in traditional fine needle carding machines, one is chain carding and the other is screw carding. The fibers are combed in a fast piercing and inserting way. This carding method can play a good and effective carding effect on traditional wool and other natural fibers with high moisture regain and is not easy to generate static electricity. When repeatedly piercing the fiber layer, due to the repeated friction effect between the metal needle surface of the needle plate and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com