Method for preparing ultra-wide aluminium-plastic composite panel and special devices thereof

A technology of aluminum-plastic composite panels and special devices, applied in the directions of lamination devices, chemical instruments and methods, lamination, etc., to save auxiliary materials and installation costs, reduce the possibility of water seepage, and reduce waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

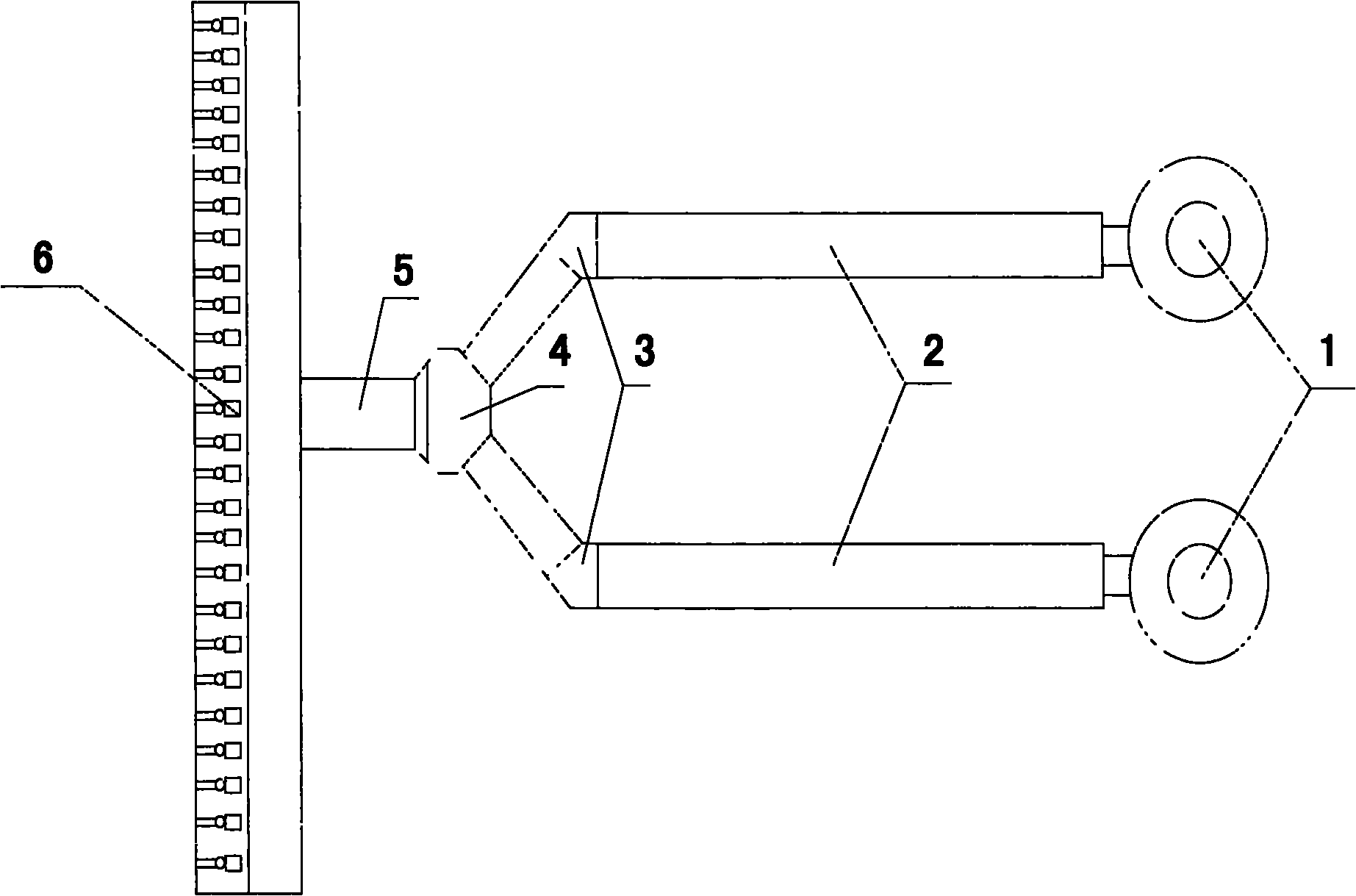

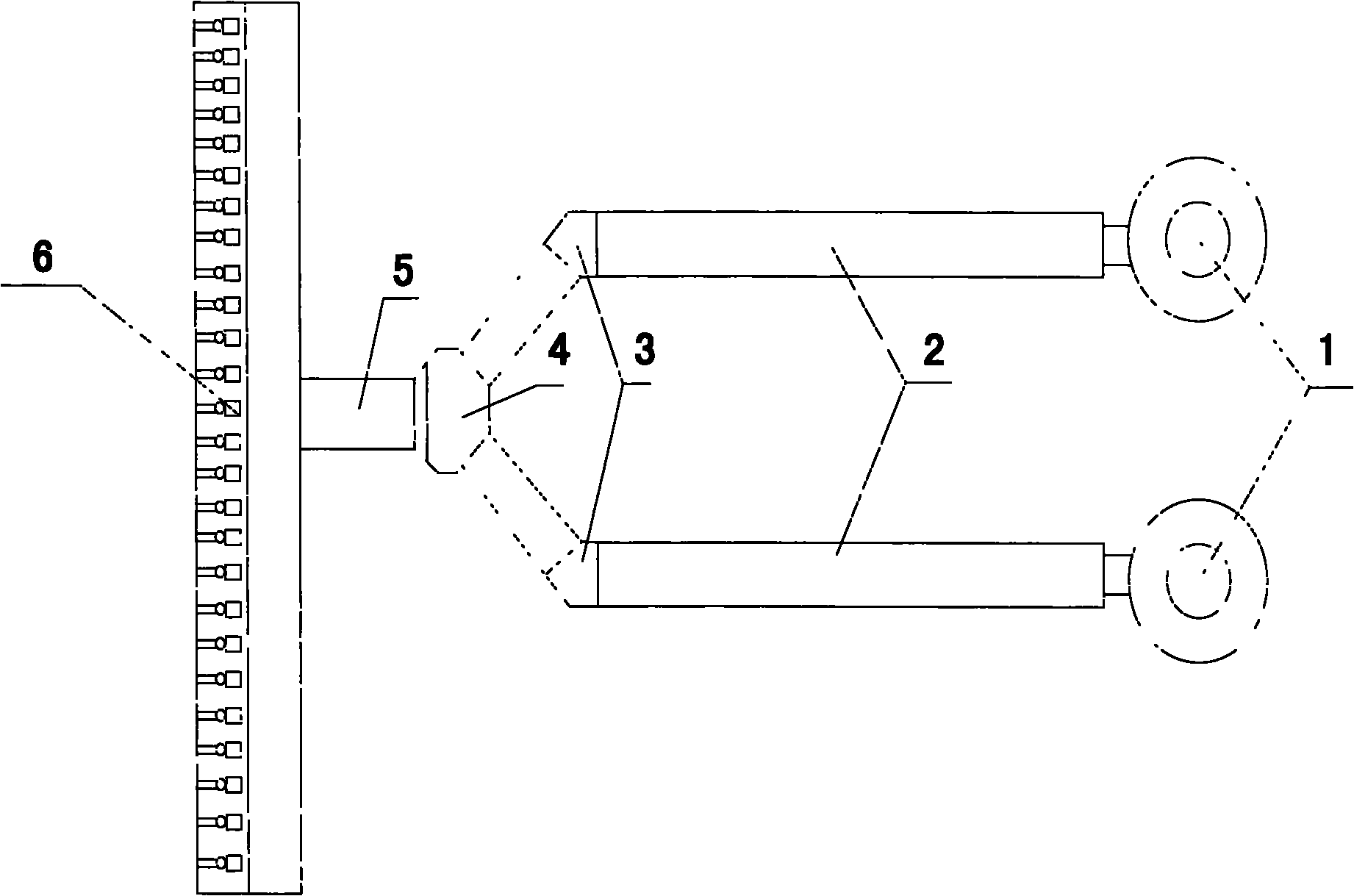

[0015] First pour the PE plastic into two preheating mixers 1 for preheating, control the temperature at 100°C-160°C, heat up for about 30 minutes before starting up, stir at 200-300r / min for 8-10 minutes, and mix at a time ≤450kg, the uniformly stirred plastic particles are sucked into the hopper of the single-screw extruder 2 by the vacuum suction machine. Extrude from die 3 of the extruder. The plastic melts from the dies 3 of the two single-screw extruders are collected in the same barrel 5 and flow into the T-shaped die 6. The outlet temperature of the T-shaped die 6 is controlled at 190-200 ° C. By adjusting the temperature of the extruded sheet The size of the width of the die head is used to form the plastic core board, and the T-die temperature of the core board is ≥175°C. The extruded plastic core board passes through the upper and lower composite polymer adhesive films and aluminum coils in sequence according to the composite process of conventional aluminum-plasti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com