Surface modified nano calcium carbonate and polychloroethylene plastisol thereof

A technology for surface modification of nano- and nano-calcium carbonate, which is applied in the treatment of fibrous fillers and dyed high-molecular organic compounds, and can solve the problems of poor bonding between nano-calcium carbonate and PVC resin and poor dispersibility of nano-calcium carbonate , to achieve the effect of reducing material cost, increasing adhesion, and increasing contact probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

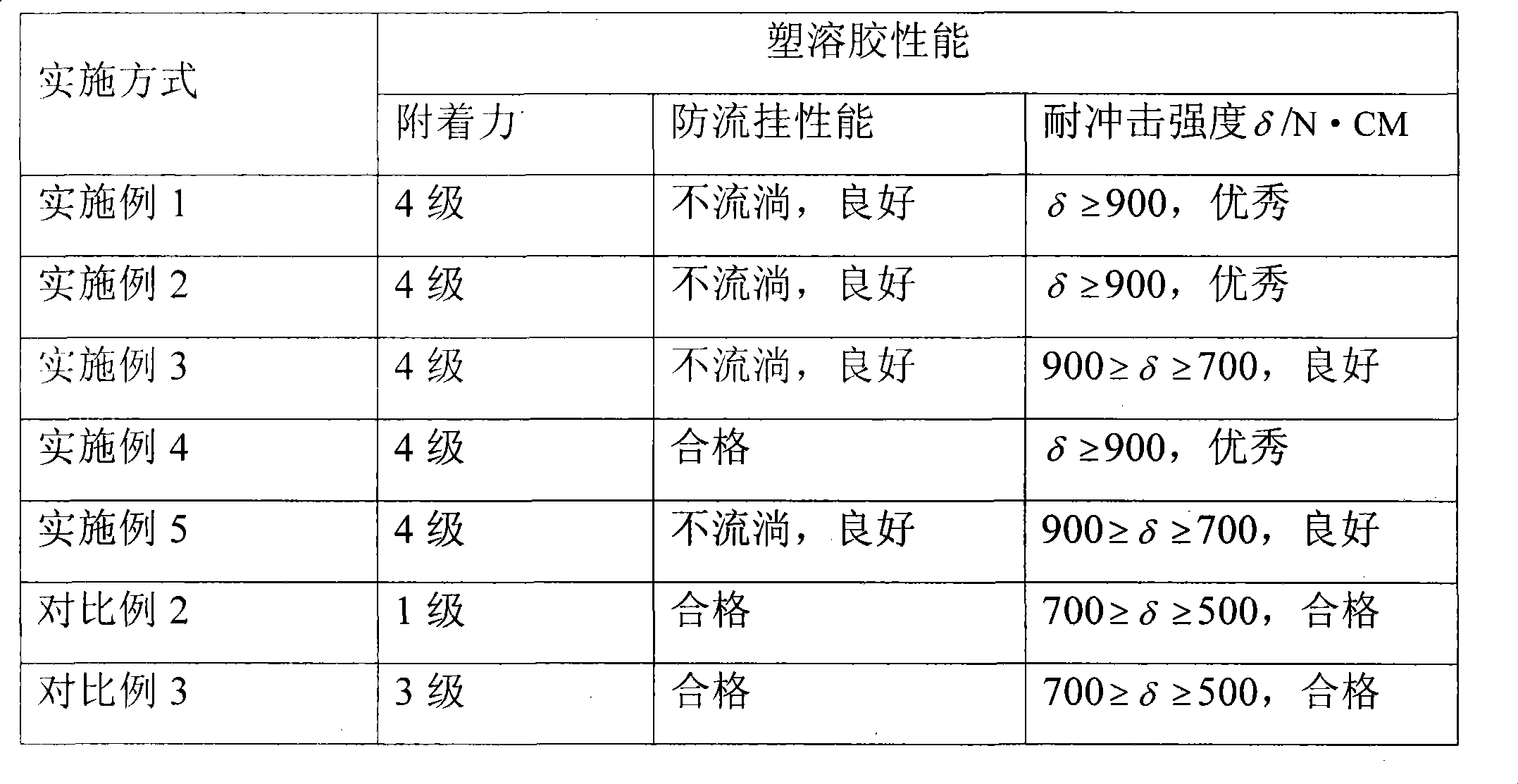

Examples

Embodiment 1

[0012] Take 100g CaO, add 900ml deionized water, heat to 65°C, and pass in CO with a volume fraction of 35% under full stirring 2 , the speed is 4L / min, after the carbonization of 80min is completed, the ventilation is stopped, and 4g of carboxyl-terminated polyamide resin (formed by condensation of stearic acid dimer and diethylenetriamine) with an acid value of 120±20mgKOH / g ) into the above system, continue stirring for 60 min, place at room temperature for 350 min, filter, and dry at 60° C. to obtain surface-modified nano-calcium carbonate with an average primary particle diameter of about 70 nm.

[0013] Add the surface-modified nano-calcium carbonate of this embodiment into the automotive PVC plastisol formulation, and stir evenly at room temperature to obtain a finished PVC plastisol. The composition and content of PVC plastisol are: PVC resin (model: E5 / 65C, produced by Vinnolit Company) accounts for 15wt%, filler (1000 mesh ordinary calcium carbonate, produced by Guan...

Embodiment 2

[0015] Except changing 4g carboxy-terminated polyamide resin into 8g in embodiment 1, all the other are identical with embodiment 1.

Embodiment 3

[0017] Change the carboxyl-terminated polyamide resin in Example 1 into the carboxyl-terminated polyamide resin (the dimer of stearic acid and the ratio of diethylenetriamine can be adjusted to obtain the present embodiment) at 160 ± 20mgKOH / g acid value The carboxyl-terminated polyamide resin of example acid value), all the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com