Special anti-sloughing liquid coagulant for foam concrete cast-in-place wall

A foamed concrete and cast-in-place wall technology, which is applied in the field of concrete additives, can solve the problems of foamed concrete collapse, restricting the wide application of foamed concrete, and low foam breaking rate of slurry setting and hardening rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

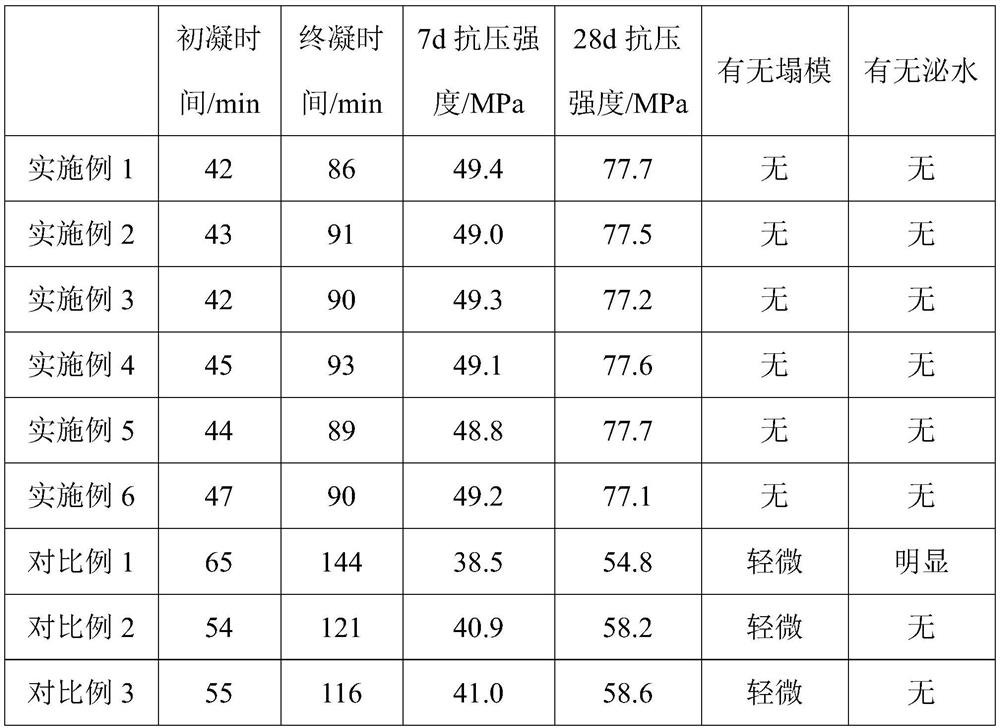

Examples

Embodiment 1

[0030] An anti-collapse liquid coagulant for foam concrete cast-in-place walls, which consists of the following components in parts by weight:

[0031] 50 parts of polyaluminum sulfate, 5 parts of magnesium sulfate, 1 part of triethanolamine, 2 parts of magnesium fluorosilicate, 0.2 parts of amide-modified polycarboxylate superplasticizer, 4 parts of mixed acid composed of lactic acid and phosphoric acid in a weight ratio of 1:10 , 0.5 parts of sodium bicarbonate, 0.5 parts of hydroxypropyl methylcellulose, 0.1 parts of carboxymethyl starch ether, 2 parts of sodium tripolyphosphate, and 400 parts of water.

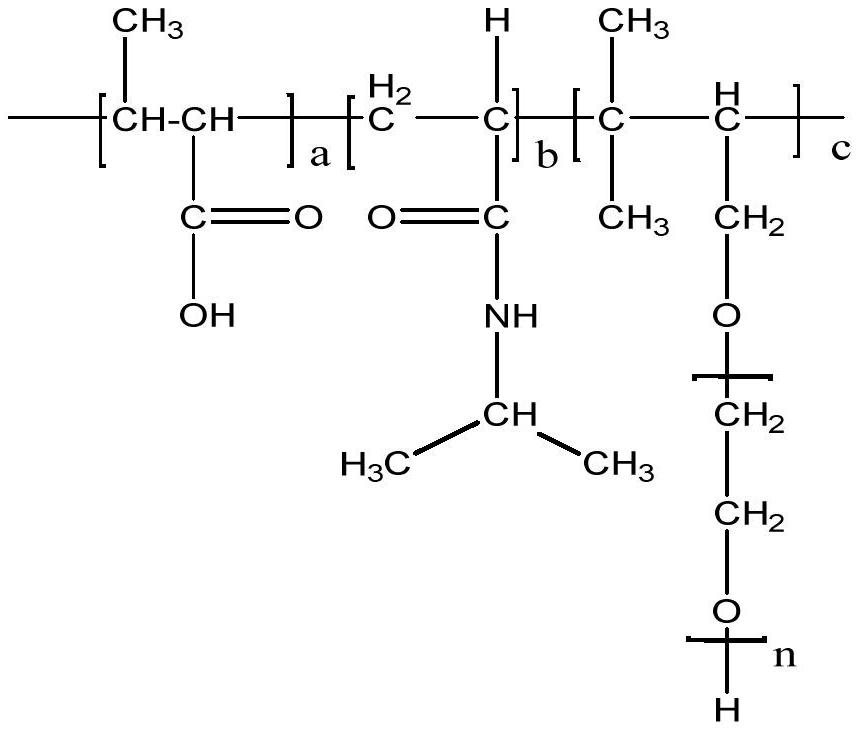

[0032] The preparation method of amide modified polycarboxylate water reducer is as follows:

[0033] The aqueous solution of prenol polyoxyethylene ether with a mass concentration of 10% is heated to 80°C, the hydroxyl value of prenol polyoxyethylene ether is 21-26mgKOH / g, the acid value is ≤0.5mgKOH / g, and the molecular weight is 2200-2600, add the mixed solution of cro...

Embodiment 2

[0037] An anti-collapse liquid coagulant for foam concrete cast-in-place walls, which consists of the following components in parts by weight:

[0038] 40 parts of polyaluminum sulfate, 5 parts of magnesium sulfate, 1 part of triethanolamine, 2 parts of magnesium fluorosilicate, 0.1 part of amide-modified polycarboxylate superplasticizer, 2 parts of mixed acid composed of lactic acid and phosphoric acid in a weight ratio of 1:20, 0.1 part of sodium bicarbonate, 0.1 part of hydroxypropyl methylcellulose, 0.1 part of carboxymethyl starch ether, 3 parts of sodium tripolyphosphate, and 500 parts of water.

[0039] The preparation method of amide modified polycarboxylate water reducer is as follows:

[0040] The aqueous solution of prenol polyoxyethylene ether with a mass concentration of 5% is heated to 85°C, the hydroxyl value of prenol polyoxyethylene ether is 21-26mgKOH / g, the acid value is ≤0.5mgKOH / g, and the molecular weight is 2200-2600, add the mixed solution of crotonic ...

Embodiment 3

[0044] An anti-collapse liquid coagulant for foam concrete cast-in-place walls, which consists of the following components in parts by weight:

[0045]30 parts of polyaluminum sulfate, 5 parts of magnesium sulfate, 0.1 part of triethanolamine, 1 part of magnesium fluorosilicate, 0.1 part of amide-modified polycarboxylate superplasticizer, 1 part of mixed acid composed of lactic acid and phosphoric acid in a weight ratio of 1:6, 0.1 part of sodium bicarbonate, 0.1 part of hydroxypropyl methylcellulose, 0.1 part of carboxymethyl starch ether, 1 part of sodium tripolyphosphate, 400 parts of water.

[0046] The preparation method of amide modified polycarboxylate water reducer is as follows:

[0047] The aqueous solution of prenol polyoxyethylene ether with a mass concentration of 5% is heated to 70°C, the hydroxyl value of prenol polyoxyethylene ether is 21-26mgKOH / g, the acid value is ≤0.5mgKOH / g, and the molecular weight is 2200-2600, add the mixed solution of crotonic acid, N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com