Environment-friendly water-based paint for living container and preparation method thereof

A container and environmental protection technology, applied in the field of water paint, can solve the problems of poor weather resistance and poor water resistance of the paint film, and achieve the effect of long weather resistance, good weather resistance and high surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

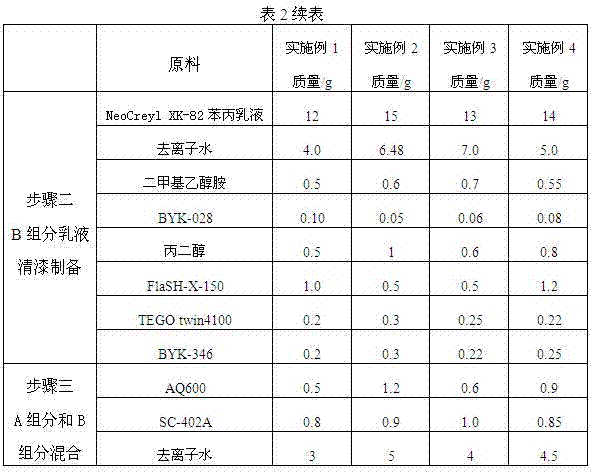

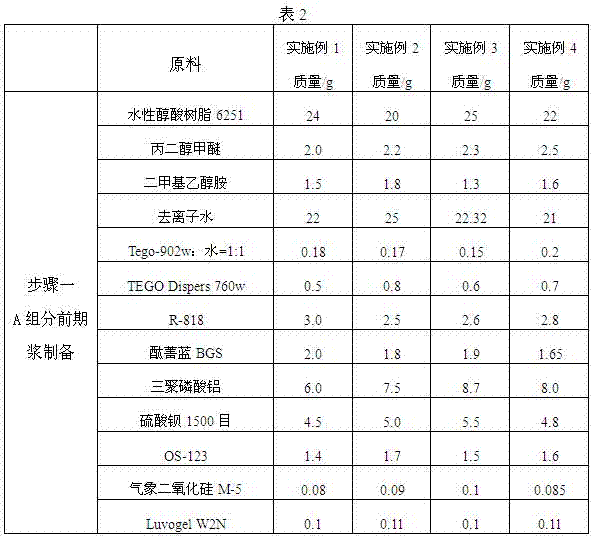

[0042] The environment-friendly water-based paint for living container of the present invention, each embodiment concretely implements group allocation as shown in table 2:

[0043]

[0044]

[0045] The preparation method of environment-friendly water-based paint for living container comprises the following steps:

[0046] Step 1 Preparation of early stage slurry of component A

[0047]According to the ratio of raw materials in parts by weight, add 20-25 parts of water-based alkyd resin 6251, 2-2.5 parts of environmentally friendly co-solvent propylene glycol methyl ether, and 1.3-1.8 parts of neutralizing agent dimethylethanolamine into the material preparation pot, 500-600r / Stir for 8-10 minutes, gradually add 21-25 parts of deionized water, 0.15-0.2 parts of Tego-902w and deionized water in a mass ratio of 1:1 to obtain the defoamer, 0.5-0.8 parts of dispersant TEGO Dispers 760w , Stir at 800-1000r / min for 10-15min, add 1.65-2.0 parts of phthalocyanine blue BGS, 2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface dry time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com