Formaldehyde-degrading degradable automotive interior foamed plastic and preparation method thereof

A technology for foamed plastics and automobile interiors, applied in the field of automobile interiors, can solve the problems of limited adsorption capacity of physical adsorbents, difficult decomposition of interior plastics, low adsorption efficiency, etc., achieve good environmental friendliness, promote uniform dispersion, use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

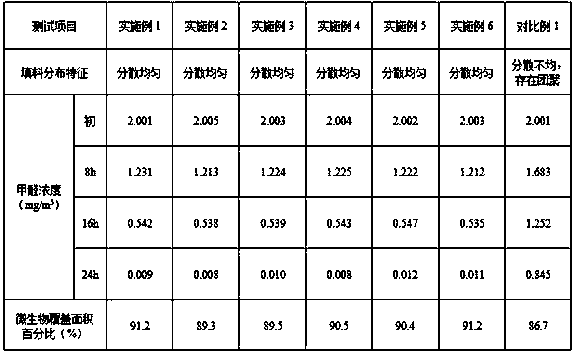

Examples

Embodiment 1

[0031] (1) Dissolve tetracarboxyphthalocyanine iron in water, add hydroxyapatite, porous powder quartz and halloysite, disperse evenly by ultrasonic, transfer to the reaction kettle, then add catalyst, heat for grafting reaction, filter , drying, and further baking to obtain a mixed filler of grafted tetracarboxyphthalocyanine iron; wherein, 3 parts by weight of tetracarboxyiron phthalocyanine, 27 parts by weight of hydroxyapatite, 27 parts by weight of porous powder quartz, and 42 parts by weight of halloysite Parts, 1 part by weight of catalyst; Catalyst is magnesium chloride; The temperature of grafting reaction is 166 ℃, and the pressure is 2.5MPa, and the time is 5h; The temperature of baking is 142 ℃, and the time is 3min;

[0032] (2) Mix vegetable oil and toluene diisocyanate, add the mixed filler prepared in step (1), heat and stir at a constant temperature to polymerize, and obtain a vegetable oil-based three-dimensional network prepolymer with evenly distributed fill...

Embodiment 2

[0040] (1) Dissolve tetracarboxyphthalocyanine iron in water, add hydroxyapatite, porous powder quartz and halloysite, disperse evenly by ultrasonic, transfer to the reaction kettle, then add catalyst, heat for grafting reaction, filter , drying, and further baking to obtain a mixed filler of grafted tetracarboxyphthalocyanine iron; wherein, 2 parts by weight of tetracarboxyiron phthalocyanine, 20 parts by weight of hydroxyapatite, 20 parts by weight of porous powder quartz, and 57 parts by weight of halloysite Parts, 1 part by weight of catalyst; Catalyst is zinc chloride; The temperature of grafting reaction is 160 ℃, and the pressure is 2MPa, and the time is 6h; The temperature of baking is 130 ℃, and the time is 5min;

[0041] (2) Mix vegetable oil and toluene diisocyanate, add the mixed filler prepared in step (1), heat and stir at a constant temperature to polymerize, and obtain a vegetable oil-based three-dimensional network prepolymer with evenly distributed filler; whe...

Embodiment 3

[0045] (1) Dissolve tetracarboxyphthalocyanine iron in water, add hydroxyapatite, porous powder quartz and halloysite, disperse evenly by ultrasonic, transfer to the reaction kettle, then add catalyst, heat for grafting reaction, filter , dried, and further baked to obtain a mixed filler of grafted tetracarboxyphthalocyanine iron; wherein, 4 parts by weight of tetracarboxyiron phthalocyanine, 35 parts by weight of hydroxyapatite, 35 parts by weight of porous powder quartz, and 24 parts by weight of halloysite Parts, 2 parts by weight of catalyst; Catalyst is magnesium chloride; The temperature of grafting reaction is 170 ℃, and the pressure is 3MPa, and the time is 4h; The temperature of baking is 150 ℃, and the time is 2min;

[0046] (2) Mix vegetable oil and toluene diisocyanate, add the mixed filler prepared in step (1), heat and stir at a constant temperature to polymerize, and obtain a vegetable oil-based three-dimensional network prepolymer with evenly distributed filler;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com