Concrete corrosion inhibitor and premixed concrete using same

A concrete rust inhibitor and ready-mixed concrete technology, which is applied in the field of ready-mixed concrete, can solve problems such as soil pollution, and achieve good pollution, better effect, and good environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

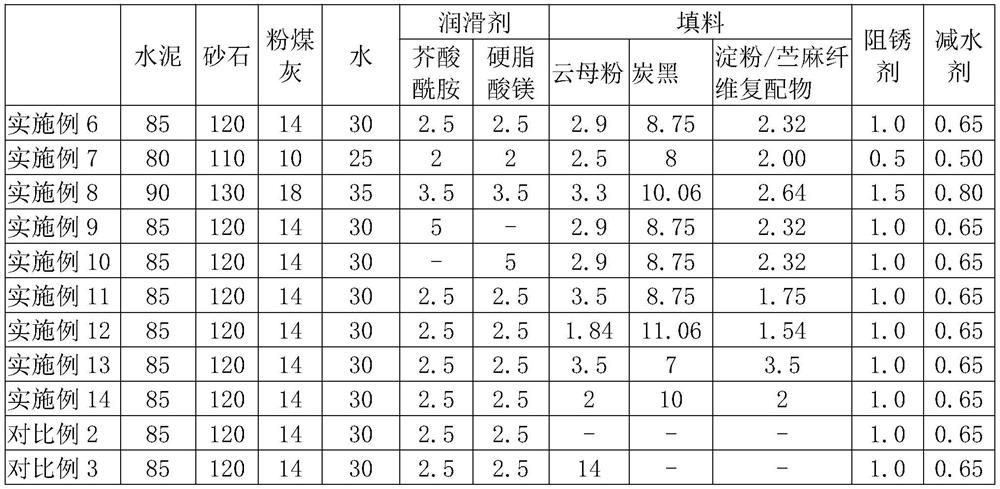

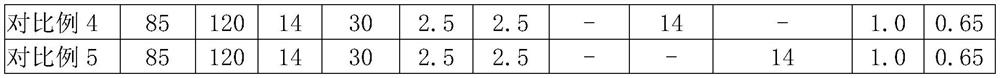

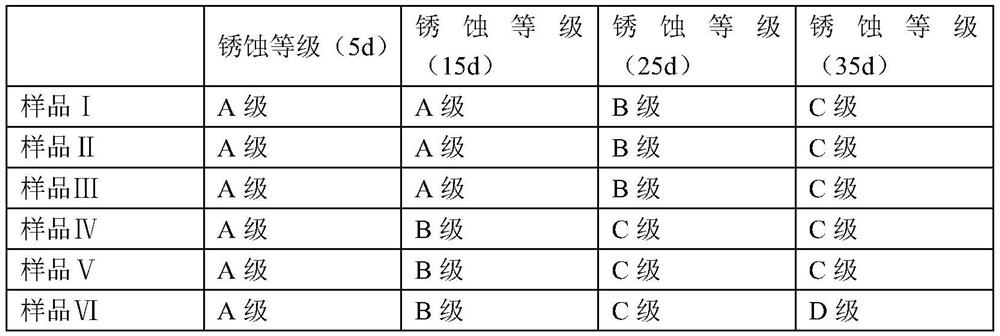

Method used

Image

Examples

Embodiment 1

[0033] Take a clean container, add 0.4 parts of sodium molybdate, 13 parts of water-soluble benzotriazole, 6 parts of epoxy resin adhesive, 15 parts of octyltriethoxysilane and 35 parts of Water, stir well to form concrete rust inhibitor.

Embodiment 2

[0035] Take a clean container, add 0.2 parts of sodium molybdate, 10 parts of water-soluble benzotriazole, 4 parts of epoxy resin adhesive, 12 parts of octyltriethoxysilane and 30 parts of Water, stir well to form concrete rust inhibitor.

Embodiment 3

[0037] Take a clean container, add 0.6 parts of sodium molybdate, 16 parts of water-soluble benzotriazole, 8 parts of epoxy resin adhesive, 18 parts of octyltriethoxysilane and 40 parts of Water, stir well to form concrete rust inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com