Spray flow gel and preparation method thereof

A technology for gel and curdlan, which is applied in the field of spray flow gel and its preparation, can solve the problems of destruction of molecular chain binding sites, low efficiency, unfavorable industrial production and the like, and achieves the effect of high preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

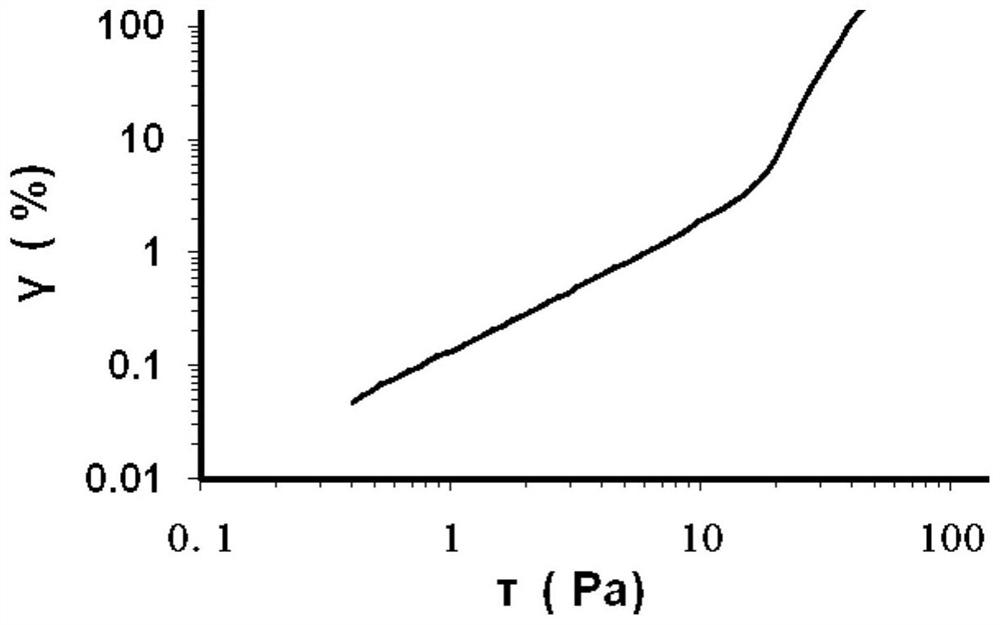

[0025] Add 1g of agar powder to 100ml of deionized water, stir in a water bath at 95°C for 2 hours, add it to the spray pot after fully swelling, start the air compressor, and spray through the spray head after the pressure reaches 0.2Mpa. 0.5mm. Start the fan to be refrigerated, and the generated cold air below 4°C will contact the spray, and the droplets will gel and fall into the collector to form a spray flow gel. The yield value measured by a rheometer is 11.2 Pa.

[0026] figure 1 The rheological spectrum of the spray flow 0.5% agar yield value prepared for this embodiment, as can be seen from the figure: the agar forms a semi-solid gel different from the static gel, and this gel has both solid gel The smoothness and flowability of liquid, and the high yield value endow it with good chewiness.

Embodiment 2

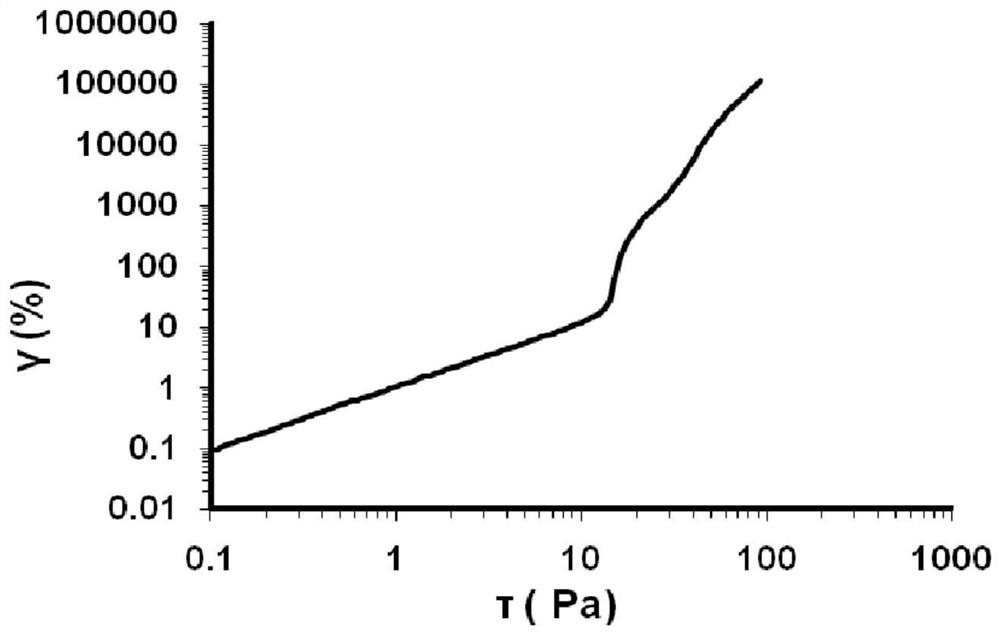

[0028] Add 1 g of sodium alginate powder to 100 ml of water, and bathe in water at 70 ° C for 2 hours; add 0.5 g of calcium chloride powder to 100 g of water, fully dissolve and set aside. The sodium alginate solution and the calcium chloride solution are sprayed through different spray heads, the spray heads are oppositely sprayed, the compressed air is 0.2Mpa, the spray hole diameter of the spray head is 0.5mm, and the distance between the spray heads is 1m, the two kinds of mist droplets collide with each other to form a gel, and In the process of falling, it is subjected to the shearing action of the air, resulting in the inability to form high-strength gel particles and forming flow gel particles with less hardness and irregular shape. The collected samples were measured by a rheometer to have a yield value of 10.8 Pa.

[0029] figure 2 It is the rheological spectrum of the yield value of the spray flow gel sodium alginate prepared in the present embodiment, as can be s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com