Preparation method of organic silicon modified cathode electrophoresis resin and cathode electrophoresis emulsion prepared by preparation method

A cathodic electrophoresis and silicone technology, which is applied in electrophoretic coatings, epoxy resin coatings, coatings, etc., can solve the problems of emulsion storage stability and uneven particle size distribution of emulsions, and improve sharp edge corrosion performance and adhesion Good, the effect of film thickness increase

- Summary

- Abstract

- Description

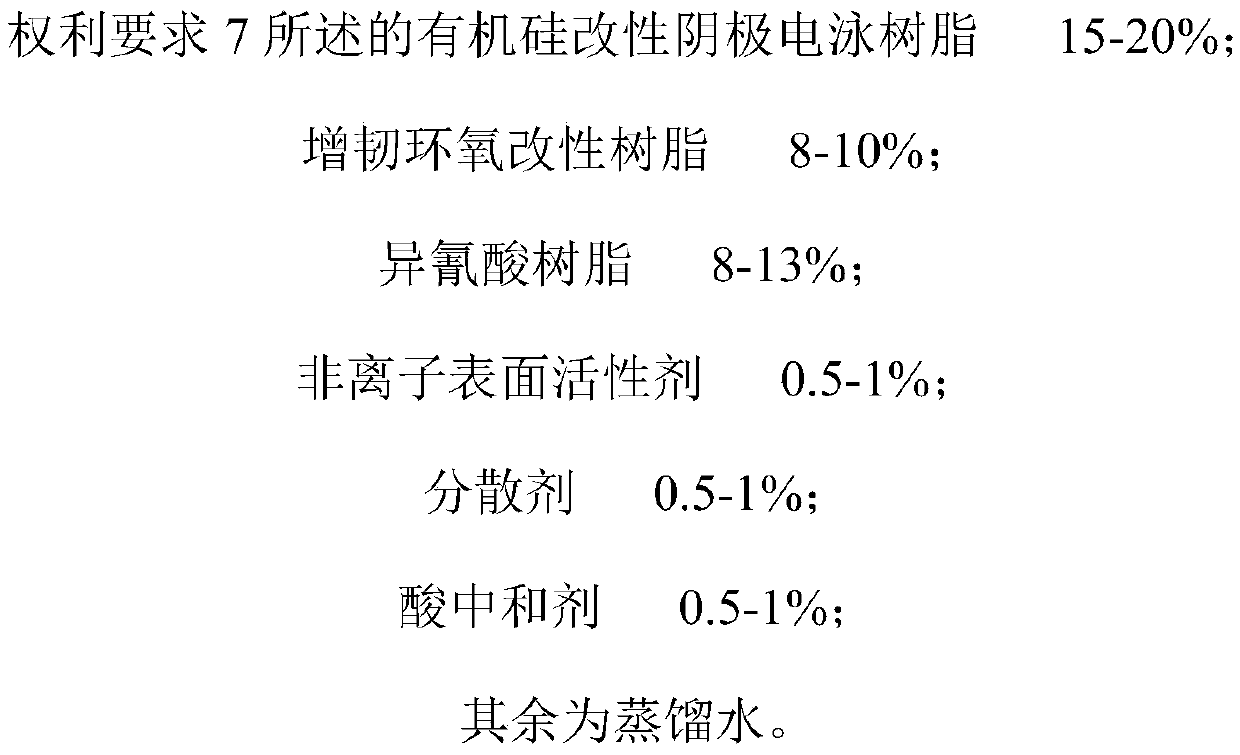

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

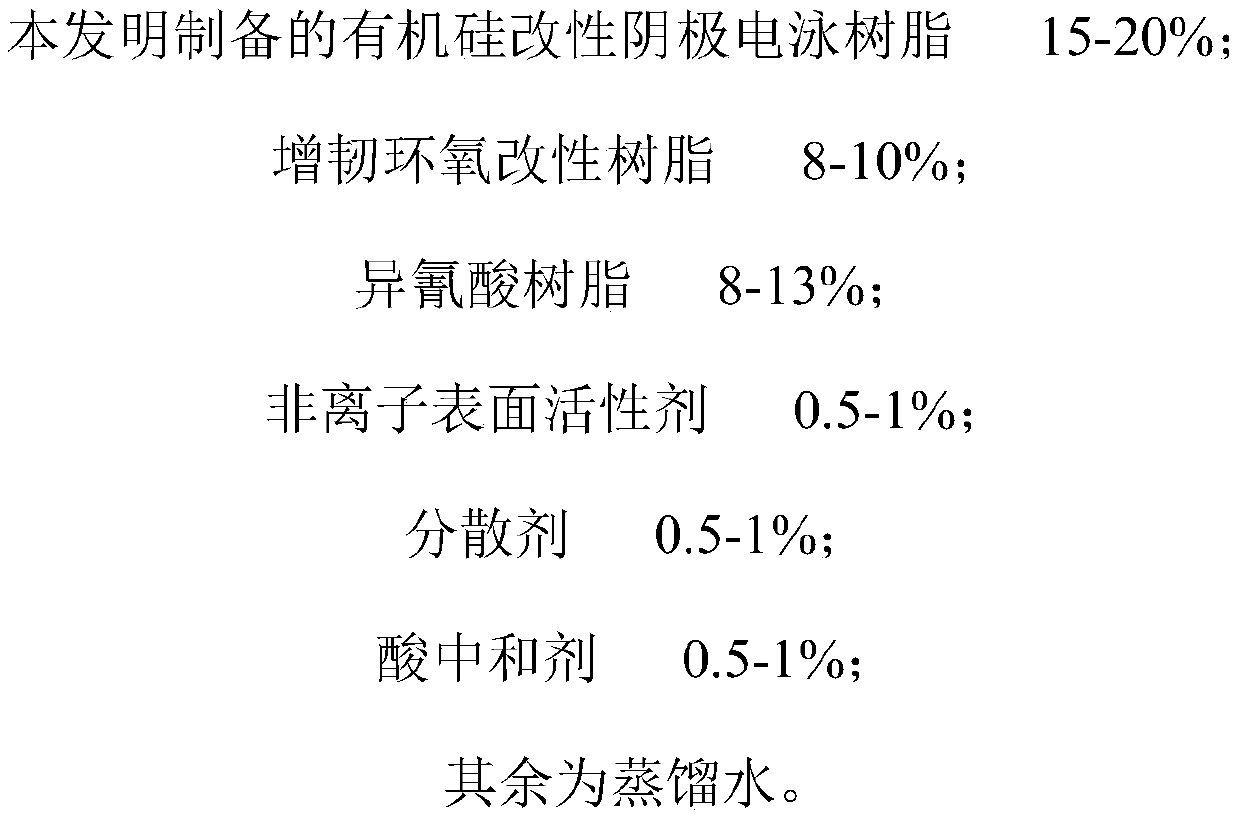

Method used

Image

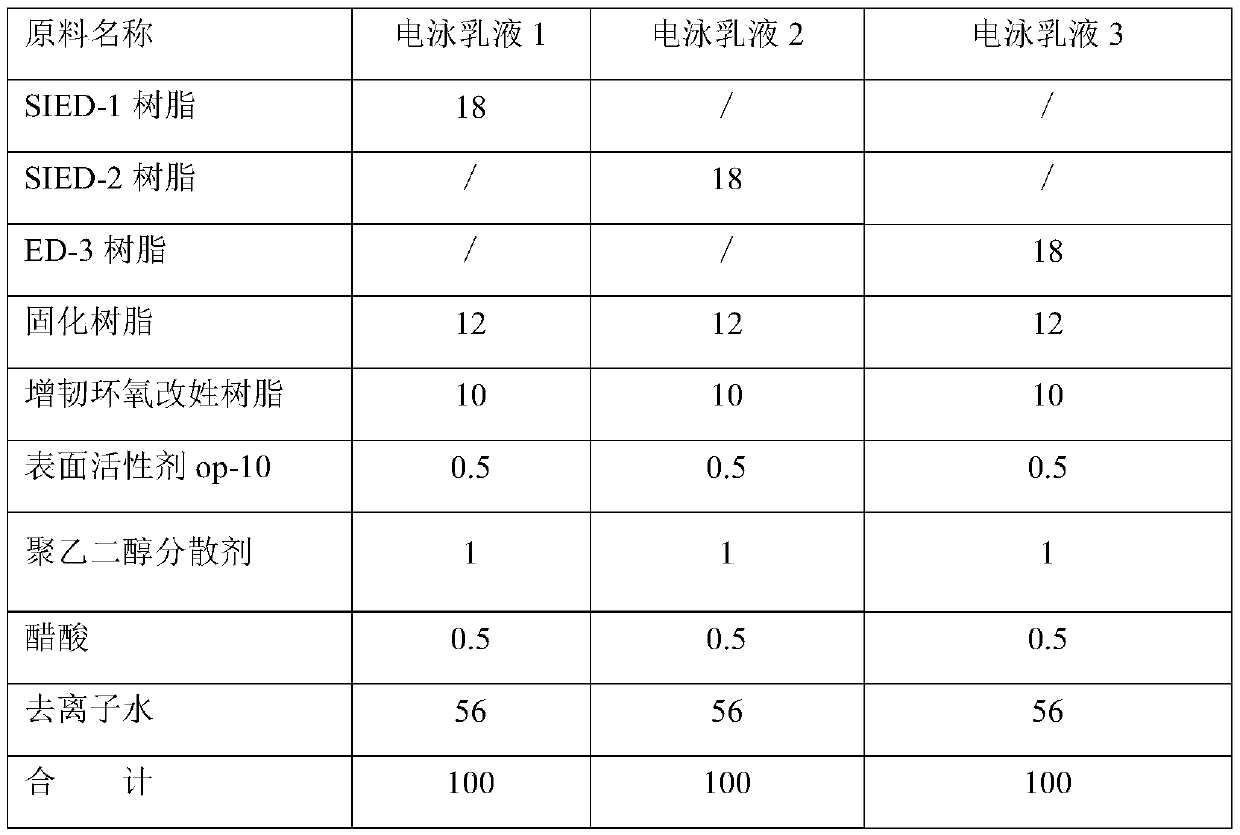

Examples

Embodiment 1

[0034] A preparation method of organosilicon modified cathodic electrophoresis resin, comprising the following steps:

[0035] (1) Mix 44 parts of epoxy resin E-51, 19 parts of bisphenol A, 0.3 parts of diethanolamine, and 3 parts of methyl isobutyl ketone, react at 120°C for 1 hour, and continue to add 2 parts of (3-glycidyloxypropoxy Propyl) methyldiethoxysilane, react 2.0h, then take a sample and test the epoxy value of reaction system, its epoxy value is 1.78;

[0036] (2) Add 10 parts of methyl isobutyl ketone to control the reaction temperature to 90°C, add 7 parts of diethanolamine, and raise the temperature to 140°C for 3 hours;

[0037] (3) Add 15 parts of methyl isobutyl ketone, mix and stir evenly, cool and discharge to obtain the organosilicon-modified cathodic electrophoresis resin SIED-1.

[0038] The solid content of the organosilicon-modified cathodic electrophoresis resin prepared in this example was 75%, and the amine value was 55.

Embodiment 2

[0040] A preparation method of organosilicon modified cathodic electrophoresis resin, comprising the following steps:

[0041] (1) Mix 44 parts of epoxy resin E-51, 19 parts of bisphenol A, 0.3 parts of diethanolamine, and 3 parts of methyl isobutyl ketone, react at 120°C for 1 hour, and continue to add 5.0 parts of (3-glycidyloxypropoxy Propyl) methyldiethoxysilane, react 2.0h, then take a sample and test the epoxy value of reaction system, its epoxy value is 1.85;

[0042] (2) Add 10 parts of methyl isobutyl ketone to control the reaction temperature to 90°C, add 7 parts of diethanolamine, and raise the temperature to 140°C for 3 hours;

[0043] (3) Add 15 parts of methyl isobutyl ketone, mix and stir evenly, cool and discharge to obtain the organosilicon-modified cathodic electrophoresis resin SIED-2.

[0044] The solid content of the organosilicon-modified cathodic electrophoresis resin prepared in this example was 75%, and the amine value was 57.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com