Coating agent and preparation method and application and drilling fluid used for petroleum drilling

A technology of coating agent and drilling fluid, which is applied in the field of coating agent and its preparation, can solve problems such as the difficulty in wellbore pressure control, the instability of deep water water-sensitive shale well walls, and the difficulty in meeting the technical requirements of deep water oil and gas drilling engineering. Achieving the effect of avoiding severe viscosity increase at low temperature and facilitating the pressure control of deepwater drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] As long as the coating agent of the present invention meets the aforementioned requirements, the purpose of the present invention can be achieved, and there is no special requirement for its preparation method. For the present invention, the preferred method includes: under polymerization conditions, acrylamide, temperature-resistant monomer and cationic The monomer is polymerized, wherein, preferably, the temperature-resistant monomer is a compound shown in the following formula (IV):

[0034] Formula (Ⅳ): and / or

[0035] The cationic monomer is a compound shown in the following formula (V):

[0036] Formula (Ⅴ):

[0037] According to the invention, preferably R 1 , R 2 Each is independently H, C1-C15 linear or branched chain alkyl.

[0038] According to the invention, preferably R 3 It is H or C1-C5 linear or branched chain alkyl.

[0039] According to the invention, preferably R 1 is methyl, decyl, undecyl or dodecyl.

[0040] According to the invention...

Embodiment approach

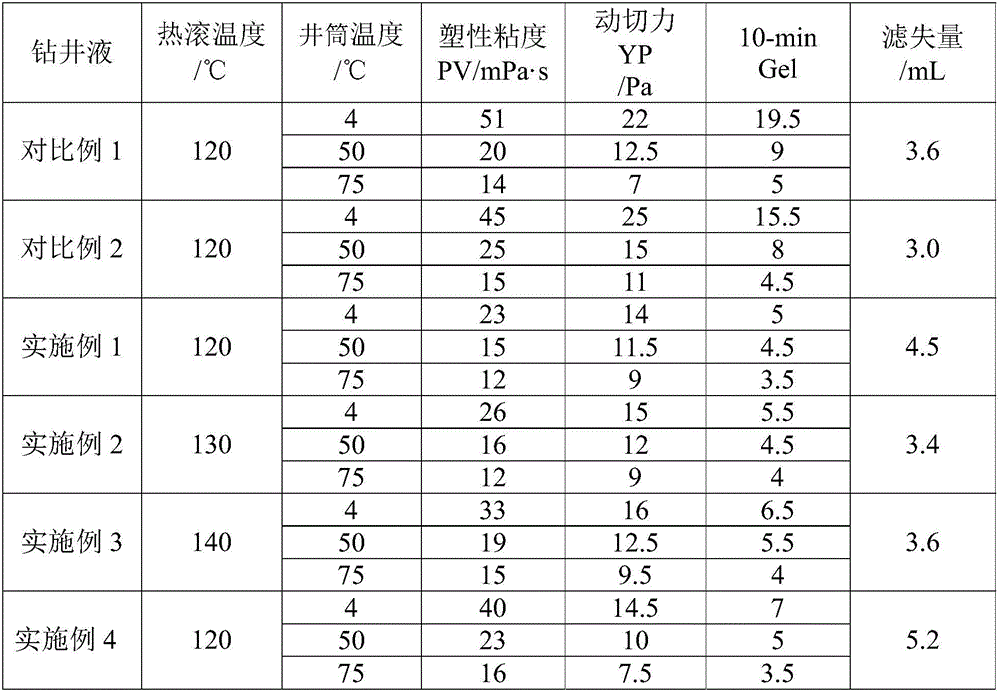

[0054] According to a preferred embodiment of the present invention, in parts by weight, the drilling fluid includes: 100 parts of water, 2-3.5 parts of amine inhibitor, 0.1-0.5 part of viscosifier, 0.15-0.5 part of coating agent, and 0.8-5.5 parts of loss agent, 10-30 parts of salt, 0-3 parts of liquid lubricant, 0-3 parts of compounding clay, and 0-20 parts of weighting agent.

[0055] The main improvement of the drilling fluid of the present invention lies in the coating agent, amine inhibitor, and slurry mixing soil. There are no special requirements for other components such as fluid loss reducer, salt, liquid lubricant, weighting agent, viscosifier, etc., which can be based on General selection of fields.

[0056] According to a preferred embodiment of the present invention, wherein the amine inhibitor is polyamine and / or dimethylcyclohexylamine.

[0057] According to a preferred embodiment of the present invention, the polyamine is an amine-based polymer obtained by poly...

Embodiment 1

[0082] Prepare clay-free deep-water water-based drilling fluid, including components in the following weight ratios:

[0083] Polyamine inhibitor: 2; Xanthan gum XC: 0.3; Coating agent: 0.25; Polyanionic cellulose PAC-LV: 0.5; Sulfonated phenolic resin SD-101: 5; NaCl: 10; KCl: 4; for 100.

[0084] The polyamine inhibitor used in this embodiment is prepared by the following method:

[0085] Add 300g of polyoxypropylene diamine and 0.3g of potassium hydroxide into the high-temperature and high-pressure reactor, vacuumize and heat the reactor, and start stirring at the same time, and the stirring rate is 300r / min. When the temperature was raised to 80° C., 25 g of propylene oxide was fed, and the temperature was continued to rise. When the temperature rose to 100° C., 105 g of propylene oxide was fed. After the reaction started, the reaction temperature was maintained at 105°C. After the pressure in the reactor dropped and remained constant, the temperature was maintained for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com