Sulfonic acid modified carboxymethyl hydroxypropyl guar gum, and preparation method and application thereof

A carboxymethyl hydroxypropyl guar gum and a modification technology are applied in the field of sulfonic acid-modified carboxymethyl hydroxypropyl guar gum and its preparation, and can solve the problem of reducing the effect of oil and gas well reconstruction and high content of raw powder residues problem, to achieve the effect of good water solubility, saving dosage, and reducing the types of additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A preparation method of organic sulfonic acid modified carboxymethyl hydroxypropyl guar gum, the steps are as follows:

[0059] (1) In the reactor that 3L65% ethanol solution is housed, add 1000.0g carboxymethyl hydroxypropyl guar gum (the degree of substitution of carboxymethyl is 0.19, the degree of substitution of hydroxypropyl is 0.28);

[0060] (2) Under a nitrogen atmosphere, add 150 g of 15% sodium hydroxide aqueous solution dropwise, stir for 0.5 hours, then heat up to 65-70° C., stir for 0.5 hours, add 68 g of vinylsulfonic acid dropwise, keep the temperature at 70° C., and complete the dropwise addition in 2 hours. Continue stirring for 4 hours;

[0061] (3) neutralize the reaction solution with hydrochloric acid to pH = 7, filter, and dry the solid product at 70°C to obtain the light yellow powder product SCMHPG;

[0062] In this structure R=H, n=0.

[0063] Determination of special performance indicators of products:

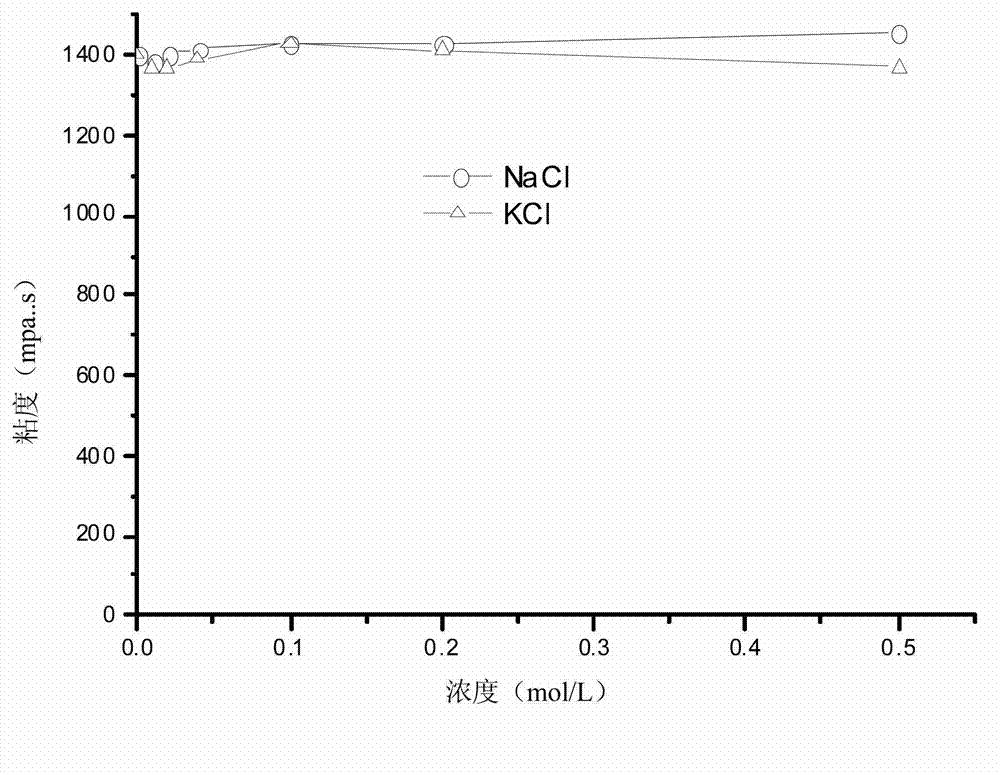

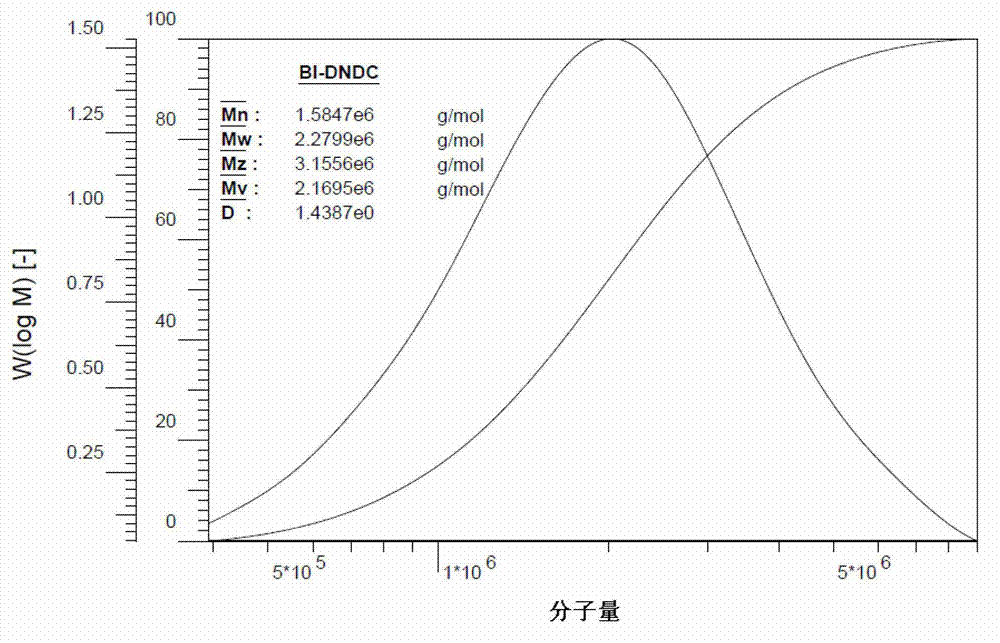

[0064] (1) Molecular weight determin...

Embodiment 2

[0082] A preparation method of organic sulfonic acid modified carboxymethyl hydroxypropyl guar gum, comprising the following steps successively:

[0083] (1) In the reactor that 3L65% isopropanol solution is housed, add 1000.0g carboxymethyl hydroxypropyl guar gum (the degree of substitution of carboxymethyl is 0.16, the degree of substitution of hydroxypropyl is 0.23);

[0084] (2) Under nitrogen atmosphere, 110g of 30% sodium hydroxide aqueous solution was added dropwise, and the temperature was raised to 80° C. after stirring for 0.5 hours, stirred for 0.5 hours, 250 g of 40% 3-chloro-2-hydroxypropanesulfonate aqueous solution was added dropwise, and kept The temperature is at 80°C, the dropwise addition is completed in 1.5 hours, and the stirring is continued for 5 hours;

[0085] (3) Neutralize the reaction solution with 5% hydrochloric acid to pH = 7, filter, and dry the solid product at 70°C to obtain a light yellow powder;

[0086] In this structure R=OH, n=1.

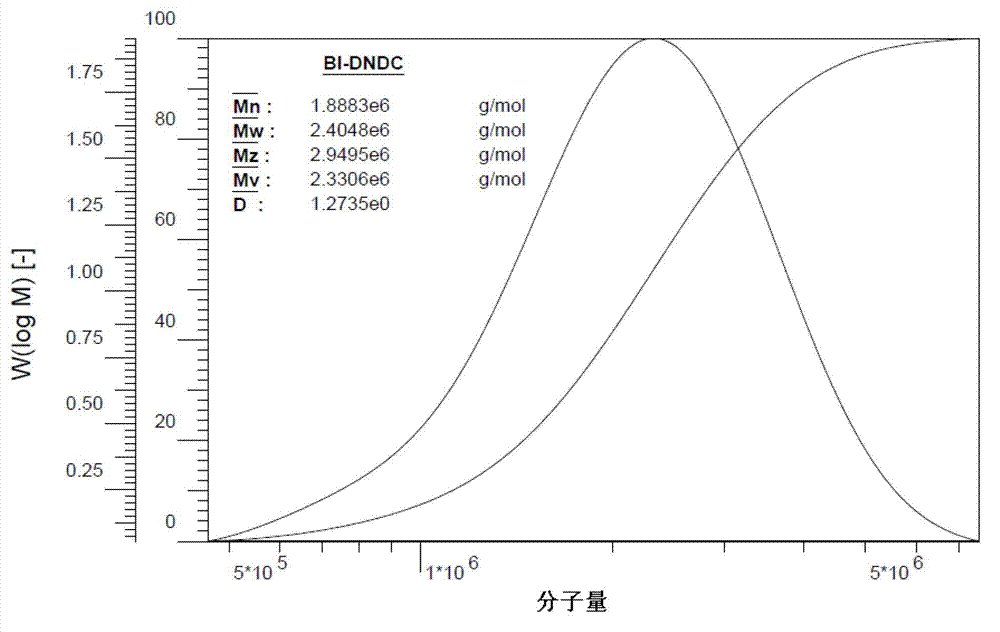

[008...

Embodiment 3

[0107] A preparation method of organic sulfonic acid modified carboxymethyl hydroxypropyl guar gum, the steps are as follows:

[0108] (1) In the reactor that 3L65% ethanol solution is housed, add 1000.0g carboxymethyl hydroxypropyl guar gum (the degree of substitution of carboxymethyl group is 0.12, the degree of substitution of hydroxypropyl group is 0.35);

[0109] (2) Under a nitrogen atmosphere, add dropwise 360 g of 30% aqueous sodium hydroxide solution, stir for 0.5 hours and then heat up to 80° C., stir for 0.5 hour, add dropwise 650 g of 40% 3-chloro-2-hydroxypropanesulfonate aqueous solution, and keep The temperature is at 80°C, the dropwise addition is completed in 1.5 hours, and the stirring is continued for 5 hours;

[0110] (3) Neutralize the reaction solution with 5% citric acid to pH = 7, filter, and dry the solid product at 70°C to obtain the light yellow powder product SCMHPG;

[0111]In this structure R=OH, n=1.

[0112] Determination of special performa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com