High temperature resistant oil-in-water drilling fluid

An oil-in-water drilling fluid with high temperature resistance technology, applied in the field of petroleum drilling, can solve the problems of high density, difficulty in meeting the needs of underbalanced drilling, and insufficient temperature resistance, and achieve good rheology, fluid loss, and strong inhibition and anti-pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

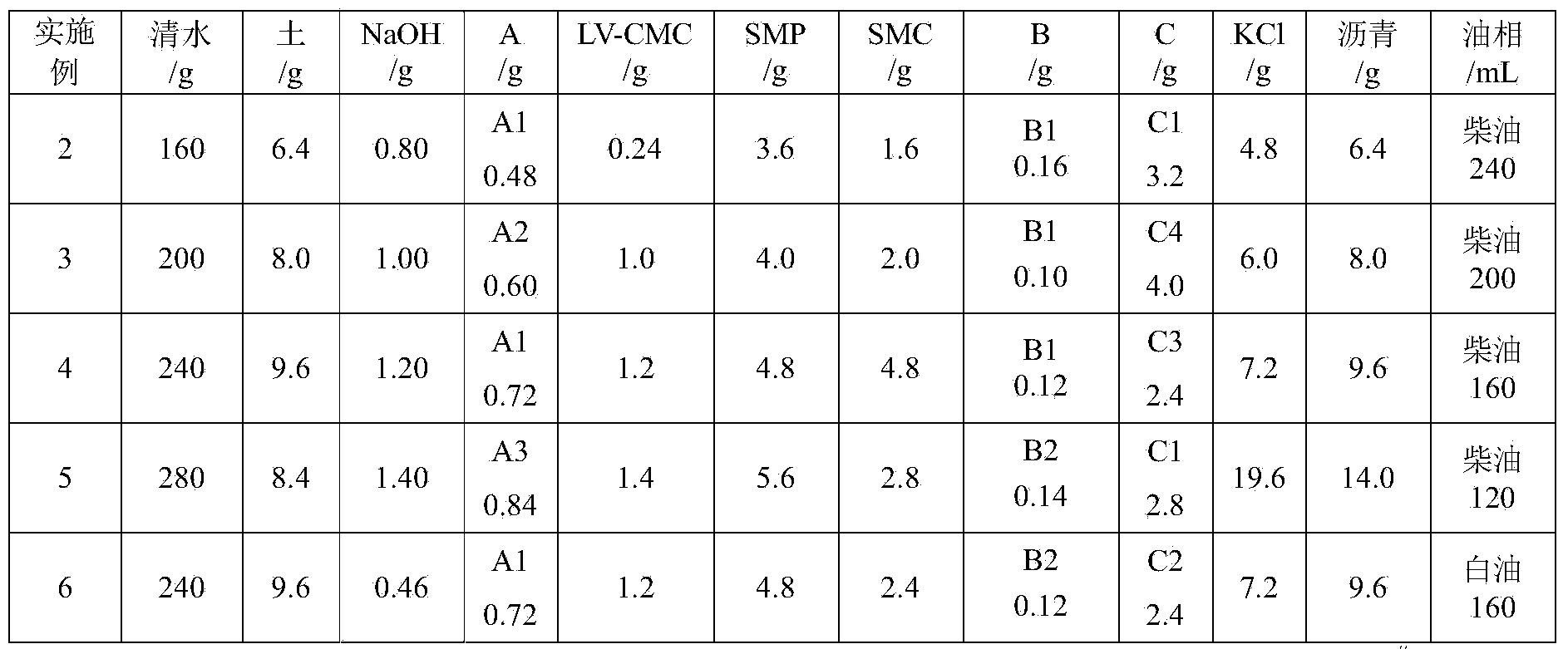

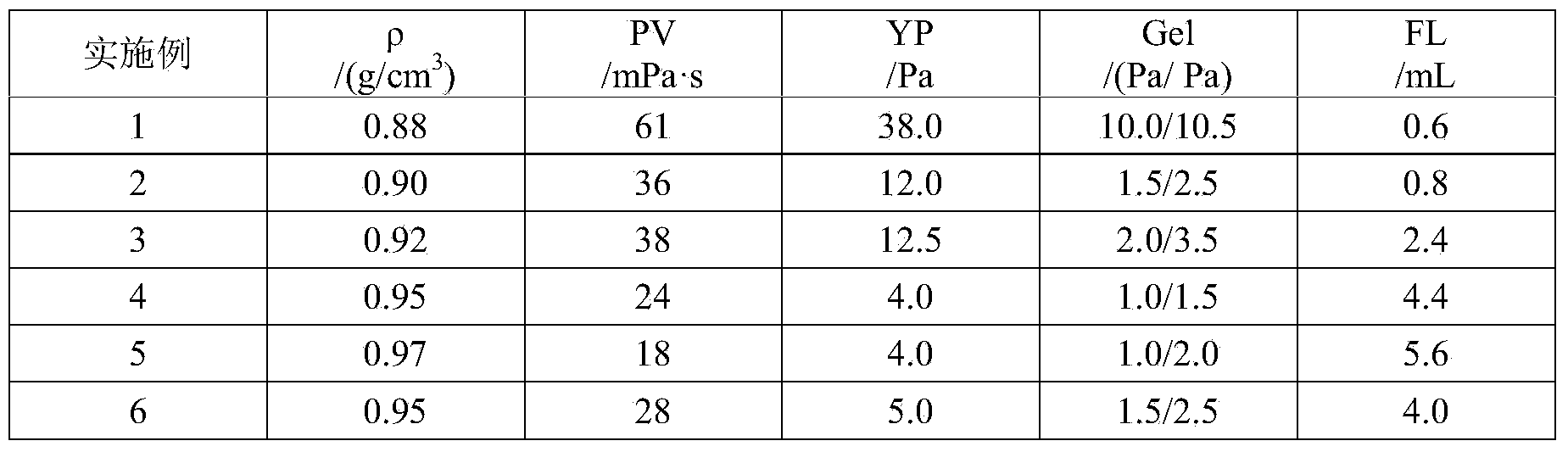

Examples

preparation example A1

[0022] raw material

[0023] The above-mentioned 2-methyl-2-acrylic acid oxypropylsulfonic acid, acrylamide, acrylic acid and 2-hydroxyl-3-methacryloyloxypropyltrimethylammonium chloride are formulated into aqueous solution at room temperature, and hydrogen Adjust the pH value of the aqueous solution to 9.0 with sodium oxide, then add ammonium persulfate and sodium bisulfite to initiate polymerization. The initial temperature of the polymerization reaction is 20°C, and the polymerization time is 5 minutes. After the polymerization reaction, the product is granulated and dried , Pulverized to obtain temperature and salt fluid loss reducer A1.

preparation example A2

[0025] raw material

[0026] The above-mentioned 2-methyl-2-acrylic acid oxypropylsulfonic acid, acrylamide, acrylic acid and 2-hydroxyl-3-methacryloyloxypropyltrimethylammonium chloride are formulated into aqueous solution at room temperature, and hydrogen Adjust the pH value of the aqueous solution to 11.0 with sodium oxide, then add ammonium persulfate and sodium bisulfite to initiate polymerization. The initial temperature of the polymerization reaction is 50°C, and the polymerization time is 20 minutes. After the polymerization reaction, the product is granulated and dried , and pulverize to obtain the temperature-resistant and salt-resistant fluid loss reducer A2.

preparation example A3

[0029] The above-mentioned 2-methyl-2-acrylic acid oxypropylsulfonic acid, acrylamide, acrylic acid and 2-hydroxyl-3-methacryloyloxypropyltrimethylammonium chloride are formulated into aqueous solution at room temperature, and hydrogen Sodium oxide adjusts the pH value of the aqueous solution to 10.0, and then adds ammonium persulfate and sodium bisulfite to initiate polymerization. The initial temperature of the polymerization reaction is 30°C, and the polymerization time is 30 minutes. After the polymerization reaction, the product is granulated and dried , and pulverize to obtain the temperature-resistant and salt-resistant fluid loss reducer A3.

[0030] (2) Anti-high temperature emulsifier C

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com