Method for screening cellulase producing strains and method for producing cellulase by means of fermentation

A screening method and cellulase technology are applied in the field of cellulase-producing strain screening and fermentation production of cellulase, and can solve the problems of high cellulase production cost, long cellulase fermentation time, and low fermentation enzyme activity. , to achieve the effect of not easy to contaminate bacteria, easy to pure culture, and high enzyme production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

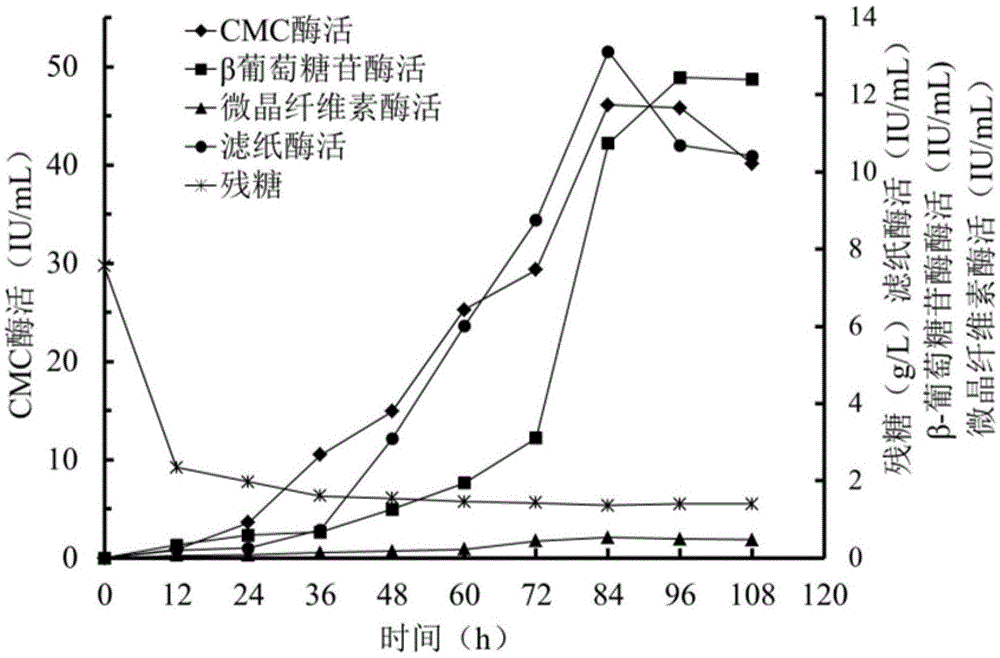

Embodiment 1

[0039] A screening method for producing cellulase strains, the screening method may further comprise the steps:

[0040] Primary screening:

[0041] Take 1g of the material containing the target strain (Huangshan ecological forest rotting wood) and pulverize; add 10mL of normal saline and shake for 1h. All the above suspensions were added to 200mL PDA medium, 30°C, 180rpm shaking culture for 12h;

[0042] The above culture was diluted 10-fold to 10-fold with normal saline -3 、10 -4 、10 -5, and spread them on the PDA plate medium respectively, and cultivate them statically at 30°C until colonies appear. Select a typical single colony and transfer it to the PDA slant, and make slices for purity inspection at the same time to obtain pure cultures; spot the pure cultures To the primary screening medium, the composition of the primary screening medium is: each L medium contains: CMC-Na5-10g; glucose 3-5g; agar 10-20g; MandelS inorganic nutrient salt 1000mL, cultured at 28°C for...

Embodiment 2

[0062] A screening method for producing cellulase strains, the screening method may further comprise the steps:

[0063] Others are the same as in Example 1, except that the composition of the primary screening medium is as follows: every L medium contains: CMC-Na 5g; Glucose 3g; Agar 10g; MandelS inorganic nutrient salt 1000mL;

[0064] The composition of the hyperosmotic primary screening medium plate is: each L medium contains: CMC-Na5g; glucose 3g; agar 10g; MandelS inorganic nutrient salt 1000mL; KCl0.6mol;

[0065] The composition of the liquid fermentation medium is: each L medium contains: 5g of 80-120 mesh corn stalks, 80g of 5% bran extract juice, (NH 4 ) 2 SO 4 20g, KH 2 PO 4 5g, MgSO 4 ·7H 2 O5g, CaCl 2 10g, Tween800.15g, trace elements: FeSO 4 ·7H 2 O0.003g, MnSO 4 ·H 2 O0.001g, ZnSO 4 ·7H 2 O0.001g, CoCl 2 ·6H 2 O0.001g, pH5.0.

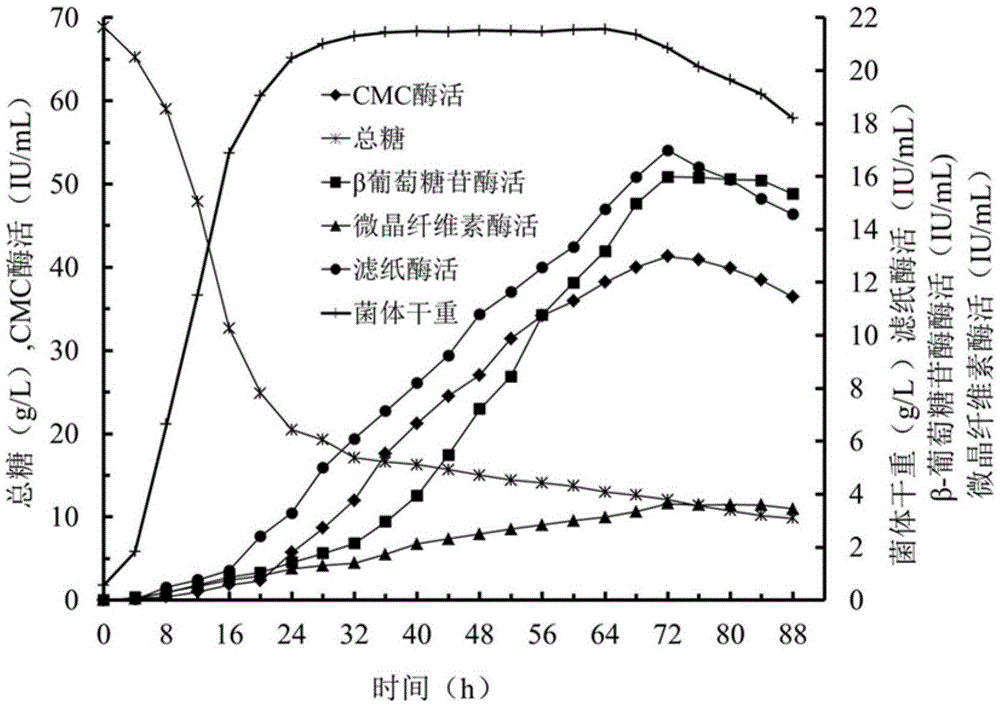

Embodiment 3

[0067] A screening method for producing cellulase strains, the screening method may further comprise the steps:

[0068] Others are the same as in Example 1, except that the composition of the primary screening medium is: each L medium contains: CMC-Na 10g; Glucose 5g; Agar 20g; MandelS inorganic nutrient salt 1000mL;

[0069] The composition of the hyperosmotic primary screening medium plate is: each L medium contains: CMC-Na10g; glucose 5g; agar 20g; MandelS inorganic nutrient salt 1000mL; KCl0.6mol;

[0070] The composition of liquid fermentation medium is: every L medium contains: 80~120 order rice straw 10g, 5% bran extract juice 100g, (NH 4 ) 2 SO 4 30g, KH 2 PO 4 10g, MgSO 4 ·7H 2 O10g, CaCl 2 20g, Tween800.25g, trace elements: FeSO 4 ·7H 2 O0.005g, MnSO 4 ·H 2 O0.00156g, ZnSO 4 ·7H 2 O0.0014g, CoCl 2 ·6H 2 O0.002g, pH5.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com