Water-based clay-free drilling fluid and application of drilling fluid to polar region frozen soil stratigraphical drilling

A drilling fluid and clay-free technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve problems such as viscosity increase, and achieve good mud shale expansion, high environmental protection requirements, and good lubricity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

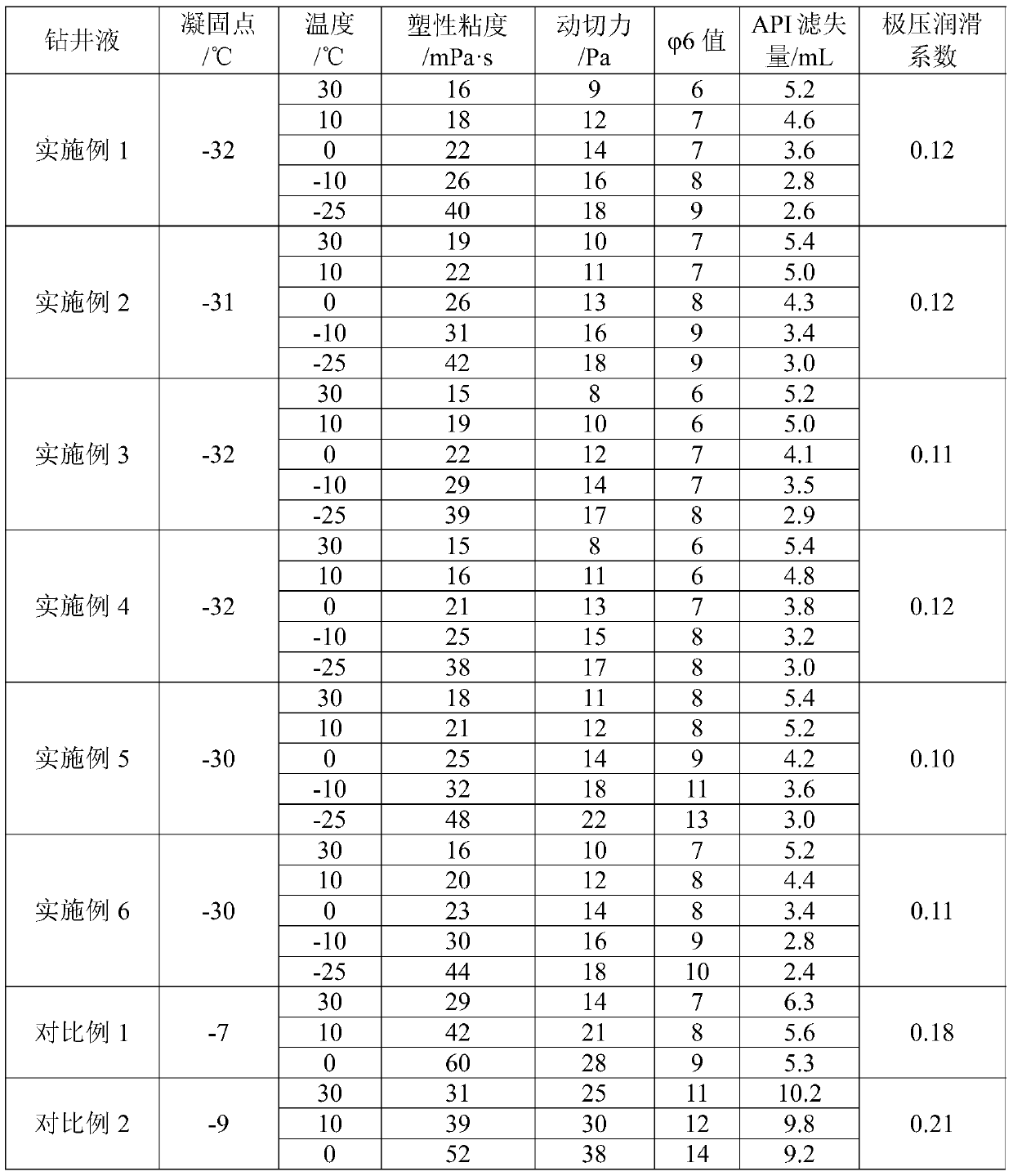

Examples

preparation example Construction

[0034] According to the present invention, the modified starch can be obtained by preparation, wherein the preparation method comprises: the modified starch is made of corn starch, 2-acrylamide-2-methylpropanesulfonic acid (AMPS) and acrylamide (AM ) a zwitterionic modified starch fluid loss reducer obtained after copolymerization; wherein, the conditions of the copolymerization include: the initiator is 0.3% ammonium persulfate, the reaction temperature is 50°C, and the reaction time is 8h.

[0035] According to the present invention, the polyanion cellulose is a low-viscosity polyanion cellulose, the VP value is less than 1 when the water addition amount is 4ppd, and the API filtration loss is less than 10mL. In the present invention, it can be purchased from Hebei Hengju Chemical Co., Ltd., the model is LV-PAC.

[0036] According to the present invention, the blocking agent is selected from one or more of ultrafine calcium carbonate, graphite and nano microspheres; preferab...

Embodiment 1

[0049] This example is to illustrate the water-based clay-free drilling fluid of the present invention.

[0050] Prepared water-based clay-free drilling fluid, which contains:

[0051] 80 parts by weight of water, 45 parts by weight of ultra-low temperature base fluid, 0.3 parts by weight of viscosifier, 0.6 parts by weight of fluid loss control agent, 2 parts by weight of plugging agent, and 2 parts by weight of lubricant.

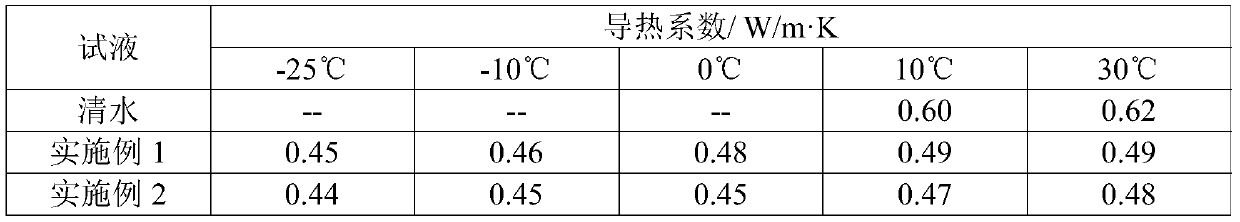

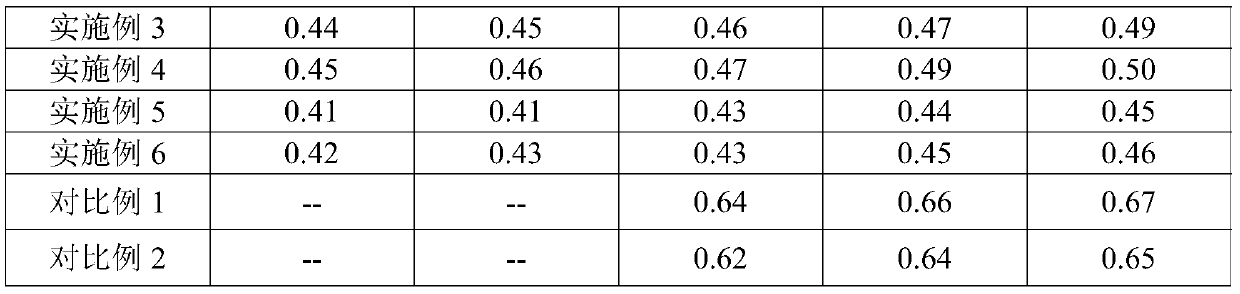

[0052] Wherein, the ultra-low temperature base fluid is mixed with sodium chloride and ethylene glycol at a mass ratio of 5:4, and the freezing point of the ultra-low temperature base fluid is -29°C; and, at normal temperature, the ultra-low temperature base fluid The thermal conductivity is 0.49W / m K;

[0053] Wherein, the tackifier is xanthan gum;

[0054] Wherein, the fluid loss reducer is formed by mixing hydroxyethyl cellulose and modified starch according to a mass ratio of 1:1;

[0055] Wherein, the plugging agent is an average particle diameter...

Embodiment 2

[0058] This example is to illustrate the water-based clay-free drilling fluid of the present invention.

[0059] Prepared water-based clay-free drilling fluid, which contains:

[0060] 85 parts by weight of water, 48 parts by weight of ultra-low temperature base fluid, 0.3 parts by weight of viscosifier, 0.7 parts by weight of fluid loss reducer, 2 parts by weight of plugging agent, and 2 parts by weight of lubricant.

[0061] Wherein, the ultra-low temperature base fluid is mixed with sodium chloride and ethylene glycol at a mass ratio of 1:1, and the freezing point of the ultra-low temperature base fluid is -28°C; and, at normal temperature, the ultra-low temperature base fluid The thermal conductivity is 0.48W / m K;

[0062] Wherein, the tackifier is xanthan gum;

[0063] Wherein, the fluid loss reducer is formed by mixing hydroxyethyl cellulose and modified starch according to the mass ratio of 3:4;

[0064] Wherein, the plugging agent is an average particle diameter of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com