Plugging-type filtrate reducer for water-based drilling fluid and preparation method thereof

A technology of water-based drilling fluid and fluid loss control agent, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of cumbersome production process, high cost, and environmental pollution, and achieve simple production process and no harm to the body Small, Inexpensive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] (1) Weigh 200kg polymer modified oxidized asphalt (PMA) and put it on the ground for manual breaking;

[0061] (2) Spray 9kg of polyol lipid nonionic surfactant Span80 and 9kg of polyol lipid nonionic surfactant Tween80 during the stirring process for preliminary surface modification;

[0062] (3) Transfer the material in step (2) to a blast mill for crushing;

[0063] (4) The discharged material enters the dry blender through a pump, and 80kg of cellulose-modified starch is added into the dry blender, and dry blended for 30 minutes, and the discharged material is bagged to obtain a sample, which is designated as NFL-120.

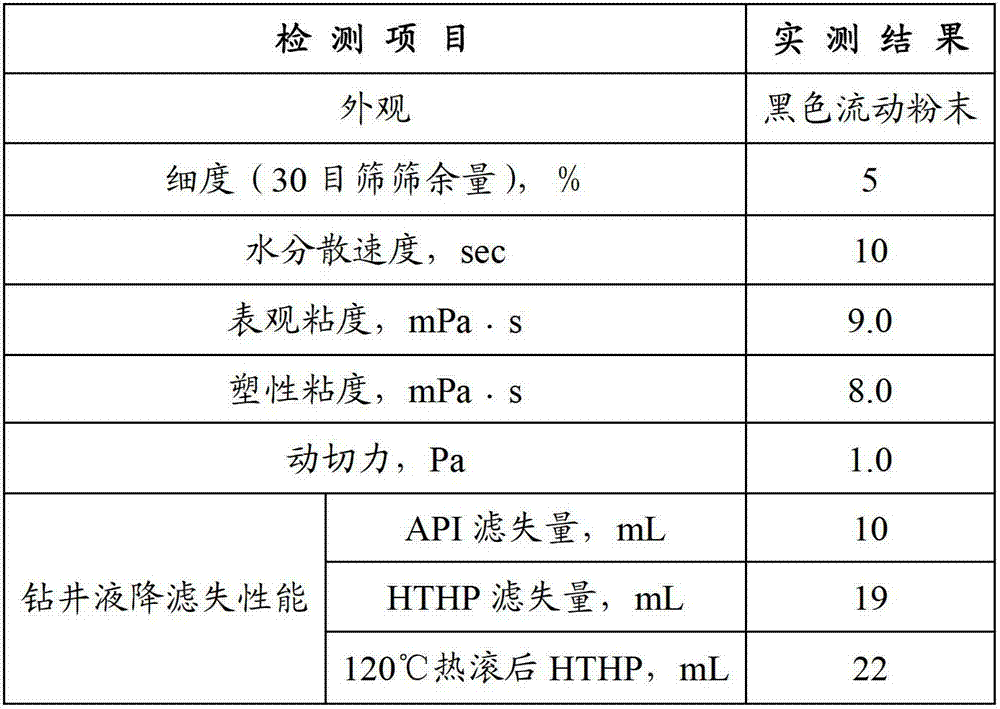

[0064] According to the above sample performance evaluation method, the sample of Example 1 is evaluated, and the results are shown in 1.

[0065] Table 1 Example 1NFL-120 quality inspection results

[0066]

Embodiment 2

[0068] (1) Weigh 200kg of polymer-modified oxidized asphalt and place it on the ground to break it up manually;

[0069] (2) Spray 6kg of industrial-grade liquid CTAB and 12kg of water-soluble silicone oil OSO-w during the stirring process for preliminary surface modification;

[0070] (3) Transfer the material in step (2) to a blast mill for crushing;

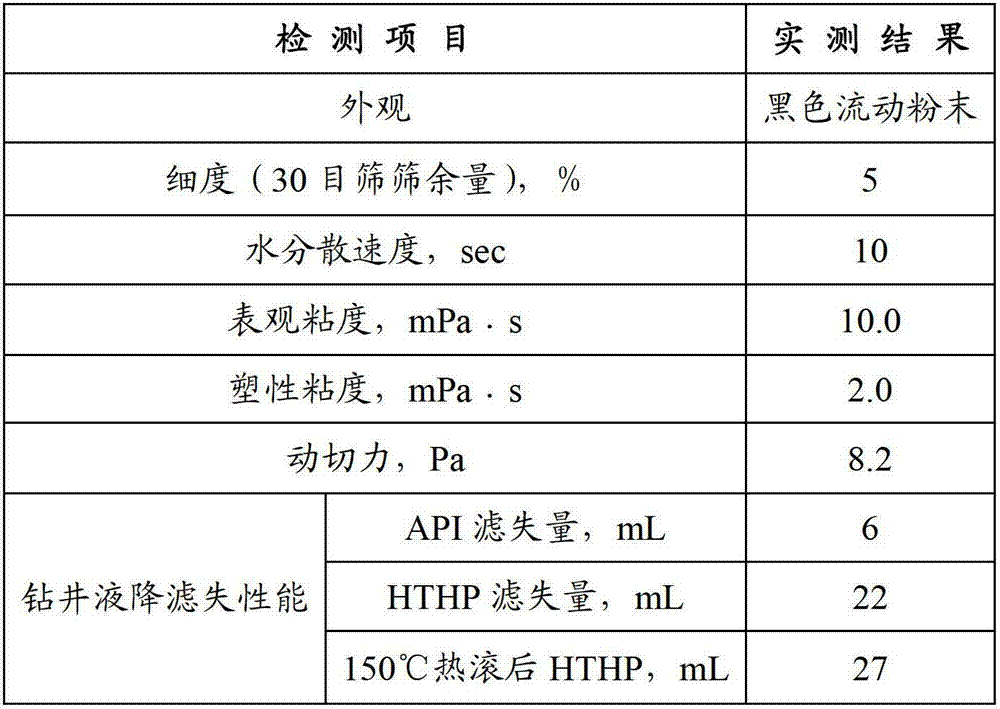

[0071] (4) The discharge material enters the dry blender through the pump, and 100kg of poly(acrylonitrile-acrylamide) ammonium salt (double polyammonium salt) (HMP-21) is added to the dry blender, and it is dry mixed for 30 minutes. bag, get the sample, and record it as NFL-150.

[0072] According to the above-mentioned product performance evaluation method, the sample of Example 2 is evaluated, and the results are shown in Table 2.

Embodiment 3

[0076] (1) Weigh 200kg of polymer-modified oxidized asphalt and place it on the ground to break it up manually;

[0077] (2) Spray 6kg of industrial-grade liquid CTAB and 12kg of water-soluble silicone oil OSO-w during the stirring process for preliminary surface modification;

[0078] (3) Transfer the material in step (2) to a blast mill for crushing;

[0079] (4) The discharged material enters the dry blender through a pump, and 45kg of lignite resin is added into the dry blender, dry blended for 30 minutes, and the discharged material is bagged to obtain a sample, which is designated as NFL-170.

[0080] According to the above sample performance evaluation method, the sample of Example 3 was evaluated, and the results are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com