Patents

Literature

63results about How to "Flexible production process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

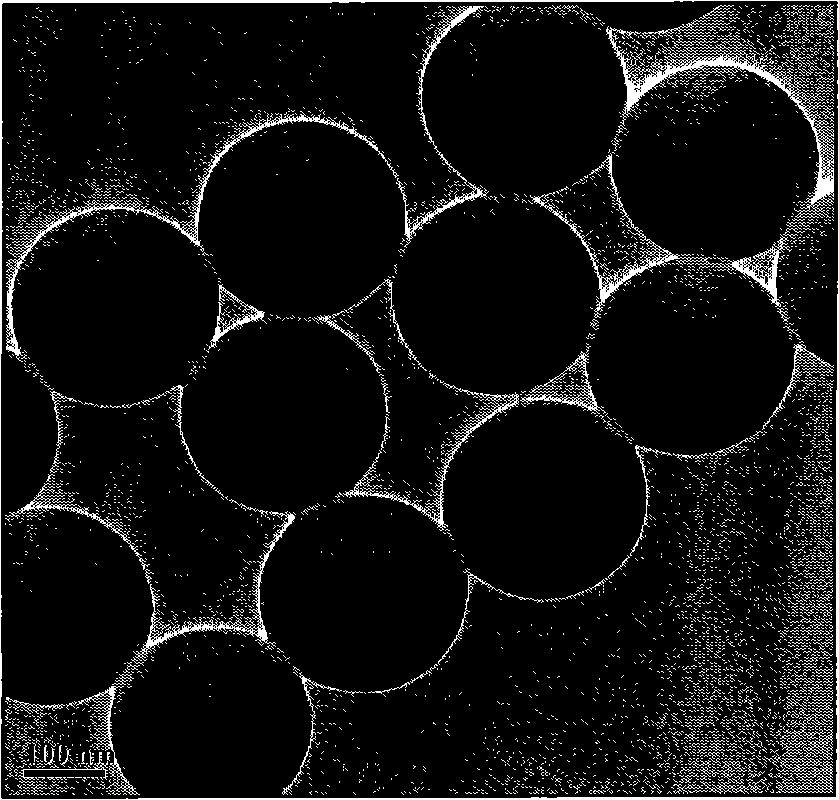

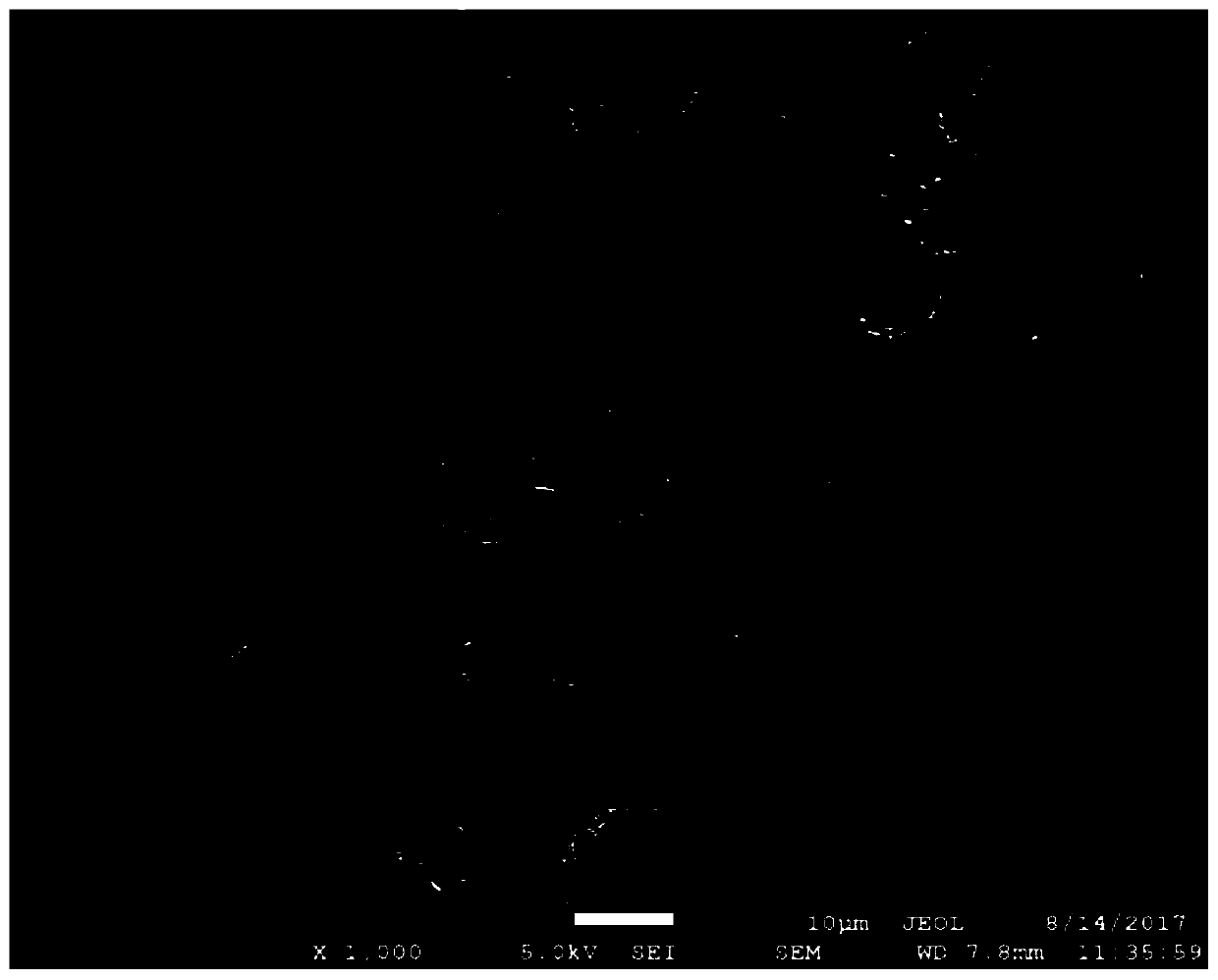

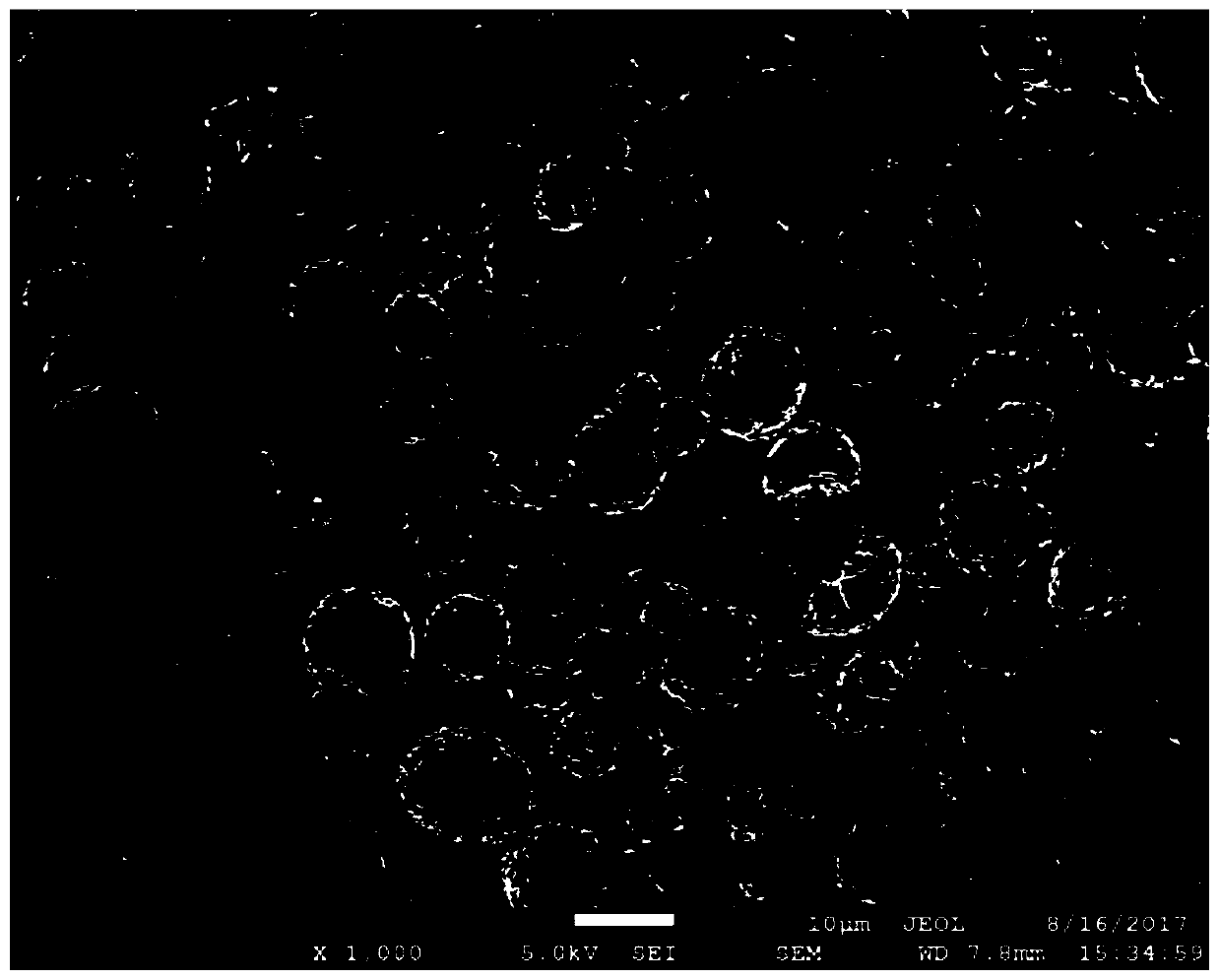

Sol-gel method for preparing earth silicon/titanic oxide hollow microballoon

InactiveCN101274246AFlexible production processRaw materials are cheap and easy to getMicroballoon preparationMicrocapsule preparationPolystyrene microsphereSol-gel

The invention provides a method for preparing an SiO2 / TiO2 hollow microsphere by a sol-gel method. The method is mainly characterized in that cation polystyrene microsphere (PS) is used as a formwork; ethyl silicate and butyl titanate are respectively used as raw material and diluted ammonia is taken as regulator of pH value; a multi-layer organic-inorganic hybrid composite microsphere is obtained by the sol-gel reaction under the temperature of 70-80 DEG C. Formwork particle of the obtained deposition is removed by a calcining process to obtain the SiO2 / TiO2 hollow microsphere. By changing the consistency of reactant, content of surfactant and calcining temperature, the SiO2 / TiO2 hollow microsphere with different spherical shell thickness, density and grain size can be obtained. The hollow microsphere prepared by the method has high photo-catalytic activity, overcomes the shortage that existing preparation method of hollow microsphere can only prepare single shell layer microsphere; the multi-layer hollow microsphere can be prepared, the technique is simple, the cost is low and the preparation method of the invention is suitable for industrialized production.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

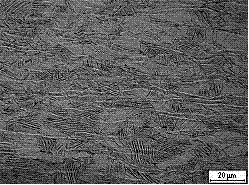

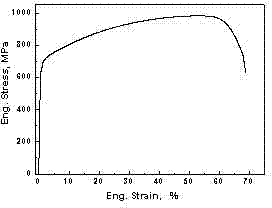

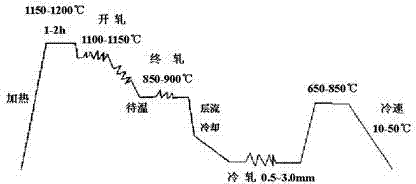

Nb, Ti alloyed low-carbon high-intensity high-plasticity TWIP steel and preparation method thereof

ActiveCN102312158AExcellent overall performanceBroad application prospectsSteel platesManufacturing sector

The invention, belonging to the field of high-intensity alloy steel, relates to a preparation method of a Nb, Ti alloyed low-carbon high-intensity high-plasticity twinning induced plasticity (TWIP) steel. The steel comprises the following ingredients: 0.05-0.10 wt% C, 23.5-27 wt% of Mn, 0.01-0.03wt% of Si, at most 1.0 wt% of Al, at most 0.01 wt% of P, at most 0.02 wt% of S, 1.0-2.5 wt% of Nb, 0.5-1.25 wt% of Ti, 0.02 -0.08 wt% of N, and the balance consisting of Fe and inevitable impurities. The preparation method comprises the following steps: melting the ingredients and then casting into a casting blank, heating the casting blank and then carrying out hot rolling at the opening rolling temperature of 1100-1150 DEG C with multiple passes and small press quantity to obtain the accumulated deformation degree of more than 60 % at the temperature of more than 950 DEG C, processing the casting blank in a finishing rolling mode at the temperature of 850-900 DEG C, after the hot rolling, rapidly cooling to 400-550 DEG C for reeling, carrying out cold rolling on the steel plate processed by hot rolling with the thickness of 0.5-3.0 mm, preserving the steel plate processed by cold rolling at the temperature of 650-850 DEG C for 3-30 min, and then rapidly cooling to room temperature with the cooling rate of 10-50 DEG C / s. The material prepared by the method can be applied in automobile manufacturing industry. The material has the yield strength of more than 550 MPa and the elongation rate of no less than 60 %, thereby obviously improving the ability of anti-collision and impact of automobile for the first time and greatly increasing the crashworthiness indexes.

Owner:SHANGHAI JIAO TONG UNIV

Slow-release compound fertilizer and production method thereof

InactiveCN103172453AAvoid secondary pollutionWide variety of sourcesFertilizer mixturesChemical industryMolecular materials

The invention relates to a slow-release compound fertilizer and a production method thereof. The slow-release compound fertilizer comprises a water-soluble granular fertilizer core and a coating layer, wherein the coating layer includes 2-3 coating layers; and the content of N, P2O5 and K2O which are contained in the slow-release compound fertilizer is respectively 4%-33%, 4%-30% and 0%-30% accounting for the total weight of the slow-release compound fertilizer. According to the invention, the coating layer of the slow-release compound fertilizer is not made from high-molecular materials or other organic polymers, the cost is reduced, and the secondary pollution of the organic polymer or the high-molecular materials on the soil is prevented; and a product formula is flexible, a production process is simplified by integrating the preparation process and compound (mixed) fertilizer production process of the slow-release compound fertilizer into a whole, the equipment investment is saved, the convenience for realizing large-scale industrial production is achieved, and no three wastes are discharged in the production process. Compared with the prior art, the slow-release compound fertilizer disclosed by the invention enhances the slow-release effect to a certain degree and meets the requirements of a chemical industry standard HG / T 4217-2011.

Owner:济南厚源化工有限公司

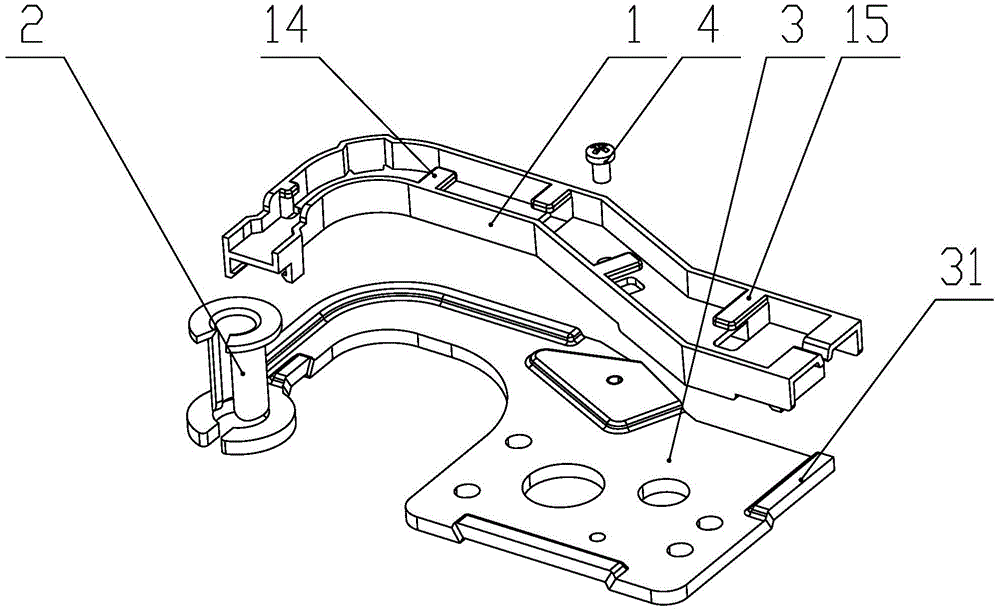

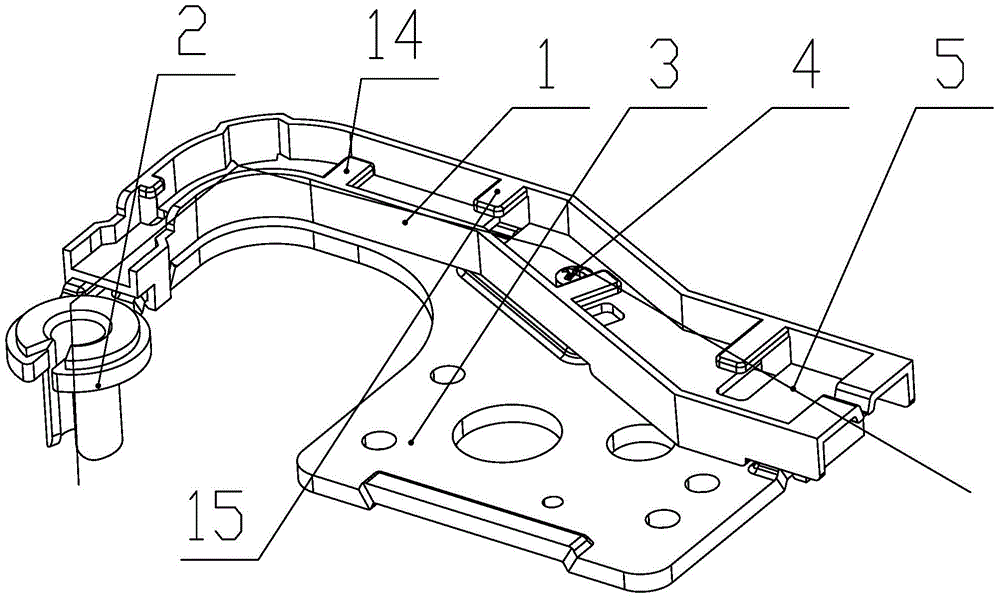

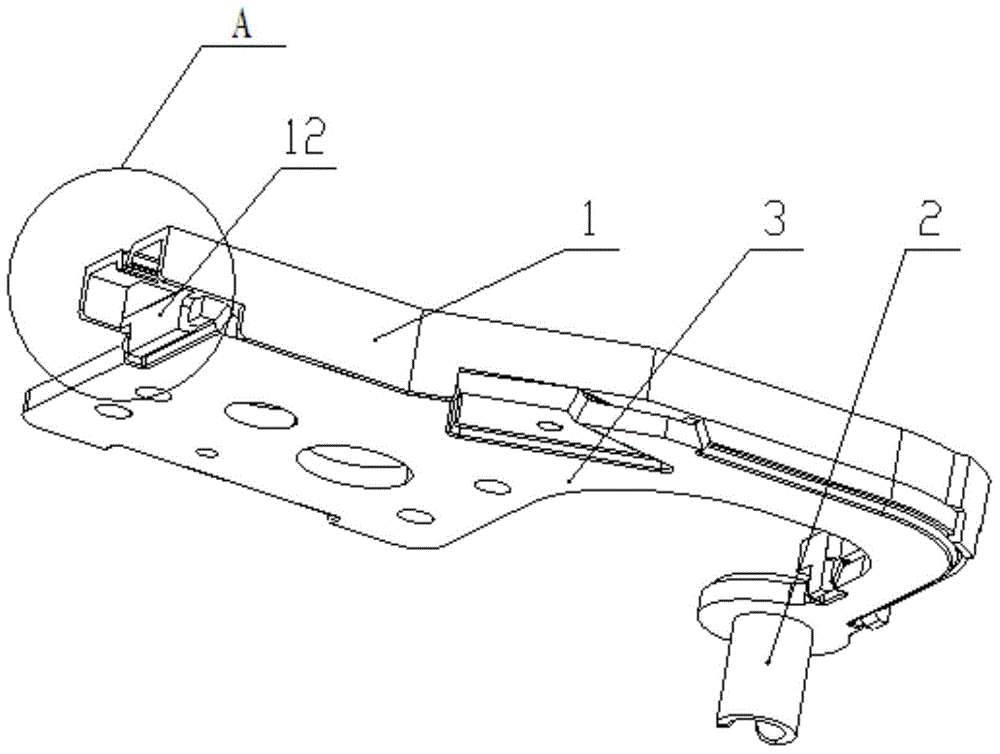

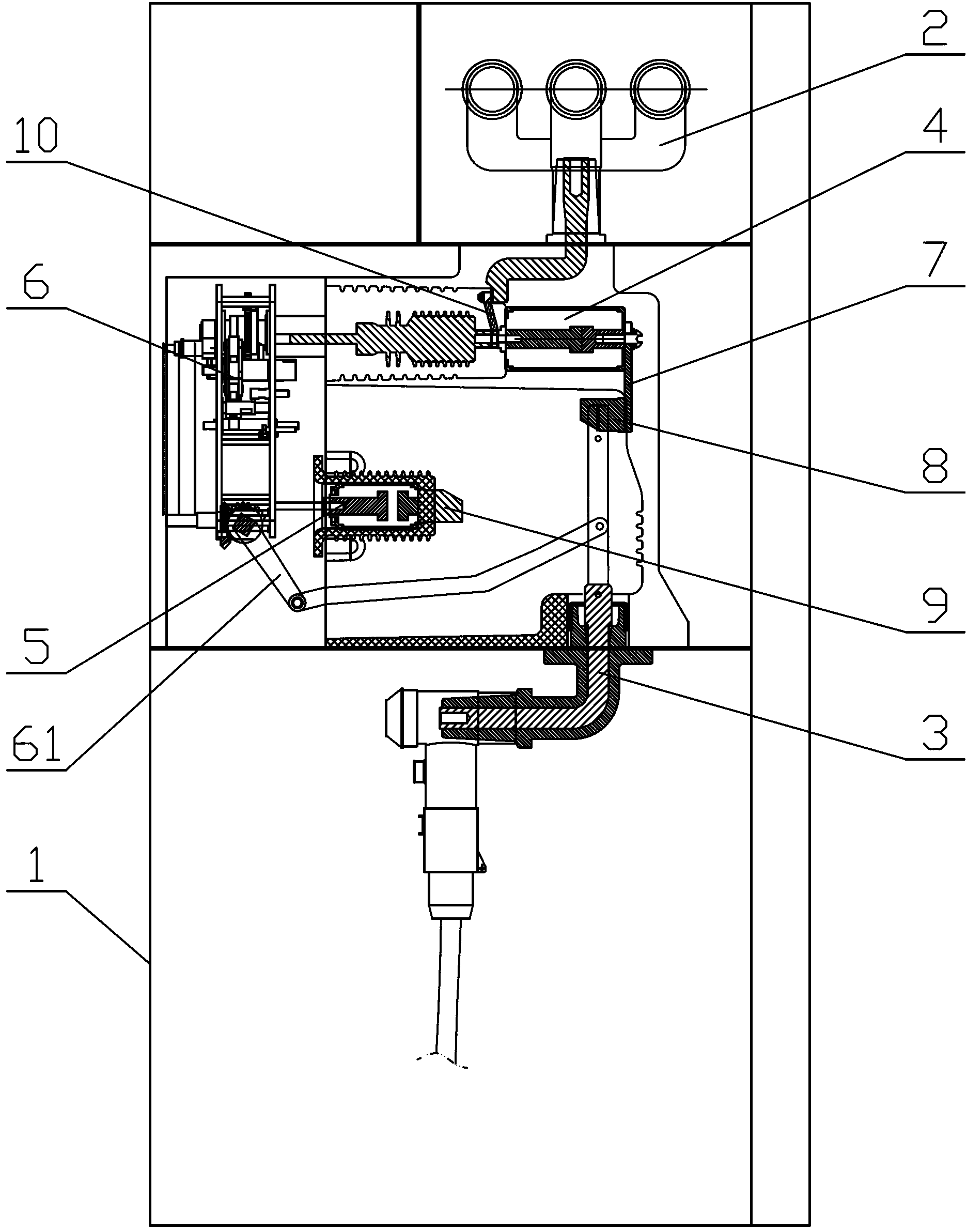

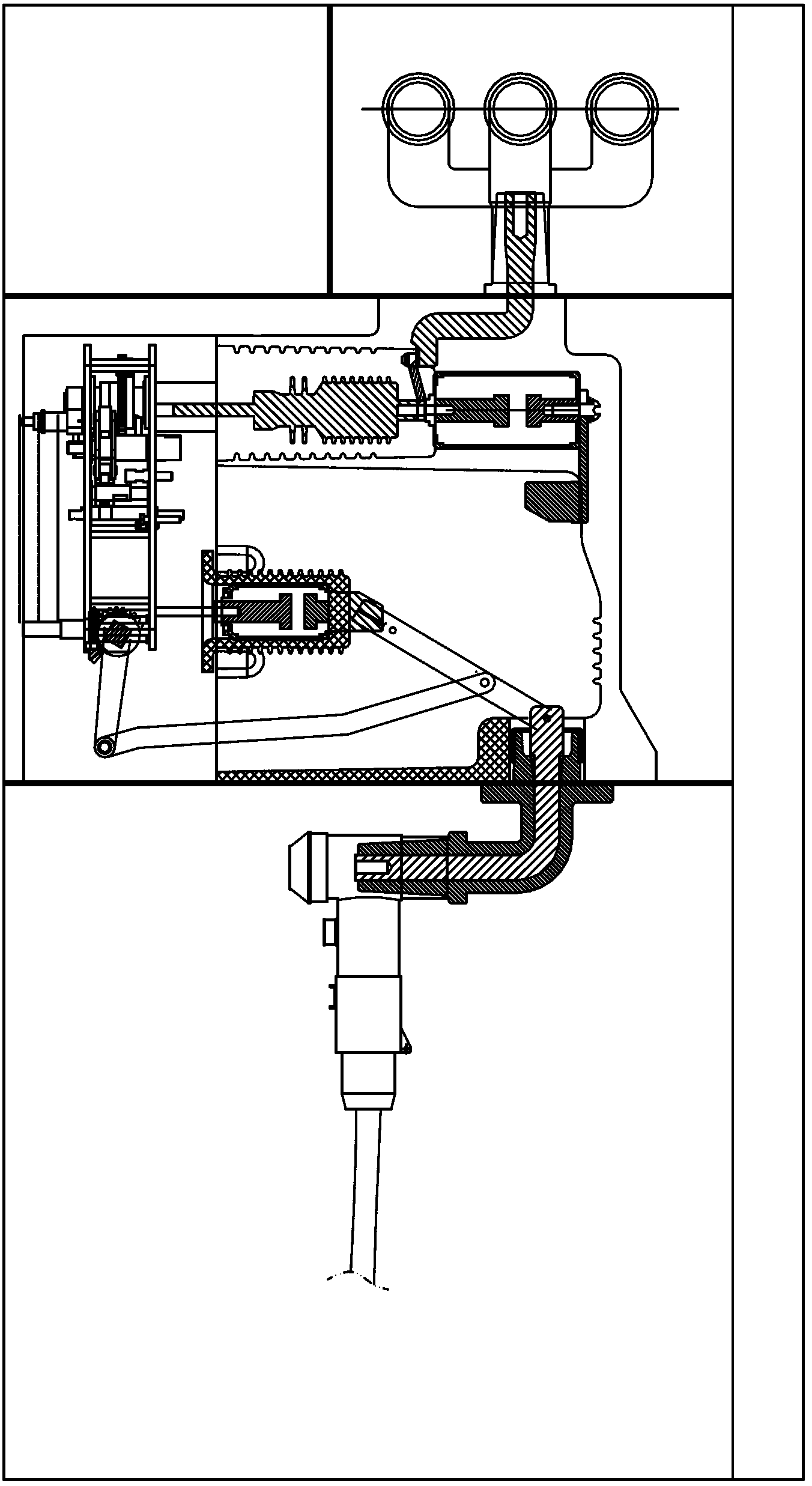

Door hinge wire harness restraining structure and refrigerator

ActiveCN104466826AHigh strengthIncreasing the thicknessElectrical apparatusHingesMechanical engineeringRefrigerated temperature

The invention relates to the field of refrigerators and discloses a door hinge wire harness restraining structure and a refrigerator. The door hinge wire harness restraining structure comprises an upper hinge plate and an upper hinge shaft which are fixedly connected together and further comprises a wiring box installed on the upper surface of the upper hinge plate. At least part of the interior of the wiring box forms a containing space for containing wire harnesses. The wiring box and the upper hinge plate are located and installed in a clamped mode. According to the structure, the wire harnesses are supported and restrained through the upper hinge plate and the wiring box, the upper hinge plate and the wiring box are separately arranged, and compared with a mode that the upper hinge plate and the wiring box are integrated in the prior art, the wire harness fixing effect is better, the wire harness assembly process is simpler, and the use effect is better.

Owner:GREE ELECTRIC APPLIANCES INC

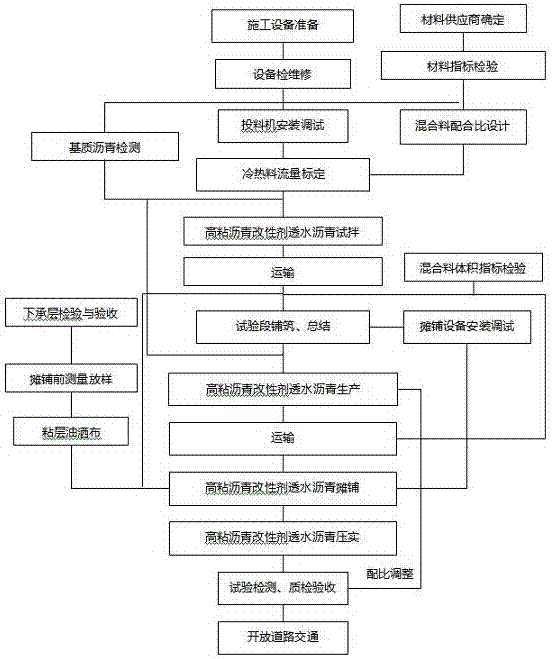

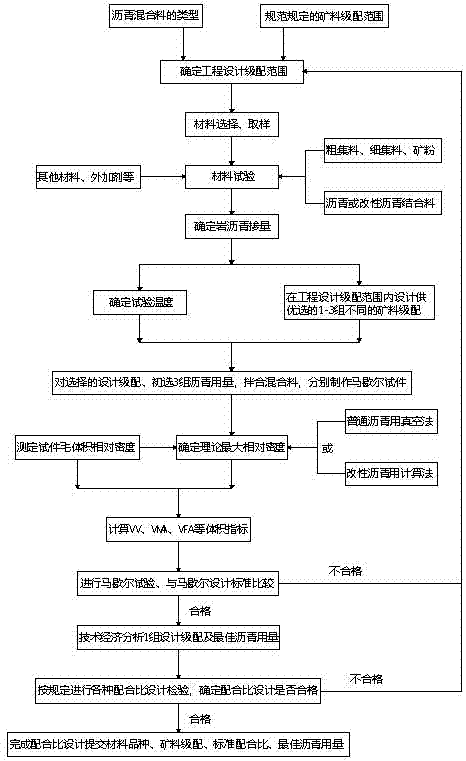

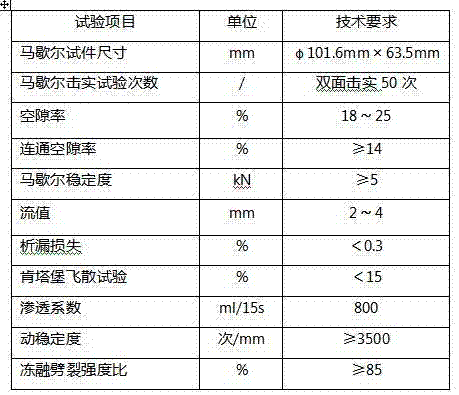

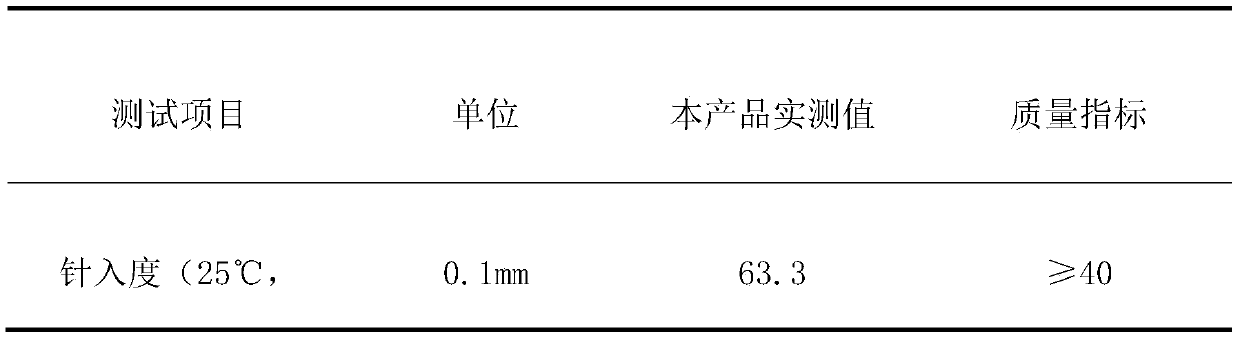

High-viscosity asphalt modifier porous asphalt pavement construction method

InactiveCN107142810ASimple production processNot easy to wasteIn situ pavingsRoads maintainencePorous asphaltRoad engineering

The invention belongs to the technical field of road engineering construction, and particularly relates to a high-viscosity asphalt modifier porous asphalt pavement construction method. The high-viscosity asphalt modifier porous asphalt pavement construction method is characterized by sequentially including the steps that construction equipment prepares to work; the mixing proportion of a direct-putting high-viscosity asphalt modifier porous asphalt mixture is designed; the direct-putting high-viscosity asphalt modifier porous asphalt mixture is produced; the direct-putting high-viscosity asphalt modifier porous asphalt mixture is transported; preparation work is conducted before the direct-putting high-viscosity asphalt modifier porous asphalt mixture is laid; use parameters of a laying machine are selected and adjusted; laying work is conducted; the direct-putting high-viscosity asphalt modifier porous asphalt mixture is rolled and formed; joint treatment is conducted. The method has the advantages of obvious construction method advantages and economic and social benefits.

Owner:SHANDONG HUITONG CONSTR GRP CO LTD

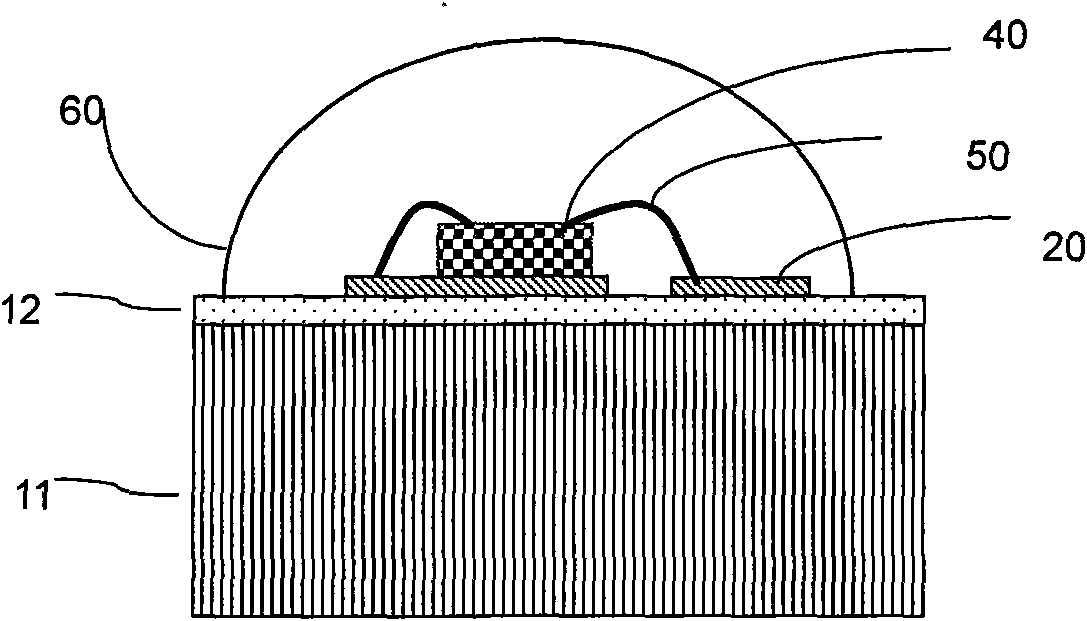

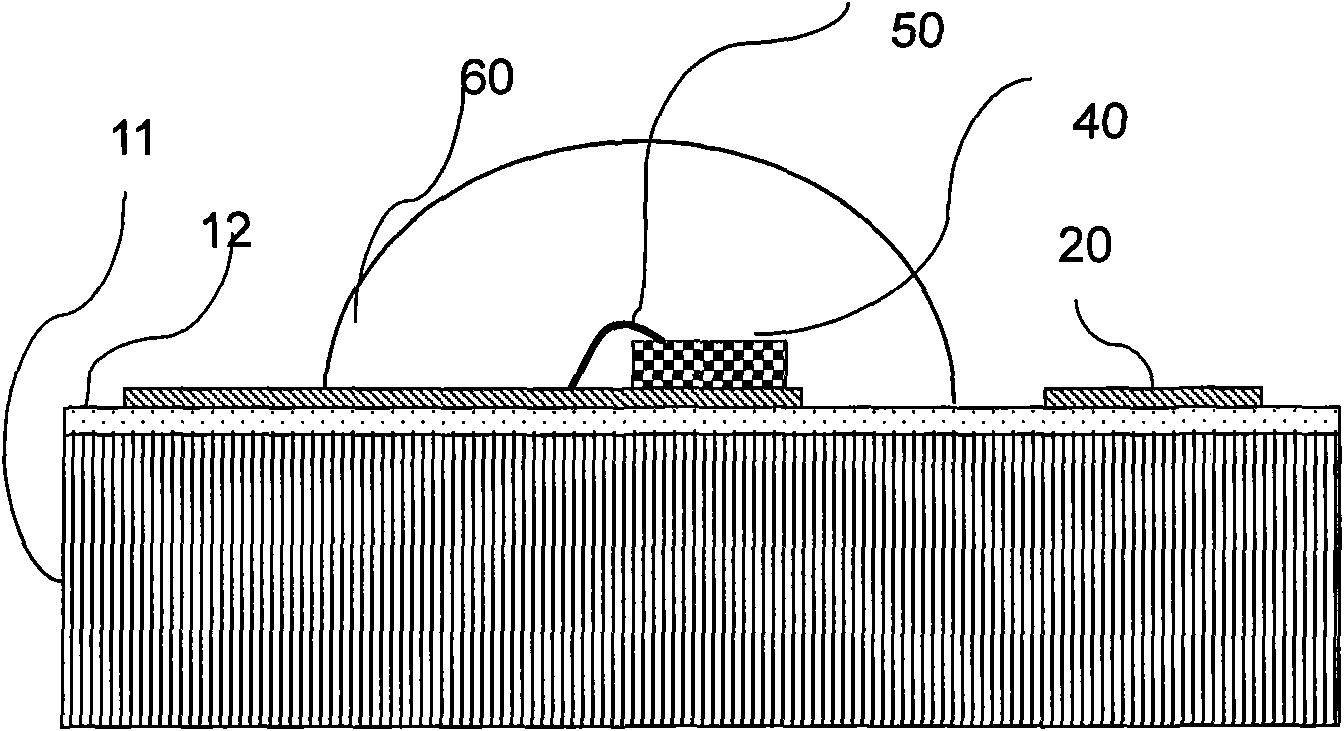

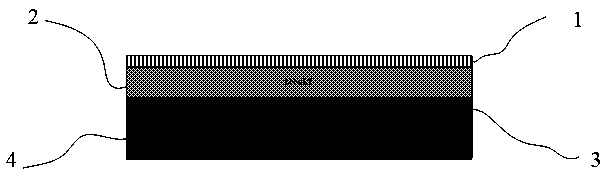

Structure for encapsulating multichip LED

InactiveCN101615612AReduce thermal resistanceIncrease contactSemiconductor/solid-state device detailsSolid-state devicesElectricityElectrical conductor

The invention provides an LED encapsulating structure which can radiate in high efficiency and has transient voltage protection and high energy efficiency. The LED encapsulating structure mainly comprises a substrate, a bracket, LED chips, a transient protection chip, a connecting wire and an encapsulating colloid. The substrate has a double-layer structure; the lower layer of the substrate is made of a metal material with good radiation; and the upper layer is a film with high thermal conductivity and electrical insulation. The bracket is a good heat and electricity conductor; and the shape of the bracket can be adjusted according to the requirements, such as the number of the chips, a connecting method and the like. The transient voltage protection chip and the LED chip are arranged on the bracket; and the bracket is directly arranged on the substrate. The positions of the chip and the connecting wire needing protection are encapsulated by the colloid; and the exposed bracket part forms a connecting part of an external power supply. A plurality of the LED chips can be connected in a parallel mode or a serial-parallel mode so as to be favorable for improving the conversion efficiency of the power supply; and a plurality of the LED chips can also form multi-circuit connection to independently control the LEDs of each circuit. A plurality of LED light sources can be flexibly obtained according to the method.

Owner:刘红超

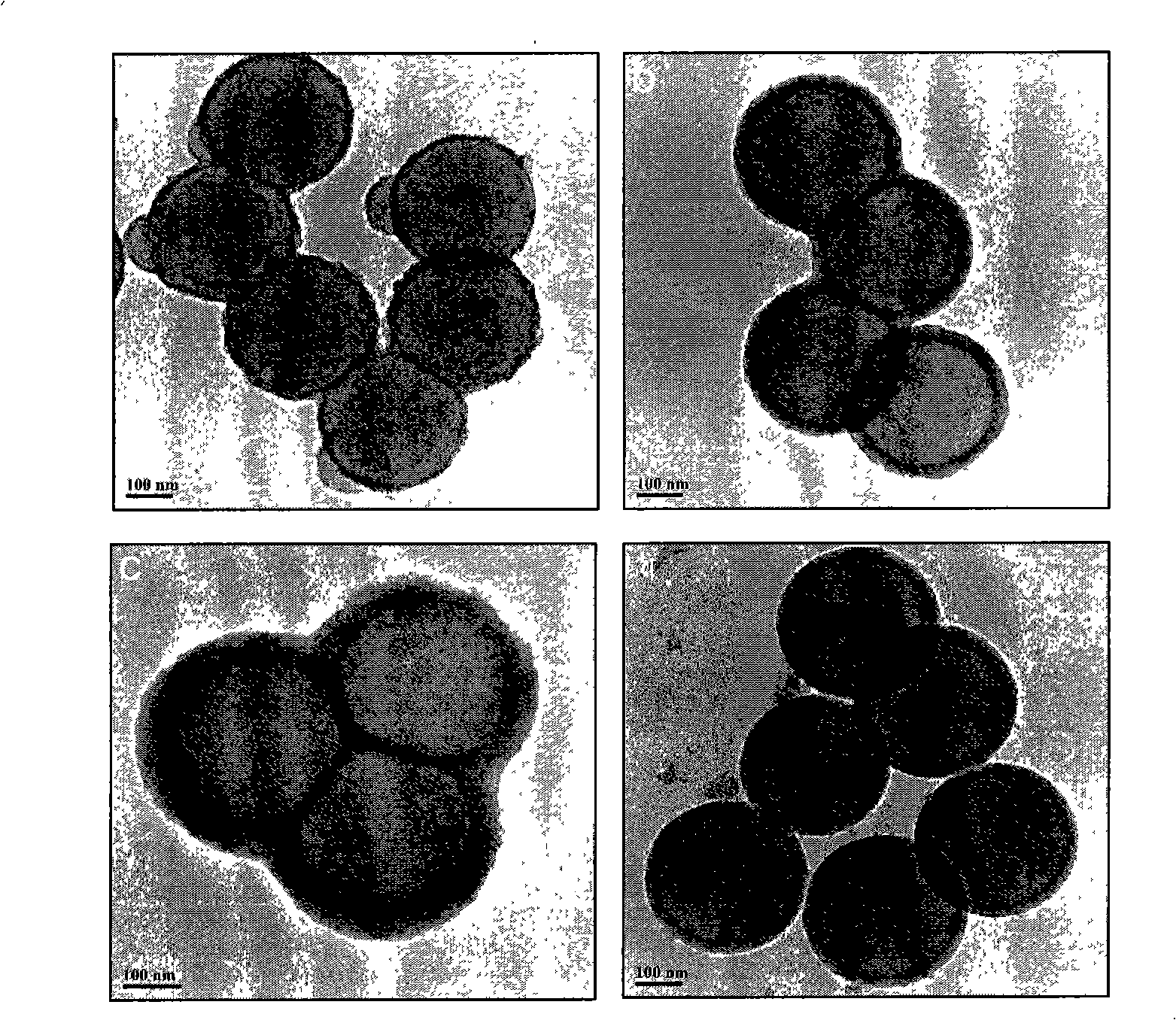

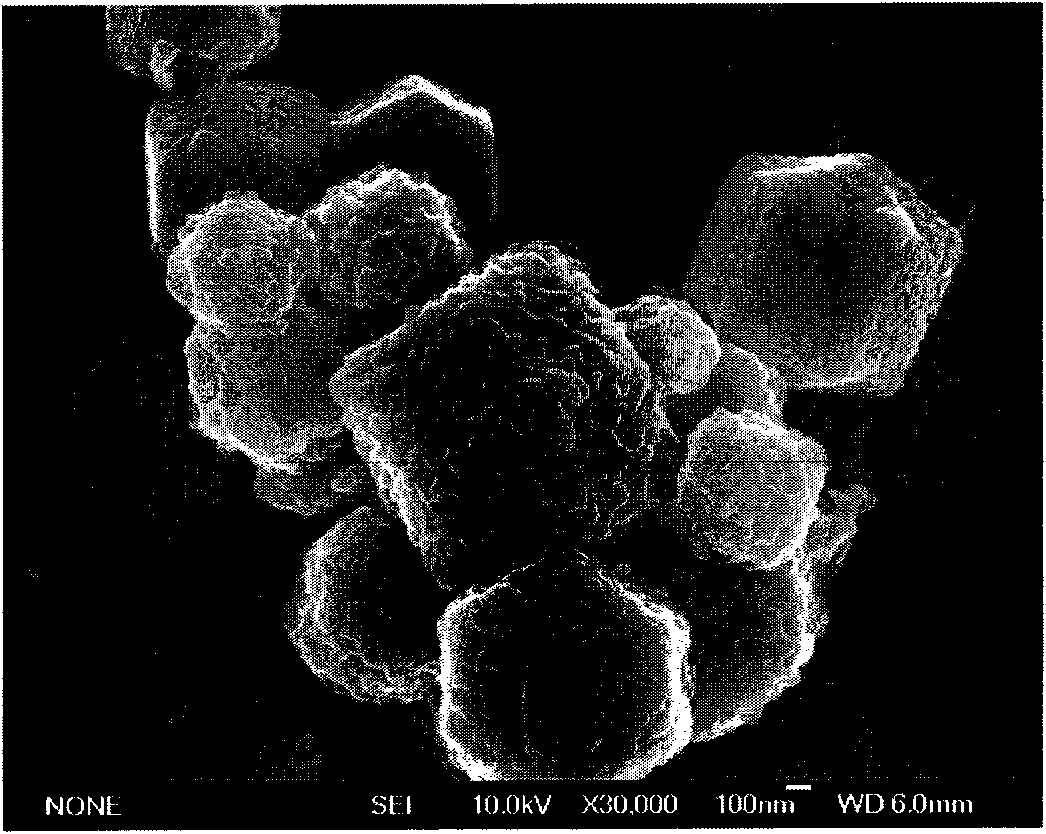

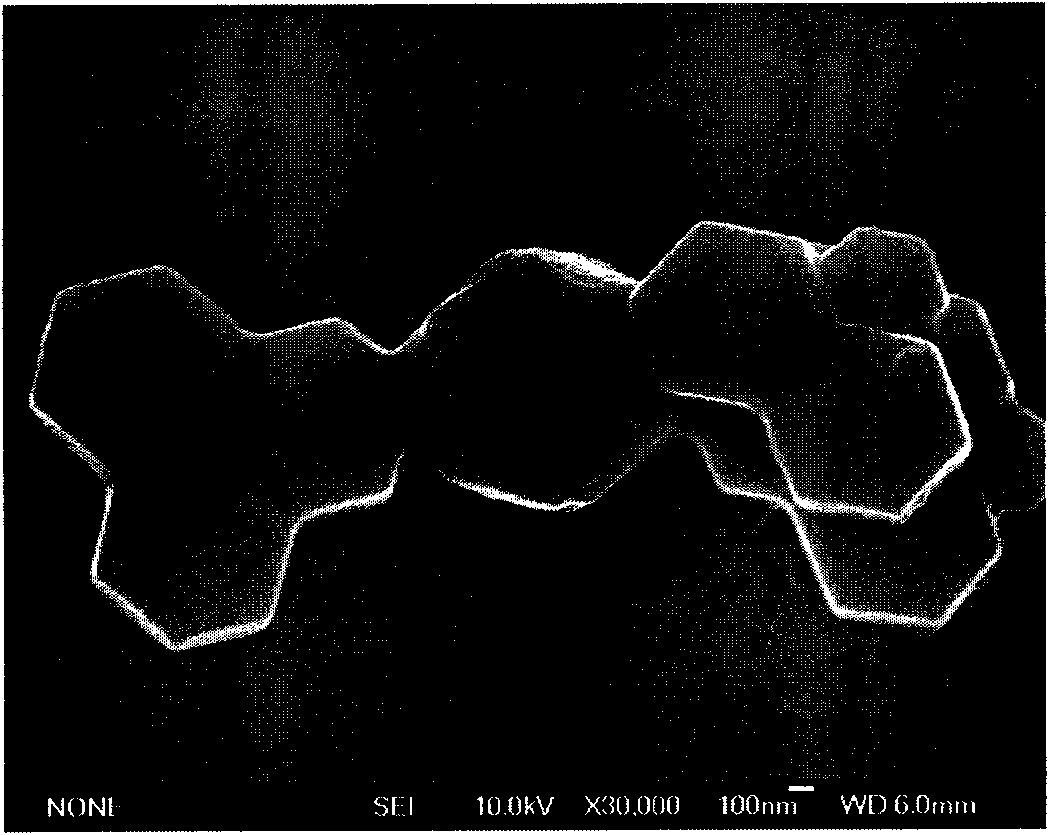

Method of preparing cuprous oxide rhombic dodecahedron and low-temperature reduction reaction

InactiveCN101549883AFlexible production processSave raw materialsCopper oxides/halidesSolventMicrometer

The invention provides a method of preparing cuprous oxide rhombic dodecahedron and low-temperature reduction reaction; the method is characterized by taking blue vitriod as copper source, taking glucose as surfactant, using mixed solvents of water and ethanol, and using sodium hydroxide to cause the whole solvent to keep alkalinity, carrying out reduction reaction under 60 to 120 degrees centigrade to obtain the cuprous oxide rhombic dodecahedron. The produced cuprous oxide rhombic dodecahedron has high photocatalytic activity. In the past, various methods are used to prepare cuprous oxide nanometer / micrometer cubes and octahedral, but the invention prepares the cuprous oxide rhombic dodecahedron formed by 12 congruent (110) crystal faces; and the method provided by the invention has simple processing equipment, low production cost and is suitable for commercial production.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

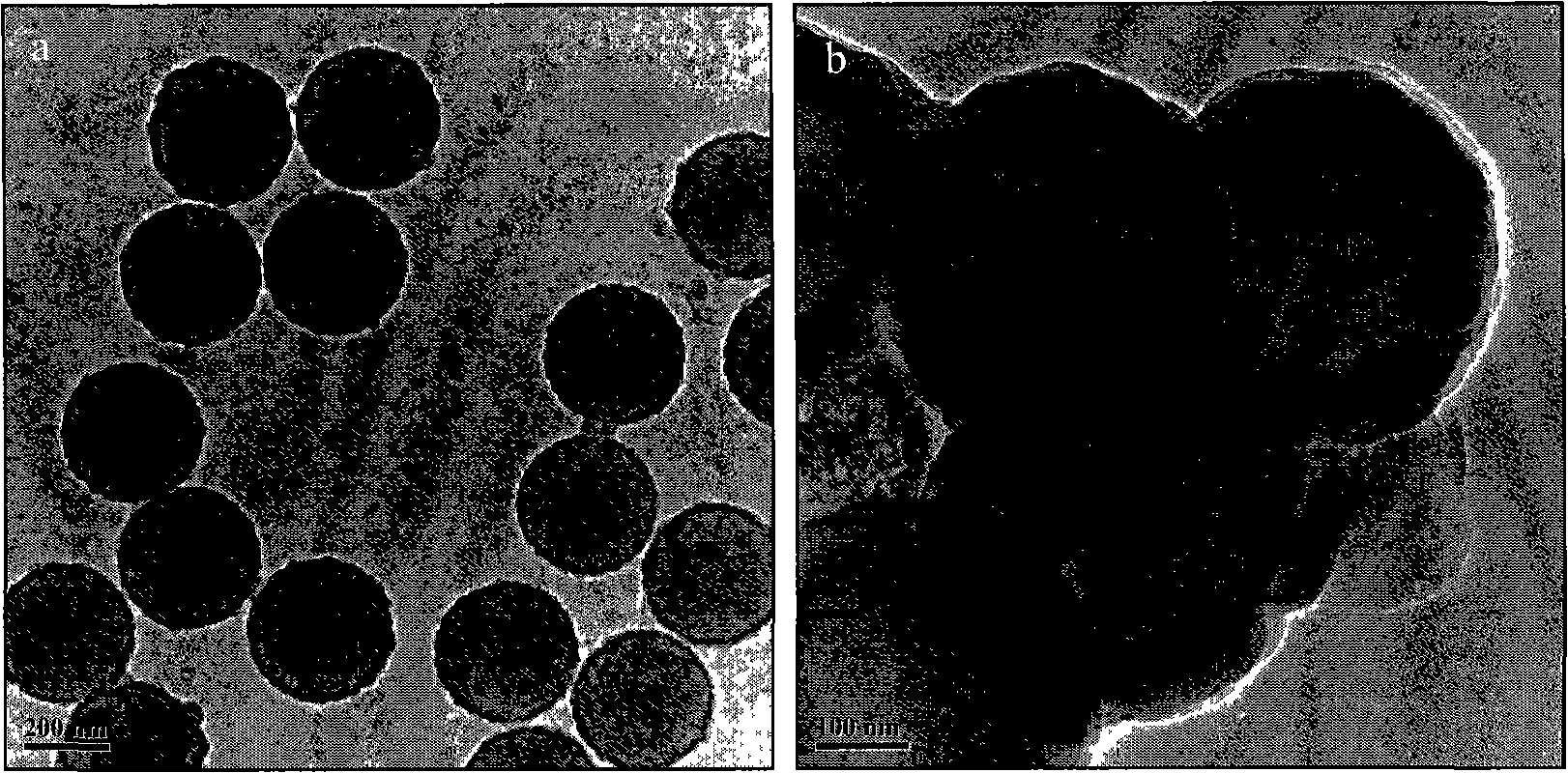

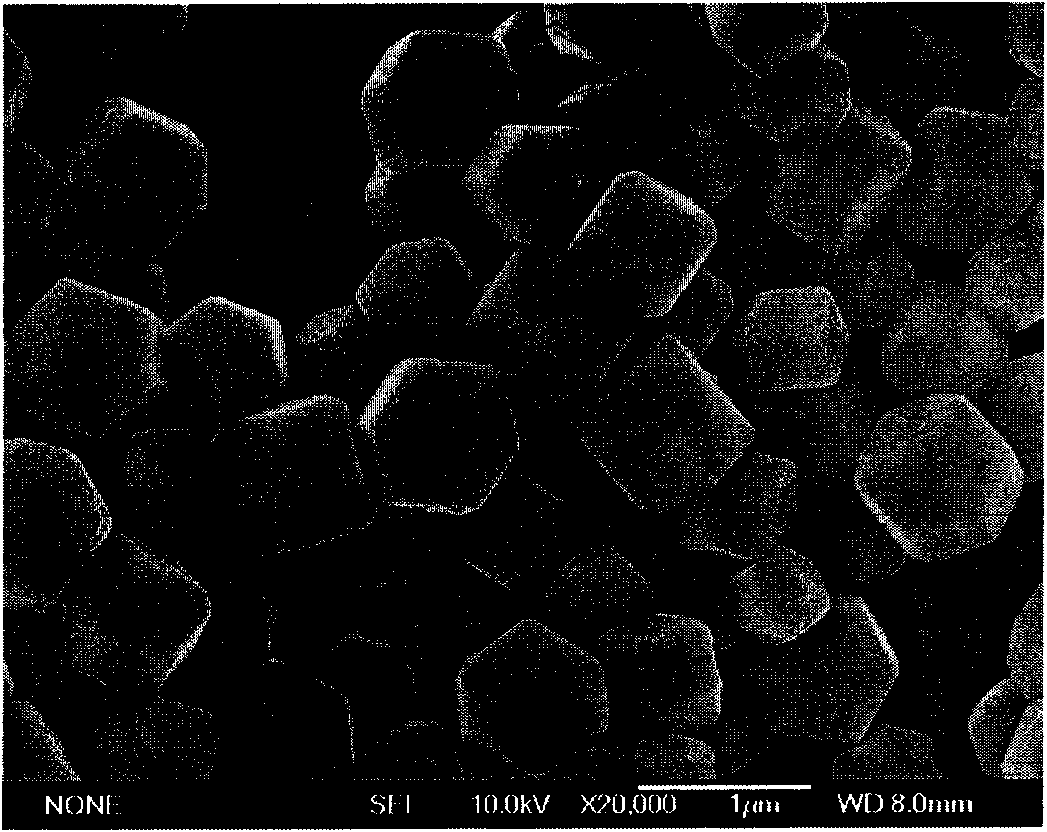

Method for preparing semi-continuous ternary precursor

ActiveCN110600683AImprove particle size distributionParticle size distribution narrowingCell electrodesSecondary cellsPolymer scienceParticle-size distribution

The invention relates to a method for preparing a semi-continuous ternary precursor. The invention provides a method for producing products with different particle size distributions and different degree of sphericity requirements by a single kettle, which solves the problems of uneven particle size distribution, generated fine powders and poor degree of sphericity in the conventional pure continuous process, and the problems of concentrated particle size distribution, dense sphere and low activity in the conventional pure intermittent process. The method uses a complexation control crystallization co-precipitation method, wherein the overflow port of a reaction kettle is connected with an aging tank, the aging tank is connected with a thickener, and the thickener is connected with the feed port of the reaction kettle. The method comprises (a) configuring a certain concentration of metal salt solution, liquid alkali and ammonia water; and adding the solution in the step (a) evenly intothe reaction kettle, wherein the material, after fully filling the reaction kettle, overflows into the aging kettle, the material in the aging kettle is pumped into the thickener by a pneumatic diaphragm, the thickener discharges the clear liquid, and the thick slurry flows back into the reaction kettle, so as to increase the solid content and prolong the residence time to improve the degree of sphericity.

Owner:ZHUJI PAWA NEW ENERGY

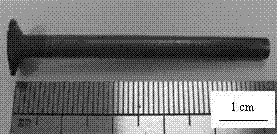

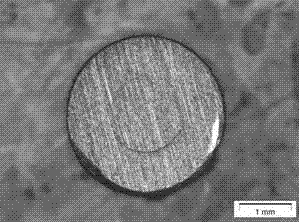

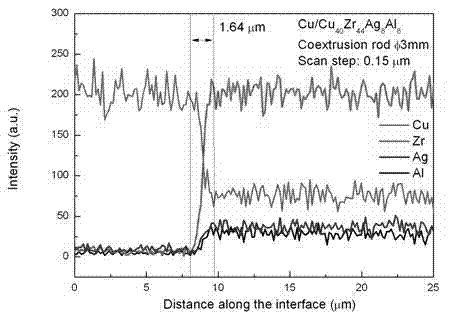

Preparation method of amorphous-reinforced copper-based composite material

InactiveCN102191401AImprove performanceEffective combinationUltimate tensile strengthMaterials science

The invention relates to a preparation method of an amorphous-reinforced copper-based composite material, comprising preparation of a Cu40Zr44Ag8Al8-based master alloy blank, characterized by comprising the steps of: pulverizing the master alloy blank, carrying out rapid induction melting and blow casting on the master alloy blank in vacuum to obtain a rod material with the diameter of 1-3mm, carrying out surface polishing treatment on the rod material, compounding the rod material as a core material with a copper alloy, wherein the volume part of amorphous alloy in the core part is 20-80%, and extruding a plate material or the rod material in a supercooled liquid phase region at an extrusion ratio of 3-10 and an extrusion rate of 0.1-0.3 mm / second. The preparation method provided by the invention realizes effective combination of strength and plasticity and improves the comprehensive properties of the composite material; by using thermoplastic shaping of large amorphous alloy, the composite material is not limited in shape, can be prepared into all kinds of sectional materials and has flexible production processes; and simultaneously, the preparation method can be applied to other similar alloy systems and has broad industrial application prospect.

Owner:NANCHANG UNIV

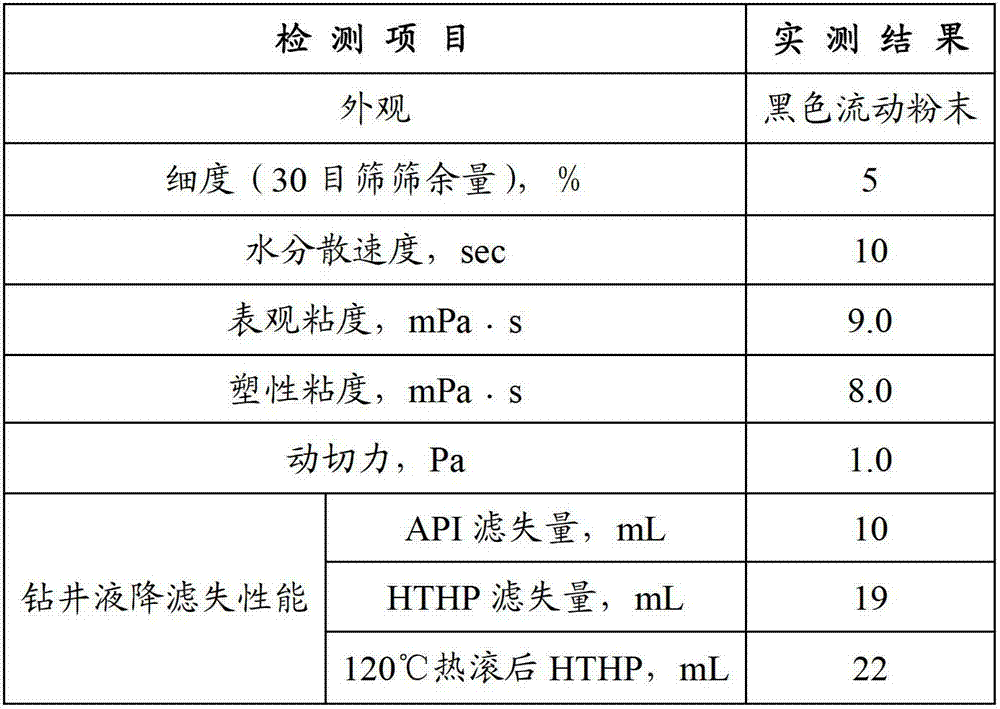

Plugging-type filtrate reducer for water-based drilling fluid and preparation method thereof

InactiveCN103045188AImprove fermentation performanceNothing producedDrilling compositionWater basedPolymer modified

The invention relates to a plugging-type filtrate reducer for water-based drilling fluid and a preparation method thereof. The filtrate reducer can be selected in accordance with different well section temperatures and strata characteristics, and comprises polymer modified oxidized asphalt (PMA), a modifying agent and an auxiliary filtrate reducer; and the filtrate reducer series samples can be prepared by a simple surface modification and dry-blending process. The sample disclosed by the invention is excellent in performance of reducing filtrate of the drilling liquid with the reducing rate of 80%, a dense and tough mud cake is formed, and the crack and fracture of the strata can be plugged in real time based on high-temperature softening and deforming characteristic of the asphalt; an appropriate product formula can be selected depending on the applied strata characteristics and well section temperatures; and the plugging-type filtrate reducer for the water-based drilling fluid is flexile to use, simple in production process, moderate in condition, high in production efficiency, low in cost, free from waste and dust, and low in harm on the body of an operator.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

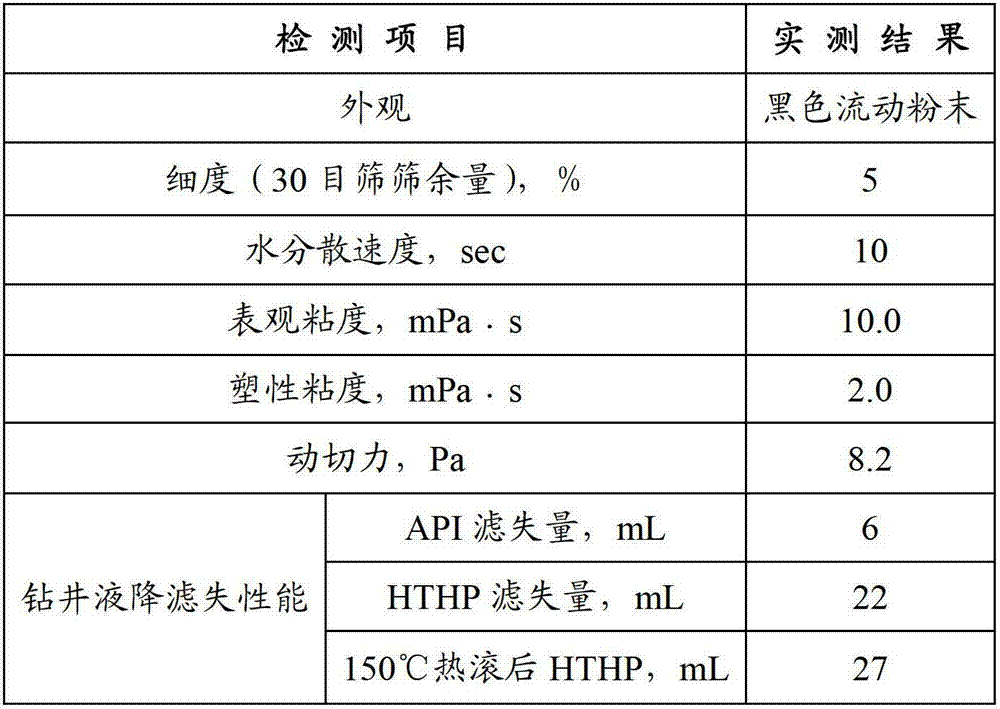

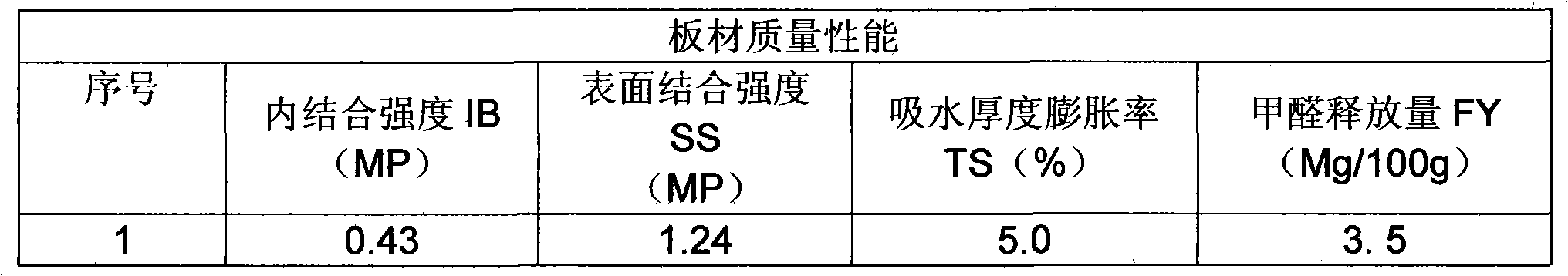

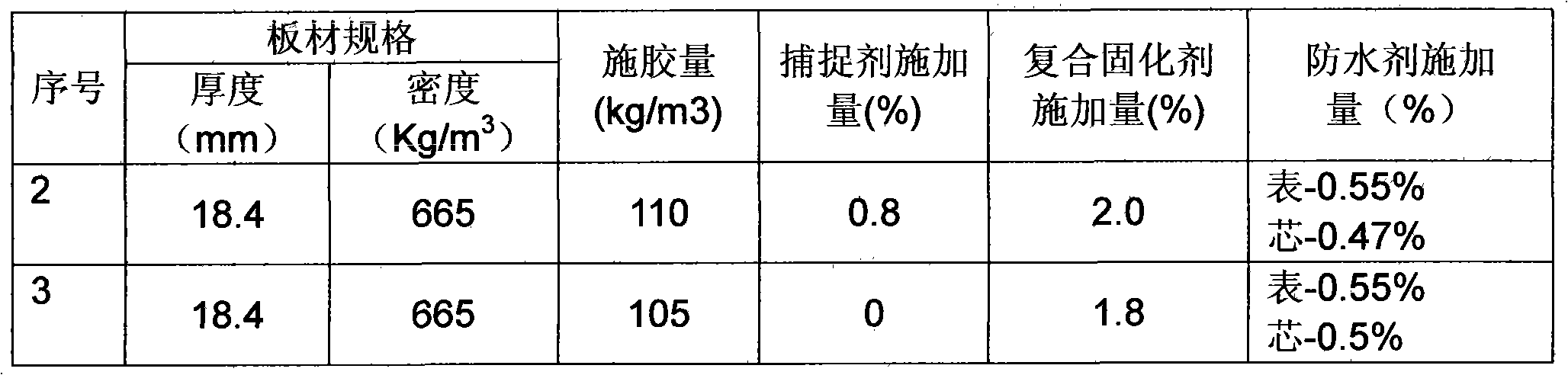

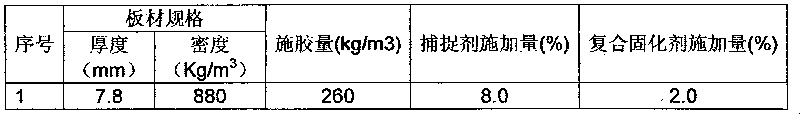

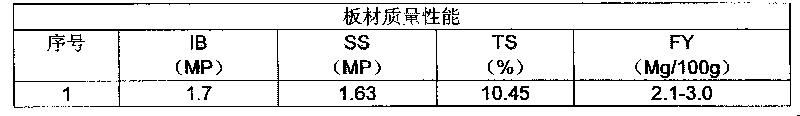

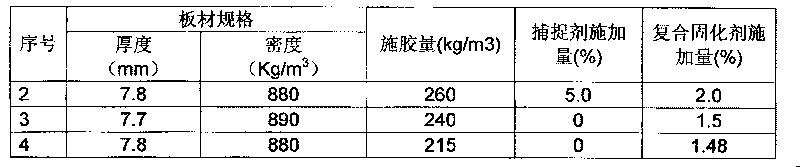

Shaving board producing method

InactiveCN101347946AStable and excellent physical and mechanical propertiesThe release amount is stable and does not reboundAldehyde/ketone condensation polymer adhesivesDomestic articlesWood shavingsManufacturing technology

The invention discloses a method for manufacturing shaving boards, which comprises a sizing process. The invention is characterized in that synthetic resin, compound curing agents, formaldehyde catching agents and waterproof agents for E1-level or E0-level shaving boards are used in the sizing process; wherein, the sizing amount accounts for 8 to 13 percent of the shaving amount; the application amount of the compound curing agents accounts for 1.48 to 2.5 percent of that of the synthetic resin; the application amount of the formaldehyde catching agents accounts for 0.0 to 3.0 percent of that of the synthetic resin; the application amount of the waterproof agents accounts for 0.45 to 1.8 percent of the shaving amount. In the method of the invention, the total molar ratio of urea resin is controlled in the range from 1.03 to 1.14, and E1-level or E2-level shaving boards with low thickness swelling rate can be manufactured by with the formaldehyde catching agents as complementation. The method has the advantages of low manufacturing cost, flexible manufacturing technology and high adaptability. The manufactured shaving boards have the advantages of stable and good performance, low thickness swelling rate, and low emission of free formaldehyde.

Owner:DARE TECH

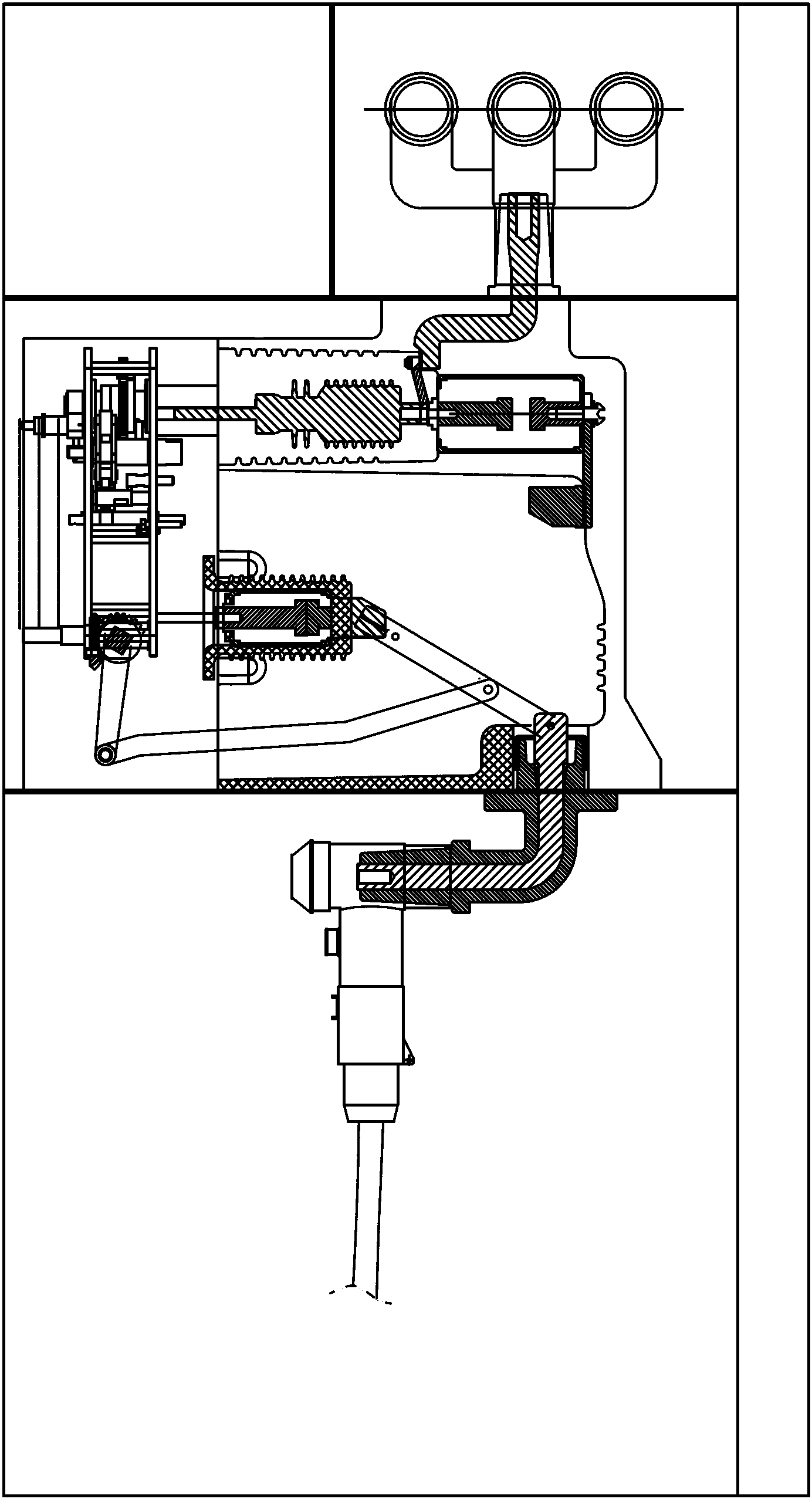

Modular solid insulation ring network cabinet

ActiveCN103219666AGuaranteed accuracyGuaranteed stabilitySwitchgear arrangementsRing networkComputer module

The invention discloses a modular solid insulation ring network cabinet which comprises a cabinet body, an insulated bus module, an isolation module, a main body module, a grounding module and an operating mechanism for controlling the main body module and the grounding module to actuate, wherein the operating mechanism is arranged on the side wall of the cabinet body, the main body module is connected with the operating mechanism through an insulated pull rod, the grounding module is arranged below the main body module, the grounding module is connected with the operating mechanism through a grounding pull rod, the isolation module is arranged at the right lower side of the grounding module, the isolation module comprises an isolation blade and an isolation pull rod movably connected with the isolation blade, and the isolation pull rod is movably connected with a rotating swing rod at the bottom of the operating mechanism. By adopting the modular design, the modular solid insulation ring network cabinet is flexible in production process, convenient to mount and maintain, and compact in structure and small in size as a fully-sealed structure is adopted in the mounting process; and in addition, the modular solid insulation ring network cabinet is provided with a working state monitoring device which can be used for avoiding an electric shock risk, thereby being high in safety.

Owner:BEIJING BOE VACUUM ELECTRONICS CO LTD

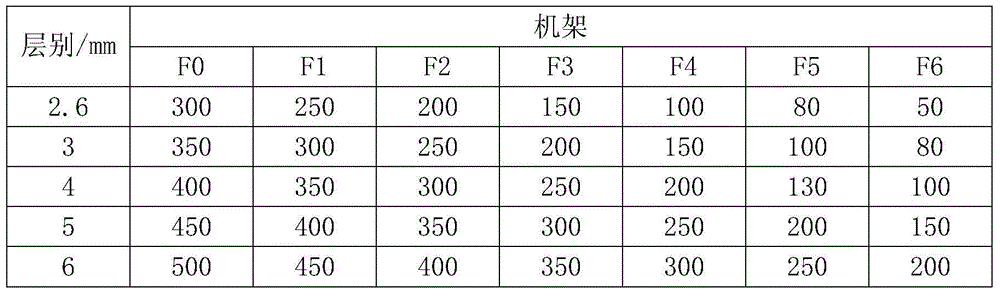

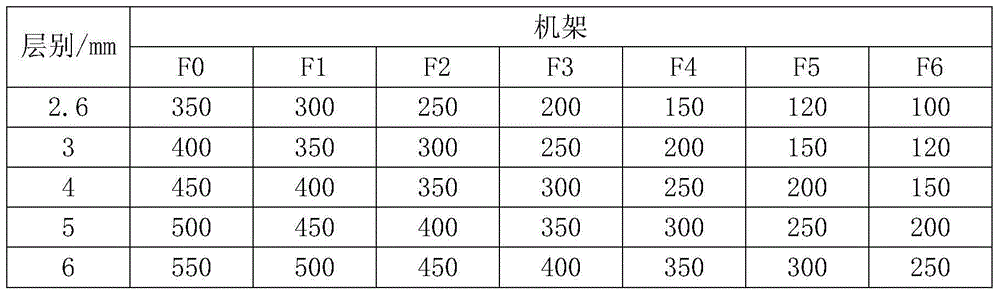

Control method of thin plate hot rolling wire finishing mill AGC system

InactiveCN104907341AHigh control precisionImprove pass rateRoll mill control devicesMetal rolling arrangementsEconomic benefitsStrip steel

The invention discloses a control method of a thin plate hot rolling wire finishing mill AGC system. According to the control method, the adjusting amplitude is subdivided according to the different thickness of the finished strip steel and different racks, and the adjusting amplitude is increased when the thickness of the finished strip steel is increased, and is decreased when the sequence number of the rack is increased. Therefore, the control concept that the adjusting amplitude of all finished strip steels at each rack of the finishing mill is a certain value is changed. The linear setting is conducted based on different thickness at each rack outlet of the racks F0, F1...Fn, the control precision of the AGC system is raised; the qualified rates of the strip steels in both thick and thin specification are increased and the production stability is improved. Therefore, the strip steels in smalllot, multi steel types and multi specification can be produced at the same time based on the order, and substantial economic benefit is realized.

Owner:SHANDONG IRON & STEEL CO LTD

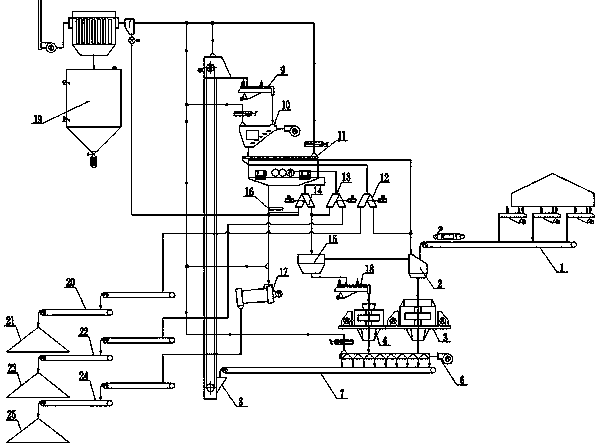

Building station type production line for simultaneous production of sand and aggregate

PendingCN108972896ALower requirementReduce dust requirementsMixing operation control apparatusPretreatment controlProduction lineFineness modulus

The invention discloses a building station type production line for simultaneous production of sand and aggregate. The building station type production line is characterized in that double-main machine crushing equipment, two stages of winnowing equipment, a finished sand fineness modulus adjusting and control device, a humidifying machine and dust collecting equipment are arranged in a building station type steel structure framework; the double-main machine crushing equipment is connected with a PLC (programmable logic controller) control system, and comprises a shaping machine, a sand makingmachine and a vibration screening mechanism; the primary winnowing equipment and the secondary winnowing equipment are respectively arranged at material outlets of the shaping machine and the sand making machine, so as to perform two stages of powder removal, effectively control the powder content of sandstone, and improve the quality of finished sandstone; a material outlet of the secondary winnowing equipment is connected with the vibration screening mechanism, and the vibration screening mechanism comprises a vibration sieve and a plurality of material distribution devices. The building station type production line has the advantages that the materials of the production line are graded by the material distribution devices, so as to only produce sand and / or simultaneously discharge sandand stone; the production technology is flexible and diversified, the effect of one machine with multiple functions is realized, the equipment investment is reduced, and the good economic practicality is realized.

Owner:GUIZHOU CHENGZHI HEAVY IND SCI TECH

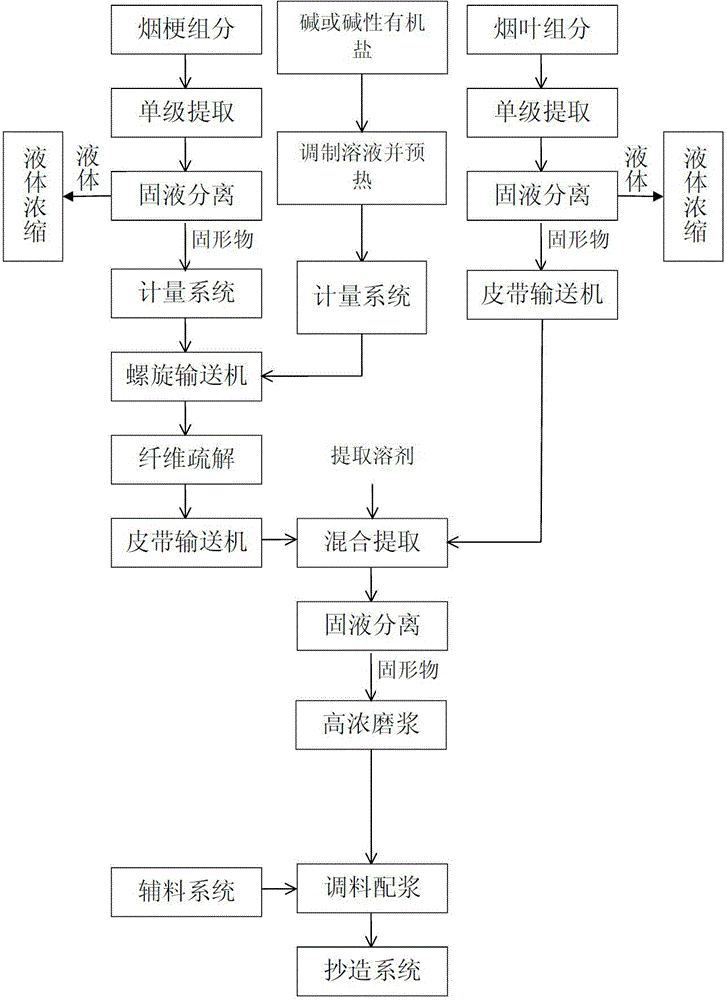

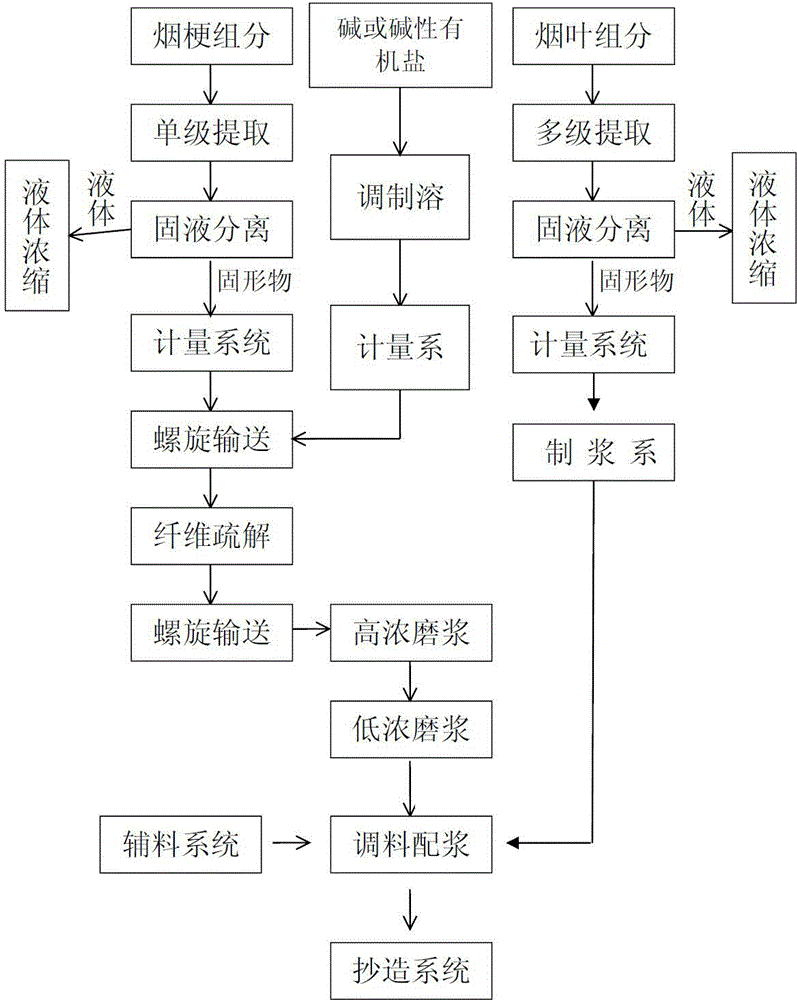

Tobacco stem modified processing method for paper-making process reconstituted tobaccos

InactiveCN104886755AReduce utilizationImprove qualityTobacco preparationEnvironmental chemistrySolid matter

The invention relates to a tobacco stem modified processing method for paper-making process reconstituted tobaccos. The method includes the steps that soft chemical modified processing is firstly carried out on solid matter parts obtained after extraction processing on tobacco stems with alkali or alkaline organic salt, and then modified solid matter parts obtained after solid-liquid separation are used for manufacturing the reconstituted tobaccos; and soft chemical modified processing is characterized in that the alkali or the alkaline organic salt which is 0.2%-5.0% of the solid matter oven dry weight is mixed into a solution with the mass ratio concentration being 10%-12%, preheating is carried out until the temperature ranges from 30 DEG C to 70 DEG C, and the solution is added into solid matter. By means of the tobacco stem modified processing method, the quality of tobacco stem components can be improved and enhanced, the using value of tobacco stem raw materials is improved, and the production cost of the reconstituted tobaccos is reduced.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

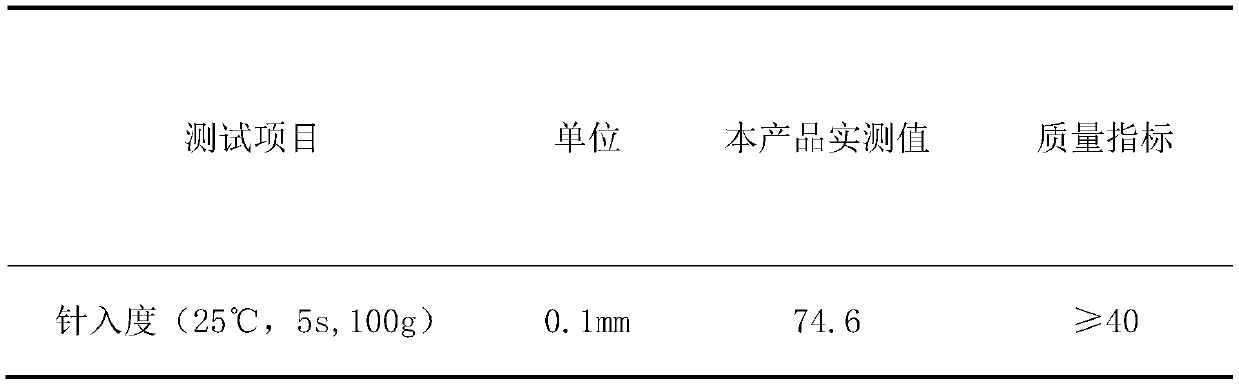

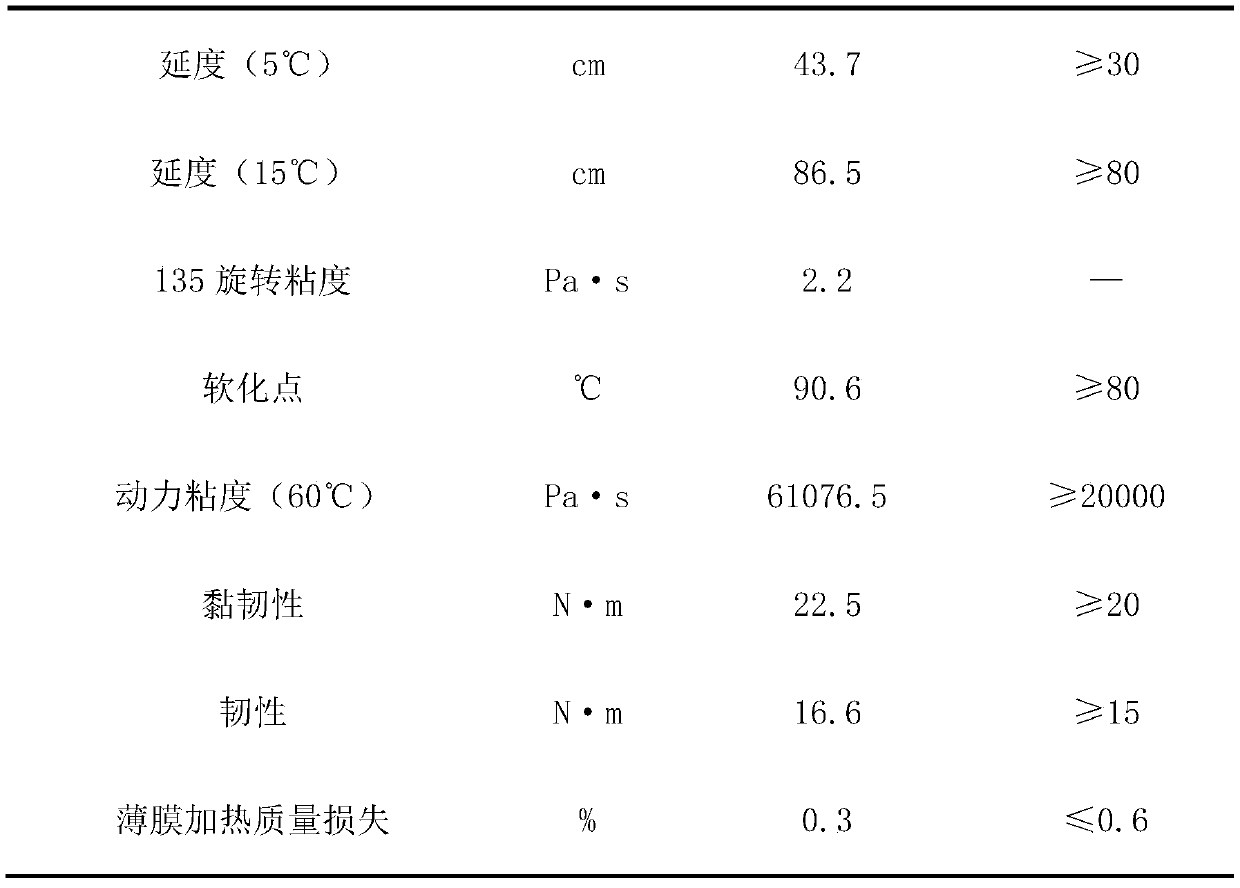

High-adhesion modified asphalt and preparation method thereof

InactiveCN109852085AIncreased durabilityImprove engineering structureBuilding insulationsPolyesterPolymer science

The invention discloses high-adhesion modified asphalt and a preparation method thereof, and belongs to the technical field of road engineering materials. The raw materials of the high-adhesion modified asphalt comprises 500 parts of base asphalt, 300-400 parts of an additive and 10-20 parts of composite reinforcing fibers, and the composite reinforcing fibers are prepared by compounding basalt fibers and polyester fibers and then being coated with base asphalt thin films. When preparing the high-adhesion modified asphalt, the composite reinforcing fibers are added, so that the adhesion, high-temperature stability, fatigue durability of asphalt pavements are greatly improved, and the asphalt has the properties of low-temperature crack prevention and reflection crack prevention. The tensile, shear, compressive and impact strength are effectively improved, and the thermal stability and low temperature resistance of the asphalt are improved.

Owner:河北长大交通科技有限公司

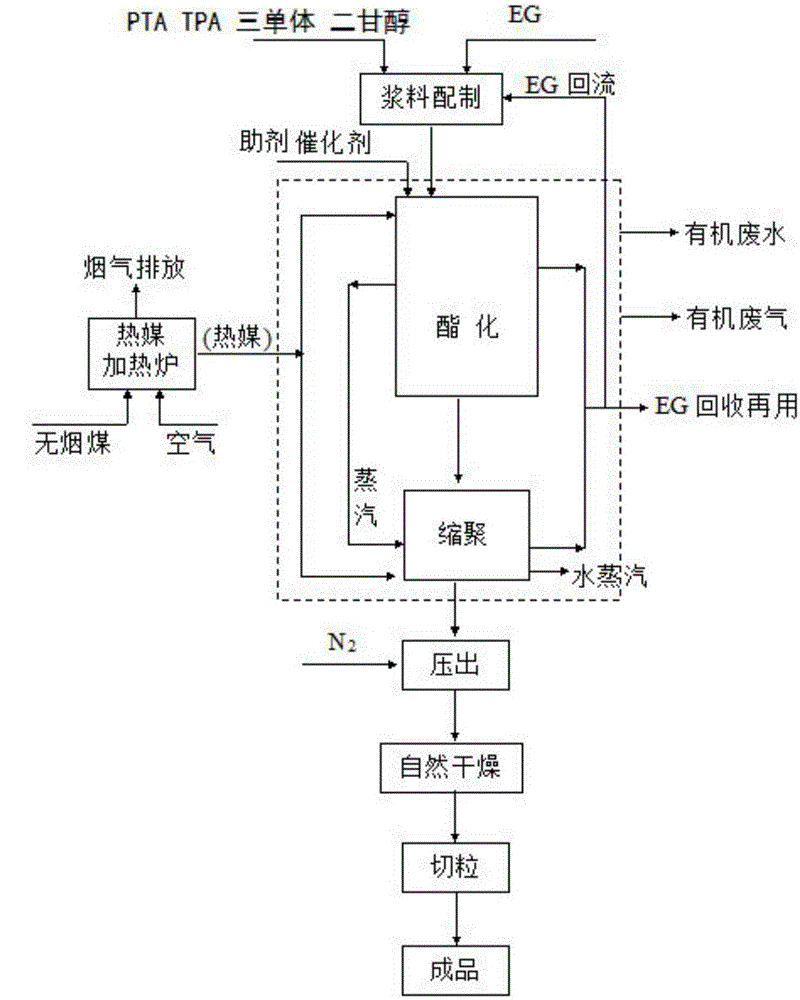

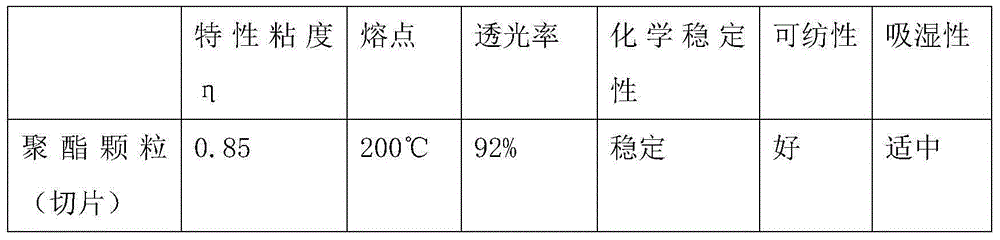

Polymer waterborne polyester and preparation method thereof

ActiveCN105111423AHigh molecular weightExcellent adhesionFibre treatmentPolymer scienceCarvacryl acetate

The invention discloses polymer waterborne polyester. The polymer waterborne polyester is prepared in the mode that terephthalic acid (PTA), isophthalic acid (IPA), ethylene glycol (BG), diethylene glycol, ternary monomers, a catalyst and other auxiliaries serve as raw materials, and the raw materials and mother liquid are subjected to esterification and condensation polymerization for synthesis. A preparation method of the polymer waterborne polyester includes the steps that firstly, terephthalic acid (PTA), isophthalic acid (IPA), ethylene glycol (BG), diethylene glycol and ternary monomers are made into paste and evenly fed into an esterification kettle through a metering pump, the catalyst is added for an esterification reaction, the auxiliaries are added to monomers generated by the esterification reaction, the mixture is filtered and guided into a condensation polymerization kettle for a condensation polymerization reaction, when a certain process value is reached, the mixture is extruded out through nitrogen, and the transparent polyester product is prepared after cooling, grain-sized dicing, drying and screening. The polymer waterborne polyester replaces traditional acrylic and vinyl acetate products, and urea resin and cyanamide resin which are not environmentally friendly, has a series of advantages of being excellent in adhesive force, high in molecular weight, good in environment friendliness and the like, and can serve as a textile hardening agent to be widely used.

Owner:广州市弘浩纺织助剂有限公司

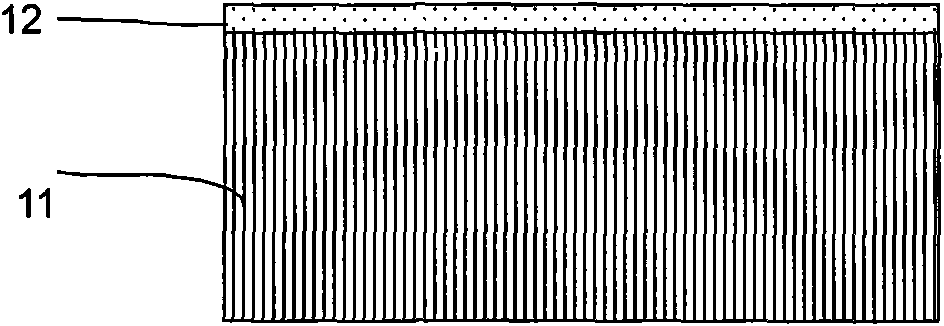

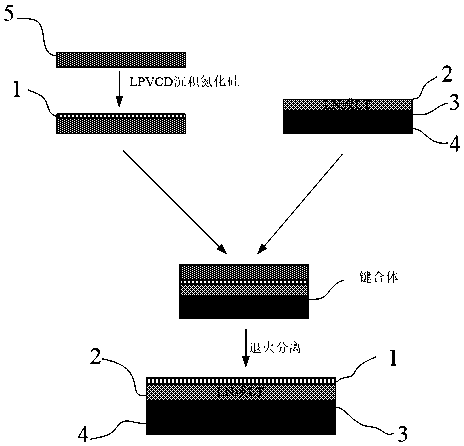

Single crystal film with silicon nitride layer and preparation method thereof

ActiveCN110618488AImprove insulation performanceMeet performance requirementsOptical waveguide light guideSilicon oxideSingle crystal

The present invention discloses a single crystal film with a silicon nitride layer and a preparation method thereof. The single crystal film with the silicon nitride layer comprises a silicon nitridelayer, a lithium niobate film layer, a silicon oxide layer and a silicon substrate layer from top to bottom. The single crystal film with the silicon nitride layer of the invention has better compatibility with the lithium niobate film, high mode limitation, low propagation loss and high power processing capacity as an optical waveguide transmission layer since silicon nitride has a good insulation effect and a wide optical transmission window. With the preparation method of the single crystal film with the silicon nitride layer in the invention, the silicon nitride waveguide is prepared by LPVCD deposition and integrated with a lithium niobate modulator, and a waveguide device with high integration level, wide bandwidth and low loss can be obtained. The preparation method of the inventionis suitable for industrial production and has a high yield.

Owner:JINAN JINGZHENG ELECTRONICS

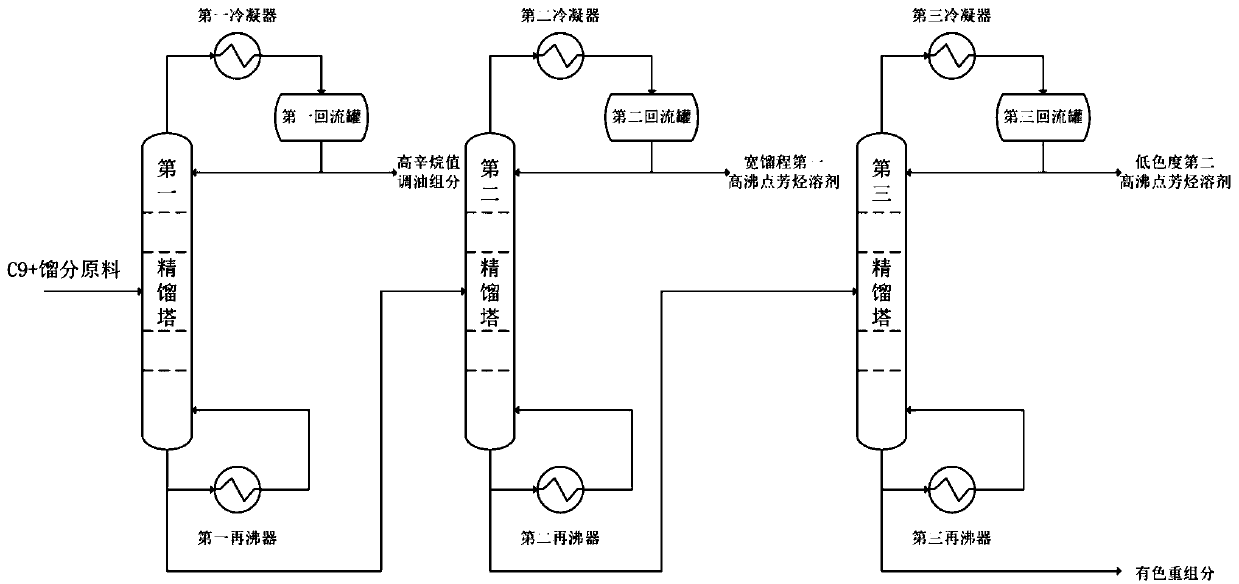

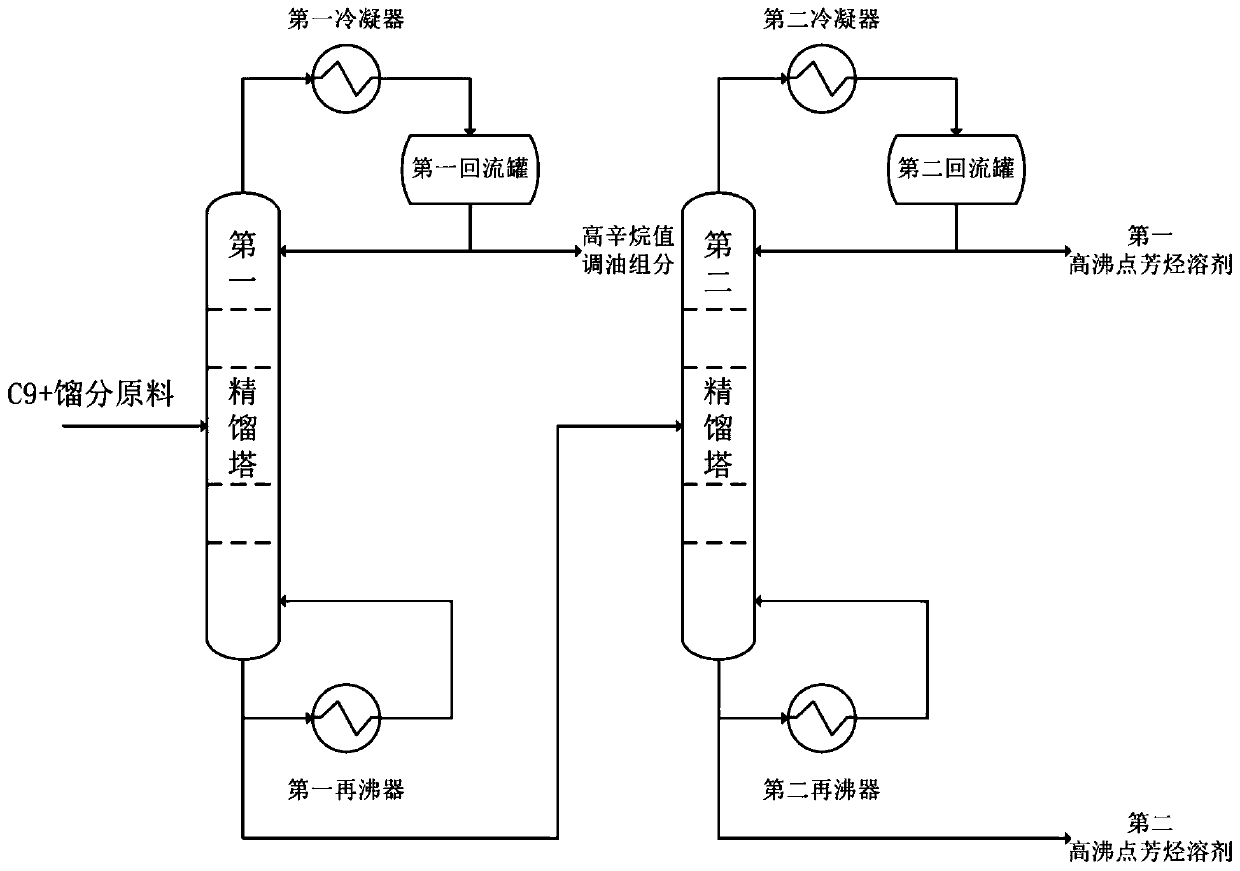

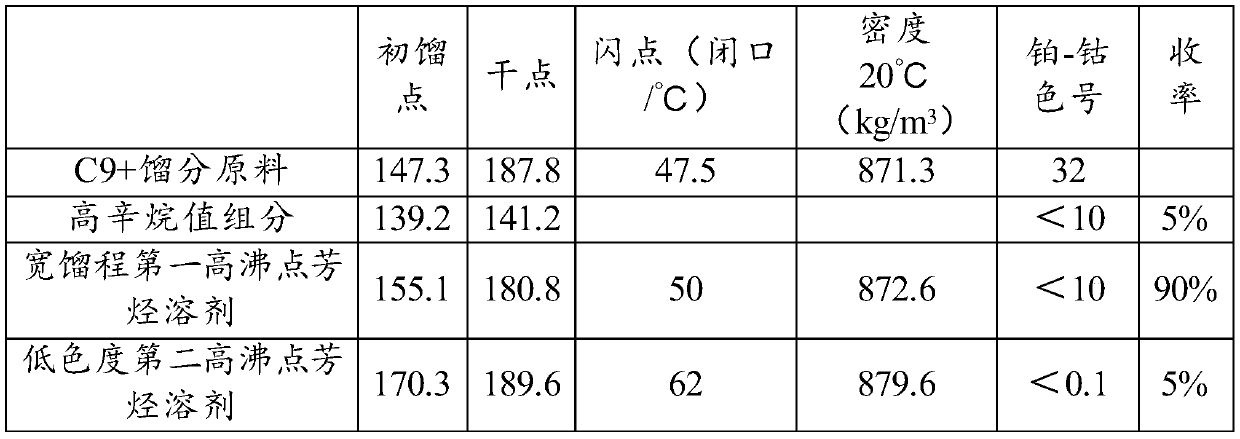

Production system and production method of aromatic hydrocarbon solvent having wide distilling range, low chromaticity and high boiling point

ActiveCN110180202AChromaticity Precise ControlPrecise control of reflux ratioDistillation regulation/controlHydrocarbon distillation control/regulationRefluxBoiling point

The invention provides a method for producing an aromatic hydrocarbon solvent having wide distilling range, low chromaticity and high boiling point. The production method of the aromatic hydrocarbon solvent having wide distilling range, low chromaticity and high boiling point of the invention includes the steps of guiding a C9+ fraction raw material into a first rectification column for rectifyingand removing a light component, then separating a first solvent product from a second solvent crude product through a second rectification column, and finally separating a second solvent product froma colored heavy component by a third rectification column; meanwhile, precisely controlling the rectification operating pressure, temperature and reflux ratio of each distillation column, which can greatly widen the distilling range of a first aromatic hydrocarbon solvent obtained, and can also effectively ensure the chromaticity of a second aromatic hydrocarbon solvent; each step performed is arectification step, no waste is discharged, and the process is environmentally friendly and non-polluting.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

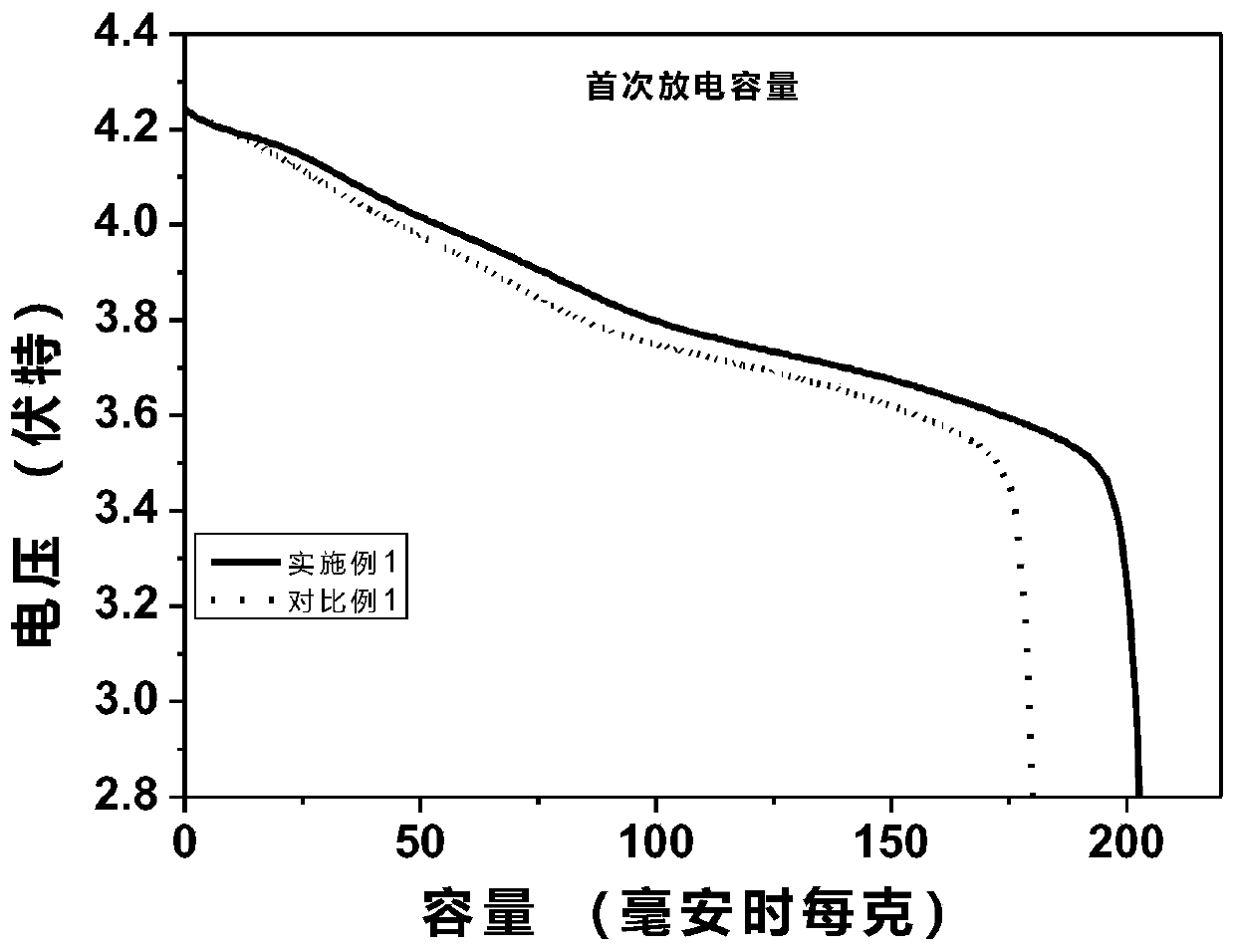

Preparation method of high-nickel positive electrode material of lithium secondary battery

InactiveCN109786734AValid entryReduce discharge capacityCell electrodesSecondary cellsNitrogenNitrogen gas

The invention discloses a preparation method of a high-nickel positive electrode material of a lithium secondary battery, the preparation process is improved and optimized, a high-nickel ternary material doped with effective elements can be obtained, the specific capacity cycle life of the material is effectively prolonged on the premise that the layered structure of the material is kept complete,excessive Li / Ni mixed arrangement and reduction of nickel ions are avoided, the sintering atmosphere is not limited and can be any one or a combination of air, oxygen or nitrogen, and the productionprocess is more flexible. The invention further discloses a high-nickel positive electrode material of the lithium secondary battery.

Owner:BEIJING TAIFENG XIANXING NEW ENERGY TECH CO LTD +1

Production process for metal composite plates

InactiveCN101559434ASimple processHigh bonding strengthMetal rolling arrangementsComposite plateMachining

The invention aims to provide a production process for metal composite plates, which can effectively meet the requirement of producing various metal composite plates in small batches. The production process is characterized in that: metal plates with the same material or different materials are cut, rolled and welded into metal pipes; the metal pipes are combined together to form metal composite pipes after the composite surfaces of the metal pipes are cleaned by mechanical processing; the metal composite pipes are subjected to hole enlargement, expanding and flanging processing, rolled and composited by a duo mill under heat condition, and cut into composite metal plates; and the composite metal plates are rolled on a four-high mill into the metal composite plates meeting the requirement.

Owner:TAIYUAN HEAVY IND SCI & TECH +1

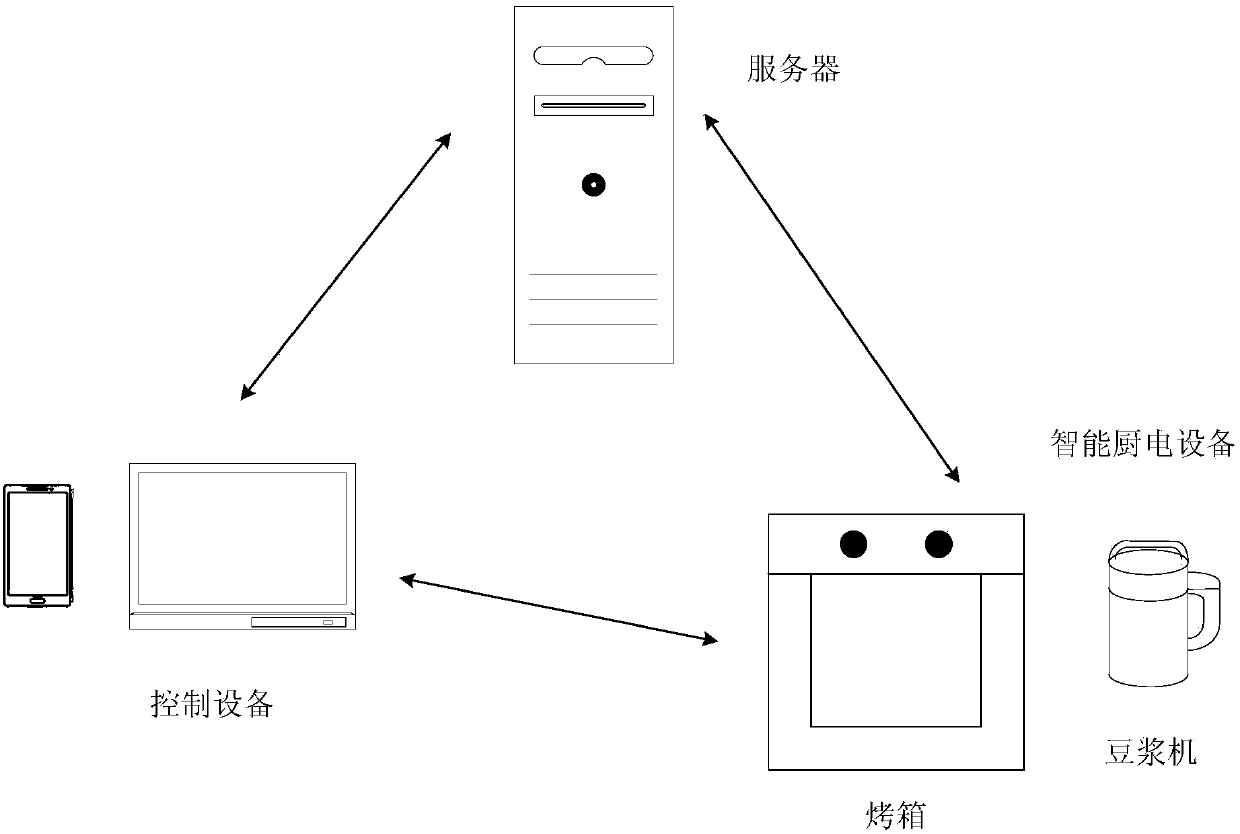

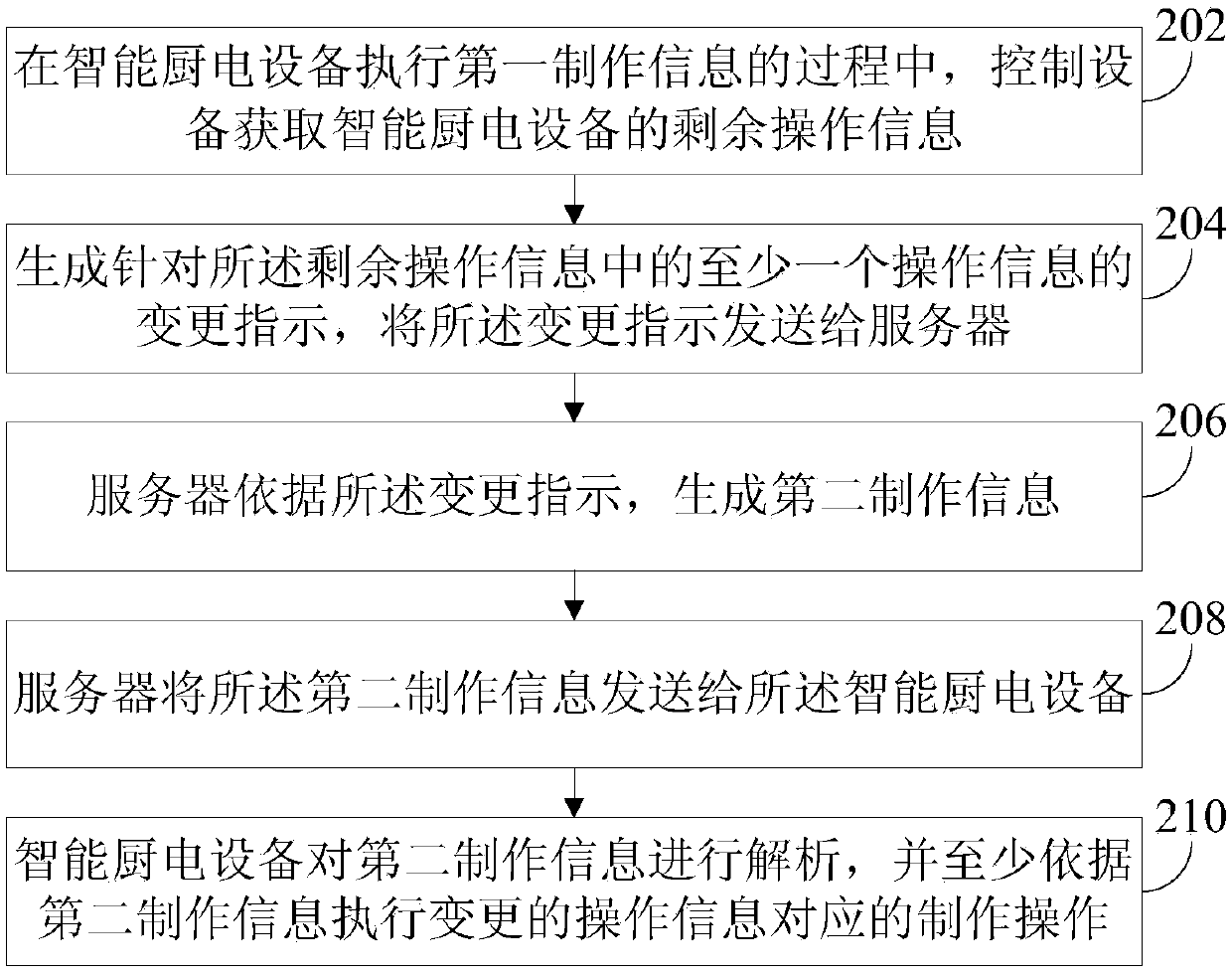

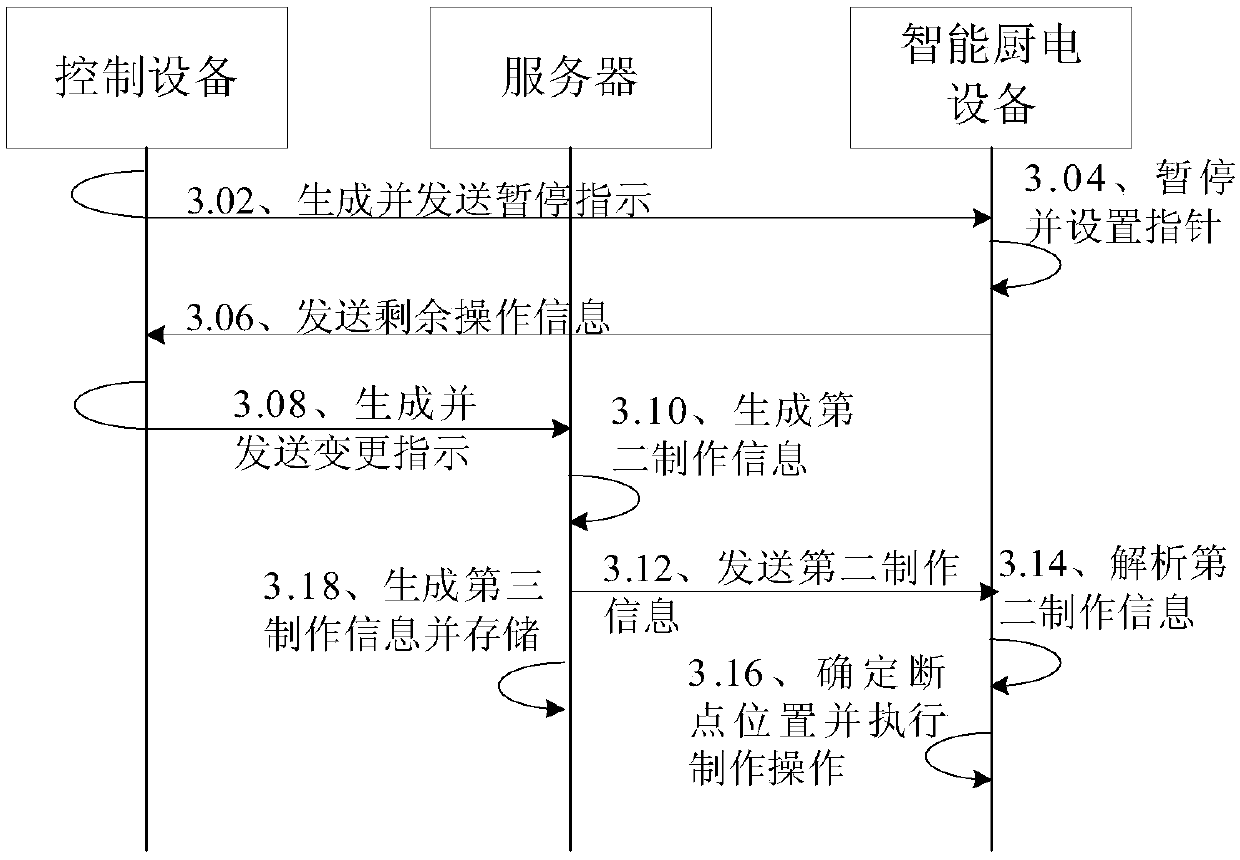

Device control method, apparatus and device

InactiveCN108023792AImprove scalabilityFlexible production processHome automation networksElectricityControl equipment

The embodiment of the invention provides a device control method, an apparatus and a device, which are used for improving flexibility and expandability of a manufacturing process. The method comprisesthe following steps: in a process of executing first manufacturing information by intelligent kitchen electrical equipment, a control device obtains residual operation information of the intelligentkitchen equipment, wherein the first manufacturing information comprises multiple operating information, the residual operating information comprises at least one of the operating information currently executed and / or the operating information which is not executed in the first manufacturing information; the control device generates a change indication aiming at the at least one operating information in the residual operating information, and sends the change indication to a server; the server generates second manufacturing information according to the change indication; the server sends the second manufacturing information to the intelligent kitchen electrical equipment; and the intelligent kitchen electrical equipment analyzes and executes the second manufacturing information.

Owner:BANMA ZHIXING NETWORK HONGKONG CO LTD

Production process of stone-plastic floor coated softwood

The invention discloses a production process of a stone-plastic floor coated softwood. The production process comprises the following steps of weighing materials, carrying out hot mixing, carrying outcold mixing, extruding and shaping, laminating, painting, curing, cutting, grooving, and covering a softwood layer, a base material is subjected to the process flows of cutting, groove and covering the softwood layer, and waste materials of the softwood layer and the base material after cut can be collected and reused, so that the resources can be saved, the production cost can be saved, and thewaste can be reduced. The tensile force of a softwood covering device to the softwood is greatly reduced, so that stretching deformation can be prevented, and the softwood layer adhered to the base material is more fit; and the softwood covering device reduces softwood layer trim in the length direction of the base material, and the softwood layer cutting and trimming in the width direction of thebase material are integrated, so that the production steps are reduced, the time is saved, and the production efficiency is greatly improved.

Owner:湖州硕业木塑科技有限公司

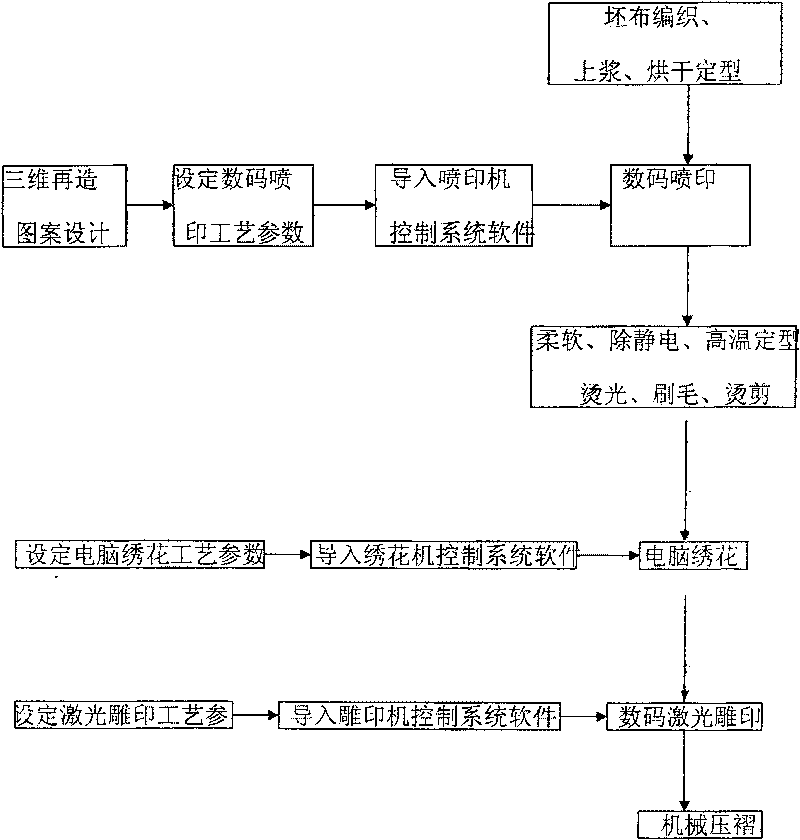

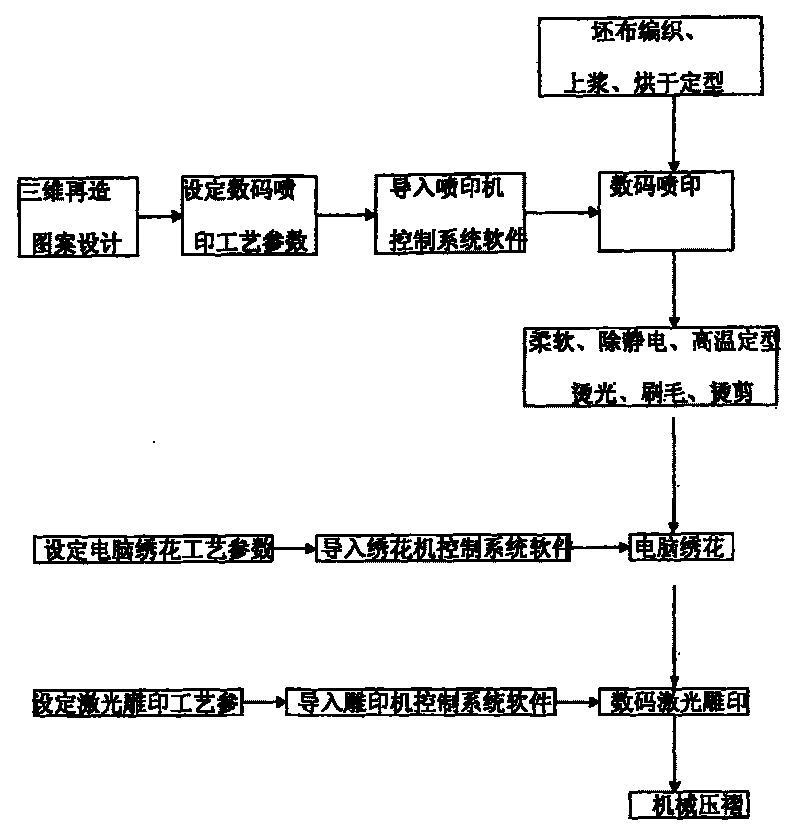

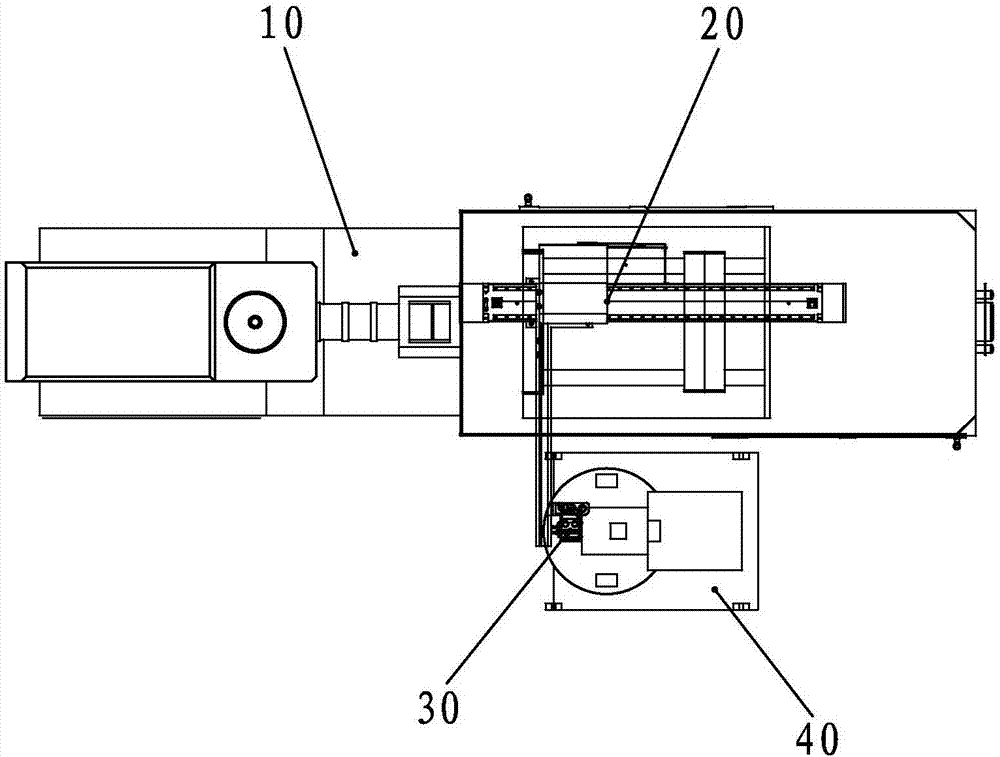

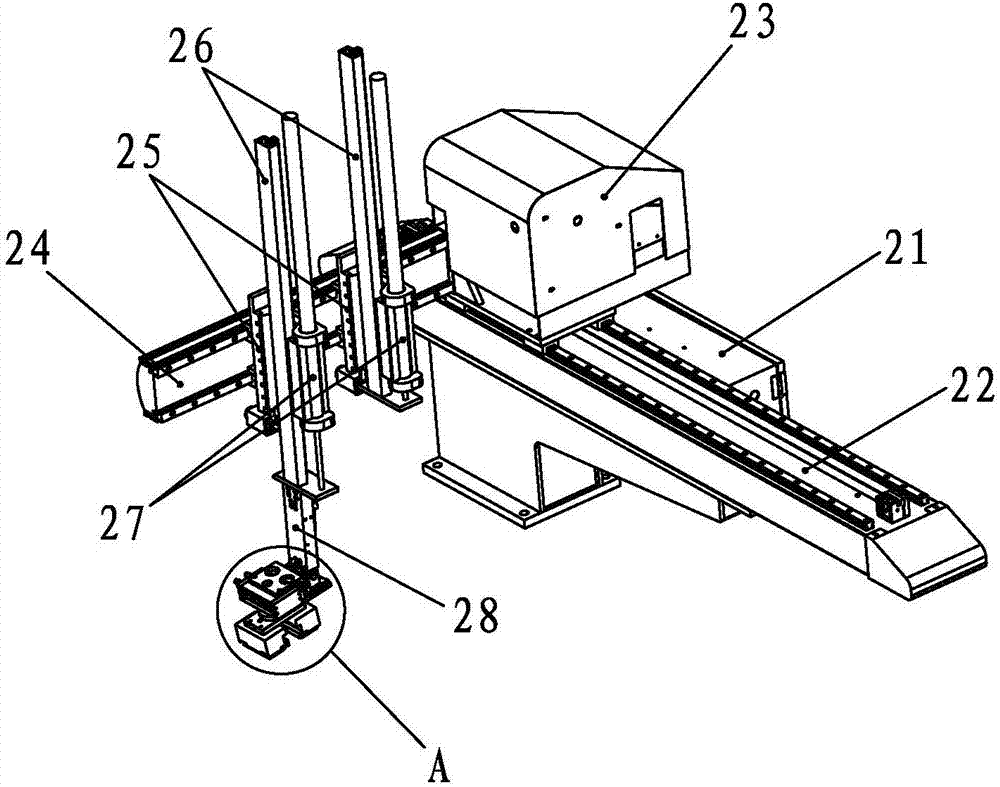

Technique for preparing three-dimensional regeneration pattern fabric

InactiveCN101235603BSimplify production preparationShorten the processing cyclePattern makingDyeing processGraphicsPersonalization

The invention relates to a technical method for manufacturing three-dimensional reconstruction pattern fabrics, which comprises technical procedures: designing three-dimensional reconstruction patterns, spray-printing digitally, embroidering with a computer, discharge-printing with digital laser, pressing pleats mechanically and the like. The method integrates a plurality of techniques such as electronic information, the computer, light mechanical and electrical integration and the like and applies a digital technique, textile surface graphic reconstruction and a textile three-dimensional memory molding reconstruction technique to assist design, the graphic visual effects which are similar to negative incising, heat printing and hollow-out pattern styles can be obtained, the grade and thetechnical added value are greatly increased, the personalized artistic requirements for small batch, multi-varieties and multi-colors can be satisfied, and the method is applied in producing fabrics such as various natural fiber, chemical fiber, synthetic fiber and the like.

Owner:内乡县地毯工艺品集团公司

Modified synergistic slow-release compound fertilizer and preparation method thereof

InactiveCN109851431ASolve compactionSolve environmental pollutionFertilizer mixturesControl releaseMolecular materials

The invention discloses a modified synergistic slow-release compound fertilizer and a preparation method thereof, and belongs to the technical field of fertilizers. The modified synergistic slow-release compound fertilizer comprises a water-soluble granular fertilizer core and wrapping layers, and the 2-4 wrapping layers sequentially wrap the outer surface of the water-soluble granular fertilizercore. According to the compound fertilizer and method provided by the invention, the problem of soil hardening and environmental pollution caused by only slow release of N and a low utilization rate of P and K of a current slow-release fertilizer is solved, secondary pollution of an organic polymer or a high-molecular material to soil is avoided while the costs are reduced, the product formula isflexible, no three waste (waste water, waste gas and solid waste) is discharged in the production process, the production process is simplified, the equipment investment is saved, the production transformation of the invention patent results is facilitated, and the slow-release controlled-release effect, fertilizer utilization rate level, and ecological environmental protection of the compound fertilizer provided by the invention are improved to a certain extent.

Owner:姜玉贞

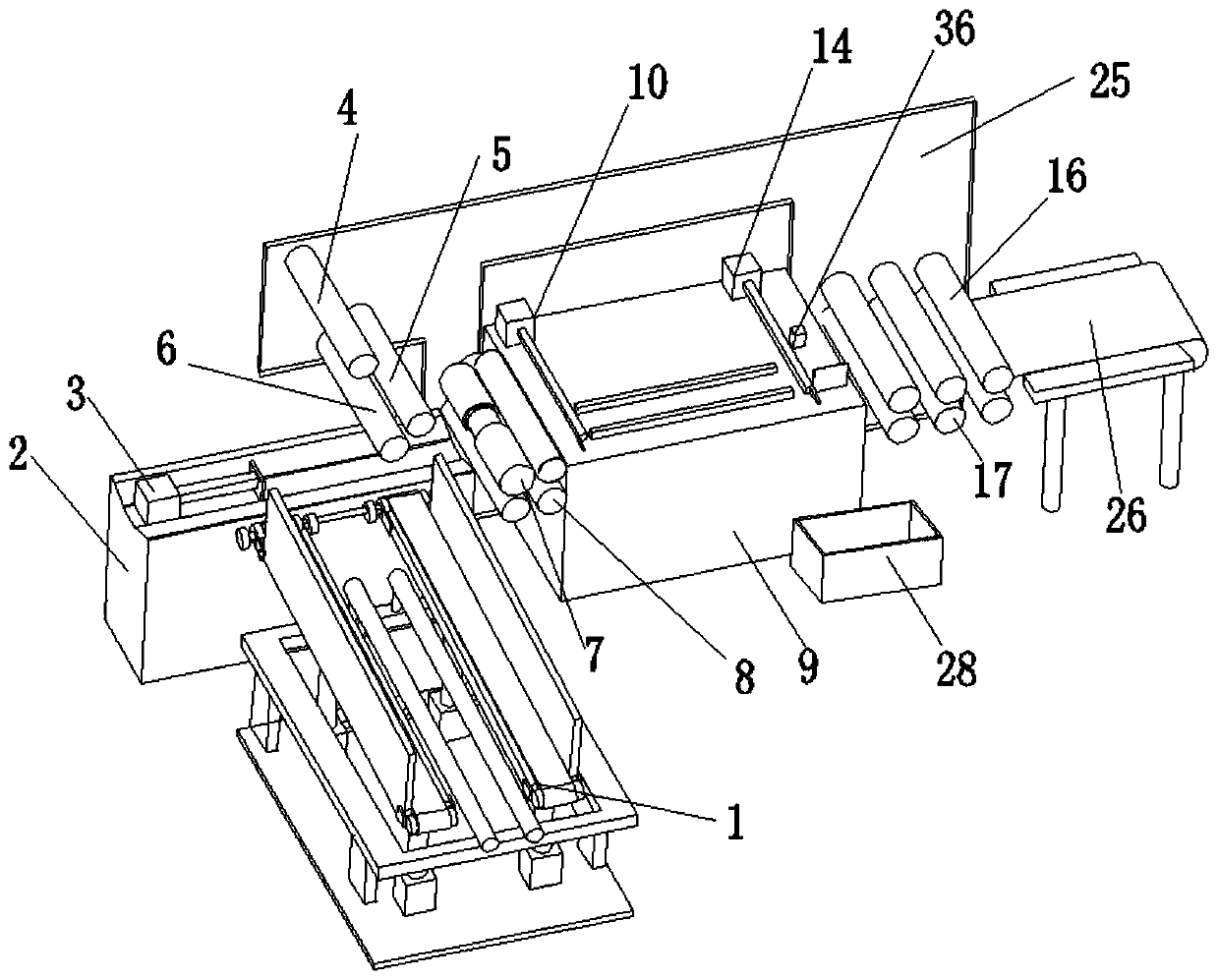

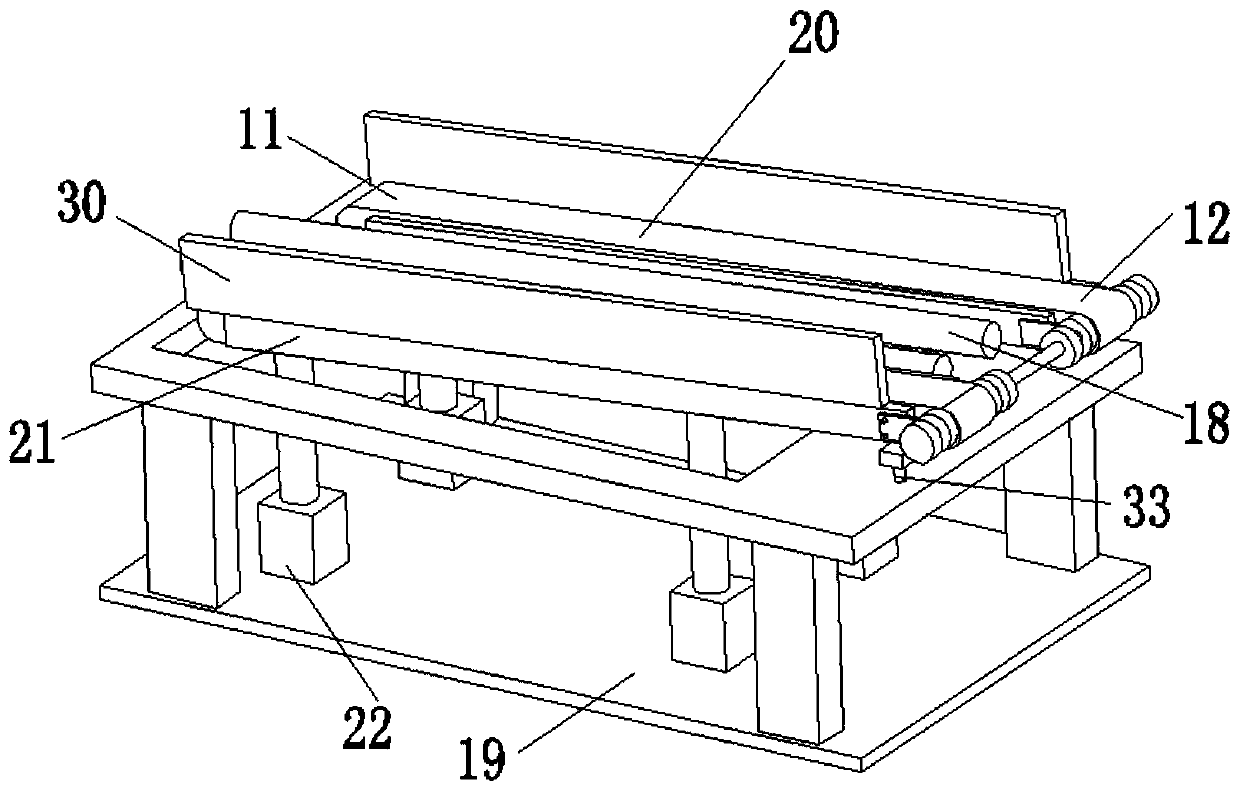

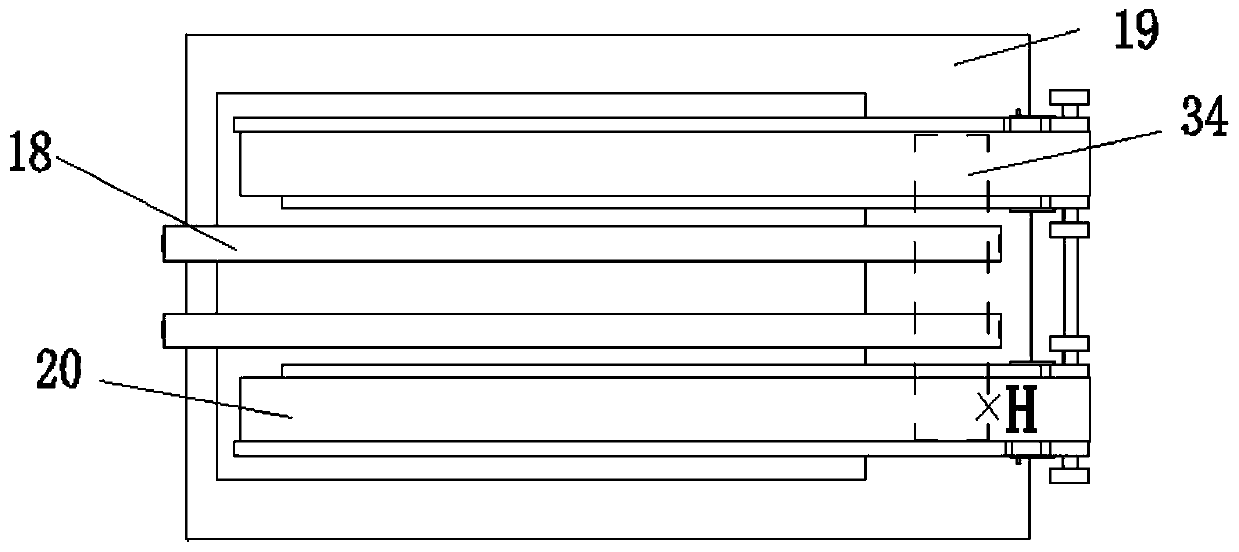

Flexible automatic hot stamping system

The invention discloses a flexible automatic hot stamping system. The flexible automatic hot stamping system comprises a mechanical arm, a material taking jig and a hot stamping machine. A self-positioning sensor of the hot stamping machine coordinates with a self-positioning sensor of an injection molding machine to achieve automatic positioning of the moving position of the hot stamping machine.The material taking jig is driven by the mechanical arm to achieve X-axis movement, Y-axis movement and Z-axis movement. The four corners of the lower portion of a base of the hot stamping machine are provided with positioning rolling wheels. A hot stamping pressing block driven by a lifting air cylinder to ascend or descend and a switching rotary table driven by a rotating air cylinder are arranged above the base. A plurality of hot stamping jigs with different specifications are arranged on the switching rotary table along the circumference in a matrix manner. According to the flexible automatic hot stamping system, the modular hot stamping machine can be moved to the position beside the corresponding injection molding machine at any time to meet the requirement for small amount of hotstamping, and existing equipment is fully utilized; by means of flexible and rapid replacing and switching of material taking chucks and the hot stamping jigs, requirements for multiple kinds of different specifications of small amount of hot stamping are achieved, and therefore the requirements for small amount and multi-order production are met.

Owner:ROSE PLASTIC KUNSHAN

Monitoring method and device for pipe thread forming machine

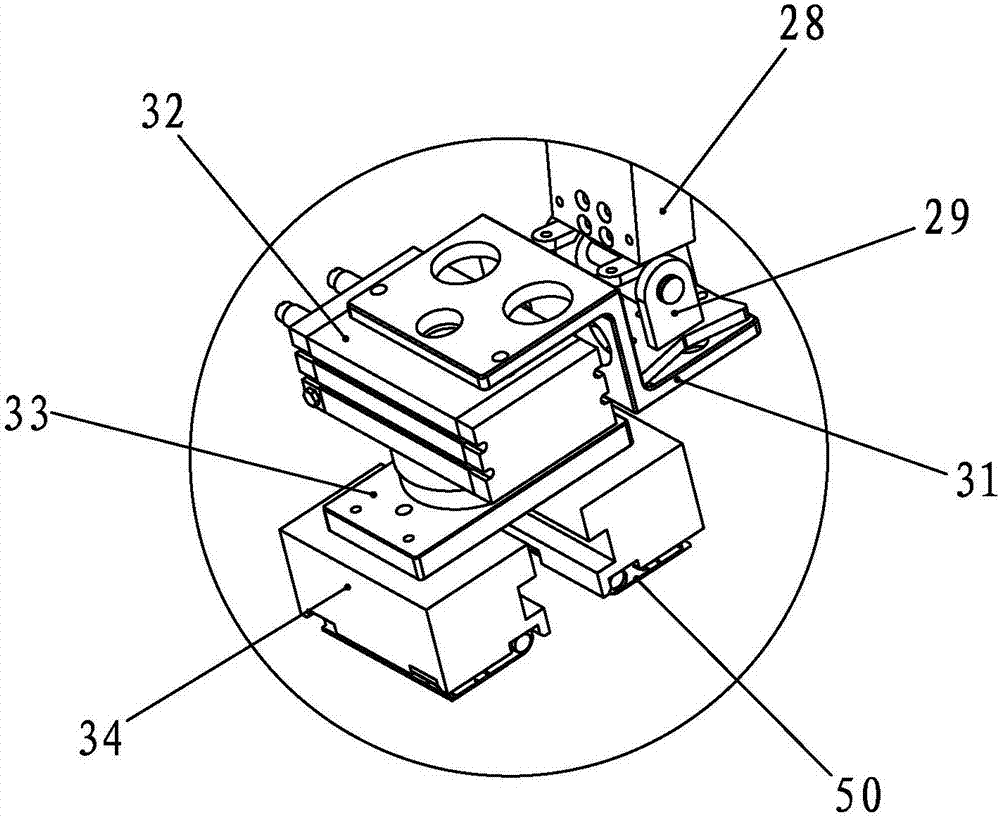

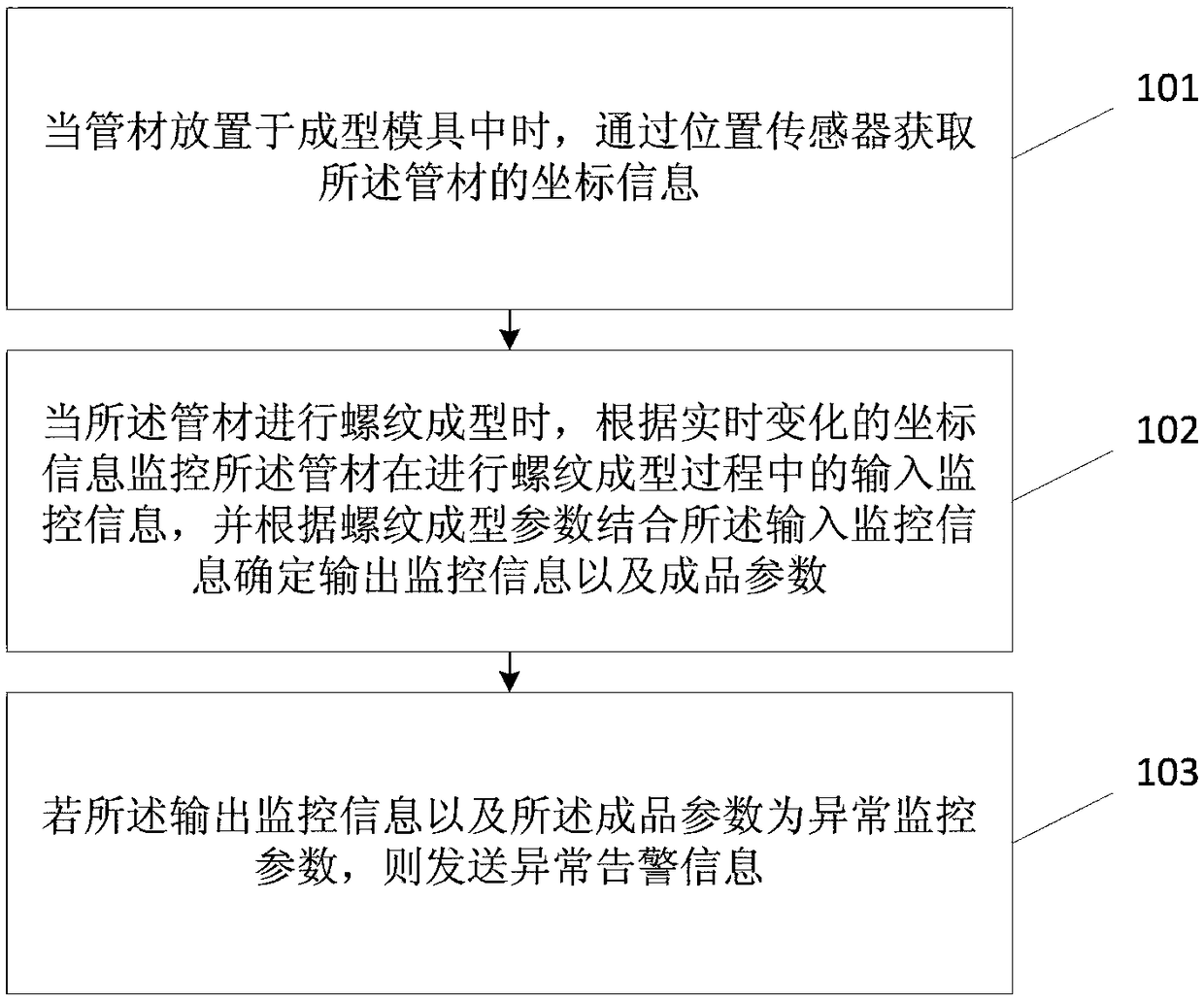

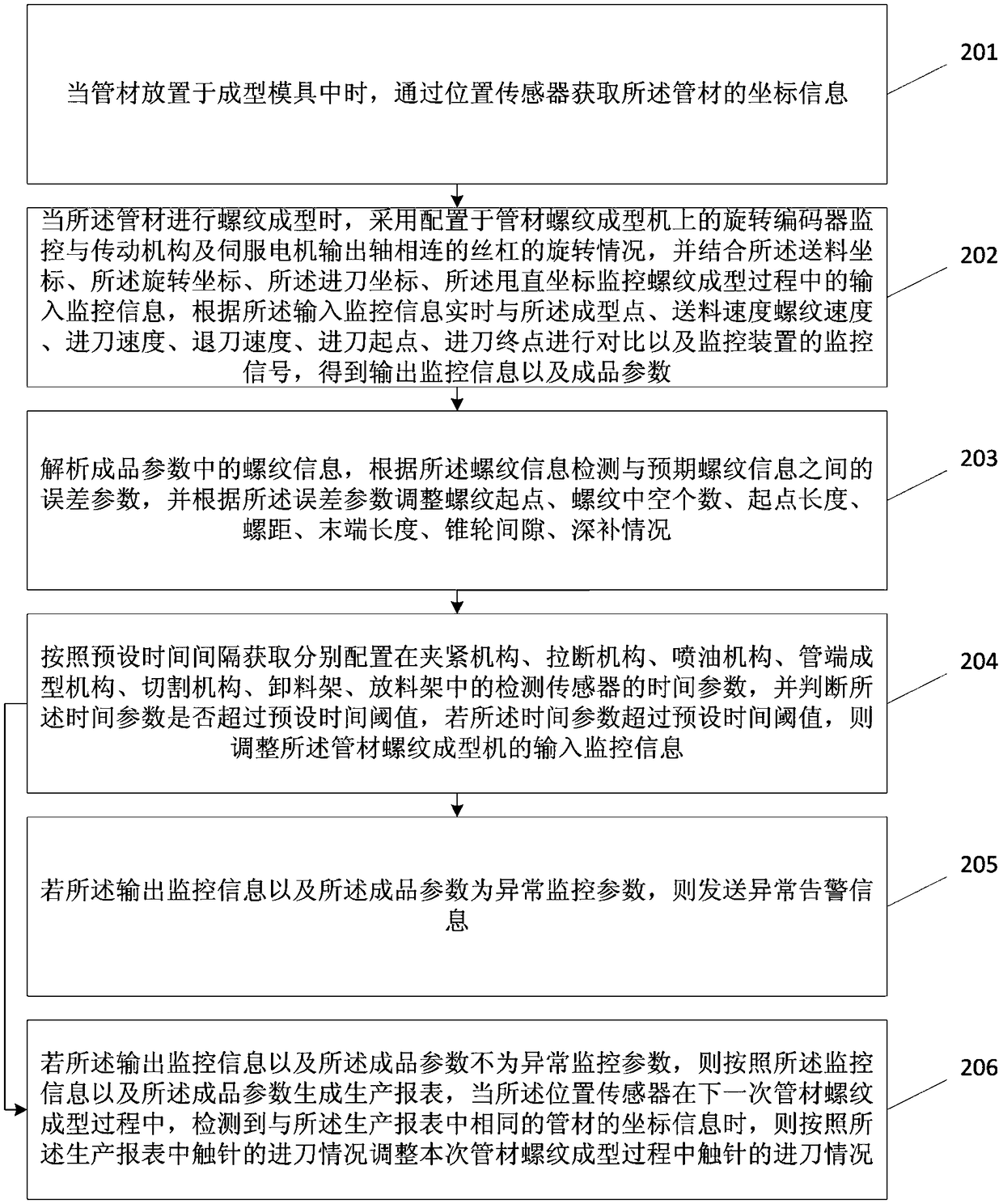

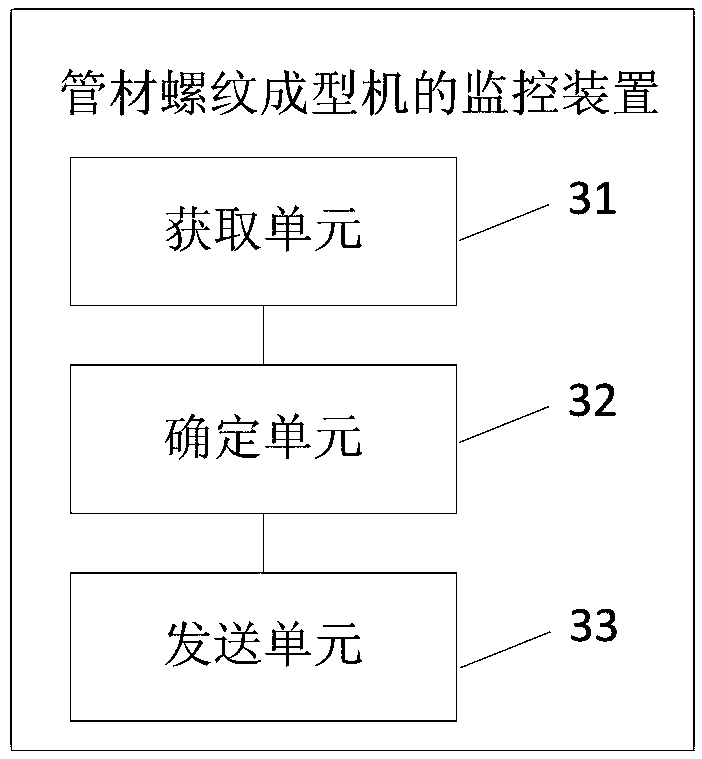

ActiveCN109175548ARealize real-time monitoringImprove accuracyAutomatic control devicesThread cutting auxillary apparatusProcess engineeringPosition sensor

The invention discloses a monitoring method and device for a pipe thread forming machine and relates to the field of pipe thread forming machines. The monitoring method and device for the pipe threadforming machine mainly aim at solving the problems that in the existing production process, parameters for producing a finished pipe with a thread cannot be monitored, and thus the production processis poor in stability, complex in operation and not flexible enough. The monitoring method comprises the steps that when a pipe is placed in a forming mould, coordinate information of the pipe is obtained through a position sensor; when the pipe is subjected to thread forming, input monitoring information of the pipe in the thread forming process is monitored according to the coordinate informationchanged in real time, and according to thread forming parameters, output monitoring information and finished product parameters are determined by combining the input monitoring information; and if the output monitoring information and the finished product parameters are abnormal monitoring parameters, abnormal warning information is sent.

Owner:锦州秀亭制管有限公司

Slow-release compound fertilizer and production method thereof

InactiveCN103172453BAvoid secondary pollutionWide variety of sourcesFertilizer mixturesChemical industryMolecular materials

The invention relates to a slow-release compound fertilizer and a production method thereof. The slow-release compound fertilizer comprises a water-soluble granular fertilizer core and a coating layer, wherein the coating layer includes 2-3 coating layers; and the content of N, P2O5 and K2O which are contained in the slow-release compound fertilizer is respectively 4%-33%, 4%-30% and 0%-30% accounting for the total weight of the slow-release compound fertilizer. According to the invention, the coating layer of the slow-release compound fertilizer is not made from high-molecular materials or other organic polymers, the cost is reduced, and the secondary pollution of the organic polymer or the high-molecular materials on the soil is prevented; and a product formula is flexible, a production process is simplified by integrating the preparation process and compound (mixed) fertilizer production process of the slow-release compound fertilizer into a whole, the equipment investment is saved, the convenience for realizing large-scale industrial production is achieved, and no three wastes are discharged in the production process. Compared with the prior art, the slow-release compound fertilizer disclosed by the invention enhances the slow-release effect to a certain degree and meets the requirements of a chemical industry standard HG / T 4217-2011.

Owner:济南厚源化工有限公司

Control method for pressure of clamping and conveying roller of strip steel coiler

The invention discloses a control method for pressure of a clamping and conveying roller of a strip steel coiler. Firstly, in a mathematical calculation model for calculating the pressure of the clamping and conveying roller of the coiler, an output value of the pressure of the clamping and conveying roller is subdivided according to the variant parameter of finished product strip steel thickness; and then according to the site actual strip steel coiling condition, the output value, given by the mathematical calculation model, of the pressure of the clamping and conveying roller is subjected to secondary manual correction according to the finished product strip steel thickness, and the manual correction can be selectively performed on pressure of an operating side and / or a transmission side of the clamping and conveying roller. The production process is flexible, the production efficiency is high, free crossed coiling at different thicknesses is achieved, the control method is suitable for simultaneous organized production of small batch, multiple steel grades and multiple specifications, the coiling stability and the shape coiling quality of strip steel in different thickness specifications are improved, the executing precision and the stability of the pressure of the clamping and conveying roller are guaranteed when finished product strip steel thickness specifications jump substantially, and the as-scheduled quality and quantity guaranteeing delivery of products is guaranteed.

Owner:SHANDONG IRON & STEEL CO LTD

Method for manufacturing low-oxymethylene-releasing high-density fibreboard

ActiveCN101306553BStable and excellent physical and mechanical propertiesThe release amount is stable and does not reboundNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesFiberHigh density

The invention discloses a method for manufacturing a low formaldehyde release quantity high density fiberboard, which comprises sizing procedures. The method is characterized in that in the sizing procedure, E1 or E0 grade fiberboard used synthetic resin, a compound curing agent and a formaldehyde capture agent are adopted; sizing quantity accounts for 30-35% of fiber quantity; the application quantity of the compound curing agent accounts for 1.48-2.5% of the synthetic resin; and the application quantity of the formaldehyde capture agent accounts for 0.0-10.0%. According to the method, the whole mol ratio of urea formaldehyde resin is controlled in the range of 1.05-0.93; and with the addition of the formaldehyde capture agent, E1 or E0 grade fiberboards can be produced. The method has the advantages of low production cost, flexible production technique and strong adaptability. The produced fiberboard has the advantages of stable and excellent performance, and low free formaldehyde release quantity, and the formaldehyde release quantity can be flexibly controlled according to the users' requirements.

Owner:DARE WOOD BASED PANEL GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com