Device control method, apparatus and device

A device control and device technology, which is applied in the direction of data exchange through path configuration, home automation network, electrical components, etc., can solve the problems of unachievable effects and poor flexibility in the production process, and achieves a flexible production process and improves scalability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

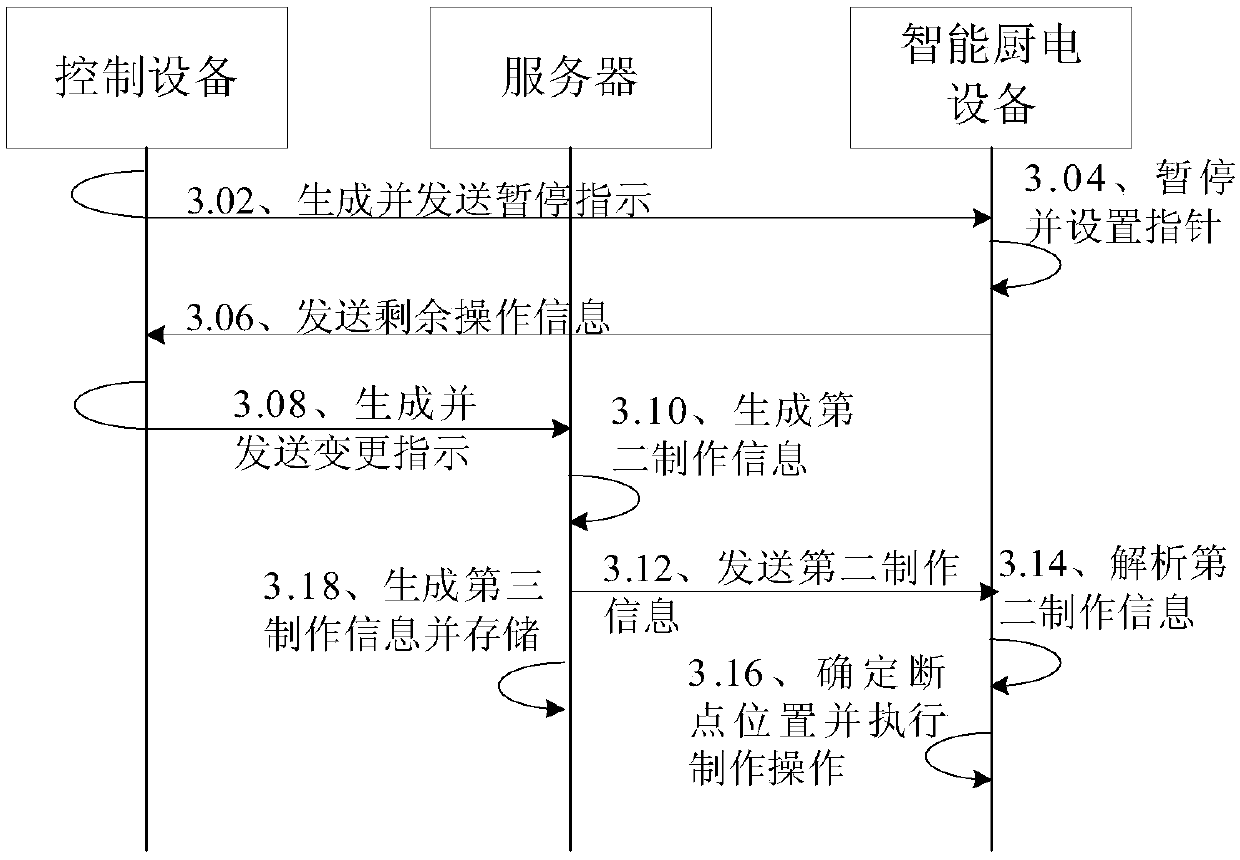

[0065] On the basis of the above-mentioned embodiments, the user can modify the ongoing production operation when necessary, so as to produce items that better meet the user's needs, wherein there are many different modification methods in the production process. For example, some smart kitchen appliances can directly receive the second production information and change the production process; while some smart kitchen appliances need to receive a pause instruction to suspend the execution of the production operation during the change process, and then follow the modified process according to the second production information For production, the pause instruction can be sent by the control device or by the server. Moreover, in order to make it easier for the smart kitchen appliance to determine the changed position, a pointer can also be set to indicate the location of the breakpoint, and the pointer can be set by the server device or the smart kitchen appliance itself.

[0066...

Embodiment 3

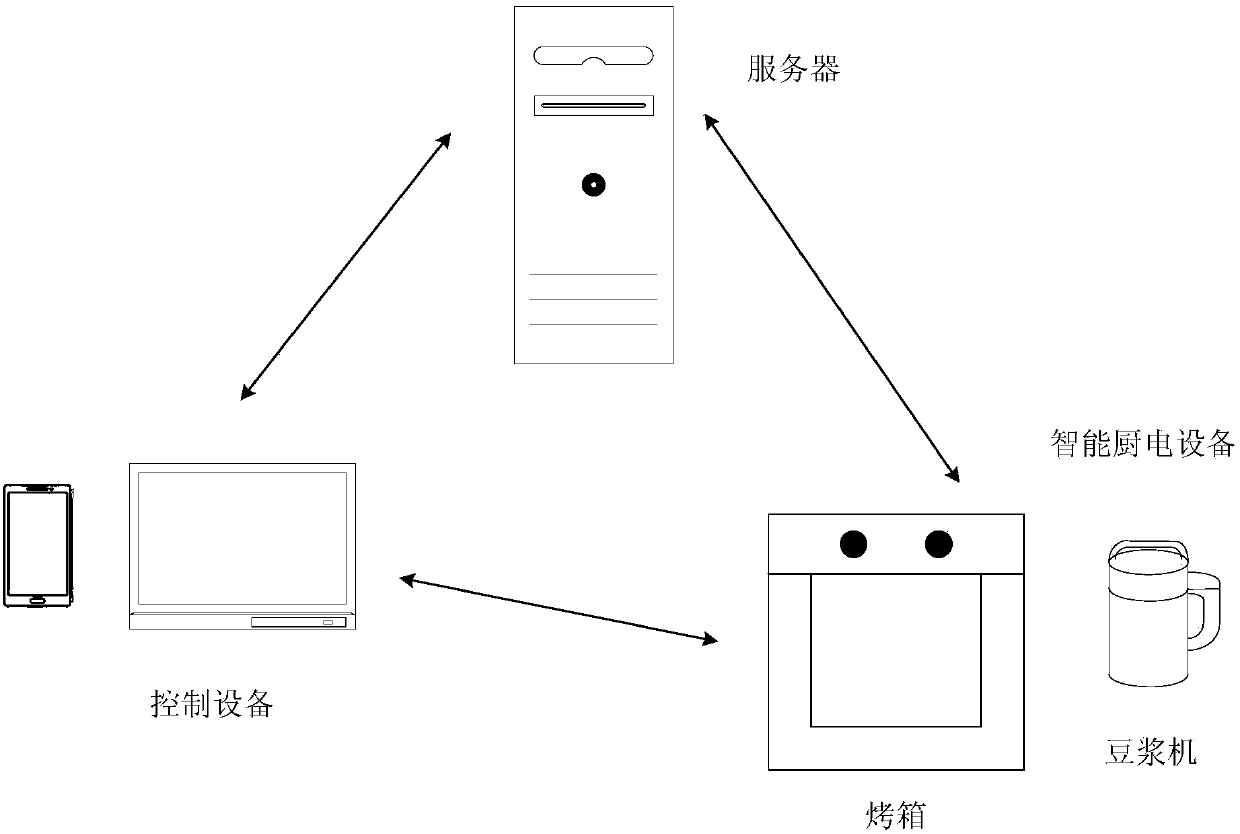

[0163] The embodiment of the present application provides a control system, the control system includes a control device 100, a server 200 and a smart kitchen appliance 300, as described above figure 1 shown.

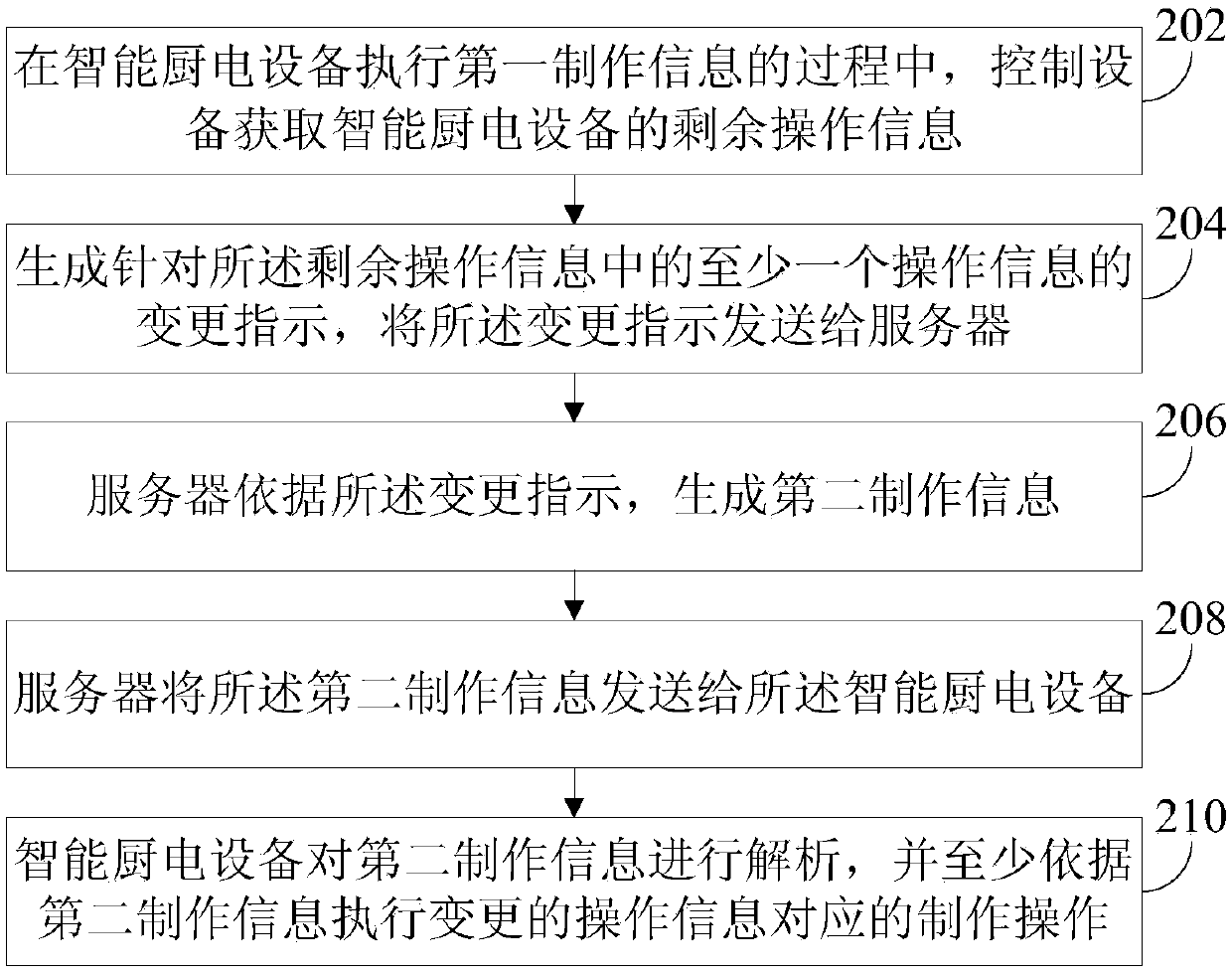

[0164] Wherein, the control device 100 acquires remaining operation information of the smart kitchen electric device during the process of executing the first production information of the smart kitchen electric device, wherein the first production information includes a plurality of operation information, and the remaining operation information The information includes at least one of the operation information being executed and / or the operation information not executed in the first production information; generating a change instruction for at least one operation information in the remaining operation information, and sending the change instruction to the server. The change instruction is used for instructing to update the remaining operation information.

[0165] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com