Technique for preparing three-dimensional regeneration pattern fabric

A technology for making crafts and fabrics, applied in the direction of thorn patterns, fabric surface trimming, dyeing, etc., can solve the problems of lack of movement, poor fabric pattern effects, and difficult quality assurance, etc., to achieve flexible production processes, consistent printing effects, and shortened printing time. The effect of the processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

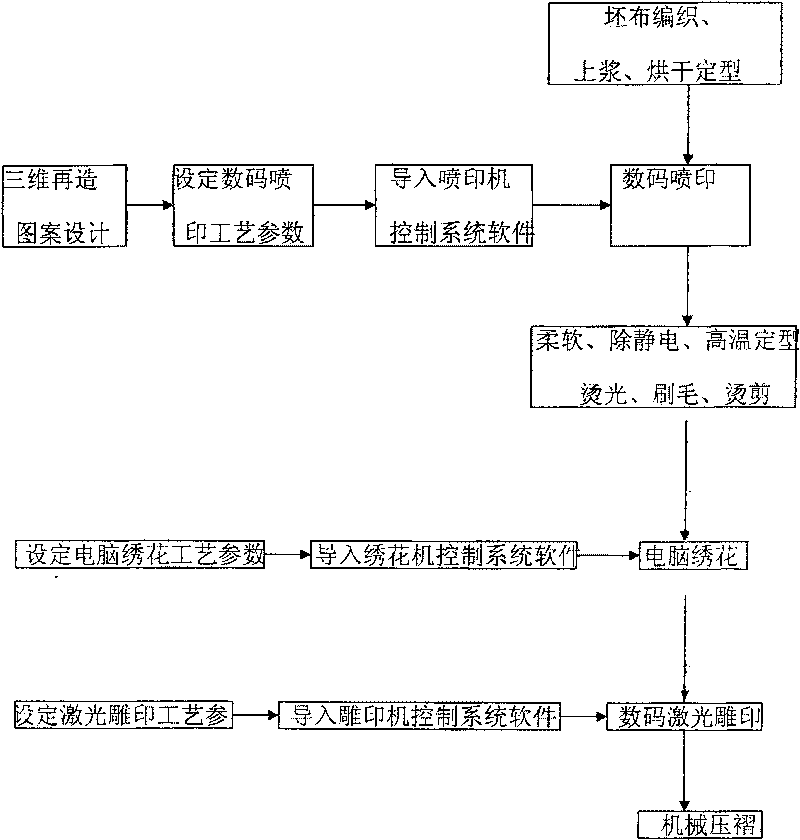

[0027] The production process steps of polyester carpet are as follows:

[0028] a) Take polyester filament as the face fleece, 150D-200D polyester elastic yarn as the base yarn, wherein the mass percentage of polyester filament can be 65-80%, and the mass percentage of polyester elastic yarn can be 20-35%, using Dayuan machine weaving Carpet greige cloth, the gray cloth is subjected to high-temperature setting with a setting machine, the setting temperature is 110-130°C, and the setting time is 3-8 minutes;

[0029] b) According to the pattern requirements put forward by the user, use digital technology-aided design and 3D reconstruction design software on the computer to design 3D patterns;

[0030] c) Set the digital printing process parameters according to the designed pattern and the dyeing performance of polyester filament: the printing width is 2150mm, the printing speed is 43 square meters per hour (16 colors 2pass), and the maximum printing color of a single group is ...

Embodiment 2

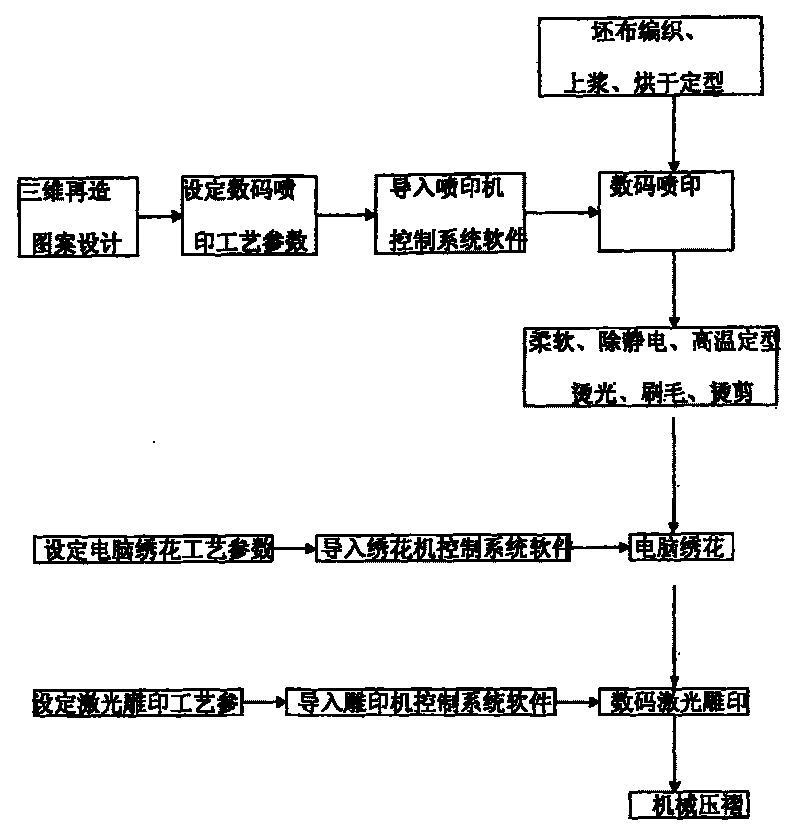

[0040] The production process steps of acrylic blanket are as follows:

[0041] a) Take 28 or 32 double-strand acrylic supersoft yarns or 16 single-strand acrylic supersoft yarns as the face fleece of the blanket, and 100-200D polyester elastic yarn as the bottom yarn of the blanket. According to the mass percentage, the acrylic supersoft yarn accounts for 70-80%, polyester stretch yarn accounts for 20-30%. The gray cloth is woven by a large garden machine, and the gray cloth is subjected to high-temperature setting with a setting machine. The setting temperature is 110-130°C, and the setting time is 3-8 minutes;

[0042] b) According to the pattern requirements put forward by the user, use digital technology aided design and 3D reconstruction aided design software on the computer to design the 3D reconstruction pattern;

[0043] c) Set the digital printing process parameters according to the designed pattern and the dyeing performance of acrylic super soft yarn: the printing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com