Patents

Literature

83results about How to "Comply with clean production requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

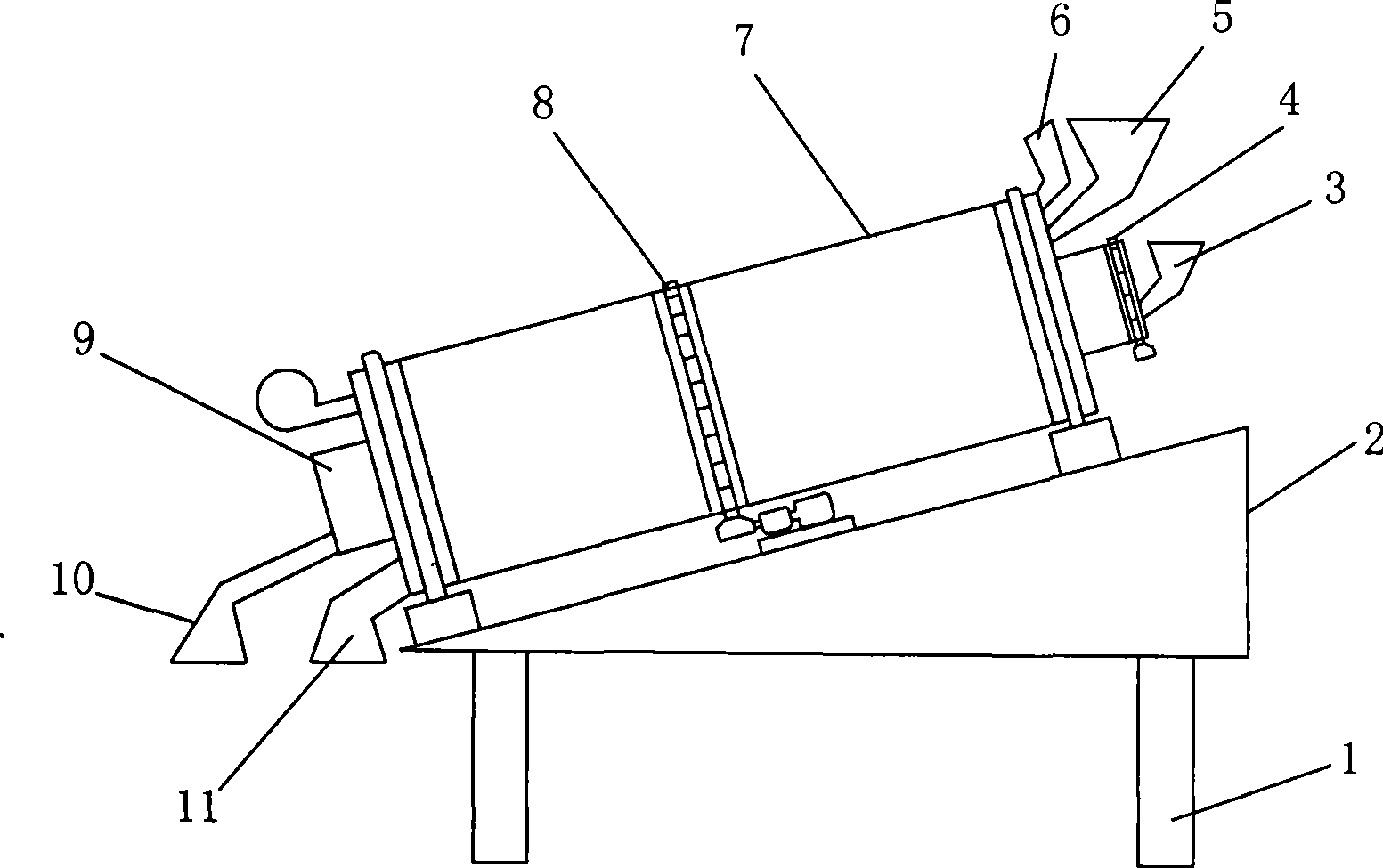

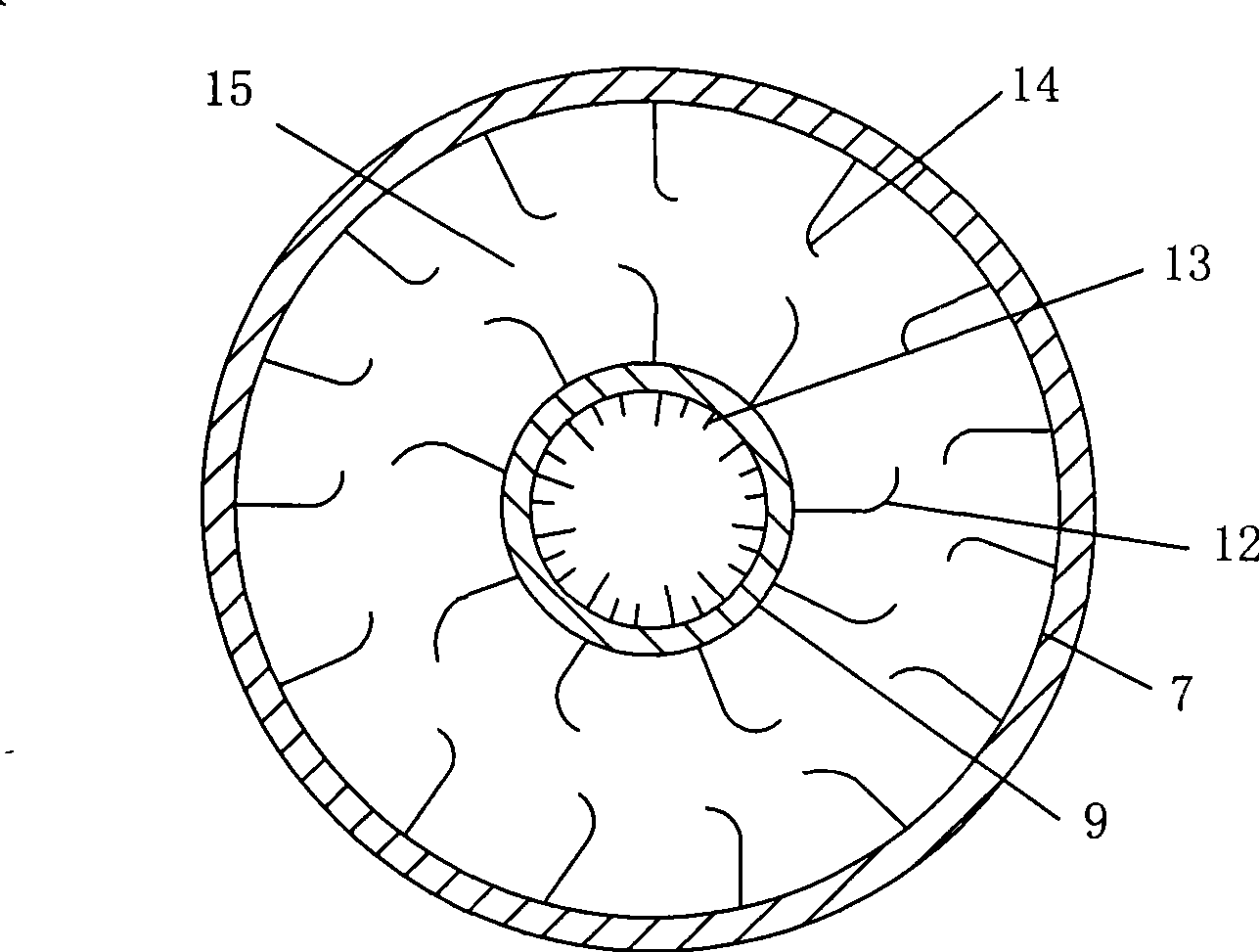

Sewage sludge drying method and drying machine

InactiveCN101508515AReduce lossReduce heat lossSludge treatment by de-watering/drying/thickeningSludgePulp and paper industry

The invention discloses a sludge drying method and a drying machine. The sludge drying method is used to dry the sludge through the afterheat from the burning of tailings. The sludge drying method adopts a drum type drying machine in which an inner drum is sleeved with an outer drum. The method comprises the following steps: putting a heat source and the sludge respectively in the inner drum or in an interlayer between the inner drum and the outer drum; rotating the inner drum and the external drum so as to make the heat source and the sludge in the inner drum or in the interlayer between the inner drum and the outer drum roll continuously; and transferring the heat of the heat source evenly to the sludge through the wall of the inner drum so as to dry the sludge. The sludge drying machine comprises a machine frame, a supporting mechanism, the inner drum, the outer drum and a driving device, wherein the outer drum is arranged on the machine frame through the supporting mechanism; the inner drum is positioned in the middle of the outer drum; the driving device respectively drives the outer drum and the inner drum to rotate; an outer material inlet and an outer material outlet are arranged at the two ends of the outer drum respectively; and an inner material inlet and an inner material outlet are arranged at the two ends of the inner drum respectively. The sludge drying method is scientific and practical and brings about high thermal efficiency; and the sludge drying machine has a reasonable structure and low drying cost.

Owner:ZHEJIANG HUAZHANG TECH

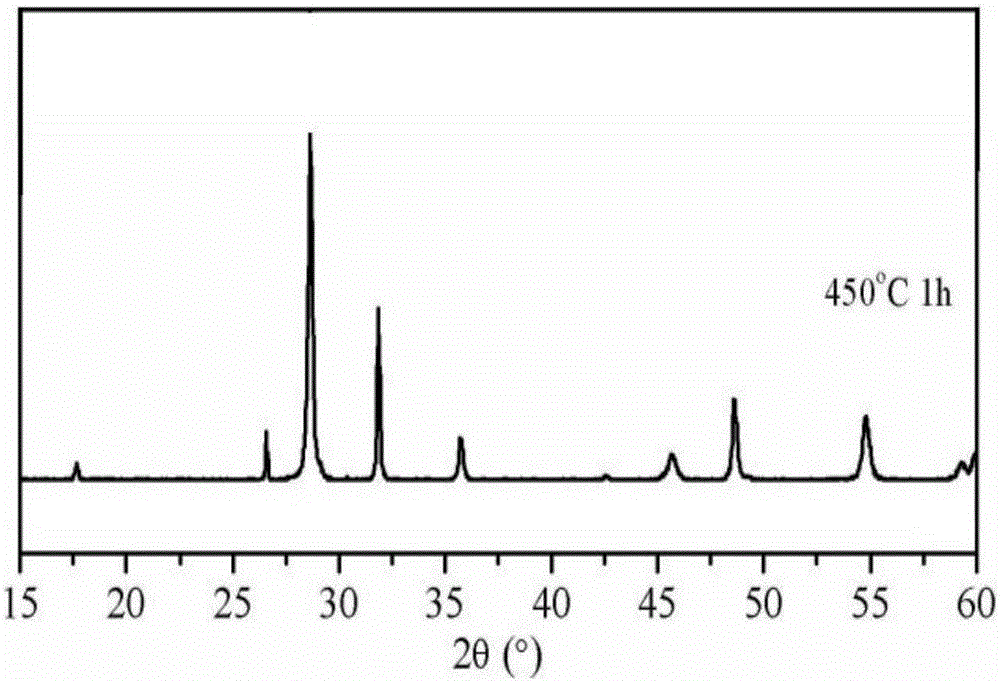

Process for preparing high-purity vanadium pentoxide by adopting ammonium metavanadate as raw material

InactiveCN102603000ASimple process controlProduct quality is stableVanadium oxidesChemistryVanadium(V) oxide

The invention discloses a process for preparing high-purity vanadium pentoxide by adopting ammonium metavanadate as a raw material. The process comprises the following step of obtaining a high-purity vanadium pentoxide product after an ammonium metavanadate crude product is treated by adopting the processes of dissolving, adjusting pH, removing impurities by an impurity removing agent, precipitating vanadium for removing impurities, and calcining and the like. By detection, the content of the high-purity vanadium pentoxide prepared by adopting the process can be up to more than 99.5%, and the content of the impurity is less than 100ppm. The process disclosed by the invention has the advantages that the control is simple, the quality of a product is stable, no pollution is caused to the environment, and the requirement for clean production is met and the like. The process is suitable for large-scale production.

Owner:湖南汇锋高新能源有限公司

novel carpet RIP printing technology

The invention relates to a novel carpet RIP printing technology. The novel carpet RIP printing technology utilizes high-fastness eight-color dispersible ink or cationic ink and color matching software of RIP and comprises steps of spray printing design, color matching, ink-jet printing and drying color-development; and according to the novel carpet RIP printing technology, patterns are directly spray-printed on the surface of a carpet by a carpet ink-jet printing machine and the color is fixated. Through the novel carpet RIP printing technology, fixation fastness is high, after-treatment processes such as water washing and ageing are avoided after spray printing, small-batch and fast-response RIP printing production is really realized, and production batch is not limited. The novel carpet RIP printing technology solves the problem that the existing printing technology produces dye waste and discharges a large amount of printing and dyeing waste water thereby causing environmental pollution. The novel carpet RIP printing technology reduces enterprise burden and satisfies environmental protection requirements. The novel carpet RIP printing technology is suitable for printing production of carpets, tapestries and blanket fabric prepared from various vegetable fibers, chemical fibers and synthetic fibers.

Owner:NANYANG HAOHAI TECH CO LTD

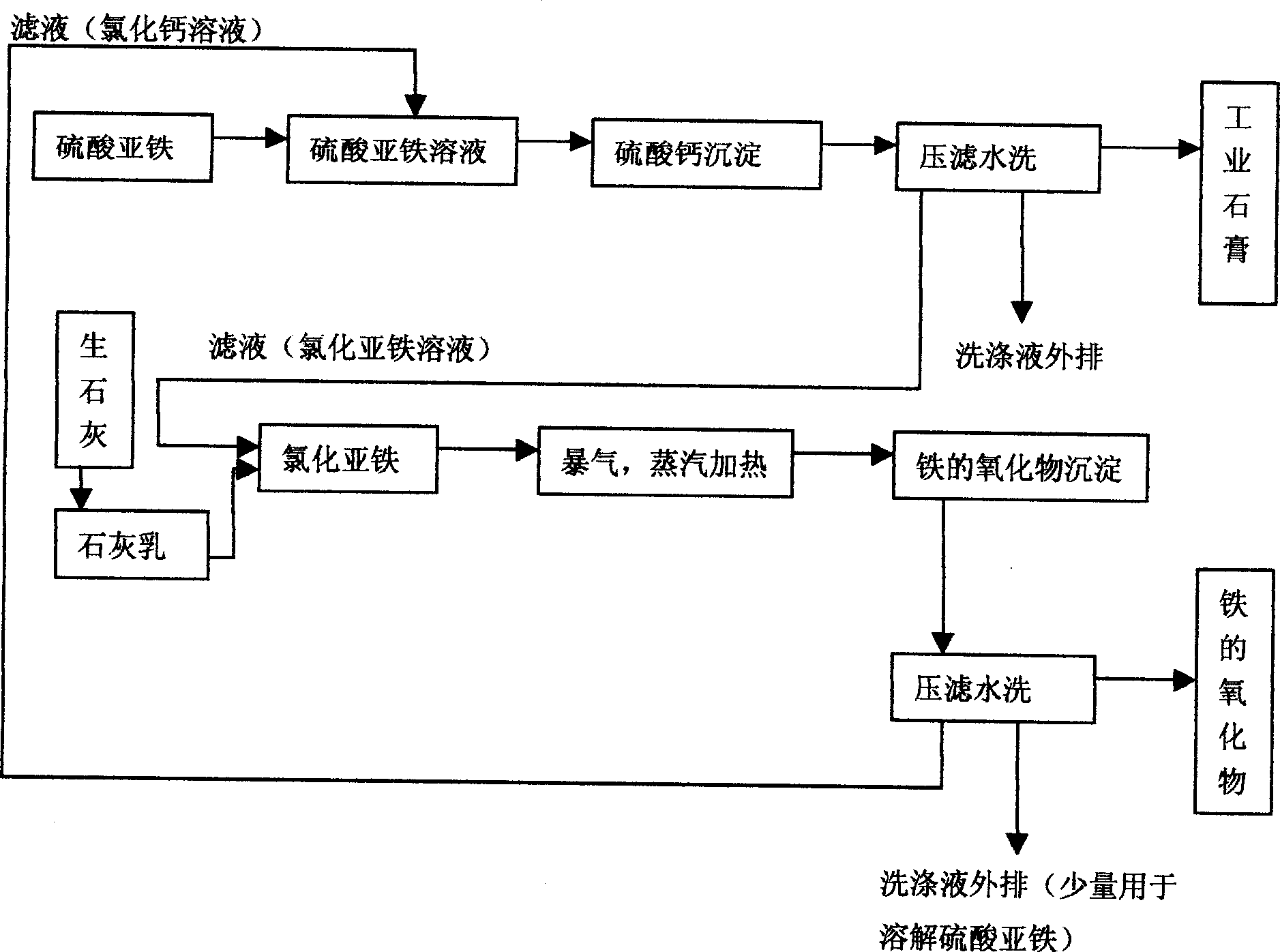

Comprehensively utilizing new process for ferrous sulfate

The technological process of utilizing ferrous sulfate comprehensively in preparing industrial gypsum and iron with lime as main material has the key point of bridging effect of calcium chloride. The technological process includes the steps of: dissolving ferrous sulfate in water, adding calcium chloride solution to produce calcium sulfate precipitate and ferrous chloride solution, filtering to separate calcium sulfate precipitate, adding lime milk into the filtrate and heating via stirring to produce ferric hydroxide precipitate, filtering, stoving the filter slag to obtain ferric oxide, and returning the filtrate. The obtained ferric oxide may be used in smelting iron, preparing iron oxide red, etc. The present invention has relatively low cost of utilizing ferrous sulfate.

Owner:刘应兵

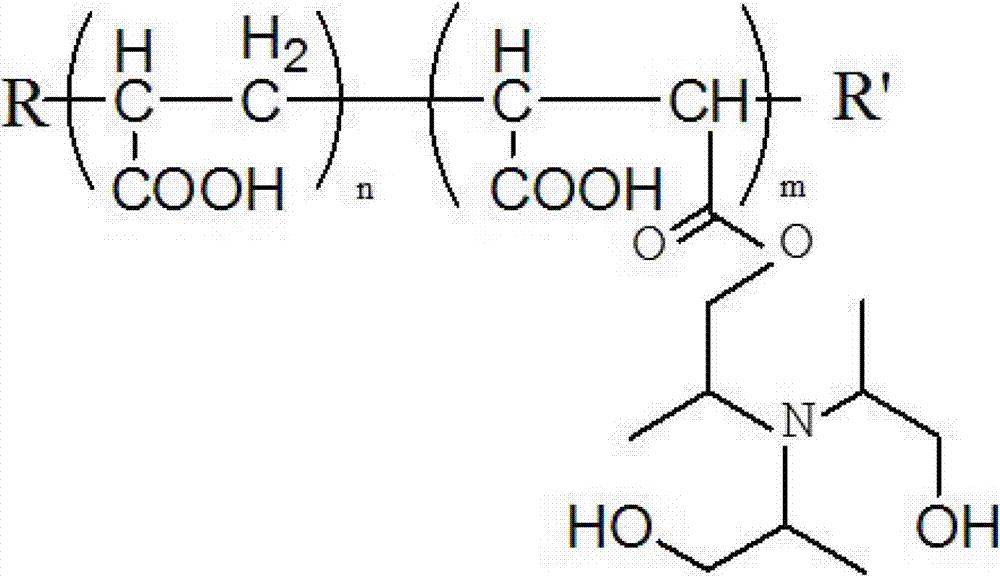

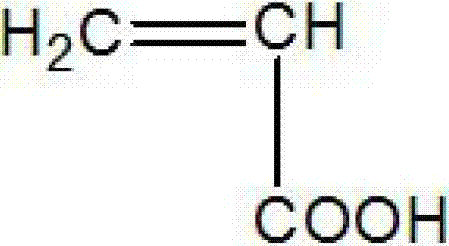

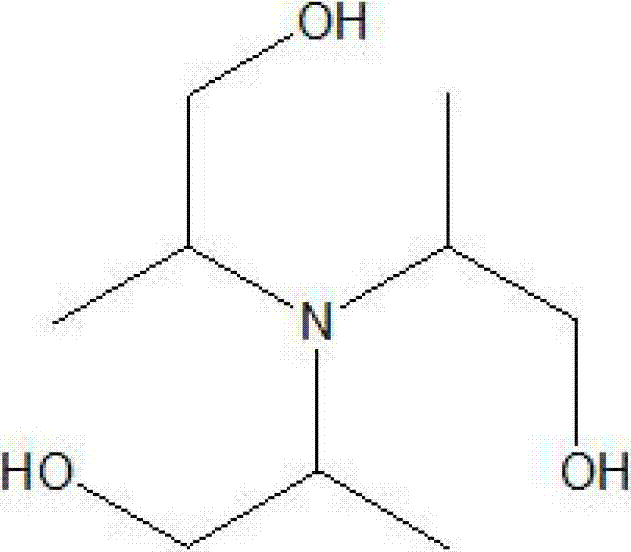

Synthetic method of polyethylene glycol amine ester-carboxylic acid macromolecule grinding aid

InactiveCN103113510ALarge specific surface areaNo adverse effect on performancePolyethylene glycolCarboxylic acid

The invention relates to a synthetic method of a polyethylene glycol amine ester-carboxylic acid macromolecule grinding aid. The synthetic method comprises the following steps of: weighing crylic acid, triisopropanolamine and maleic anhydride according to molar ratio of raw materials, firstly adding the maleic anhydride and the triisopropanolamine, and heating for reaction to obtain solution 1; then neutralizing the crylic acid by NaOH solution to obtain solution 2; dropwise adding an initiator peroxosulfuric acid after the two solutions are mixed, and stirring for reaction to obtain the polyethylene glycol amine ester-carboxylic acid macromolecule grinding aid. By utilizing the synthetic method, the effective mixing amount of the grinding aid can be greatly reduced to reduce the production cost.

Owner:NANCHANG UNIV

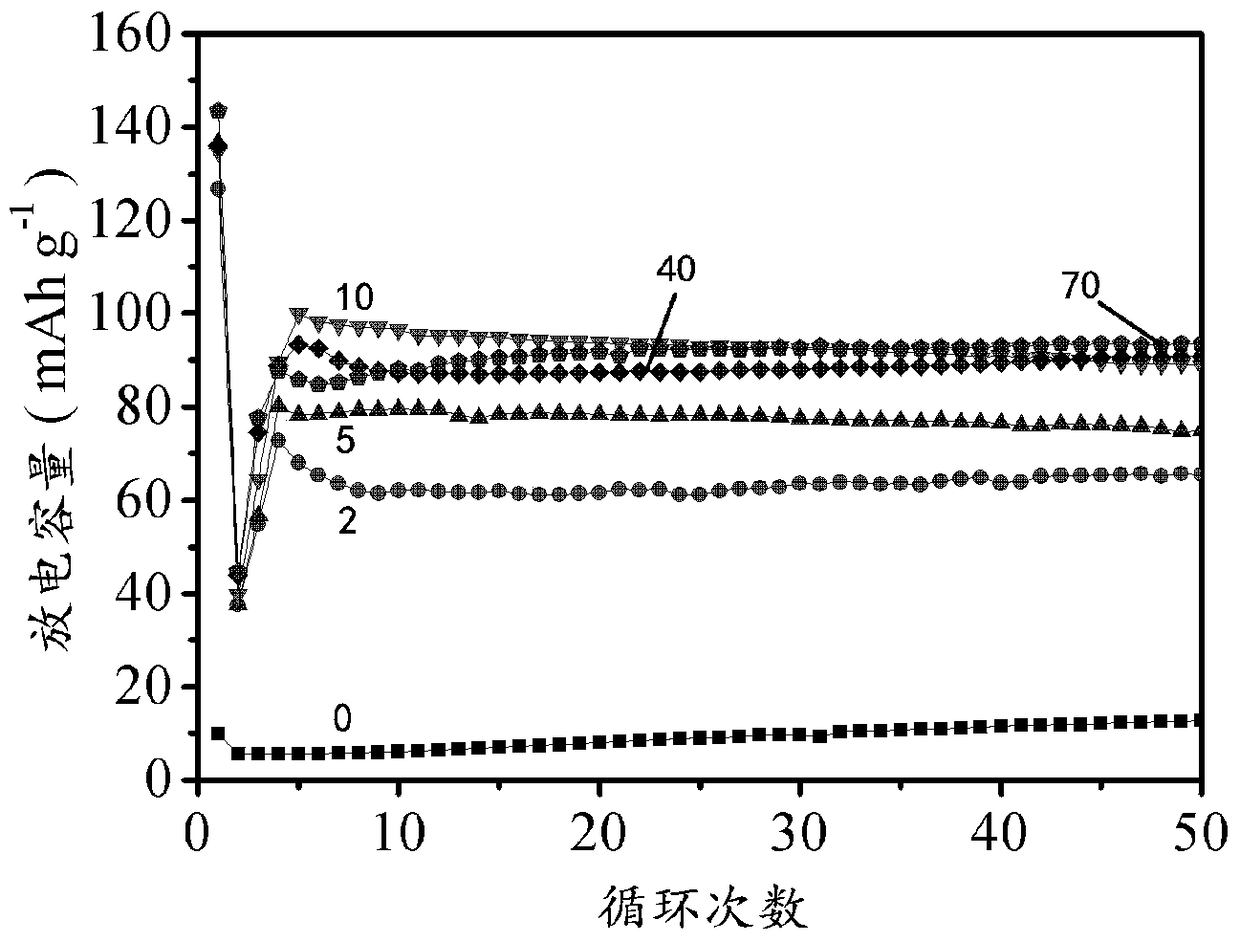

Method for preparing new lead-acid battery from active substances of waste and old lead-acid battery

ActiveCN105226342APrevent restoreEasy to handleFinal product manufactureSecondary cells manufactureElectricityEngineering

The invention discloses a method for preparing a new lead-acid battery from active substances of a waste and old lead-acid battery. The method comprises the following steps of dismounting the waste and old lead-acid battery to obtain a positive electrode plate and a negative electrode plate; respectively processing the positive electrode plate and the negative electrode plate to obtain positive electrode powder and negative electrode powder; respectively performing desulfurization and calcination on the obtained positive electrode powder and the negative electrode powder to obtain new positive electrode powder and new negative electrode powder with high electrochemical performance; using the obtained new positive electrode powder and the new negative electrode powder for manufacturing the new lead-acid battery. The prepared new positive electrode powder and the prepared new negative powder can be directly used for manufacturing the new lead acid battery; the method is simple; the implementation is easy. The method has the advantages that the reduction process in the traditional waste and old lead-acid battery positive powder processing process is avoided; the electrochemical performance of the positive electrode powder can be obviously improved; the formation process of the lead acid battery is accelerated; the preparation process conforms to clean production requirements; the battery production period is shortened; the production cost is reduced.

Owner:SOUTHEAST UNIV

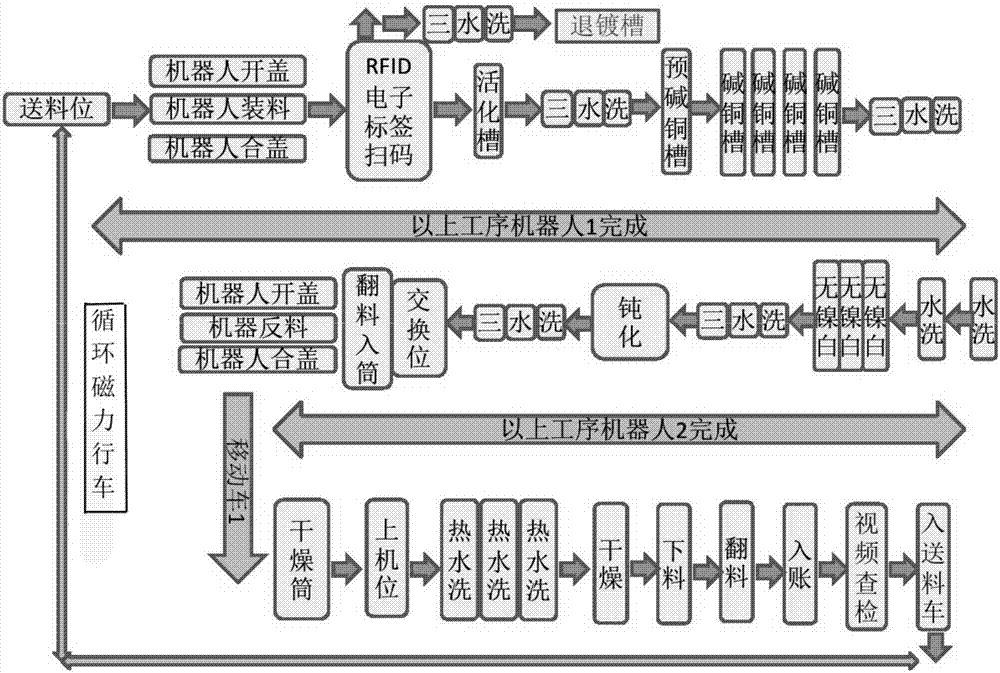

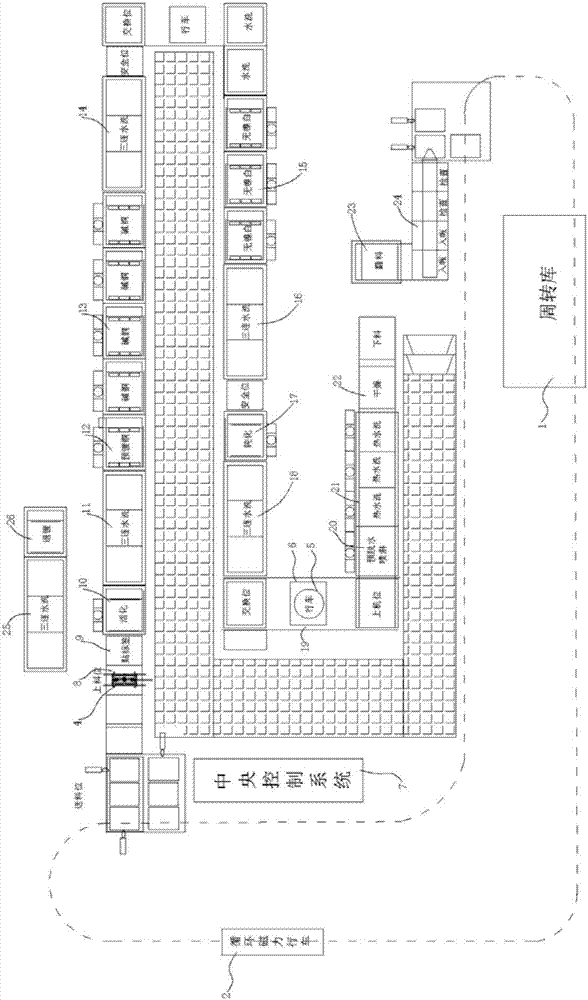

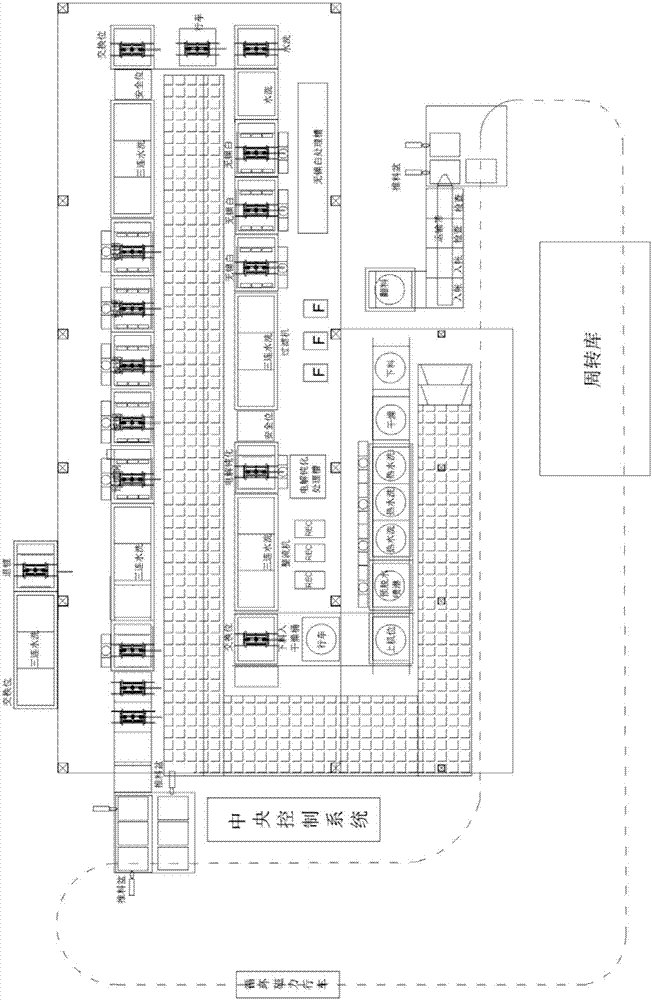

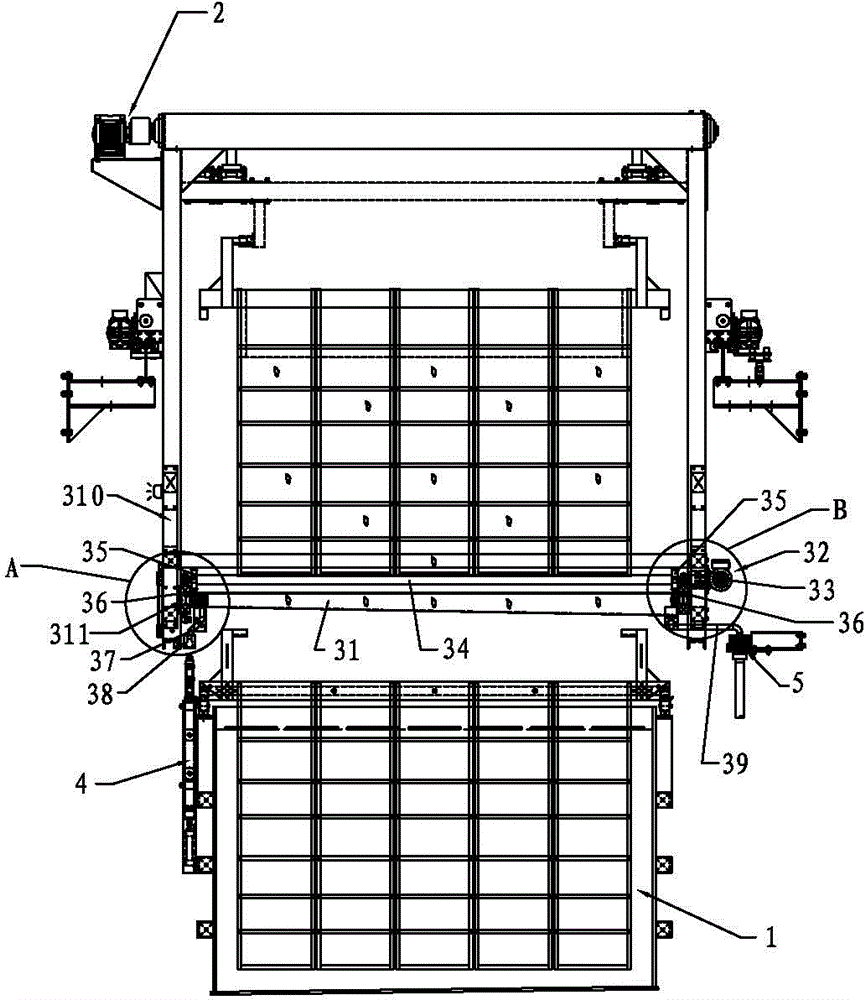

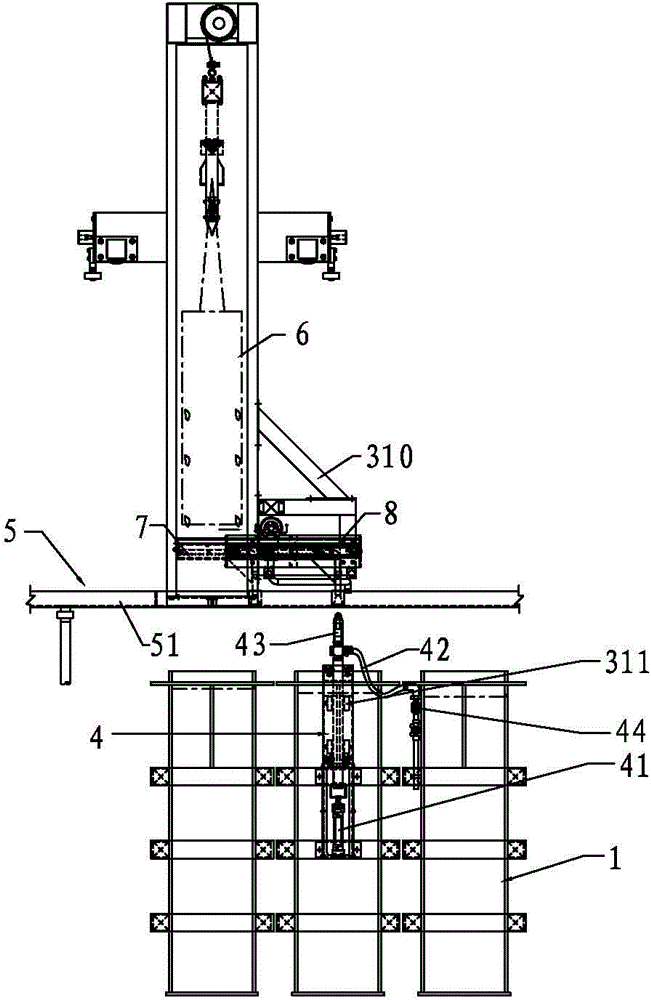

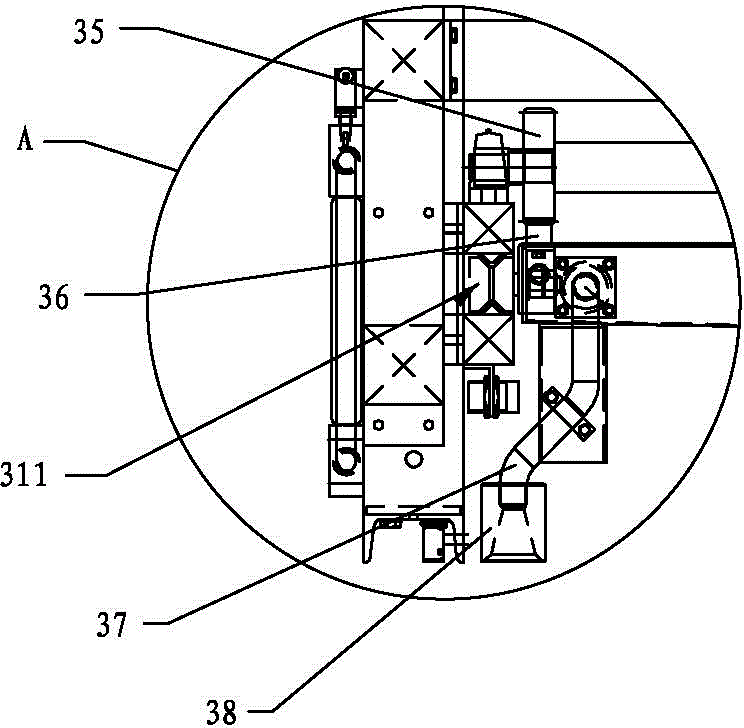

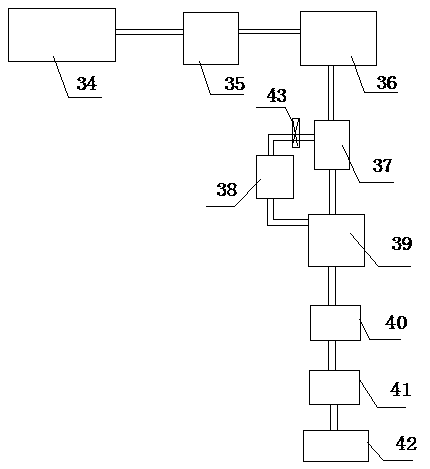

Full-automatic intelligent environment-friendly production system for surface treatment

ActiveCN107541767AEfficiently monitor emissionsEfficiently supervise workshop production work and monitor emissionsCellsWaste water treatment from metallurgical processIntelligent environmentStorage garage

The invention relates to a full-automatic intelligent environment-friendly production system for surface treatment. The full-automatic intelligent environment-friendly production system comprises a transfer warehouse, a circulating magnetic force travelling vehicle, a material box, a manipulator, a roller, a drying cylinder, a moving vehicle, a surface treatment electroplating production line, a drying clean production line, a pure water treatment system and a central control system. The circulating magnetic force travelling vehicle circularly moves among the transfer warehouse, surface treatment electroplating production line and the drying clean production line, pre-electroplated products are taken out from the transfer warehouse to be placed into the material box, the circulating magnetic force travelling vehicle drives the material box to move to a feeding position, and the central control system controls all devices to synergistically work. The circulating magnetic force travelling vehicle carries the primary products and electroplated products, and the manipulator clamps the products for feeding and discharging on the surface treatment electroplating production line and the drying clean production line to complete corresponding machining. The clean production requirement is met, the automation degree is high, machining is accurate, the product quality is improved, on-siteoperation does not need a great number of people, the labor intensity is small, the production speed is high, and the cost is reduced.

Owner:DONGGUAN CRAY AUTOMATION TECH

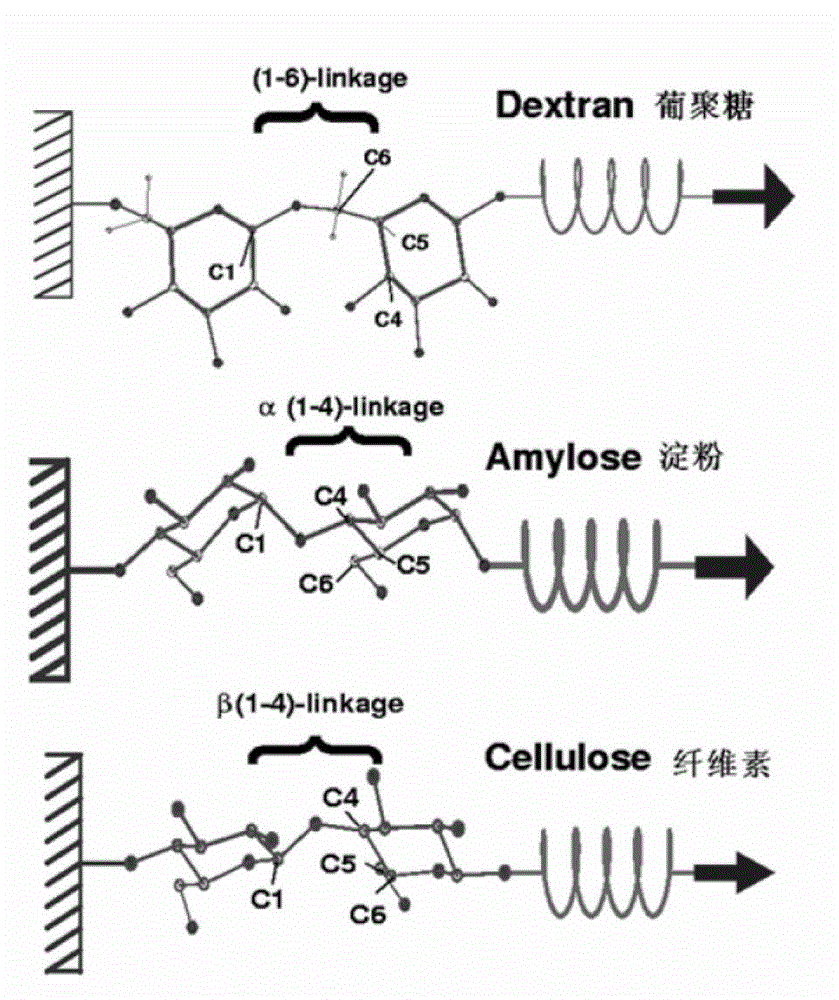

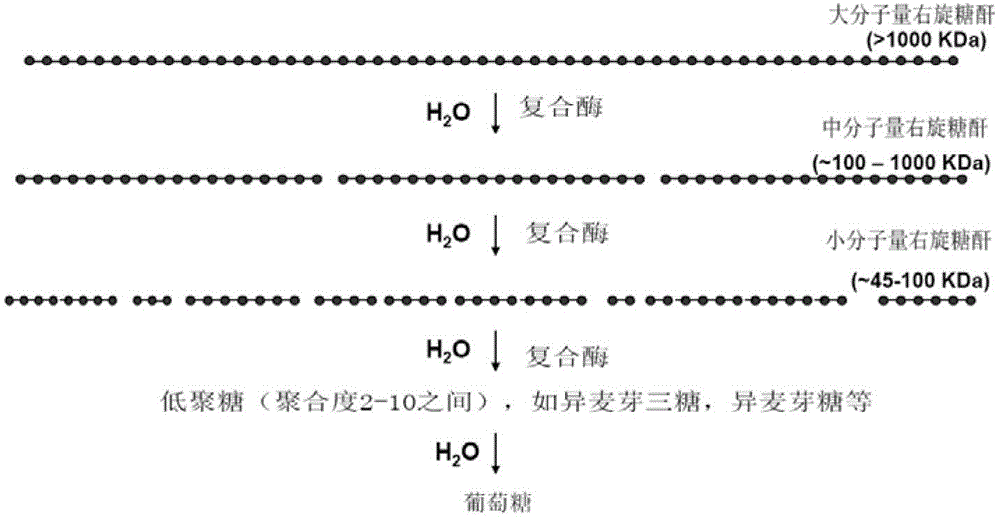

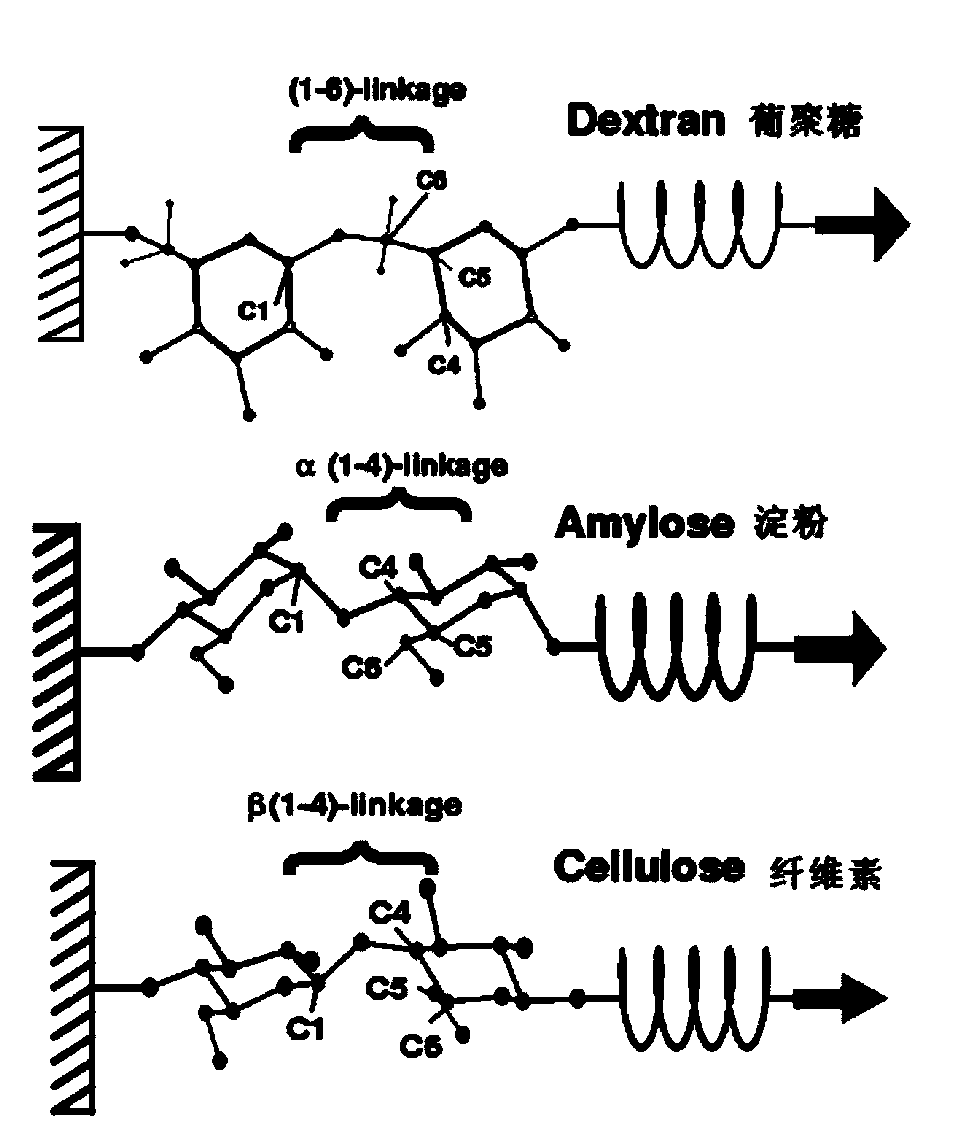

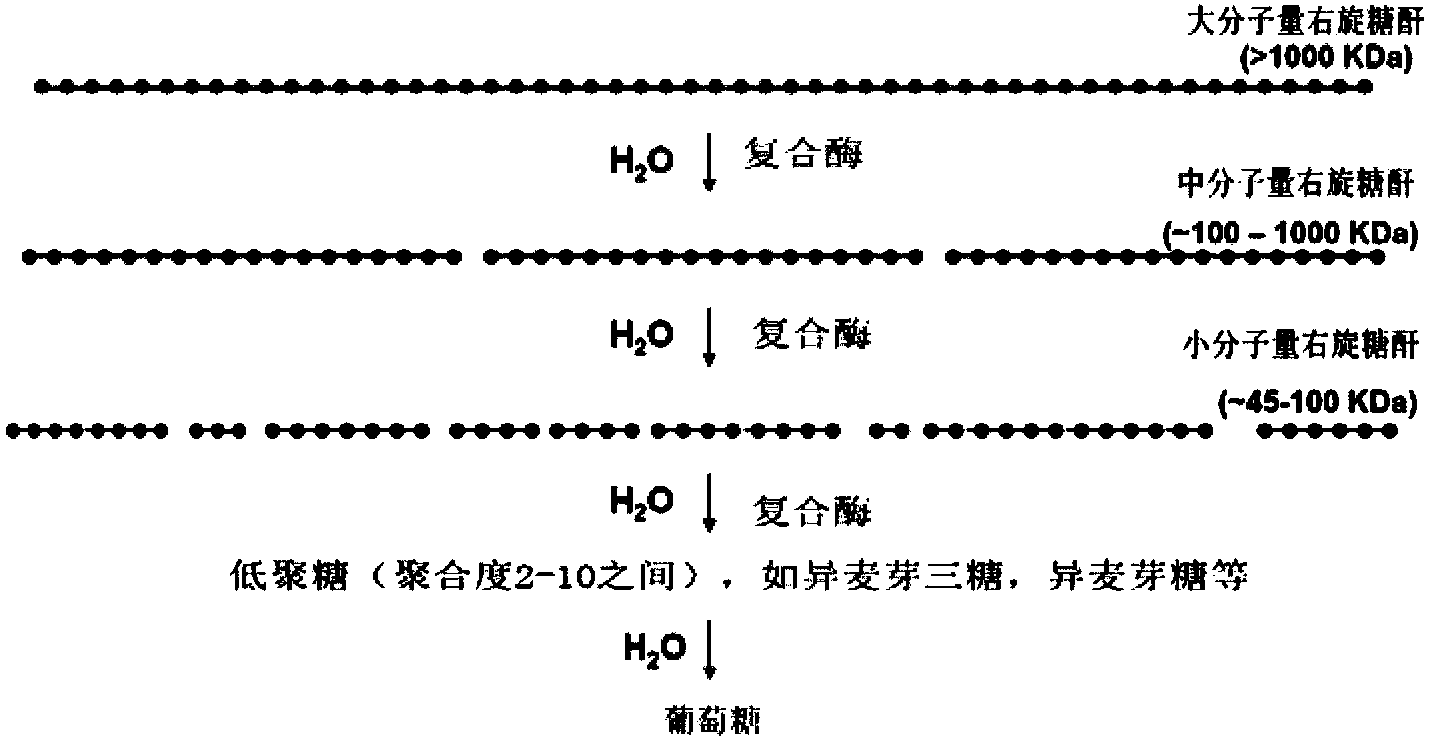

Compound enzymatic clarifying agent for sugar industry and preparation method and application for compound enzymatic clarifying agent

ActiveCN102911924AEasy to joinWithout changing the sugar production processEnzymesSugar juice purificationPectinaseAmylase

The invention discloses a compound enzymatic clarifying agent for the sugar industry and a preparation method and application for the compound enzymatic clarifying agent. The compound enzymatic clarifying agent comprises, by weight, from 35% to 60% of alpha-glucanase, from 20% to 30% of pectinase, from 10% to 35% of amylases, from 5% to 10% of cellulase and from 0% to 15% of water. The preparation method includes proportionally mixing the alpha-glucanase, the pectinase, the amylases and the cellulase which are raw materials to obtain a mixture; and filtering the mixture via a fine filter membrane to obtain the compound enzymatic clarifying agent. The compound enzymatic clarifying agent is added during a working section for extracting juice from sugar crops, the feeding quantity of compound enzymatic clarifying agents added into 1kg of the sugar juice ranges from 10mg to 30mg, the sugar juice clarifying efficiency can be effectively improved, the viscosity of sugar liquor is reduced, the filtering speed and the settling speed are increased, the quality of sugar products is improved, the sugar yield is increased, an original sugar production process is unchanged, and operation is simple and feasible.

Owner:SOUTH CHINA UNIV OF TECH

Clean production process of xylose

InactiveCN104498559AEasy to separateStrong penetrating powerSugar derivativesFermentationSulfate radicalsSulphate Ion

The invention provides a clean production process of xylose. The clean production process of xylose mainly comprises the following steps of: pretreating, namely steaming and exploding; hydrolyzing with an enzyme; refining by separating chromatographically; concentrating continuously with a membrane; and concentrating by evaporating steam. Due to the adoption of the clean production process of xylose, the problems in the prior art that sewage contains sulfate ions and can not be treated biochemically can be solved, and the problems of high consumption of water, acids, alkalis and energy, large discharge amount of wastewater, serious pollution to environment, high cost and long production cycle can be also solved.

Owner:山东福田科技集团有限公司

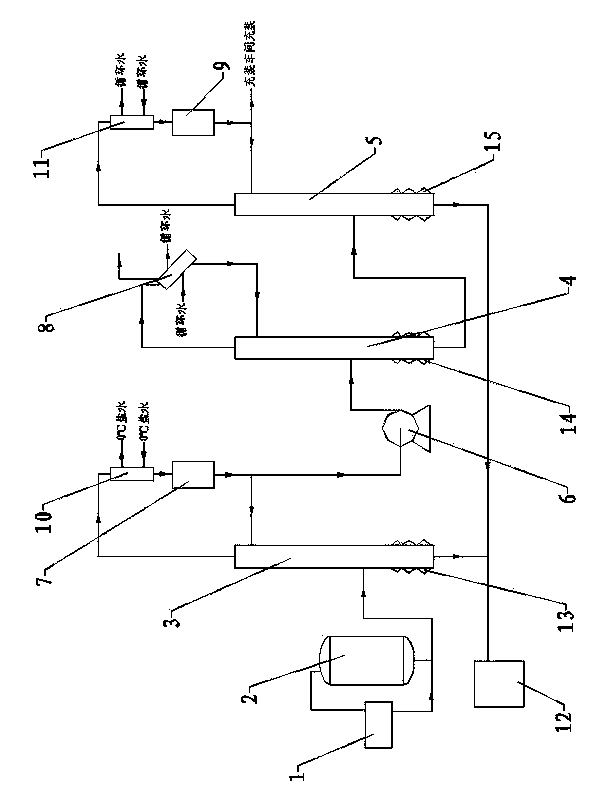

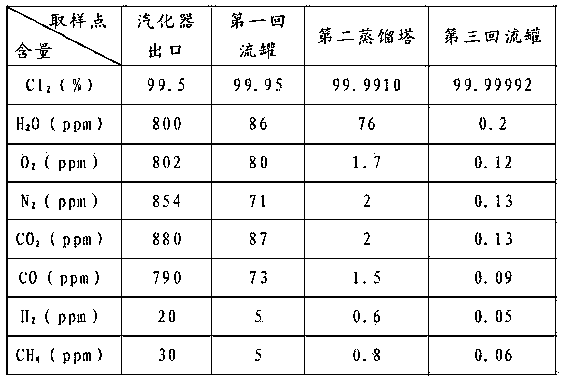

High-purity chlorine gas rectifying technology and equipment thereof

ActiveCN103466549AEasy to control temperatureSave energyChlorine/hydrogen-chloride purificationRefluxFractionating column

The invention relates to a high-purity chlorine gas rectifying technology. The technology comprises the following steps: delivering industrial liquid chlorine to a vaporizer, and sending vaporized chlorine into a first distillation tower under the pressure of 1.2 Mpa until the liquid level of the first distillation tower reach 85%; boosting the pressure of the first distillation tower to 1.0 Mpa, condensing the vaporized chlorine by a first condenser, then sending into a first reflux tank, and delivering 60% residue in the first reflux tank to a second distillation tower; enabling the liquid level of the first reflux tank to be 30% to 40%, and boosting the pressure of the second distillation tower to be 1.8 Mpa; back flowing residue condensed by a second condenser in to the second distillation tower, then sending into a third distillation tower, controlling the liquid level of the second distillation tower to be 60% to 75% until the liquid level of the third distillation tower reaches 85%, and boosting the pressure of the third distillation tower to be 1.5 Mpa; condensing by a third condenser, then sending into a third reflux tank until the purity reaches 99.9999%, enabling the liquid level of the third reflux tank to reach 60%, enabling the purity of the liquid chlorine in the third reflux tank to be 99.9999%, and obtaining high-purity chlorine gas. Through the adoption of the method, raw material input and product output can be carried out stably and continually, the production capacity can be improved, energy consumption can be reduced through continuous rectification, the running is stable, and the operation is safe.

Owner:北京华宇同方化工科技开发有限公司

Method for synthesizing phenoxy carboxylate herbicide original medicine

ActiveCN103159610AHigh viscosityReduce moisture contentOrganic compound preparationCarboxylic compound preparationBiotechnologyBiochemical engineering

The invention discloses a method for synthesizing a phenoxy carboxylate herbicide original medicine. The method comprises the following steps of: adding chlorophenol and alkaline liquid to a reactor, reacting to produce soluble chlorophenate, and drying liquid through evaporating, so as to obtain solid soluble chlorophenate; adding chlorinated carboxylate liquid into the reactor, reacting to produce soluble phenoxy carboxylate, and additionally adding an alkaline substance during reaction; and adding water to the reactor to cool, adding acid to acidify, filtering and washing so as to obtain a wet phenoxy carboxylate material, and drying the wet material, thereby obtaining the phenoxy carboxylate herbicide original medicine. According to the method, after the reacting synthesis is completed, qualified products can be obtained through direct acidification; and due to the reduction of processing links, the influence on a producing environment is reduced, the water consumption is reduced, the synthesis is more environment-friendly, the problem of high water consumption in the traditional synthesis is solved, and the requirements on clean production are met, so that the method has an obvious economic benefit and a cost advantage.

Owner:SHANDONG WEIFANG RAINBOW CHEM

Preparation method of oat product with rich beta-hyskon

ActiveCN101606710ANo pollution in the processComply with clean production requirementsFood preparationBaked goodsViscosity

The invention discloses a preparation method of oat products with rich beta-hyskon, comprising the steps: using oat bran as a raw material; adding water and evenly mixing; heating the oat bran to dissolve the wall of the oat bran by alkali under an alkaline condition; squeezing, dehydrating and drying formed oatmeal; and reprocessing the dried oat bran after being milled and sieved step by step to obtain oat products with rich beta-hyskon. The preparation method has simple technology, easy operation and low cost, and the prepared products have high viscosity, high beta-hyskon content in the oat bran, thereby being suitable for being used in bakery food.

Owner:WENGYUAN GUANGYE QINGYI FOOD TECH +1

Zincium base heavy corrosion protection technique of environment protection type steel component

The invention discloses a zinc-based heavy-duty corrosion prevention protecting process of a steel structural component, which belongs to the metal coating protecting technology field. The invention has the following process flows: the rim angle position burnishing of the steel structural component, the first impact cleaning, the second impact cleaning, the rim angle hot spraying, the bottom powder spray, the agglomerating semi-solidification, the surface powder spraying, the solidification, and the cooling and packaging. The invention has the advantages that through the zinc-based heavy-duty corrosion prevention compound coating technology processing to the steel structural component, the protecting effect is prominent, and the application value is good.

Owner:XUZHOU ZENITH COATING

Magnesium and magnesium alloy surface silver-plating method

The invention discloses a magnesium and magnesium alloy surface silver-plating method, and relates to the technical field of magnesium alloy silver plating. According to the method, eight steps including shot blasting, oil removal, excitation, residual film removal, zinc immersion, copper plating, silver plating in advance and silver plating are adopted, good silver plating layers are obtained after magnesium and magnesium alloy surfaces are specially treated, according to magnesium and magnesium alloy silver pieces processed through operation of the process, the silver plating layer bonding force is checked by thermal shock tests, the plating layers are free of peeling, blistering and falling, parts obtained after thermal shocks are subject to bonding force tests according to a QJ479-90 marking method, and the plating layers are free of peeling, blistering and falling. Through trials and errors, all silver plating layers are good in bonding force and free of peeling, blistering and falling; through an QJ458-88 anti-sulphur test, the silver plating layers are not subject to aftertreatment, the anti-sulphur performance is larger than 1 min, and the anti-sulphur performance of partssubject to aftertreatment after silver plating is larger than 5 min. The electroplating magnesium and magnesium alloy silver-plating parts are good in bonding force, high in anti-sulphur performance and resistant to corrosion, the plating layers are free of peeling, blistering and falling, and the method is worthy of application and popularization on industry.

Owner:贵州航天风华精密设备有限公司

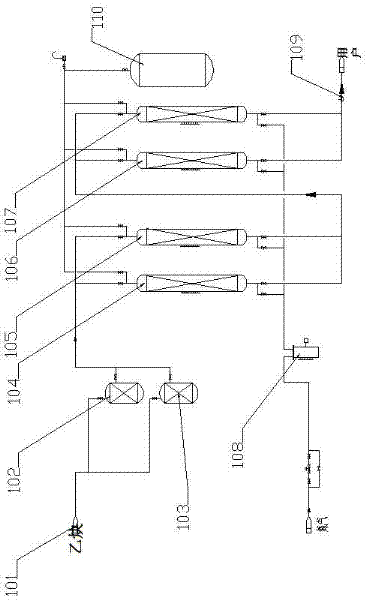

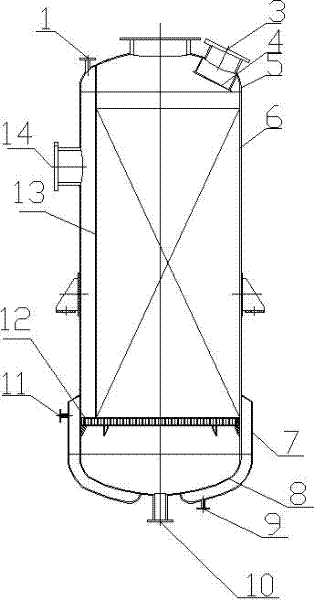

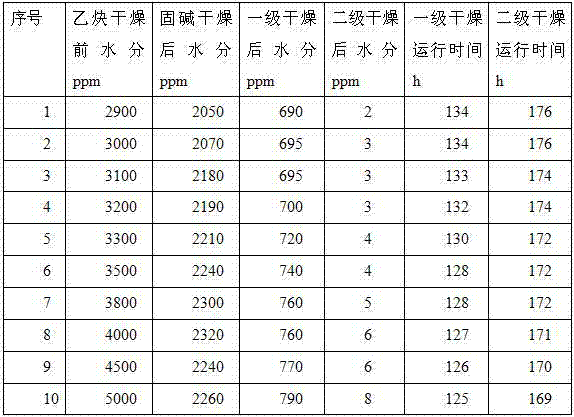

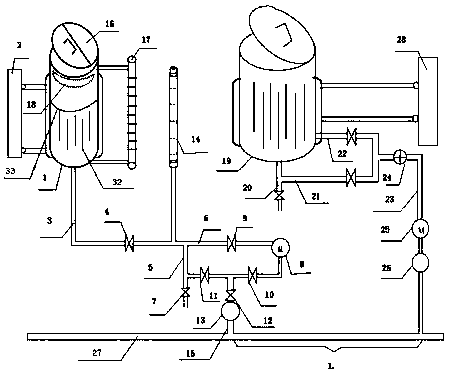

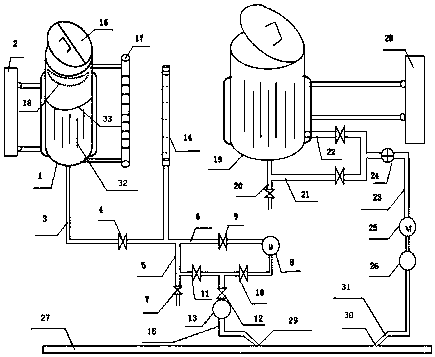

Acetylene drying process and equipment thereof

ActiveCN102580480AReduce loadExtend the life cycleDispersed particle separationHydrocarbonsWater contentGas cabinet

The invention discloses an acetylene drying process and equipment thereof. The process comprises the following steps of: conveying acetylene into an acetylene solid caustic soda drying tower, controlling the flowing speed at 2m / s, feeding acetylene gas into a first-stage acetylene drying tower when the water content of acetylene of which the pressure is 0.1MPa is lowered to 2,000ppm, and feeding into a second-stage acetylene drying tower when the water content is lowered to 700ppm; conveying acetylene gas which is exhausted out of the second-stage acetylene drying tower and of which the watercontent is lower than 10ppm into a subsequent utilization system; and returning acetylene gas of which the water content is higher than 10ppm into an acetylene gas cabinet for drying once again. The equipment comprises an acetylene solid caustic soda drying tower, a first-stage acetylene drying tower and a second-stage acetylene drying tower which are communicated in sequence. The acetylene drying process has the advantages that good dewatering effect, easiness for equipment operation, running safety, avoidance of pollution, capability of fully drying the acetylene gas, saving in cost, increase in economic efficiency and capability of lowering the water content of acetylene from 3,000-5,000ppm to 10ppm.

Owner:李通

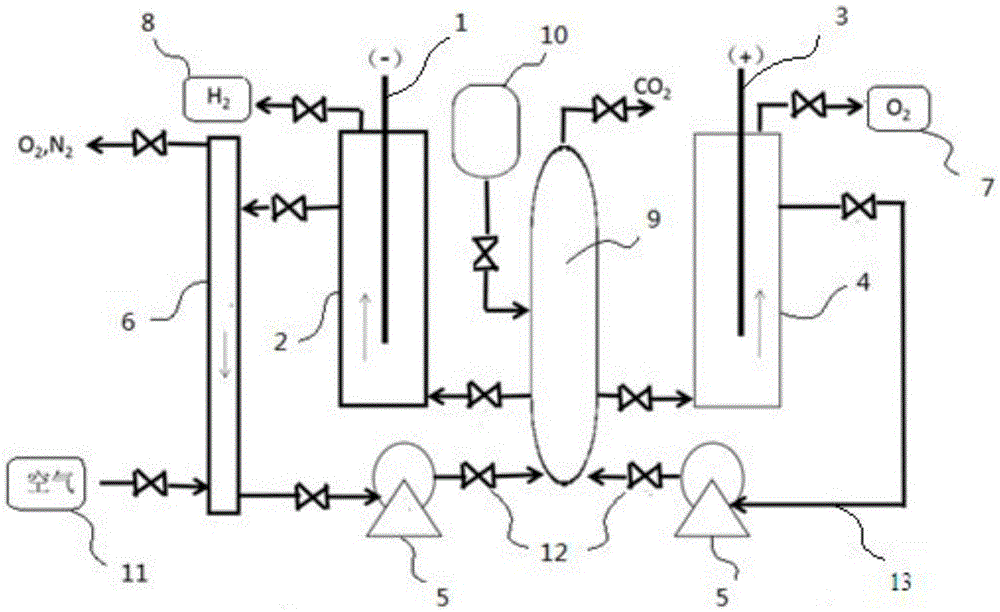

Device for separation and purification of carbon dioxide

ActiveCN105617842AComply with clean production requirementsExquisite designGas treatmentDispersed particle separationCollection systemElectric energy

The invention discloses a device for separation and purification of carbon dioxide. The device comprises a water electrolysis system with forced flow, a carbon dioxide absorption device and a gas-liquid separated collection system, wherein the water electrolysis system comprises a cathode chamber, an anode chamber and a pump for pushing electrolyte to flow, and the gas-liquid separated collection system comprises an oxygen separated collector connected with the anode chamber, a hydrogen separated collector connected with the cathode chamber, and a carbon dioxide separated collector. When the device is in use, alkaline electrolyte produced from the cathode chamber is pushed by the pump into the carbon dioxide absorption device to absorb carbon dioxide coming from air or other mixed gas, and then has neutral reaction with acidic electrolyte produced from the anode chamber in the carbon dioxide separated collector so as to release carbon dioxide. The device is used for separating carbon dioxide from air, and only water and electric energy are consumed in the process; hydrogen and oxygen produced are separated naturally to produce hydrogen energy; and the device can be used for obtaining carbon dioxide in any position on the earth surface.

Owner:SOUTHEAST UNIV

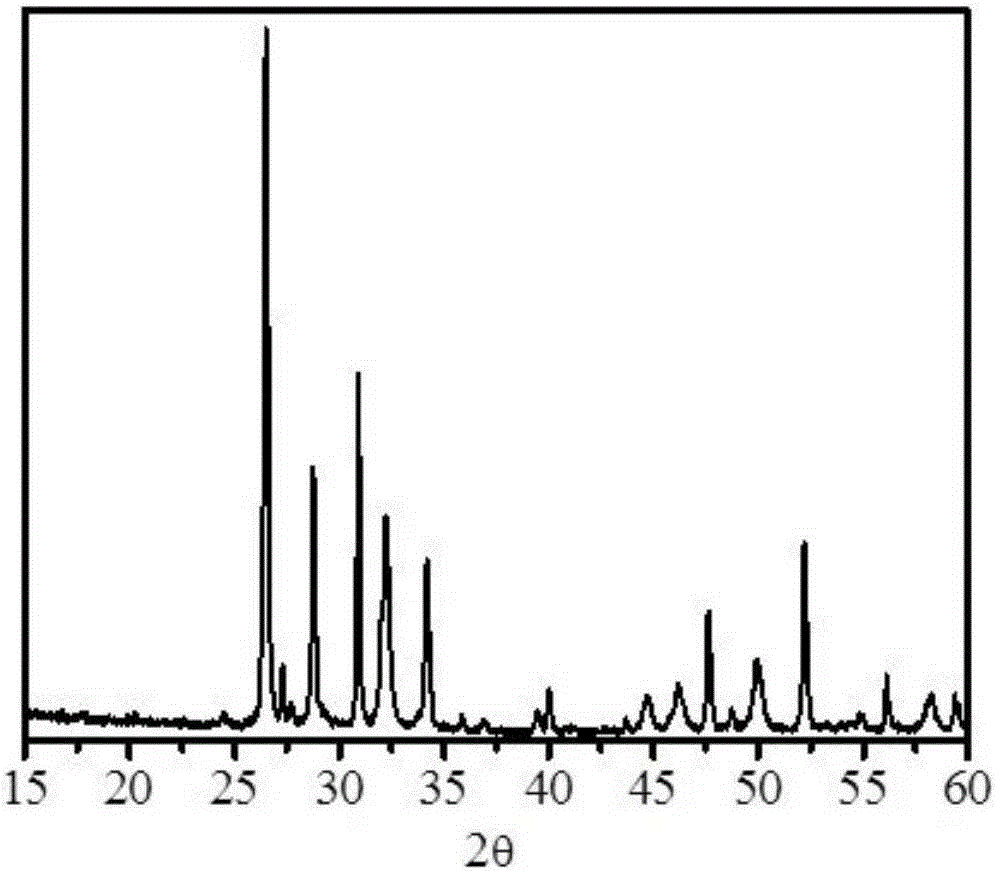

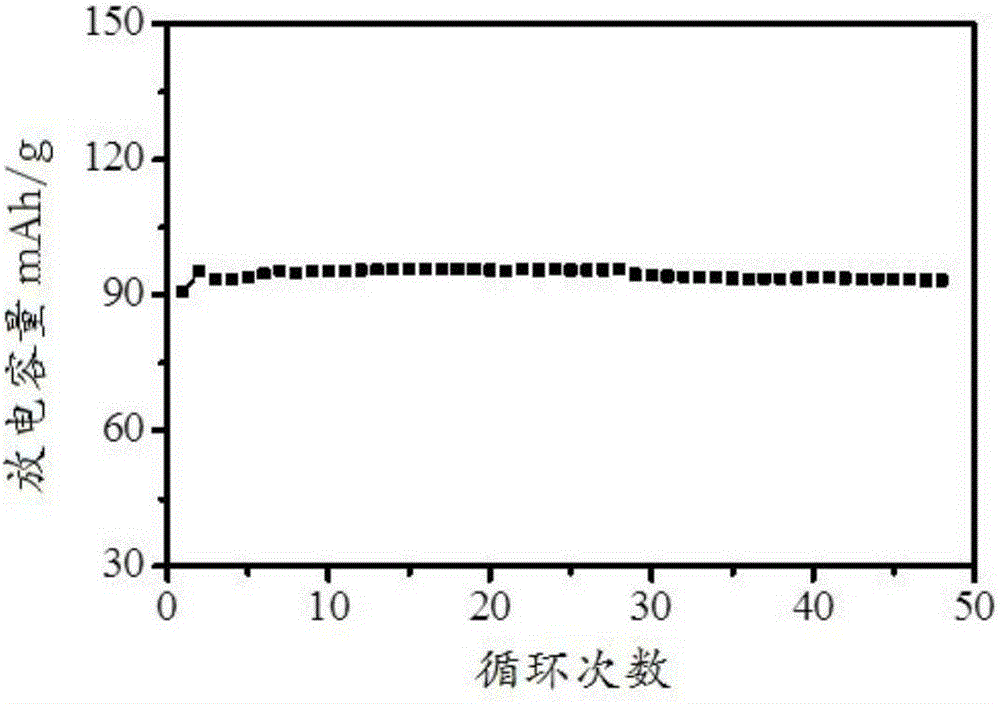

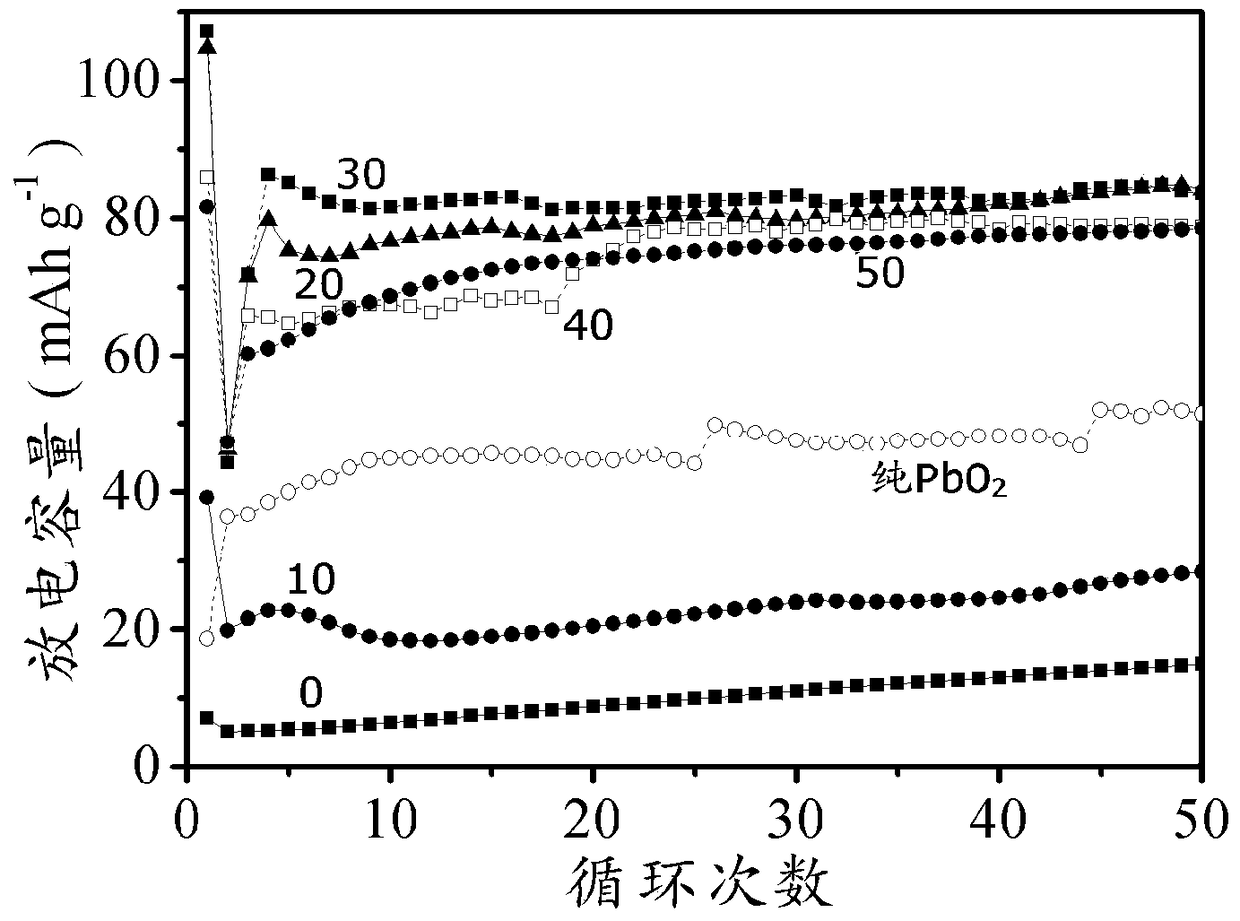

A positive electrode of a lead-acid battery using lead sulfate as an active material and a method for preparing a lead-acid battery using the positive electrode

ActiveCN105206800BImprove electrochemical performanceReduce manufacturing costLead-acid accumulator electrodesFiberLead smelting

Owner:SOUTHEAST UNIV

Electroplating drop liquid recycling device and recycling method

InactiveCN104651911ATo achieve the effect of recyclingReduced carry-out lossCellsOutfallWater collection

The invention relates to the technical field of electroplating equipment and in particular relates to a recycling device and a rcycling method of electroplating drop liquid generated in the electroplating workpiece and rack conveying and transferring process. The device comprises at least one electroplating bath, a control mechanism, a conveying mechanism used for lifting an electroplating workpiece, a dropping water collection mechanism, an automatic water supply cleaning mechanism and a sectioned water receiving ditch, wherein the dropping water collection mechanism is positioned above the electroplating bath; the conveying mechanism is positioned above the dropping water collection mechanism; the dropping water collection mechanism comprises a water dropping disc and a transmission mechanism used for driving the water dropping disc to horizontally move; the automatic water supply cleaning mechanism is connected with the water inlet of the water dropping disc; the sectioned water receiving ditch is connected with the water outlet of the water dropping disc; and the conveying mechanism, the transmission mechanism and the automatic water supply cleaning mechanism are respectively and electrically connected with the control mechanism. According to the device and method disclosed by the invention, the electroplating drop liquid generated in the electroplating workpiece and rack conveying and transferring process can be effectively recycled, the outlet loss of electroplating materials is effectively reduced, and the load of wastewater treatment is reduced.

Owner:东莞庞思化工机械有限公司

Compound enzymatic clarifying agent for sugar industry and preparation method and application for compound enzymatic clarifying agent

ActiveCN102911924BEasy to joinWithout changing the sugar production processEnzymesSugar juice purificationPectinaseAmylase

Owner:SOUTH CHINA UNIV OF TECH

Method of simultaneously producing crystallized sorbitol and daily chemical sorbitol

The invention discloses a method of simultaneously producing crystallized sorbitol and daily chemical sorbitol. According to the method disclosed by the invention, the crystallized sorbitol and the daily chemical sorbitol are simultaneously obtained by taking starch as a raw material and through size mixing of the starch, liquefying, saccharifying, impurity removal, deacidification and desalination, evaporation and concentration, hydrogenation, sedimentation and decoloration, desalination, as well as washing, filtering and purifying. The method disclosed by the invention has the advantages of high efficiency, high raw material utilization rate, high additional value of products, short process flow, low production cost, low energy consumption, energy saving and water saving, and a prepared crystallized sorbitol product is high in purity and capable of meeting the requirements of applying to the field of industries, such as medicines, food and Vc; in the meantime, the obtained daily chemical sorbitol as a side product has good physical and chemical properties and can meet the requirements of preparing the daily chemical products, such as toothpaste, cosmetics and cigarettes.

Owner:CHENGDU LIANJIE MEMBRANE TECH

Warp beam printing sizing-free weaving method

ActiveCN108486909AReduce processing difficultyEliminate the sizing processDyeing processWastewaterPulp and paper industry

The invention discloses a warp beam printing sizing-free weaving method. The method adopts a printing and weaving technique of weaving printed warp without sizing, directly fully prints the sheet-likewarp yarns which are unwound from a plurality of warp beams on the sizing machine pedestal, is free of sizing after fixation and produces a fabric beam. Finally, the fabric beam on the weaving machine and weft yarn are woven to form a fabric. In the warp beam printing color paste, a binder and a thickener provide a certain viscosity to the color paste. After the warp beam paint printing, the warpyarn has the effect of conventional sizing and can be directly woven so that the sizing process is avoided, the desizing process and the washing process after desizing are avoided, the processes arereduced, the water consumption is reduced and the difficulty of wastewater treatment is reduced. The method is a clean production process. The method can reduce the processes, reduce energy consumption and reduce costs.

Owner:NANTONG UNIVERSITY

Pure cotton warp yarn foam printing and weaving method

ActiveCN108442147AReduce water consumptionReduce the difficulty of wastewater treatmentDyeing processSizingWeft yarn

The invention discloses a pure cotton warp yarn foam printing and weaving method. The printing and weaving method contains no sizing process, and concretely comprises the following steps: pure cottonraw yarn preparation, beam warping, beaming, foam coating printing, weaving, and grey cloth shaping for obtaining a finished product, wherein the foam coating printing process comprises: foam generation using a foam generator, foam coating color paste preparation, foam coating spraying and color fixing. A printing and weaving technology for sizing-free weaving after foam printing of warp yarns isused to directly perform large-area blotch printing on sheet-like warp yarns unwound from a plurality of warp shafts on the shaft bracket of a warp sizing machine, and a weave beam is produced after color fixing without sizing. The weave beam and weft yarns are woven on a loom to form a fabric, so the water washing process after desizing is omitted, the water consumption is saved, and the wastewater treatment difficulty is reduced, so the method is clean production technology. The method has the advantages of flow shortening, energy consumption reduction and cost reduction.

Owner:NANTONG UNIVERSITY

Preparation method for ethyl formate

ActiveCN102746145ALow costLower requirementPreparation by carbon monoxide or formate reactionAnhydrous ethanolHydrolysis

The invention relates to a preparation method for ethyl formate. The method does not generate a great quantity of water and does not need to take sulfuric acid as a catalyst. The ethyl formate can be prepared by reacting anhydrous ethanol with carbonic oxide under the action of a basic catalyst. By the technical scheme, equipment requirements can be lowered, cost of raw materials is reduced, hydrolysis of the ethyl formate is avoided, and yield and acceptance rate of the ethyl formate are increased.

Owner:LINHAI LIANSHENG CHEM

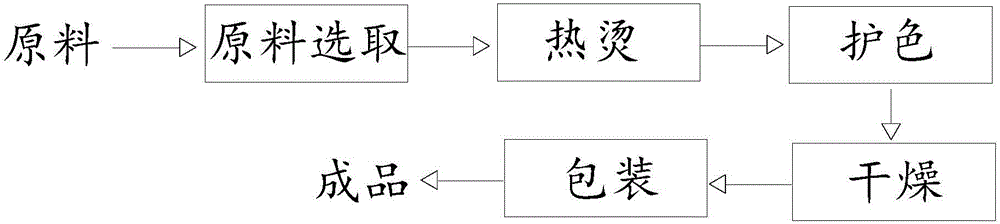

Method for producing dried mulberries by virtue of closed-loop dehumidification-heat pump technique

The invention provides a method for producing dried mulberries by virtue of a closed-loop dehumidification-heat pump technique. The dried mulberries are produced by the step of raw material selection, hot ironing, color protection, drying and packaging processing by virtue of the closed-loop dehumidification-heat pump technique. By virtue of the closed-loop dehumidification-heat pump technique, the original tissue form, odor, good sensory evaluation and nutrients are furthest maintained, the product is low in moisture content and has complete internal cell structures, and the original form, color, odor, flavor and active components of fresh mulberries can be basically preserved; and furthermore, the process is simple, the production efficiency is high, the energy consumption is low, and the method is accordant with clean production requirements on energy conservation, emission reduction and effect enhancement.

Owner:FOSHAN UNIVERSITY

Non-cyanide alkaline copper plating agent and using method thereof

InactiveCN105154929AEasy to handleSolve the worldwide problem of destroying pollutionCopper platingEcological environment

The invention discloses a non-cyanide alkaline copper plating agent and a using method thereof. The non-cyanide alkaline copper plating agent comprises the following substances: a pH regulator, a current stabilizer, a change agent and a complexing agent. By using the non-cyanide alkaline copper plating agent, sodium cyanide in the conventional cyanide copper plating solution can be replaced without changing the original process, and the totally non-cyanide alkaline copper plating process can be used to solve the multiple disadvantages existing in the conventional non-cyanide alkaline copper plating processes at home and abroad, thereby allowing the non-cyanide alkaline copper plating process to reach a cyanide copper plating level. The non-cyanide alkaline copper plating agent and the using method have the characteristics that the current efficiency and the deposition velocity are high; the cathode polarization capability and a binding force are good; a coating layer is exquisite, tamping-resistant and scratch-resistant, and has no brittleness; no bubble is generated under high temperature baking; the non-cyanide alkaline copper plating agent can be directly used for barrel plating and rack plating of steel and brass, and used for copper plating of zinc die castings, zinc alloys and aluminium alloys; the treatment on waste water is easy; the requirements of cleaning production are met; the long-standing worldwide problems of harms to persons, and damage and pollution to the ecological environment caused by cyanide are solved; and an international blank is filled.

Owner:钱宏彬

Method for primarily separating components of oat bran

The invention discloses a method for primarily separating the components of oat bran, which comprises the following steps of: adding the oat bran serving as a raw material into salt solution for stirring to inhibit viscous polysaccharide from precipitating and ensure that the fiber polysaccharide, starch, protein of the oat bran are more fully separated in the salt solution, and filtering with a screen to obtain an oversize product and an undersize product respectively, wherein the oversize product is mainly the fiber polysaccharide, and the undersize product is mainly the starch and the protein. The method solves the technical problem that: a single function ingredient is obtained by breaking other components, so that various functional factors in the oat bran cannot be developed simultaneously in the conventional process.

Owner:GUANGDONG FOOD IND INST

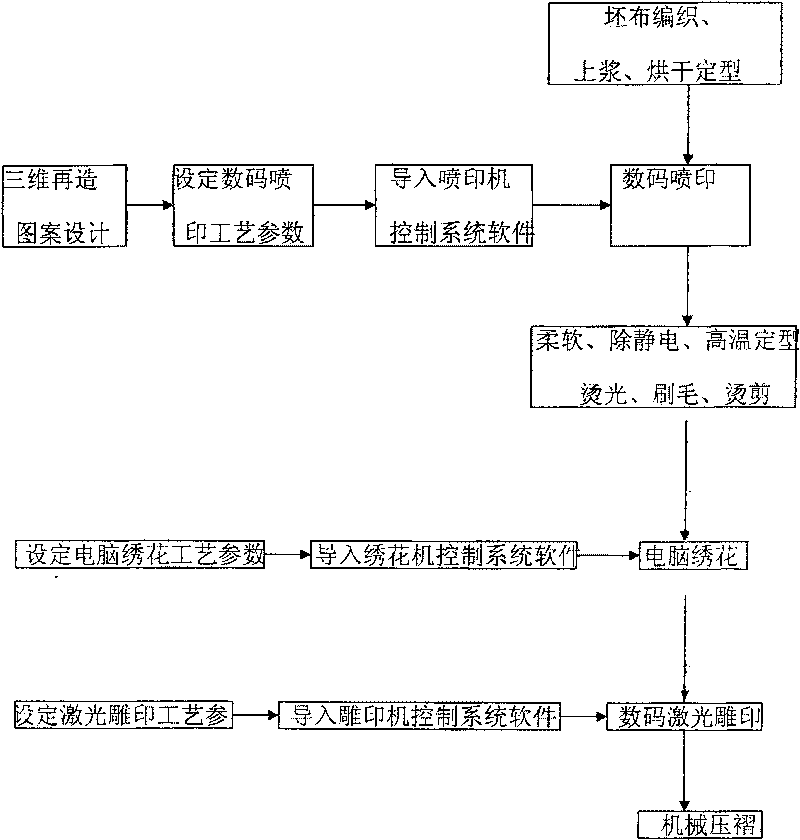

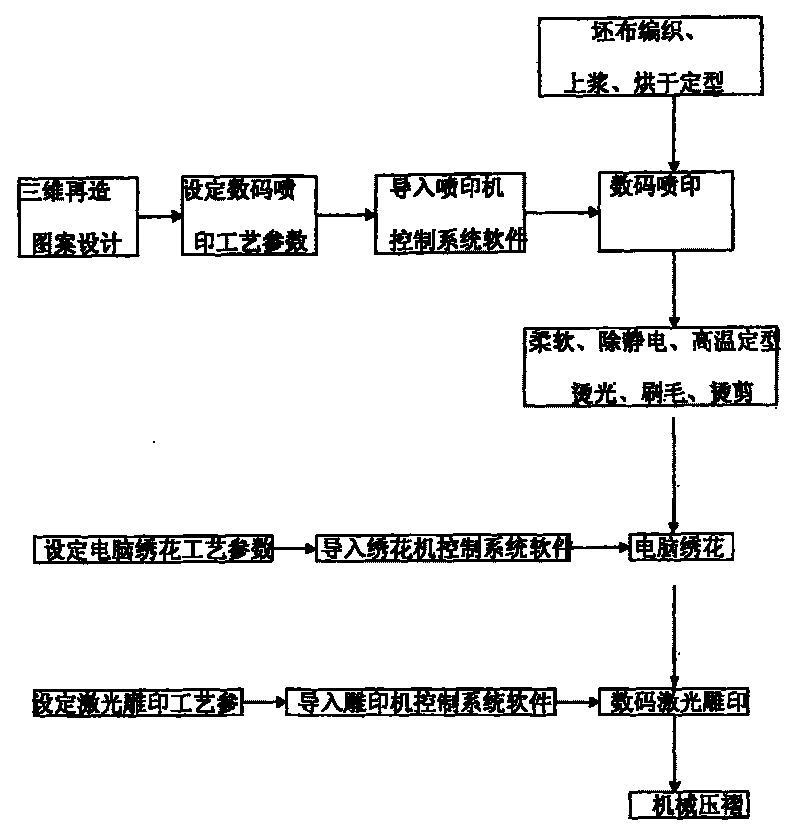

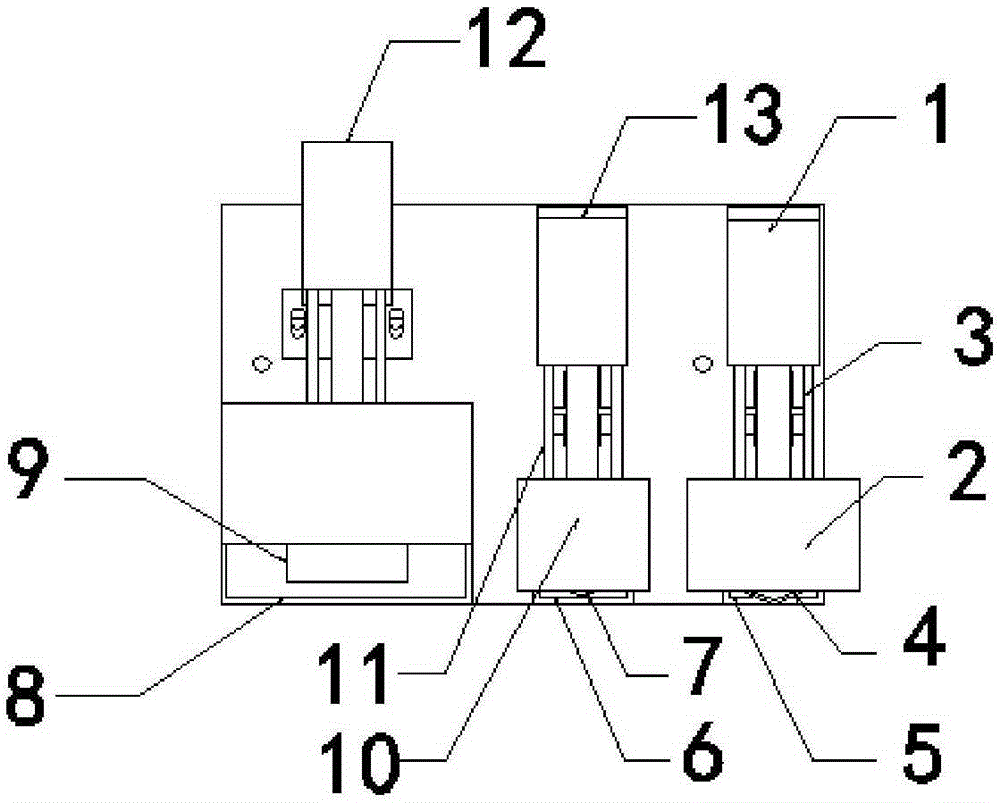

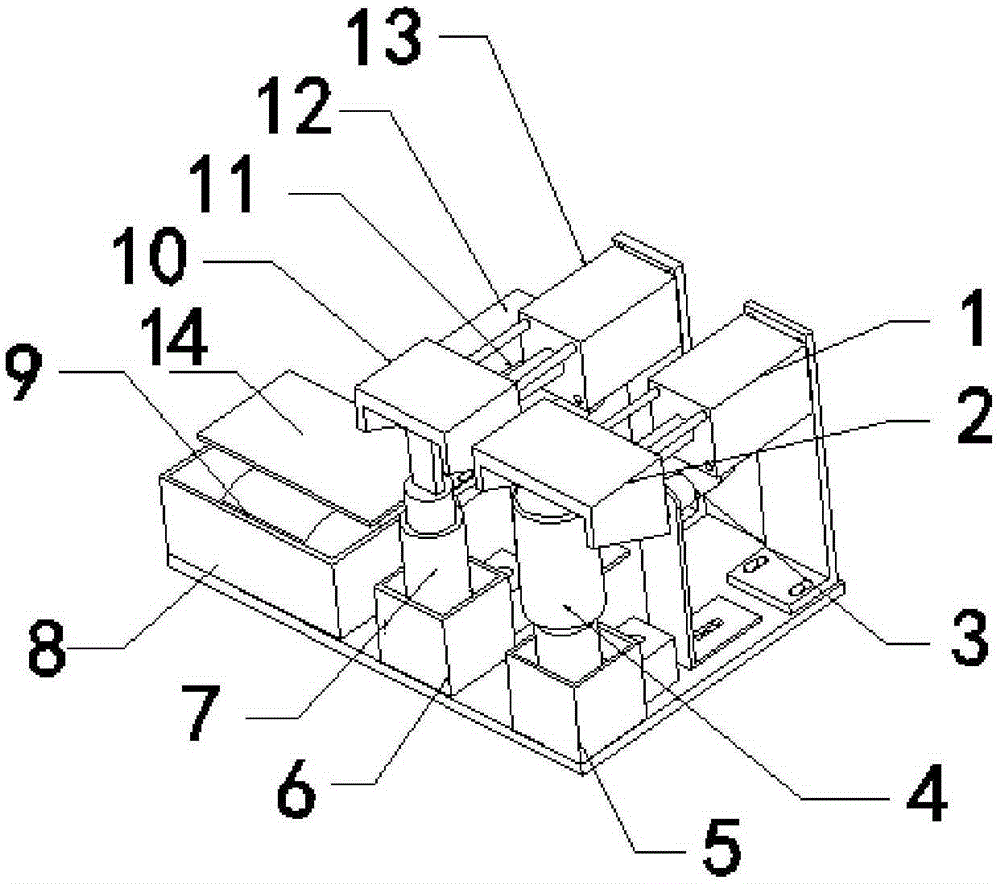

Technique for preparing three-dimensional regeneration pattern fabric

InactiveCN101235603BSimplify production preparationShorten the processing cyclePattern makingDyeing processGraphicsPersonalization

The invention relates to a technical method for manufacturing three-dimensional reconstruction pattern fabrics, which comprises technical procedures: designing three-dimensional reconstruction patterns, spray-printing digitally, embroidering with a computer, discharge-printing with digital laser, pressing pleats mechanically and the like. The method integrates a plurality of techniques such as electronic information, the computer, light mechanical and electrical integration and the like and applies a digital technique, textile surface graphic reconstruction and a textile three-dimensional memory molding reconstruction technique to assist design, the graphic visual effects which are similar to negative incising, heat printing and hollow-out pattern styles can be obtained, the grade and thetechnical added value are greatly increased, the personalized artistic requirements for small batch, multi-varieties and multi-colors can be satisfied, and the method is applied in producing fabrics such as various natural fiber, chemical fiber, synthetic fiber and the like.

Owner:内乡县地毯工艺品集团公司

Automotive glass base adhesive sequence control device and method

InactiveCN105195391AEliminate quality problems such as reduced adhesionReduce defective ratePretreated surfacesCoatingsSequence controlAutomatic control

The invention relates to an automotive glass base adhesive sequence control device and method. The device comprises a pressure sensor, two base adhesive units which are arranged in parallel, a wiping cloth unit and a controller, wherein each base adhesive unit comprises a base adhesive control cylinder, a base adhesive protective cover, a base adhesive photoelectric detector and a base adhesive accommodating structure; the wiping cloth unit comprises a piece of naphtha wiping cloth, a naphtha wiping cloth control cylinder and a naphtha wiping cloth placing box; after detection on the base adhesive, the glass and the naphtha wiping cloth through the photoelectric detectors and the sensor, the controller automatically controls the coating sequence of the base adhesive. Compared with the prior art, the automotive glass base adhesive sequence control device and method have the advantages that the base adhesive coating sequence is controllable, the base adhesive coating procedure is started by detecting the glass on a worktable, and various types of base adhesives are output automatically according to the order of sequence, the quality problem that the binding power is decreased after injection molding of glass due to disordered base adhesive coating sequence, which is caused by fatigue of workers, is solved, the product quality is ensured, the cleanness of the worktable is ensured, and the applicability is wide.

Owner:SHANGHAI FUYAO BUS GLASS

Electrolyte and method for preparing lead and lead dioxide through electrochemical deposition

PendingCN113046788AReduce consumptionIncrease conversion rateElectrolysis componentsPhotography auxillary processesSupporting electrolyteElectrolytic agent

The invention discloses an electrolyte and method for preparing lead and lead dioxide through electrochemical deposition. The method comprises five unit operation steps of supporting electrolyte solution preparation, electrolyte preparation, electrochemical deposition, washing and drying; Pb < 2 + > in the electrolyte is subjected to a reduction reaction at a cathode to obtain lead; the lead obtained through deposition can be directly used as a negative active material of a lead storage battery; meanwhile, Pb < 2 + > is subjected to oxidation reaction at an anode to obtain lead dioxide; and the lead dioxide obtained through deposition can be directly used as a positive active material of the lead storage battery. According to the electrolyte and method for preparing lead and lead dioxide through electrochemical deposition, the solution composed of lead trifluoromethanesulfonate, trifluoromethanesulfonic acid alkali metal salt, trifluoromethanesulfonic acid and water is adopted as the electrolyte, the paired electrochemical reaction of Pb < 2 + > is achieved, the efficiency and the energy utilization rate of the electrochemical deposition process are improved, the clean production requirements of energy conservation and emission reduction are met, economic value is achieved, and remarkable environmental and social benefits are also achieved.

Owner:YANGZHOU UNIV

Vegetable oil physical refining device and vegetable oil physical refining method

PendingCN107574015ARealize remote metering automatic controlGuaranteed antibacterial environmentFatty-oils/fats refiningOil and greaseOil processing

The invention belongs to the field of vegetable oil refining and oil processing as well as industrial application equipment thereof, and in particular relates to a vegetable oil physical refining device and a vegetable oil physical refining method. All system devices in the vegetable oil physical refining device cooperate with one another, thus forming an organically coordinated whole. An enzyme preparation applied in the device and the method is free from pollution and meets the requirements of clean production; the best activity of the enzyme preparation can be kept and excited from storageto production, so that the enzyme preparation can be utilized efficiently; the using process is finer and more efficient, and the production process is flexibly and steadily controlled. By using the system to keep the activity of the enzyme preparation, the efficient and fine utilization of enzyme and the stable control of the production process are realized, so that the stability and consistencyof quality of products can be effectively guaranteed in a mass production process.

Owner:SHANDONG XIWANG FOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com