Acetylene drying process and equipment thereof

A drying process and drying equipment technology, applied in the direction of hydrocarbons, organic chemistry, adsorption purification/separation, etc., can solve problems such as easy generation of waste residue, waste water, waste acid, shortened catalyst service life, acetylene explosion and combustion accidents, etc., to achieve The effect of less equipment, reduced load, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

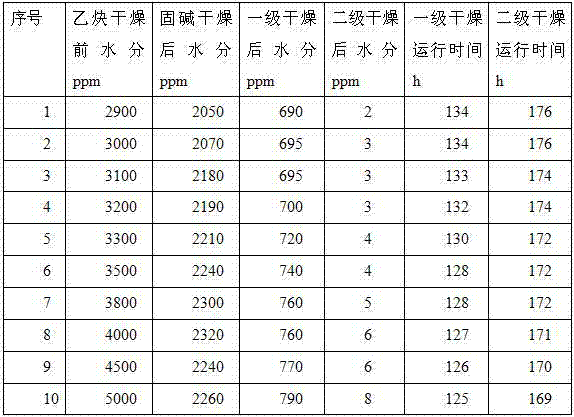

[0052] A kind of acetylene drying process, comprises the following steps:

[0053] (1) The acetylene comes from the acetylene station. After cleaning, the water content is controlled below 5000ppm, the pressure is 0.1MPa, and the temperature is 5°C. If the water content is too high, add a 0°C dehydrator;

[0054] (2) Send acetylene gas with a pressure of 0.1MPa and a water content of 3000-5000ppm into the acetylene solid alkali drying tower, and the flow rate is controlled below 2m / s. After drying in the acetylene solid alkali drying tower, measure the acetylene moisture;

[0055] (3) When the moisture content of acetylene with a pressure of 0.1MPa drops to 2000ppm, the acetylene gas enters the primary acetylene drying tower, and enters the secondary acetylene drying tower when the water content drops to 700ppm; the moisture content of the acetylene gas coming out of the secondary acetylene drying tower is lower than After 10ppm, it is sent to the subsequent utilization system...

Embodiment 2

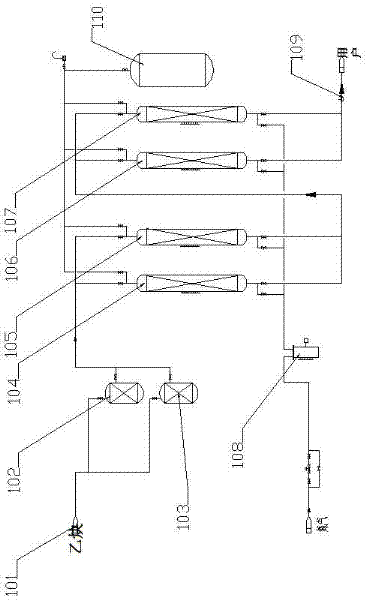

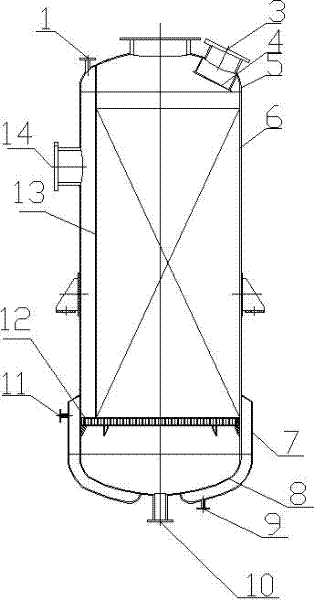

[0067] Such as figure 1 and 2 As shown, a kind of equipment that is used for the acetylene drying process of above-mentioned embodiment 1, comprises the acetylene solid base drying tower, the primary acetylene drying tower, the secondary acetylene drying tower connected successively;

[0068] Described acetylene solid alkali drying tower is provided with two: the first acetylene solid alkali drying tower 102 and the second acetylene solid alkali drying tower 103, connected in parallel;

[0069] The first-level acetylene drying tower is provided with two: the first-level acetylene drying tower 104 and the second-level acetylene drying tower 105, which are connected in parallel;

[0070] Described secondary acetylene drying tower is provided with two: the first secondary acetylene drying tower 106 and the second secondary acetylene drying tower 107, connected in parallel;

[0071] The first-level acetylene drying tower 104, the second-level acetylene drying tower 105, the firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com