Automotive glass base adhesive sequence control device and method

A technology for sequence control and automotive glass, which is applied to the device for coating liquid on the surface, pretreatment surface, coating, etc. It can solve the problems of safety hazards, increase customer complaints, easy fatigue, quality problems, etc., and reduce product defects. High efficiency and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

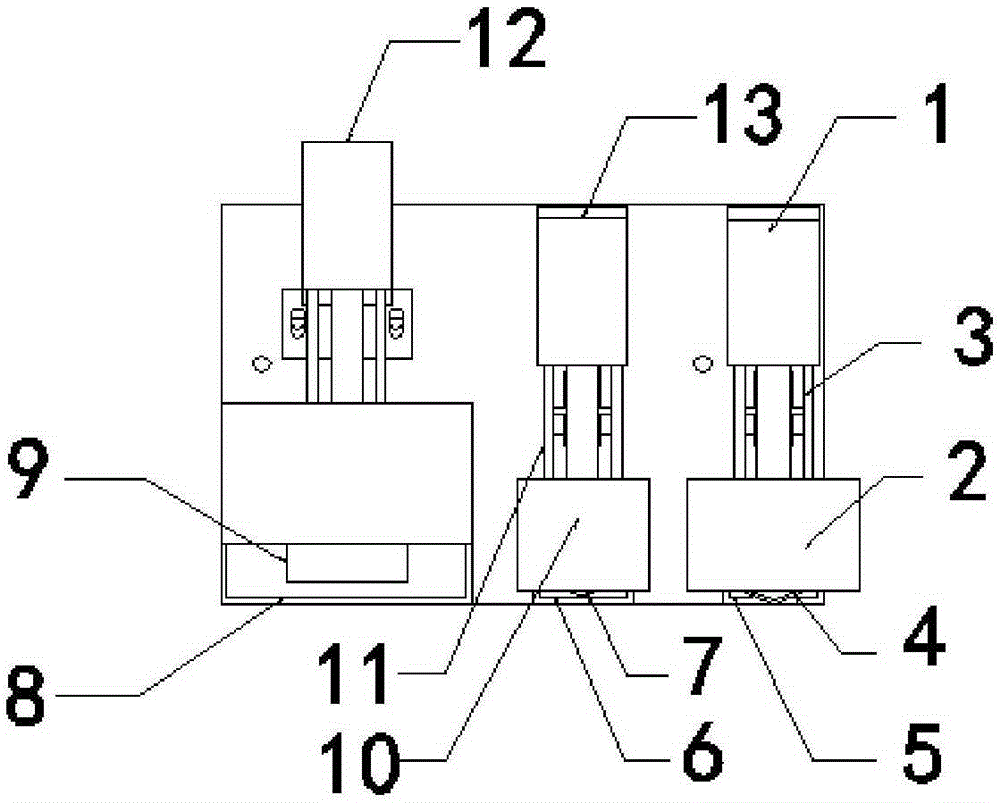

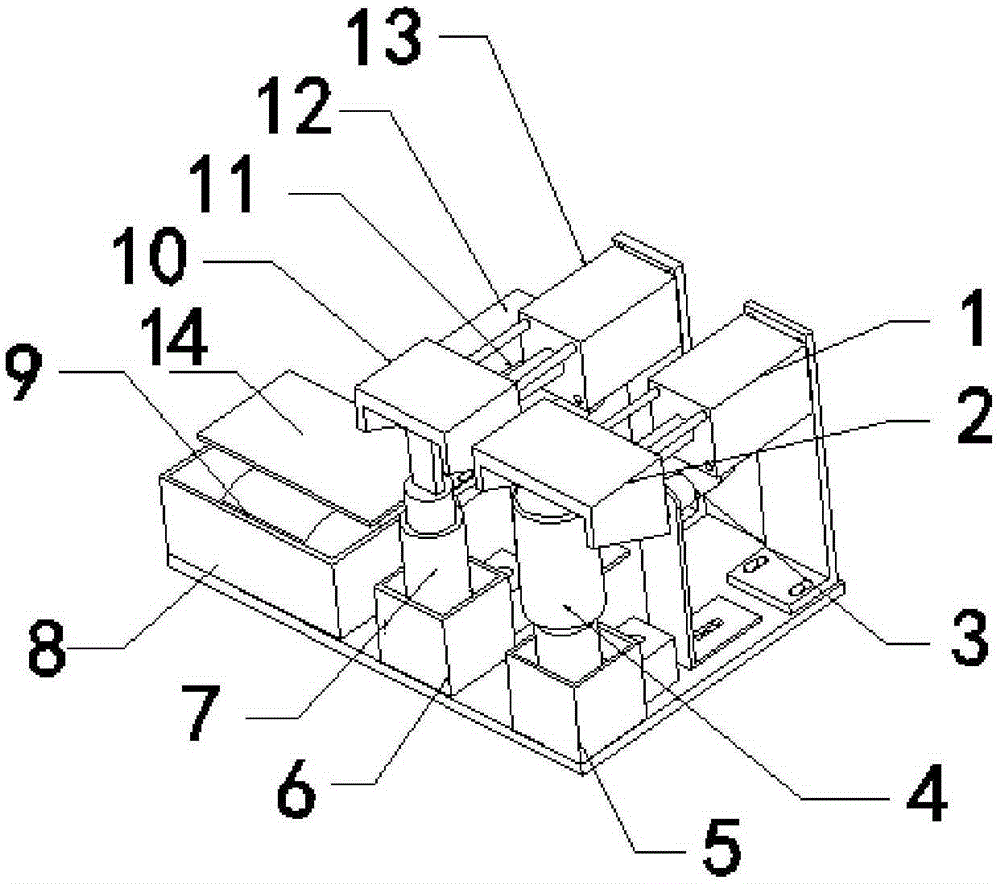

[0035] The automotive glass primer sequence control device is set on the workbench, the structure is as follows figure 1 , figure 2 As shown, including: primer A cylinder 1; primer A protective cover 2; primer A photoelectric detector 3; primer A bottle 4; primer A box 5; primer B box 6; primer B bottle 7; Naphtha wiping cloth placement box 8; naphtha wiping cloth 9; primer B protective cover 10; primer B photoelectric detector 11; naphtha wiping cloth control cylinder 12; primer B control cylinder 13; naphtha Wipe Cloth Guard 14; Controller.

[0036] The primer A unit includes the primer A control cylinder 1, the primer A protective cover 2, the primer A photoelectric detector 3, the primer A bottle 4 and the primer A box 5. The primer A photoelectric detector 3 and the primer A box 5 are fixed on the workbench, and the primer A photoelectric detector 3 is located below the primer A control cylinder 1 and is arranged side by side. The top of the primer A box 5 is open, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com