Vegetable oil physical refining device and vegetable oil physical refining method

A physical refining, vegetable oil technology, applied in the direction of oil/fat refining, fat production, etc., can solve the problems of extensive use and low efficiency, the production process cannot be stably controlled, etc. The effect of bacterial environment guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

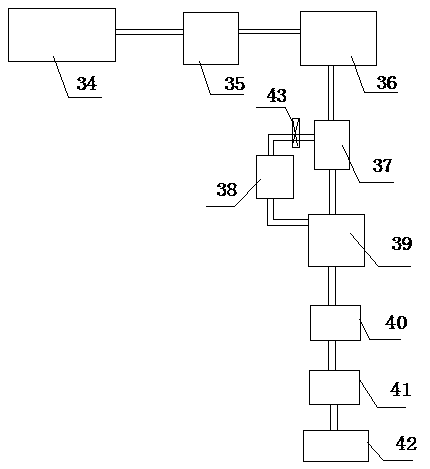

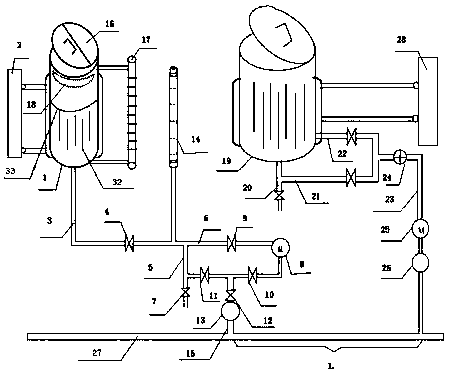

[0048] A vegetable oil physical refining device, comprising an enzyme adding control device, an oil enzyme high-efficiency mixing device, an oil separation device, a dewaxing device, a decolorizing device, a deodorizing device and a fine filtration device, characterized in that: the enzyme adding control device includes An enzyme control system for enzyme preparation control, a reagent control system for reagent addition control, and a temperature control system for temperature control, the temperature control system includes a temperature control unit for controlling the temperature of the enzyme control system. The temperature control unit two for controlling the temperature of the agent control system and the temperature control unit three for controlling the temperature of the workshop or independent room where the system is located; the enzyme control system includes an enzyme storage tank, a delivery unit one and a control system one, and the agent control unit The system...

Embodiment 2

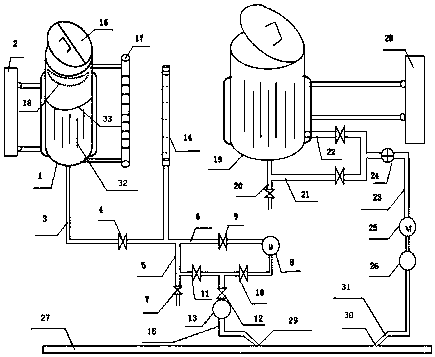

[0060] A vegetable oil physical refining device, comprising an enzyme adding control device, an oil enzyme high-efficiency mixing device, an oil separation device, a drying device, a dewaxing device, a decolorizing device, a deodorizing device and a fine filtration device, characterized in that: the enzyme adding The control device includes an enzyme control system for enzyme preparation control, a reagent control system for reagent addition control, and a temperature control system for temperature control, and the temperature control system includes a temperature control unit for controlling the temperature of the enzyme control system 1. The temperature control unit 2 used to control the temperature of the agent control system and the temperature control unit 3 used to control the temperature of the workshop or independent room where the system is located; the enzyme control system includes an enzyme storage tank, a delivery unit 1 and a control system 1. The agent control sy...

Embodiment 3

[0074] The vegetable oil of this example selects purely physically pressed corn oil crude oil, the main index of crude oil is acid value 3.8 (KOH) (mg / g), peroxide value 7.77 mmol / kg, and insoluble impurities<0.2%.

[0075] A method for physical refining of vegetable oils, comprising the following processes: enzyme addition control, high-efficiency mixing of oil enzymes, oil separation, dewaxing, decolorization, deodorization and fine filtration; the enzyme addition control process is completed by an enzyme addition control device. Said adding enzyme control procedure comprises the following steps:

[0076] (1) When the enzyme storage tank is empty, ignite the fuel in the flame tank, add the enzyme preparation to the enzyme storage tank under the protection of the flame circle, and use the temperature control unit to control the circulating fluid in the jacket, tubes and coils. Adjust the temperature in the enzyme storage tank to 1°C to 10°C; add the required reagents into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Pov | aaaaa | aaaaa |

| Pov | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com