Electroplating drop liquid recycling device and recycling method

A recovery device and electroplating solution technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of resource waste, material loss, pollutants, etc., to avoid pollution and corrosion, reduce carry-out loss, and simple recovery method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in conjunction with the following drawings and examples.

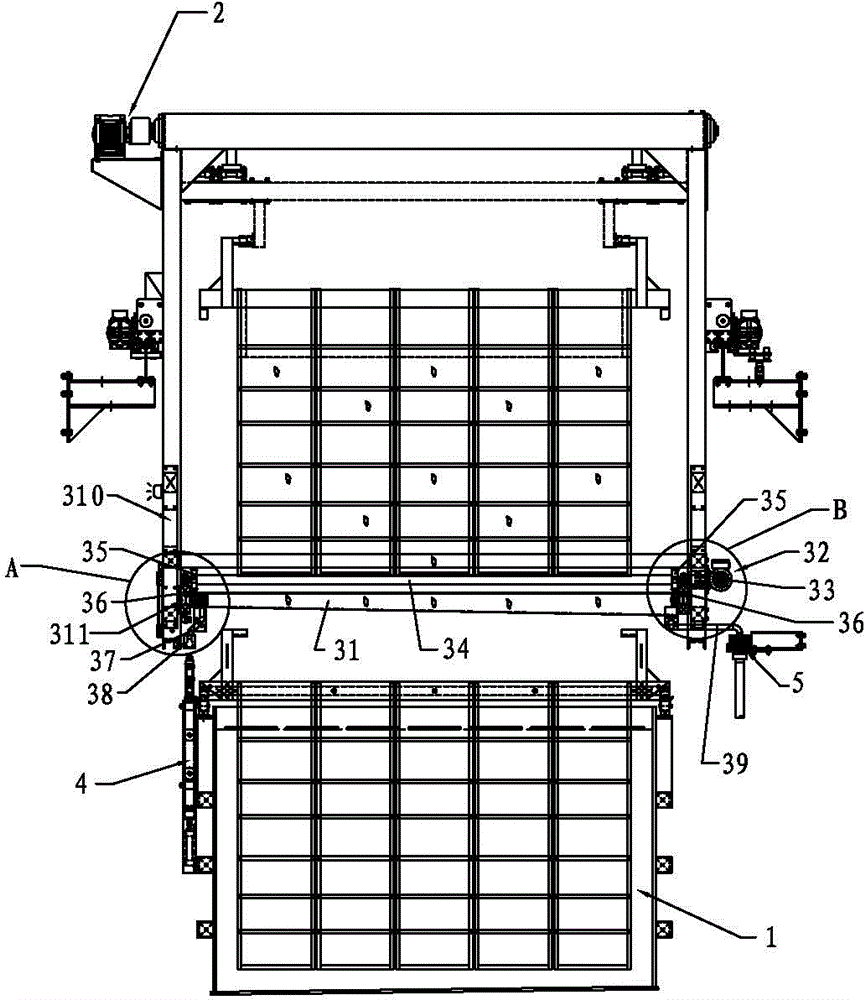

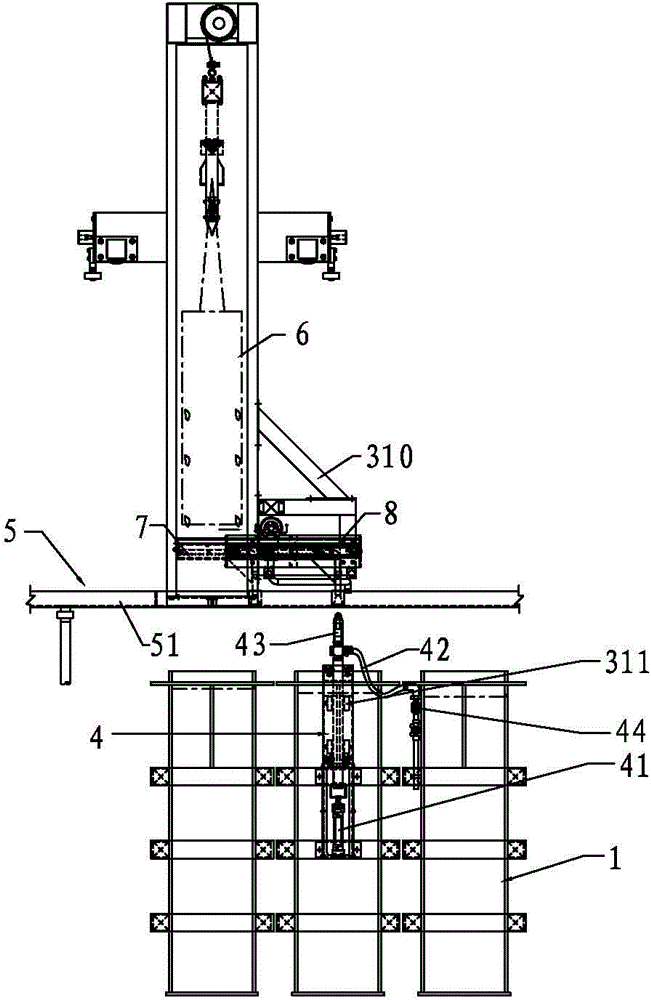

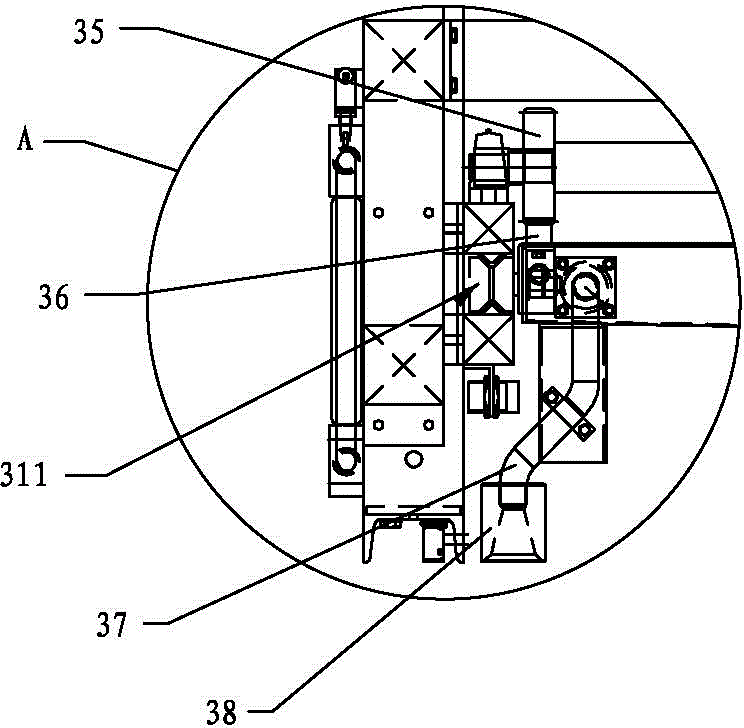

[0039] Such as Figure 1 to Figure 4 As shown, a recovery device for electroplating dripping liquid in this embodiment includes at least one electroplating tank 1, a control mechanism, a transport mechanism 2 for hoisting electroplating workpieces 6, a drip collecting mechanism, an automatic water supply cleaning mechanism 4 and a subsection Type water receiving ditch 5, the drip collecting mechanism is located above the electroplating tank 1, the transport mechanism 2 is located above the drip collecting mechanism, and the drip collecting mechanism includes a drip tray 31 and is used to drive the drip tray 31 horizontally The moving transmission mechanism 32, the automatic water supply cleaning mechanism 4 is connected to the water inlet of the drip tray 31, the segmented water receiving ditch 5 is connected to the water outlet of the drip tray 31, the transport m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com