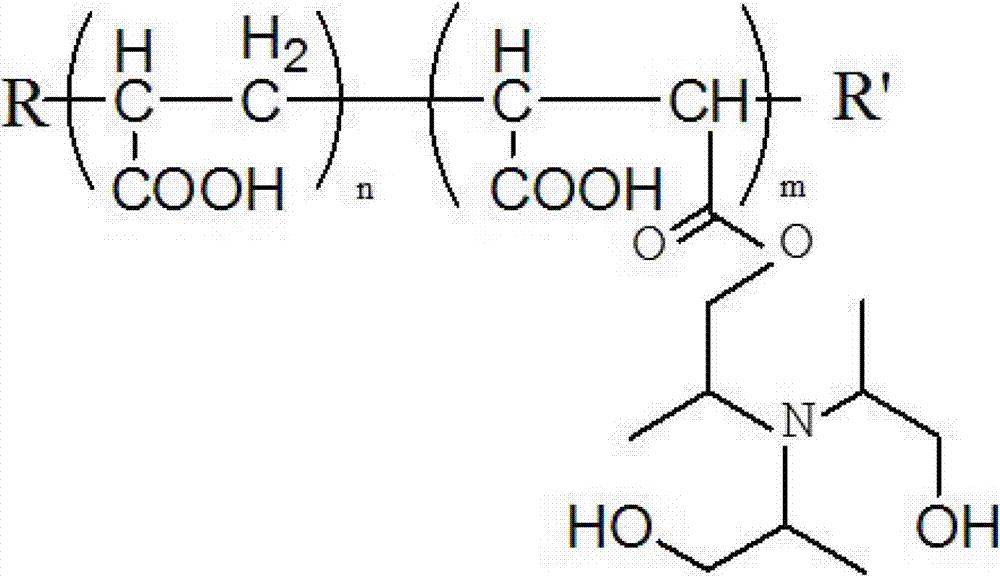

Synthetic method of polyethylene glycol amine ester-carboxylic acid macromolecule grinding aid

A technology of polyolamine ester and synthesis method is applied in the synthesis field of preparing triisopropanolamine maleate-sodium acrylate polymer grinding aid, and can solve the problem of complex composition, high effective dosage and negative influence on cement performance. and other problems, to achieve the effects of stable physical and chemical properties, simple production process and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

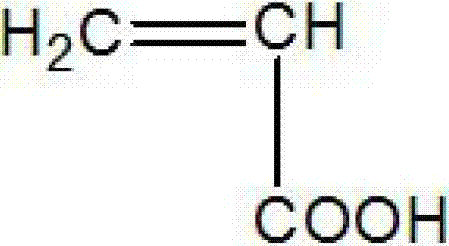

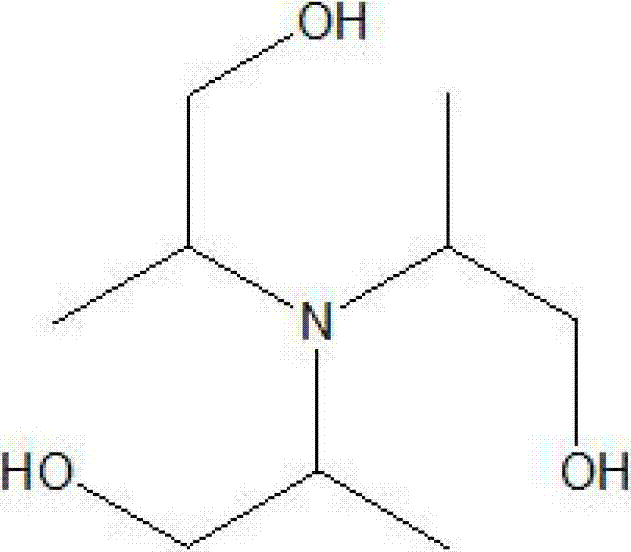

[0034] According to the molar ratio: acrylic acid: maleic anhydride: triisopropanolamine = 1.6: 0.8: 1.0 Prepare the raw materials.

[0035] In a container equipped with a magnetic stirrer, a condenser, a thermometer and a water bath heating, add maleic anhydride and triisopropanolamine according to the above molar ratio, heat and stir for 2 hours, cool down, and dilute the esterification product with deionized water to a mass concentration of 50%, to obtain solution 1.

[0036] Acrylic acid was neutralized to pH=8 with NaOH solution, and distilled water was added to dilute the solution to acrylic acid mass concentration of 30%, to obtain solution 2.

[0037] According to the maleic anhydride: acrylic acid molar ratio is 1:1, the weighed solution 2 is added to the solution 1, and heated to a constant temperature of 90 °C; when adding the initiator ammonium persulfate dropwise, continue to add solution 2 dropwise until Until the addition is complete; the amount of the initiato...

Embodiment 2

[0039] According to the molar ratio: acrylic acid: maleic anhydride: triisopropanolamine = 2.0: 1.0: 1.0 Prepare the raw materials.

[0040] Technological process is the same with embodiment 1.

Embodiment 3

[0042] According to the molar ratio: acrylic acid: maleic anhydride: triisopropanolamine = 3.6: 1.2: 1.0 Prepare the raw materials.

[0043] Product of the present invention small grinding test verification:

[0044] The grinding aid product of the present invention obtained in Examples 1, 2, and 3 and the cement clinker without grinding aid were subjected to small grinding tests under the same conditions, and the grinding aid and strengthening effects of the polymer grinding aid were obtained in the table 1. Table 2.

[0045] Grinding aid effect of table 1 polymer grinding aid

[0046]

[0047] Remarks: Sample numbers in the above table: A0 blank sample; A1, A2, and A3 are polymer grinding aids obtained in Examples 1, 2, and 3, respectively.

[0048] The reinforcing effect of table 2 polymer grinding aid

[0049]

[0050]

[0051] Remarks: Sample numbers in the above table: A0 blank sample; A1, A2, and A3 are polymer grinding aids obtained in Examples 1, 2, and 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com