Sol-gel method for preparing earth silicon/titanic oxide hollow microballoon

A titanium dioxide and silicon dioxide technology, applied in the field of nano-scale hollow microspheres, can solve the problem of only preparing a microsphere shell composed of one kind of inorganic particles, and achieves easy industrial production, simple production equipment and flexible production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

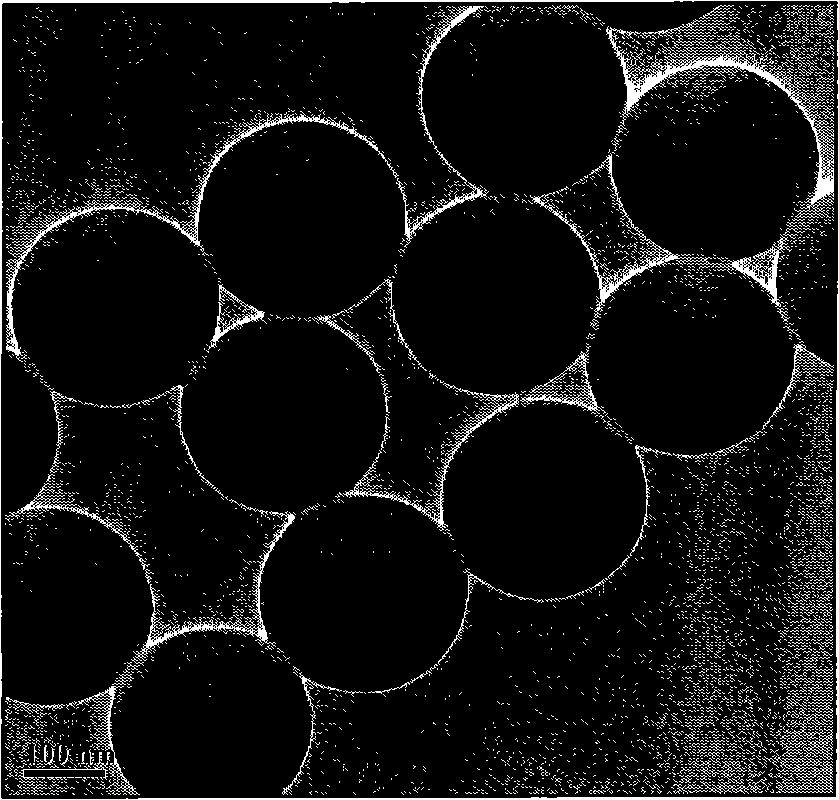

[0025] Add 20mL of styrene into a 300mL three-necked round-bottomed flask equipped with a condenser tube and a protective gas port with 200mL of deionized water inside, then add 0.6g of azobisisobutyl ether hydrochloride (AIBA) and 2.5g of poly Vinylpyrrolidone k30 (PVP), using magnetic stirring to mix evenly, and nitrogen into the reactor to evacuate oxygen for 1h, then use a water bath to heat to 70 ° C, keep warm for 24h. High-speed centrifugation to separate the white precipitate (PS), use Wash with deionized water and absolute ethanol 3 times. figure 1 The TEM photo of the PS microsphere template prepared for this example shows that the microsphere template is very uniform and has a diameter of about 262 nm.

Embodiment 2

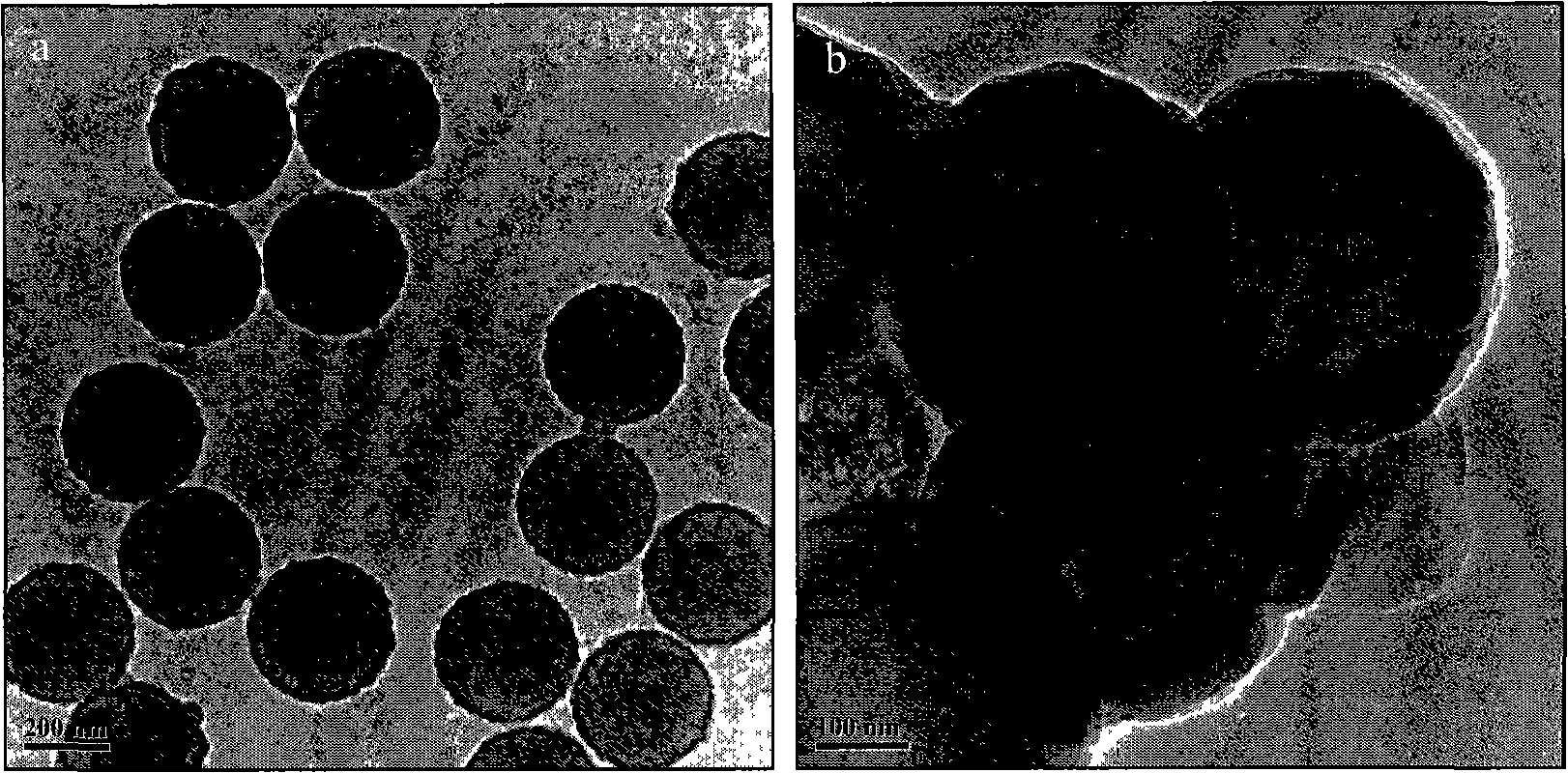

[0027]After dispersing 1mL of polystyrene microsphere suspension (3wt%) into 15mL of deionized water and 50mL of isopropanol mixed solution, the solution was added to a 300mL three-neck round-bottomed flask equipped with a condenser tube and a protective gas port, After magnetically stirring for 15 min, 0.15 g of ethyl silicate (TEOS) was added, and the pH value of the solution was adjusted to ~10 with diluted ammonia (5 vol%) solution, and magnetically stirred at room temperature for 2 h. The white precipitate was separated by high-speed centrifugation and washed three times with isopropanol to obtain PS / SiO 2 Composite microsphere particles. figure 2 (a) is the PS / SiO described in this embodiment 2 TEM photo of organic-inorganic hybrid microspheres, the SiO of the resulting composite microspheres 2 The thickness of the shell layer is about 8nm, and the thickness of the shell layer is uniform, and the dispersion of the microspheres is good.

Embodiment 3

[0029] After dispersing 1mL of polystyrene microsphere suspension (3wt%) into 15mL of deionized water and 50mL of isopropanol mixed solution, the solution was added to a 300mL three-neck round-bottomed flask equipped with a condenser tube and a protective gas port, After magnetic stirring for 15 min, 0.6 g of ethyl silicate (TEOS) was added, and the pH value of the solution was adjusted to ~10 with diluted ammonia (5 vol%) solution, and magnetically stirred at room temperature for 2 h. The white precipitate was separated by high-speed centrifugation and washed three times with isopropanol to obtain PS / SiO 2 Organic-inorganic hybrid microsphere particles. When the content of ethyl silicate increases, SiO 2 The thickness of the shell layer also increases, but the dispersion of the microspheres becomes worse, which is due to more SiO 2 The generation of secondary particles leads to aggregation of microspheres. PS / SiO prepared in this embodiment 2 TEM pictures of organic-inorg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com