Flexible automatic hot stamping system

A flexible and automatic technology, applied in printing, printing machines, transfer printing, etc., can solve problems such as easy to be pressed by human hands, difficult to move robots, and insufficient flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

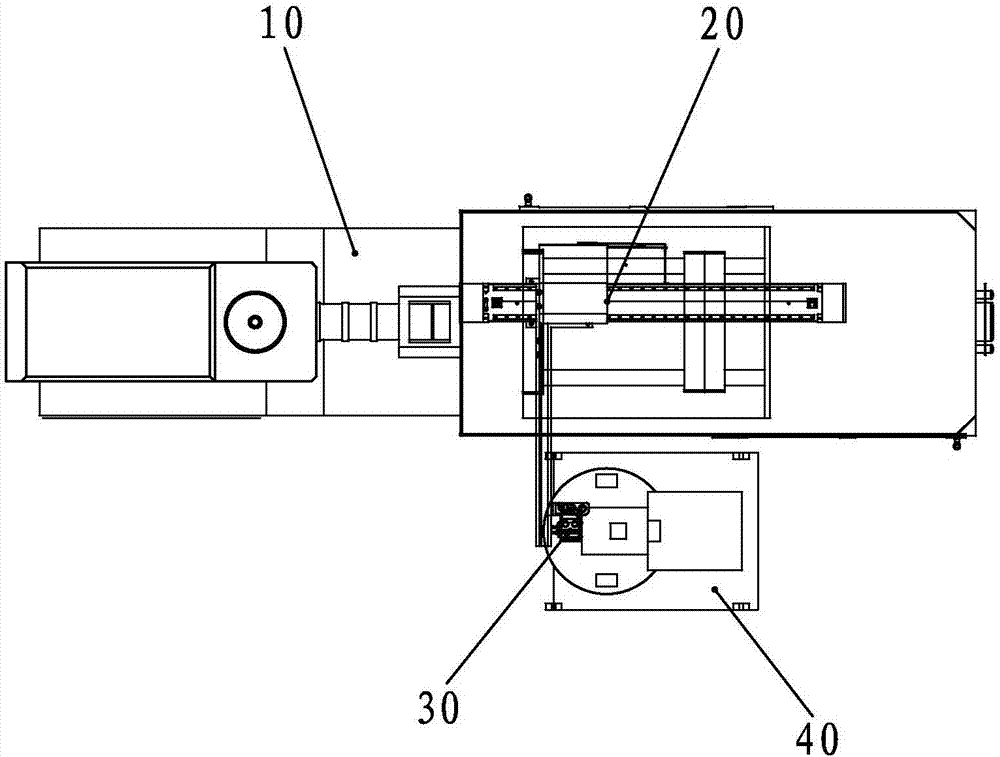

[0036] refer to figure 1 , the flexible automatic hot stamping system provided by the present invention includes: a manipulator 20 installed on the injection molding machine 10, a flexible and switchable retrieving jig driven by the manipulator 20, and a hot stamping machine corresponding to the retrieving jig; hot stamping The machine has a self-positioning sensor corresponding to the injection molding machine 10, which realizes automatic positioning of the moving position of the hot stamping machine by cooperating with the self-positioning sensor of the injection molding machine 10 to determine the fixed position of the hot stamping machine.

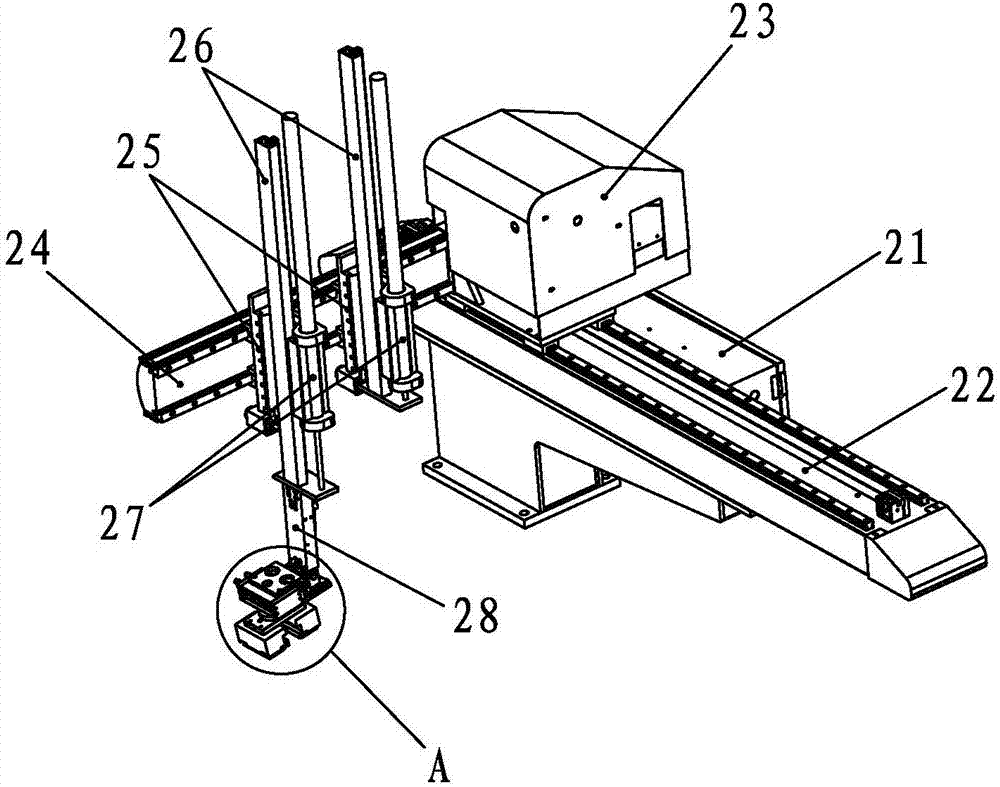

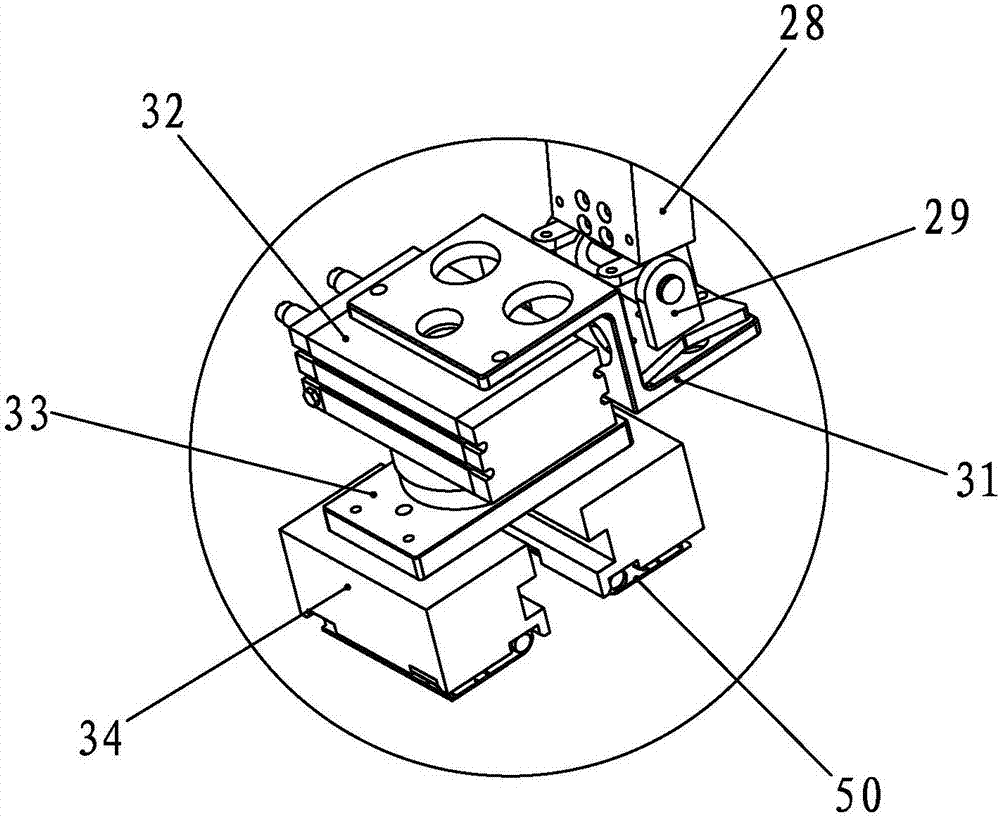

[0037] refer to figure 2 and 5 , the manipulator 20 includes a mounting table 21 installed on the injection molding machine 10, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com