Production system and production method of aromatic hydrocarbon solvent having wide distilling range, low chromaticity and high boiling point

A high-boiling point aromatics, production system technology, applied in chemical instruments and methods, separation methods, hydrocarbon oil treatment products, etc. Process, process environmental protection, no pollution, ensure the effect of chromaticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

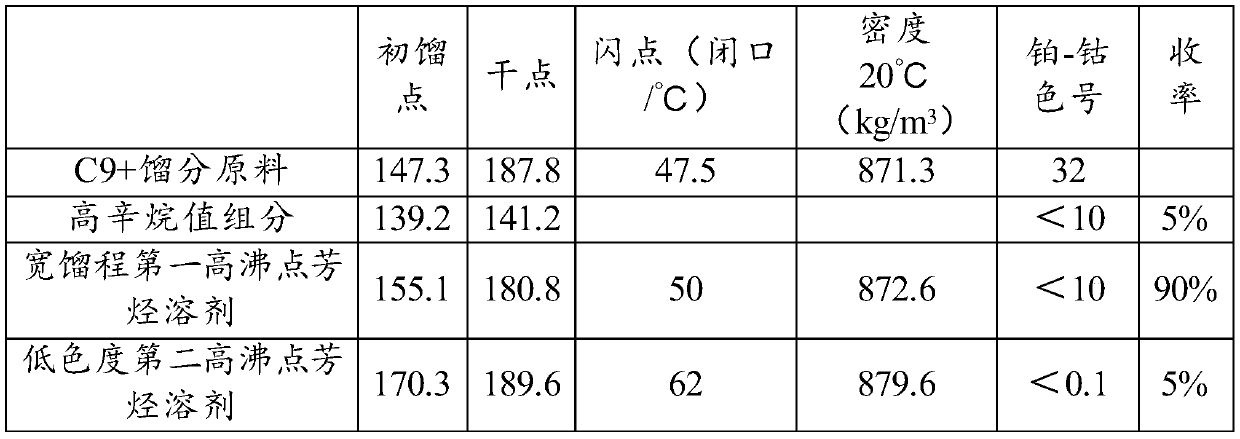

Embodiment 1

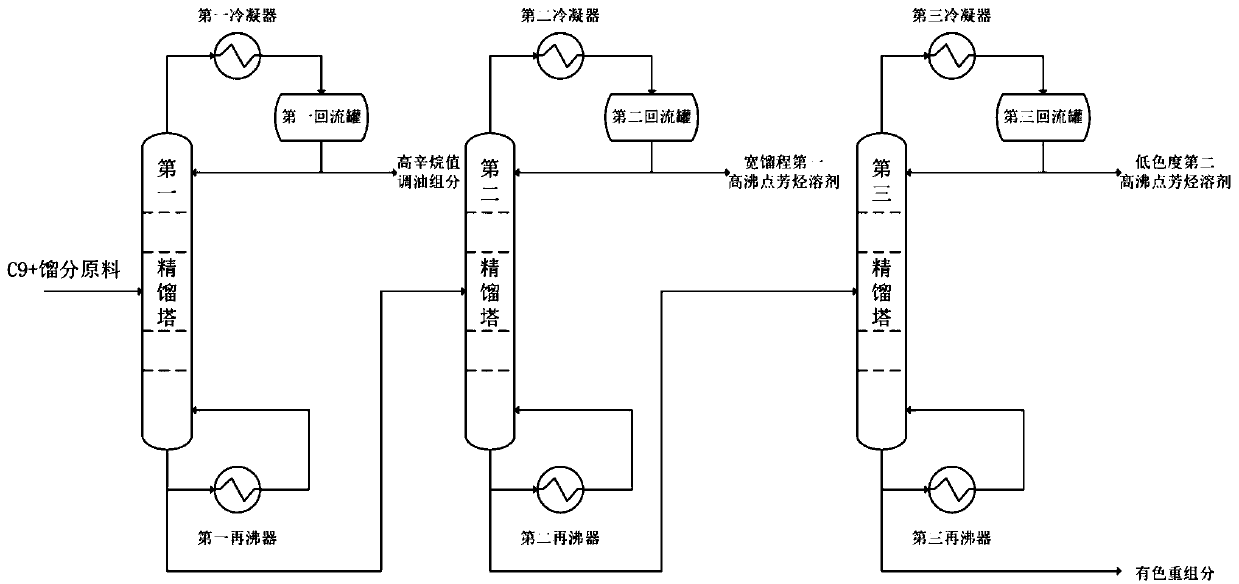

[0073] The production system of wide distillation range, low color and high boiling point aromatic hydrocarbon solvent includes:

[0074] The first rectification tower, the middle part of the first rectification tower is provided with a C9+ fraction raw material inlet, the top of the first rectification tower is provided with a first overhead distillate outlet, and the first rectification tower The bottom is provided with a first bottom distillate outlet;

[0075] The first overhead distillate outlet is sequentially connected to the first condenser and the first reflux tank, the first reflux tank is provided with a first material outlet, and the first material outlet is provided with a first three-way valve, One end of the first three-way valve is connected to a pipeline connected to the first rectification tower, and the other end is connected to a pipeline leading out high-octane oil-adjusting components.

[0076] The second rectifying tower, the middle part of the second r...

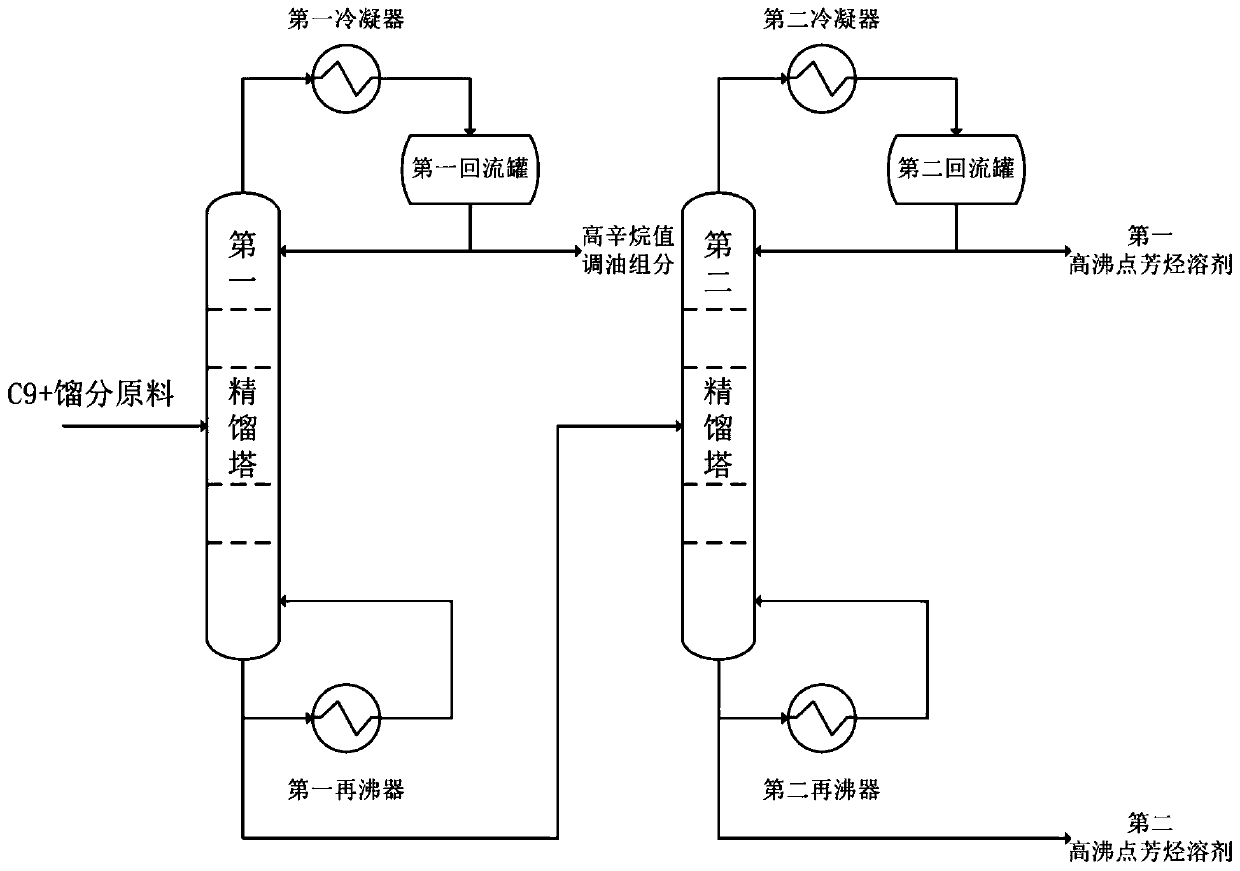

Embodiment 2

[0085] The invention discloses a method for producing an aromatic hydrocarbon solvent with a wide distillation range, low color and high boiling point, which is produced by a rectification process under reduced pressure.

[0086] The specific steps are:

[0087] (1) Carry out rectification and separation of the C9+ cut raw material from the middle part of the feed in the first rectification tower to obtain the first overhead distillate, which is communicated with the first condenser at the top of the first rectification tower After condensing, it enters the first reflux tank connected with the first condenser, and is drawn out as a high-octane oil adjustment component;

[0088] (2) The bottom distillate of the first rectification tower is rectified and separated from the middle feed in the second rectification tower to obtain the second overhead distillate, which is combined with the second rectification The second condenser connected to the top of the tower is condensed and ...

Embodiment 3

[0098] The invention discloses a method for producing an aromatic hydrocarbon solvent with a wide distillation range, low color and high boiling point, which is produced by a rectification process under reduced pressure.

[0099] The specific steps are:

[0100] (1) Carry out rectification and separation of the C9+ cut raw material from the middle part of the feed in the first rectification tower to obtain the first overhead distillate, which is communicated with the first condenser at the top of the first rectification tower After condensing, it enters the first reflux tank connected with the first condenser, and is drawn out as a high-octane oil adjustment component;

[0101] (2) After fully mixing the bottom distillate of the first rectification tower and the C10+ heavy aromatics from the reforming unit, enter the middle part of the second rectification tower, and carry out in the second rectification tower The rectification separates the second overhead distillate, which ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dry point | aaaaa | aaaaa |

| dry point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com