Rectification system and solvent purification system

A technology of rectification system and rectification tower, which is applied in the field of purification of chemical products, can solve the problems of complex control system, failure to meet requirements, high production cost, etc., and achieve the effect of simple equipment, meeting the requirements of rectification, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

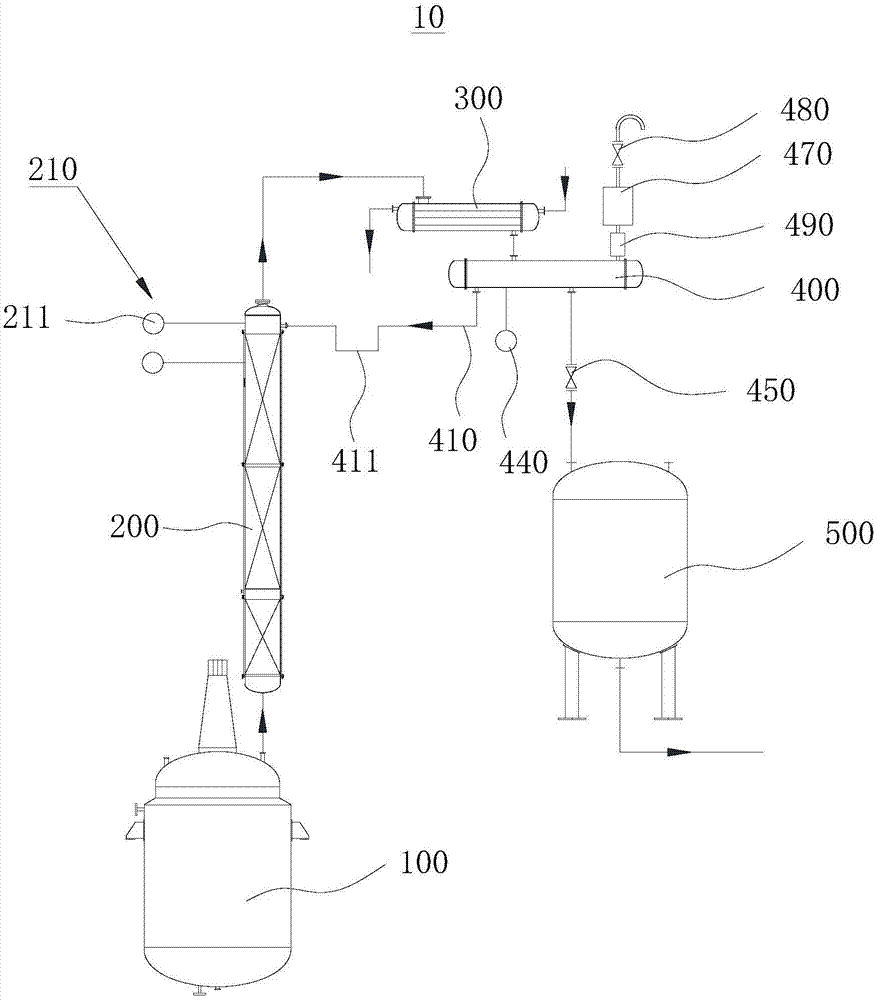

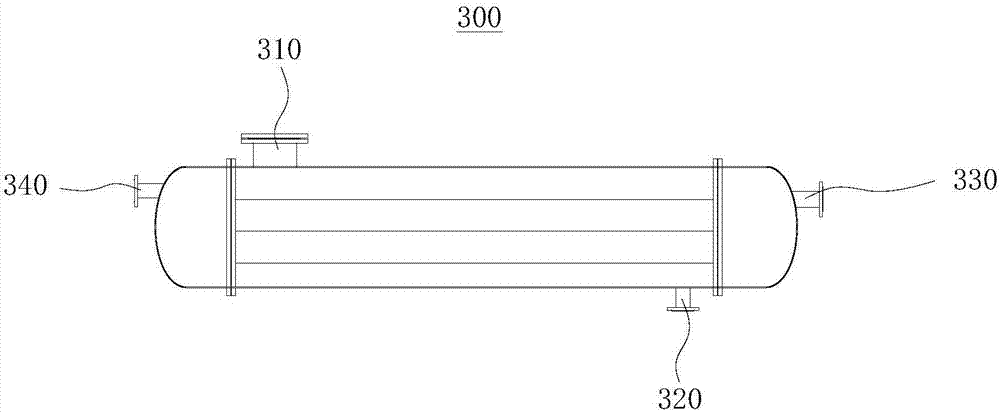

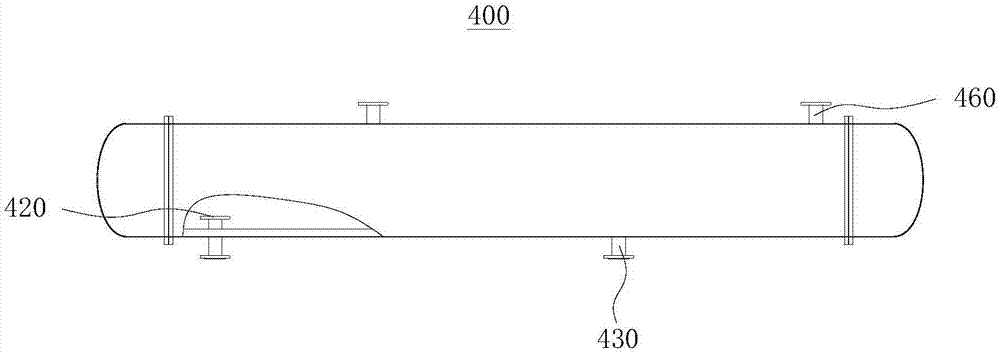

[0032] This embodiment provides a rectification system 10, refer to figure 1 As shown, it includes a rectification tank 100 , a rectification column 200 , a condenser 300 and a reflux tank 400 . Wherein, the rectification kettle 100 , the rectification tower 200 , the condenser 300 and the reflux tank 400 are connected in sequence, and the reflux tank 400 is connected to the top of the rectification tower 200 through the reflux pipeline 410 .

[0033] Such as figure 1 As shown, the rectification kettle 100 is used to hold the mixed solution to be rectified and heat the mixed solution to form a mixed gas. The gas phase outlet at the top of the rectification still 100 communicates with the gas phase inlet at the bottom of the rectification tower 200, and the mixed gas generated in the rectification tank 100 can enter the rectification tower 200 through the gas phase inlet at the bottom of the rectification tower 200 for rectification. Wherein, the rectifying still 100 is prefe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com