Preparation method of amorphous-reinforced copper-based composite material

A copper-based composite material, amorphous technology, applied in the field of metal materials, to achieve broad industrial application prospects, improve comprehensive performance, and effectively combine the effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

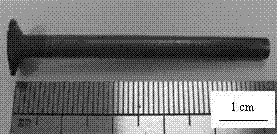

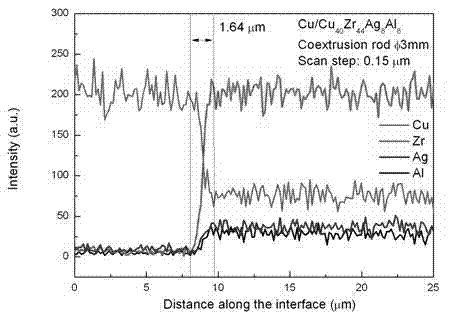

[0016] Embodiment 1: (extruded rod 1)

[0017] Cu 40 Zr 44 Ag 8 al 8 Preparation of bulk amorphous alloys:

[0018] Melting pure Cu, Zr, Ag and Al metals into Cu 40 Zr 44 Ag 8 al 8 The base alloy button blank; the surface is mechanically polished, and then the master alloy is pulverized. Under vacuum conditions, it is blow-cast into Cu with a diameter of 3mm by rapid induction melting. 40 Zr 44 Ag 8 al 8 Amorphous alloy bars.

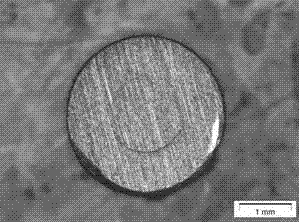

[0019] Preparation of new amorphous reinforced copper matrix composites (extruded rods):

[0020] Using the prepared hollow copper alloy tube with an outer diameter of 7 mm and an inner diameter of 3 mm and the above Cu 40 Zr 44 Ag 8 al 8 The amorphous alloy bar is placed in the bar extrusion die according to the extrusion ratio of 5.4, and is extruded under the extrusion process conditions of the extrusion temperature of 703K and the extrusion rate of 0.1mm / s. Finally, the required Cu with a diameter of 3 mm is obtained 40 Zr 44 Ag ...

Embodiment 2

[0021] Embodiment 2: (extruded rod 2)

[0022] Cu 40 Zr 44 Ag 8 al 8 The preparation of bulk amorphous alloy is as described in Example 1.

[0023] Preparation of new amorphous reinforced copper matrix composites (extruded rods):

[0024] Use the prepared hollow copper alloy tube with an outer diameter of 7 mm and an inner diameter of 3 mm and the above Cu 40 Zr 44 Ag 8 al 8 The amorphous alloy bar is placed in the bar extrusion die according to the extrusion ratio of 5.4, and is extruded under the extrusion process conditions of the extrusion temperature of 726K and the extrusion rate of 0.3mm / s. Finally, the required Cu with a diameter of 3 mm is obtained 40 Zr 44 Ag 8 al 8 Base amorphous reinforced copper matrix composite rod.

Embodiment 3

[0025] Embodiment 3: (extrusion plate)

[0026] Cu 40 Zr 44 Ag 8 al 8 The preparation of bulk amorphous alloy is as described in Example 1.

[0027] Preparation of New Amorphous Reinforced Copper Matrix Composite (Extrusion Sheet):

[0028] Use the prepared hollow copper alloy tube with an outer diameter of 9mm and an inner diameter of 3mm and the above Cu 40 Zr 44 Ag 8 al 8 Amorphous alloy rods are placed in a plate extrusion die at an extrusion ratio of 8.1, and extruded at an extrusion temperature of 703K and an extrusion rate of 0.3mm / s to obtain a thickness of 2 ㎜, Cu with a width of 5㎜ 40 Zr 44 Ag 8 al 8 base amorphous reinforced copper matrix composite sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com