Control method of thin plate hot rolling wire finishing mill AGC system

A control method and technology of a finishing rolling unit, which are applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of low production stability of thin-gauge products, difficulty in thickness control, and low thickness qualification rate of thick-gauge products , to solve the instability of production process control and product quality, solve production process control and products, improve the qualification rate and production stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105] To produce strip steel with a thickness of 2.0 mm, a 7-stand finishing mill is used, and the carbon content (mass percentage) in the strip steel is 0.103% to 0.105%.

[0106] According to the above control method, since 2.0mm is in the range of finished product thickness < 2.1mm, the corresponding adjustment range and adjustment rate are implemented according to the 2.1mm layer standard, specifically: F0, F1, F2, F3, F4, The corresponding adjustment ranges at F5 and F6 racks are: 350 μm, 300 μm, 250 μm, 200 μm, 150 μm, 100 μm, and 80 μm; the corresponding adjustment rates at F0, F1, F2, F3, F4, F5, and F6 racks are: 650μm / s, 600μm / s, 550μm / s, 500μm / s, 450μm / s, 400μm / s, 350μm / s.

[0107] Through the actual verification of an enterprise, strip steel with a thickness of 2.0mm and below can be mass-produced stably, and the average monthly output has increased from 204 tons to 7088 tons, which is 35 times higher than before.

Embodiment 2

[0109] To produce strip steel with a thickness of 2.5 mm, a 7-stand finishing mill is used, and the carbon content (mass percentage) in the strip steel is 0.103% to 0.105%.

[0110] According to the above control method, since 2.5mm is located between the 2.1 layer and the 2.6 layer, the corresponding adjustment range and adjustment rate need to be calculated according to the above formula. After calculation, the results are: the corresponding adjustment ranges at F0, F1, F2, F3, F4, F5, and F6 racks are: 390 μm, 340 μm, 290 μm, 240 μm, 190 μm, 140 μm, 96 μm; F0, F1, F2, F3 , F4, F5, and F6 racks corresponding adjustment rates are: 690μm / s, 640μm / s, 590μm / s, 540μm / s, 490μm / s, 440μm / s, 390μm / s.

[0111] Through the actual verification of an enterprise, the thickness of 2.5mm and below can be mass-produced, and the average monthly output has increased from 5,984 tons to 19,575 tons, which is 3.3 times higher than before.

Embodiment 3

[0113] Produce deep drawing steel with a carbon content (mass percentage) of 0.003% to 0.005%. A 7-stand finishing mill is used.

[0114] On the basis of the above control method, the layers are further refined, adding 4.0mm layers and 6.0mm layers.

[0115] The specific scheme of adjustment range and adjustment rate is as follows:

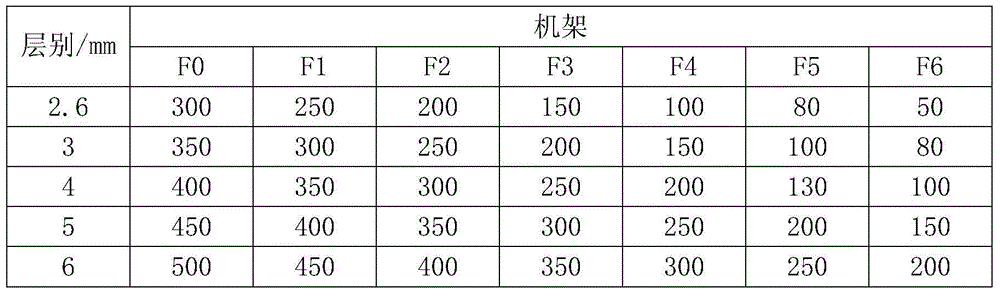

[0116] Table 1 Corresponding adjustment range / μm

[0117]

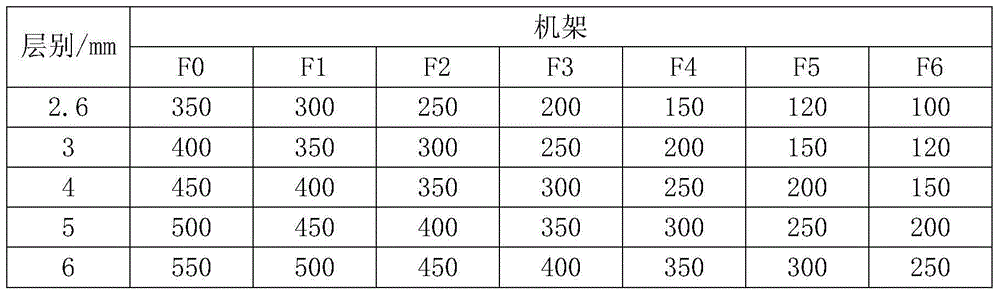

[0118] Table 2 Corresponding adjustment rate / μm / s

[0119]

[0120] The adjustment range in Control Table 1 increases by 50 μm as the carbon content (mass percentage) in the deep-drawing steel increases by 0.05%.

[0121] The adjustment rate in Control Table 2 increases by 50 μm as the carbon content (mass percentage) in the deep-drawing steel increases by 0.05%.

[0122] Through the actual verification of an enterprise, deep-drawing steel can be produced in batches, stably, and efficiently. The pass rate of deep-drawing steel has increased from 97.8% to 99.5% at present, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com