Patents

Literature

31results about How to "Guaranteed rolling stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

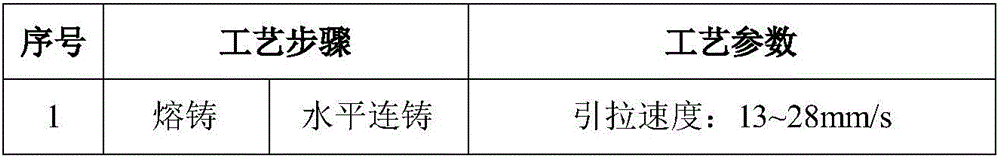

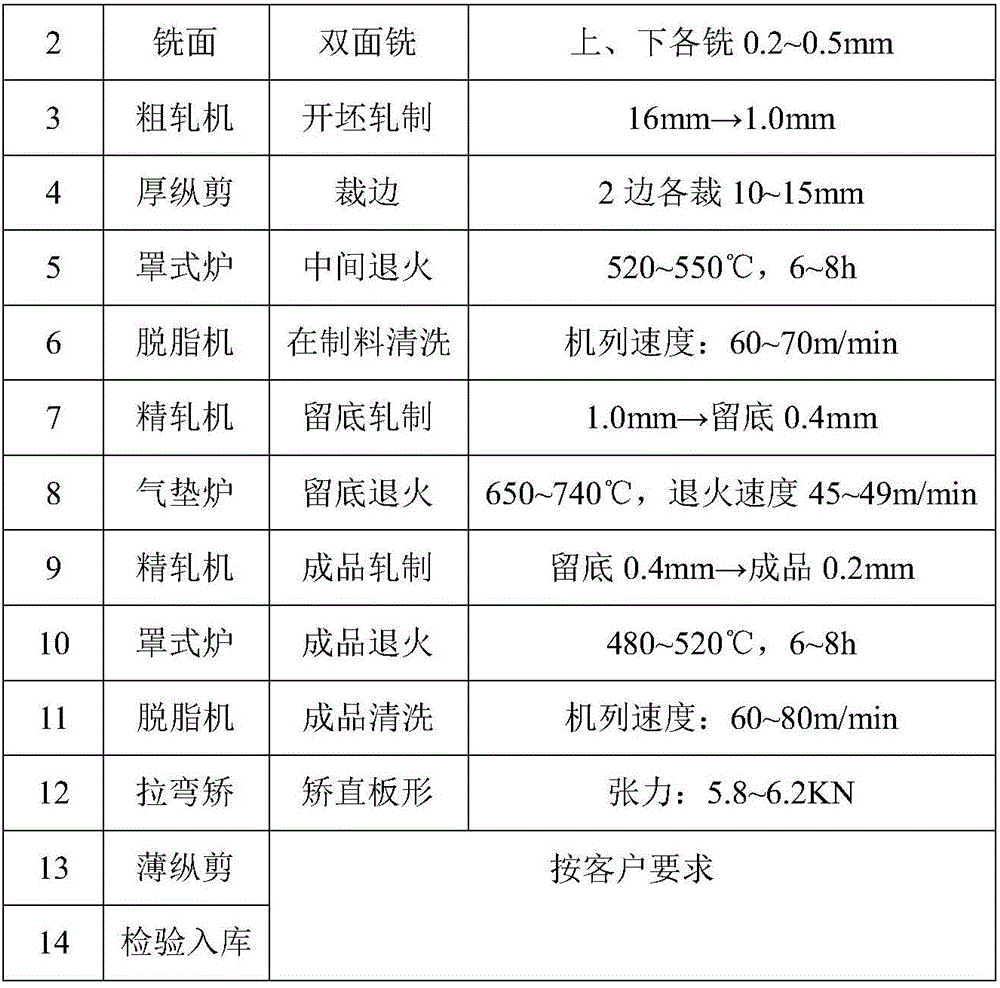

High-performance tin-phosphor bronze strip and production method thereof

The invention discloses a high-performance tin-phosphor bronze strip and a production method thereof. The high-performance tin-phosphor bronze strip comprises, by weight percent, 9% to 11% of Sn, 0.03% to 0.35% of P, not larger than 0.2% of Zn, not larger than 0.1% of Fe, not larger than 0.2% of Pb and the balance copper. Through the strict control over a casting technology, a rolling technology and an annealing technology of a tin-phosphor bronze alloy, a high-performance tin-phosphor bronze strip alloy product with the tin content ranging from 9% to 11% can be produced, and the application requirement of an IT industry and an electrommunication industry for a high-elasticity, high-strength and high-hardness copper alloy can be met.

Owner:安徽鑫科铜业有限公司

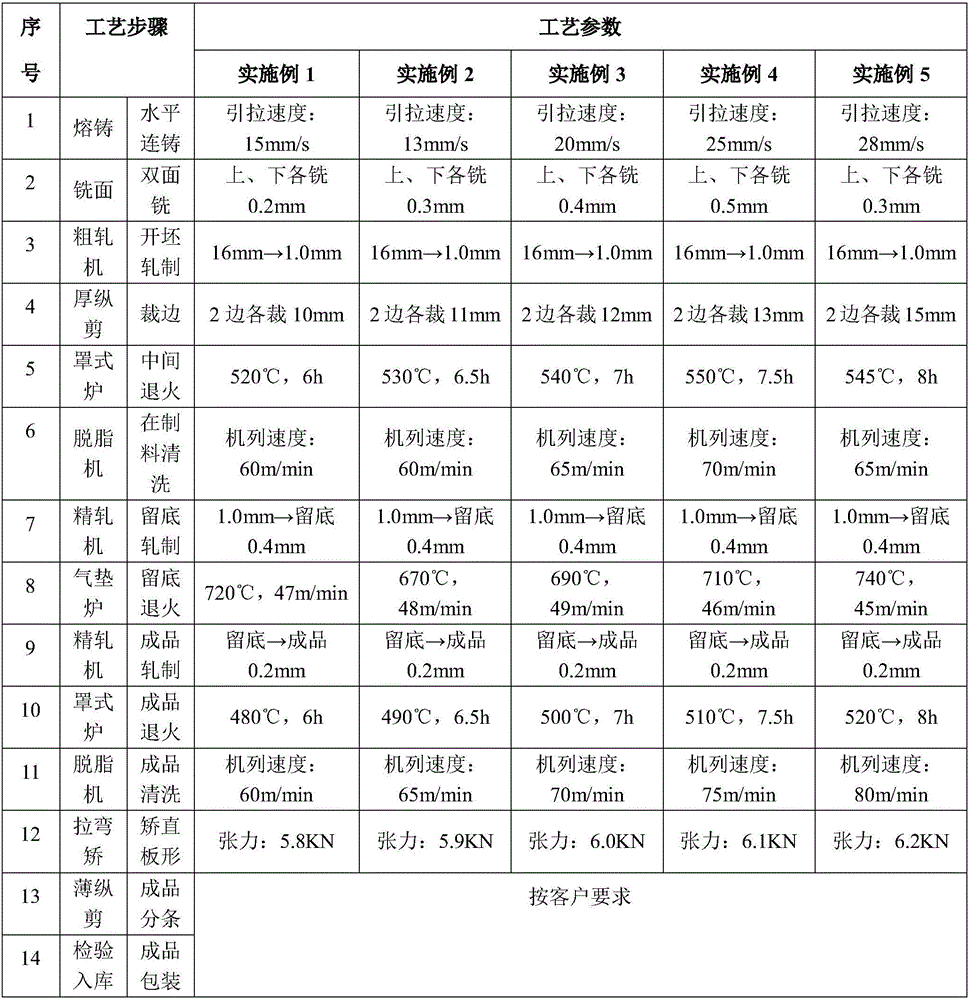

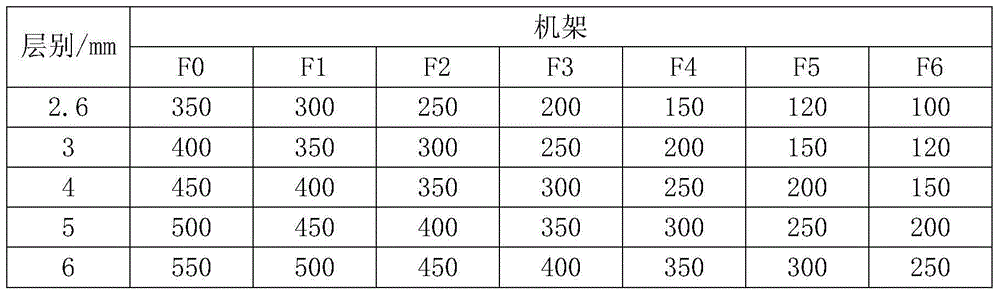

Control method of thin plate hot rolling wire finishing mill AGC system

InactiveCN104907341AHigh control precisionImprove pass rateRoll mill control devicesMetal rolling arrangementsEconomic benefitsStrip steel

The invention discloses a control method of a thin plate hot rolling wire finishing mill AGC system. According to the control method, the adjusting amplitude is subdivided according to the different thickness of the finished strip steel and different racks, and the adjusting amplitude is increased when the thickness of the finished strip steel is increased, and is decreased when the sequence number of the rack is increased. Therefore, the control concept that the adjusting amplitude of all finished strip steels at each rack of the finishing mill is a certain value is changed. The linear setting is conducted based on different thickness at each rack outlet of the racks F0, F1...Fn, the control precision of the AGC system is raised; the qualified rates of the strip steels in both thick and thin specification are increased and the production stability is improved. Therefore, the strip steels in smalllot, multi steel types and multi specification can be produced at the same time based on the order, and substantial economic benefit is realized.

Owner:SHANDONG IRON & STEEL CO LTD

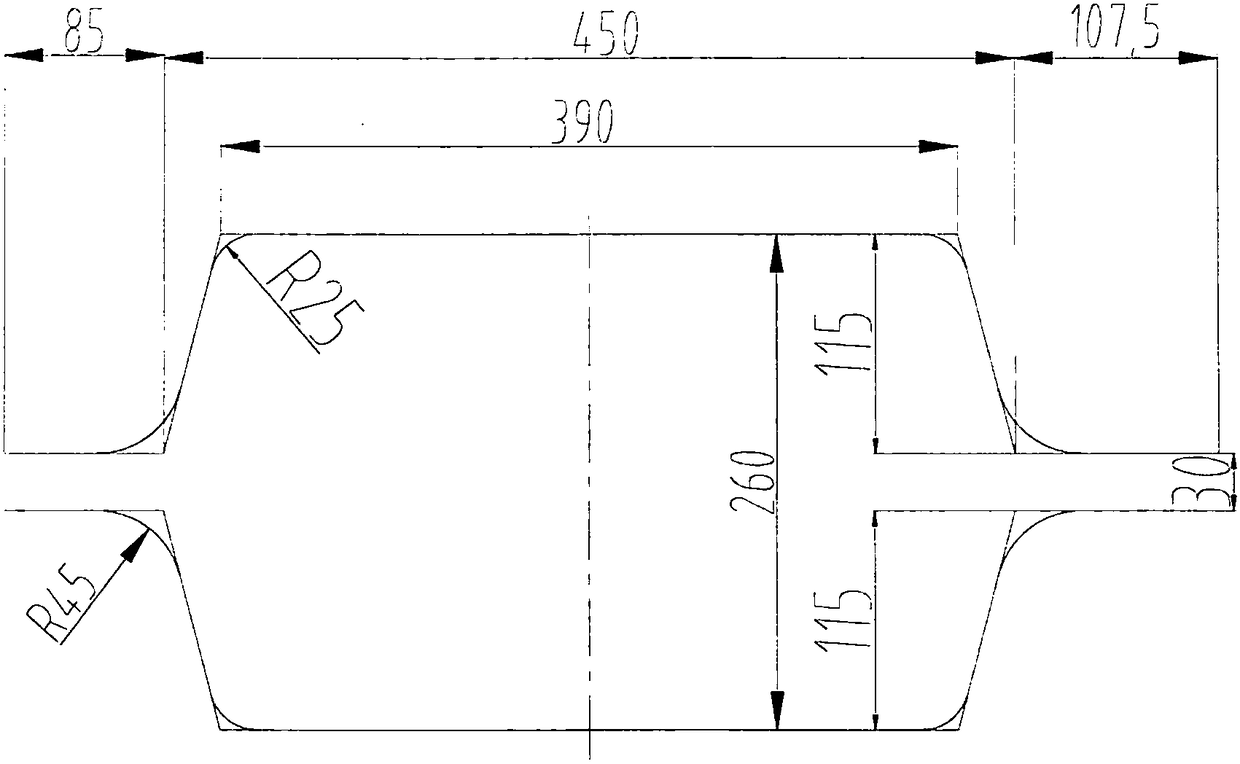

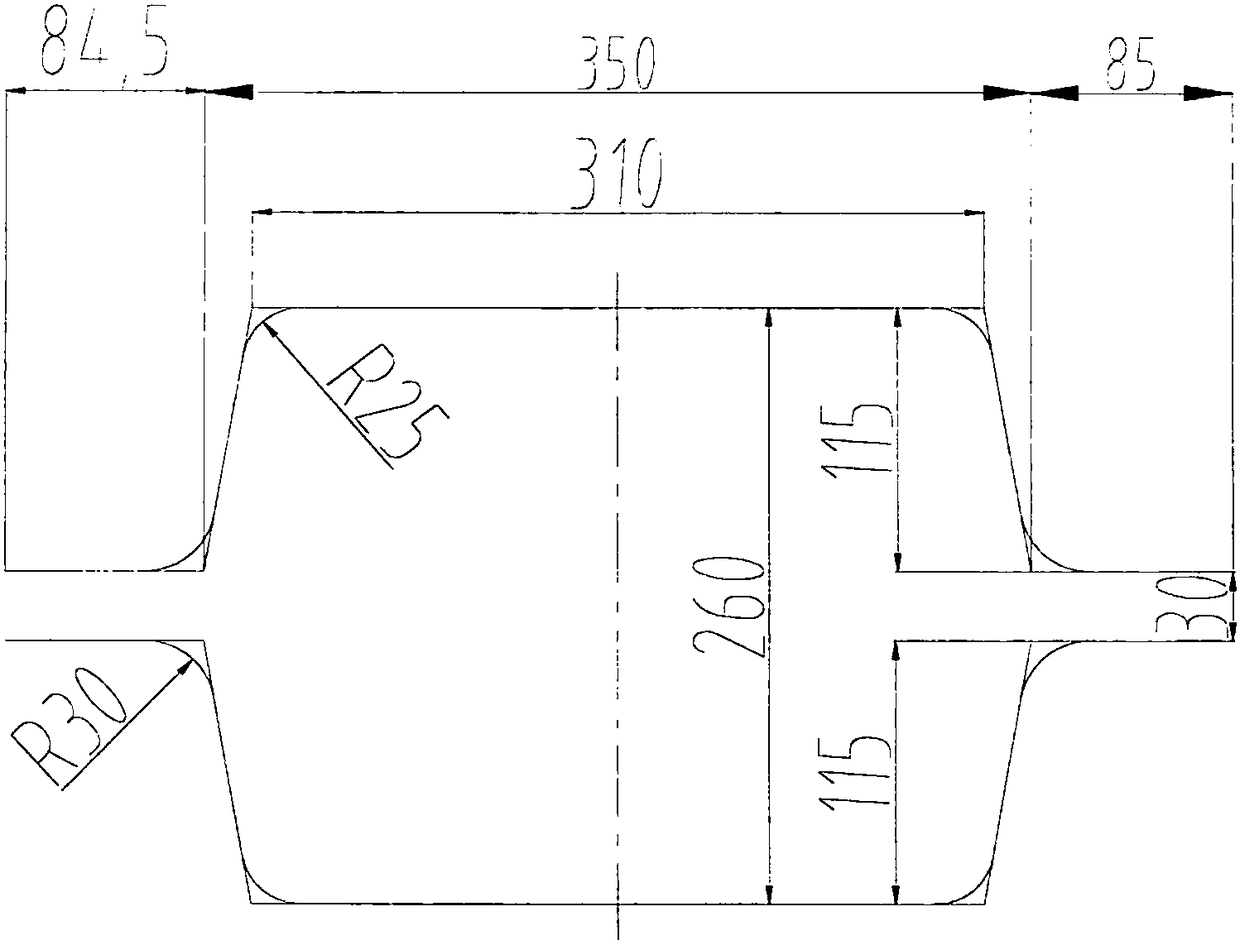

Method for producing large-specification circular blanks in rolling mode instead of forging mode

InactiveCN108356073AThe compression ratio meetsGuaranteed to burn throughRollsWork heating devicesHeating timeControl manner

The invention relates to a method for producing large-specification circular blanks in a rolling mode instead of a forging mode. The method mainly comprises the following steps that 1, rough rolling pass designing is conducted, specifically, rough-rolled holes are a combination of flat holes, box-type holes and intermediate billet finished holes; 2, firstly, the heating time before rough rolling is prolonged, secondly, the pass reduction of the front passes is made to be small while the pass reduction is increased in later passes in order to ensure rolling stability, and thirdly, the tapping temperature is improved, the number of rolling passes is reduced by adjusting the pass reduction; 3, firstly, two-radius oval holes with small long axes and short axes are adopted as finishing pass before finished products are formed, and secondly, circular holes are adopted as last pass for rolling; and 4, firstly, the position of the blanks in a furnace is adjusted, and it is ensured that the temperature difference of surfaces of the blanks is within 30 DEG C, secondly, the control mode of cooling water of a roller is adjusted, and thirdly, the assembly quality requirement is determined, quantitative management is conducted, and the assembly quality of a tool is ensured. The forging mode is replaced with the rolling mode through improvement of the rolling process and selection and designof the rolling mill passes, and the product competitiveness is improved.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Plate shape control method of high-strength steel for commercial vehicle longitudinal beam

ActiveCN112077152AReduce cooling-heating historySmall footprintTemperature control deviceProfile control deviceShape controlControl mode

Owner:武汉钢铁有限公司

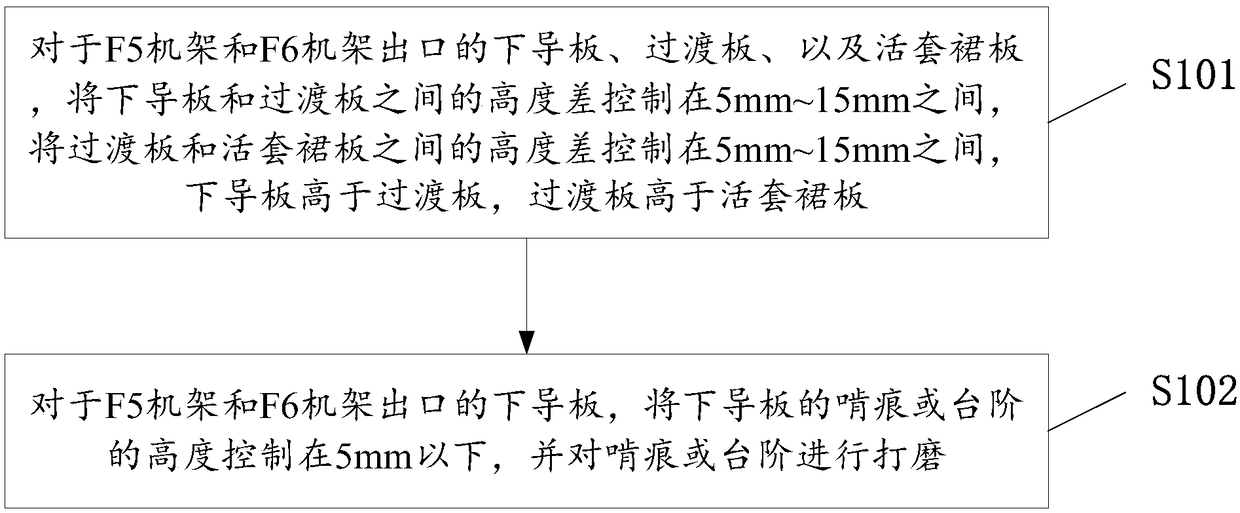

Production method controlling warping of strip steel on finishing mill

ActiveCN108435803AGuaranteed rolling stabilityEliminate flying warpingProfile control deviceMetal rolling arrangementsHeight differenceEngineering

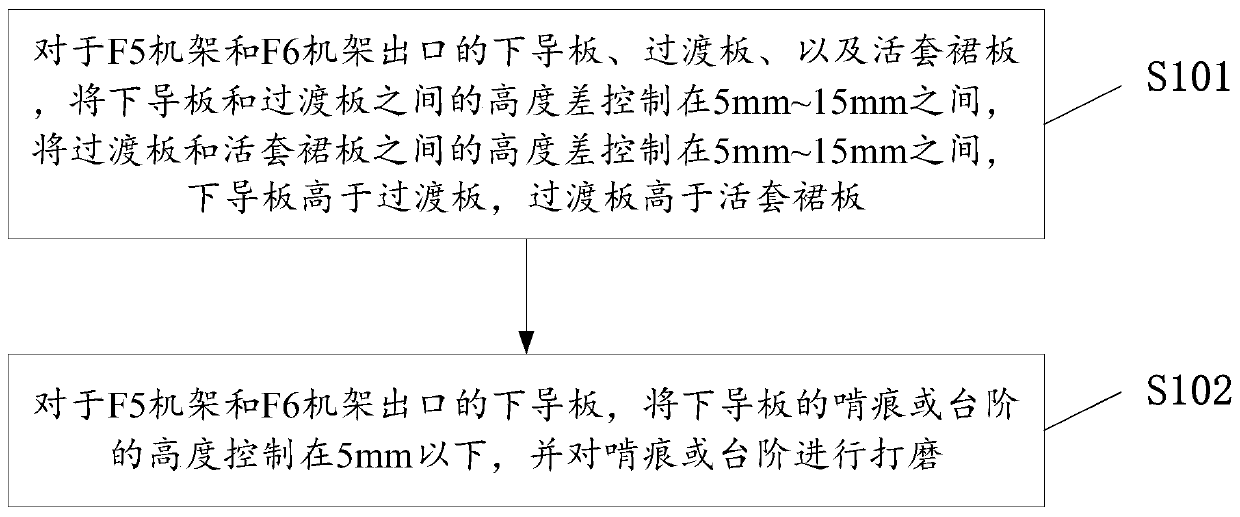

The invention discloses a production method controlling warping of strip steel on a finishing mill. The production method comprises the steps that for a lower guide plate at outlets of an F5 rack andan F6 rack of a finishing mill set, a transition plate and a movable overskirt plate, the height difference between the lower guide plate and the transition plate is controlled to be between 5 mm-15 mm, the height difference between the transition plate and the movable overskirt plate is controlled to be between 5 mm-15 mm, the lower guide plate is higher than the transition plate, and the transition plate is higher than the movable overskirt plate; and for the lower guide plate at the outlets of the F5 rack and the F6 rack, the height of the gnawing marks or steps of the lower guide plate iscontrolled to be lower than 5 mm, and the gnawing marks or the steps are polished. Through the production method, stable and smooth operation of thin-gauge strip steel in the finish rolling strip penetrating process can be ensured, the problem of warping of the head of the strip steel between the finish rolling racks and at the finish rolling outlet is avoided completely, meanwhile rolling stability of the strip steel is ensured, and the risk of steel piling accidents is reduced.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

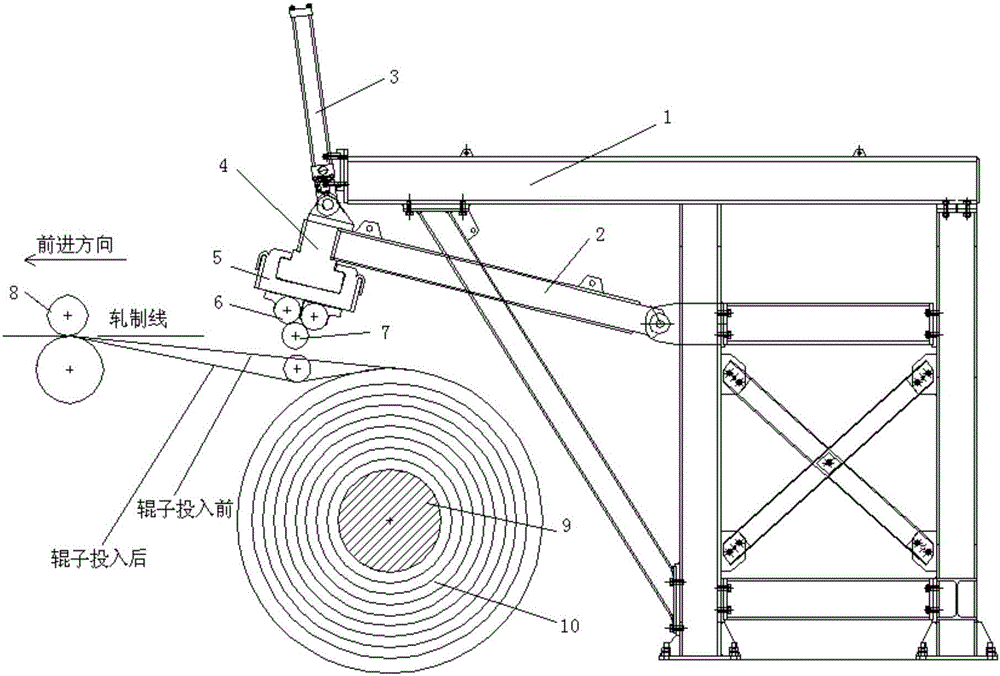

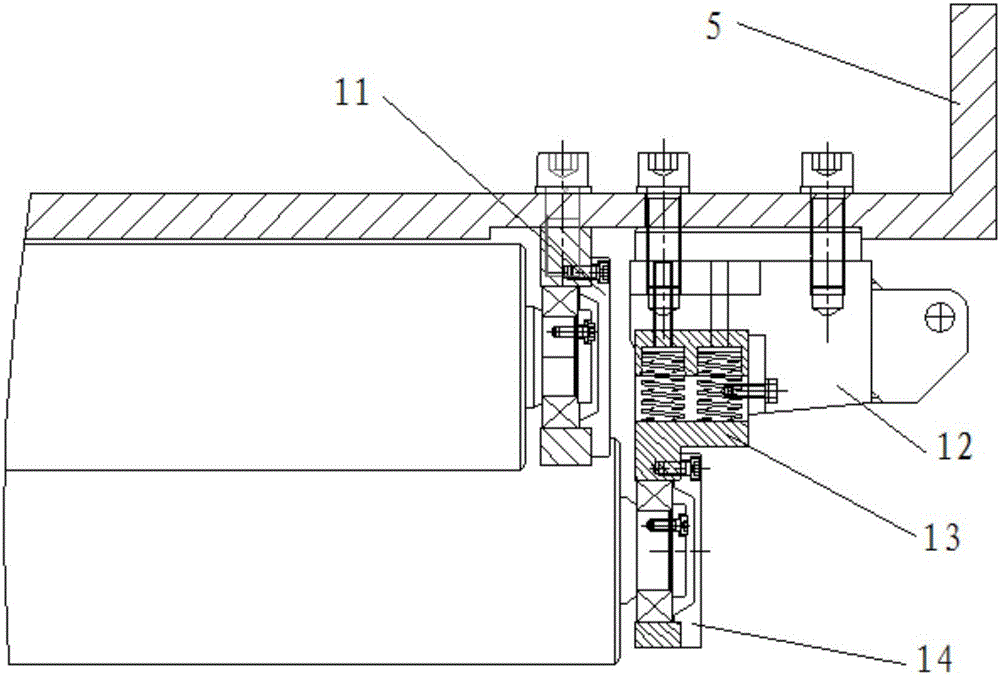

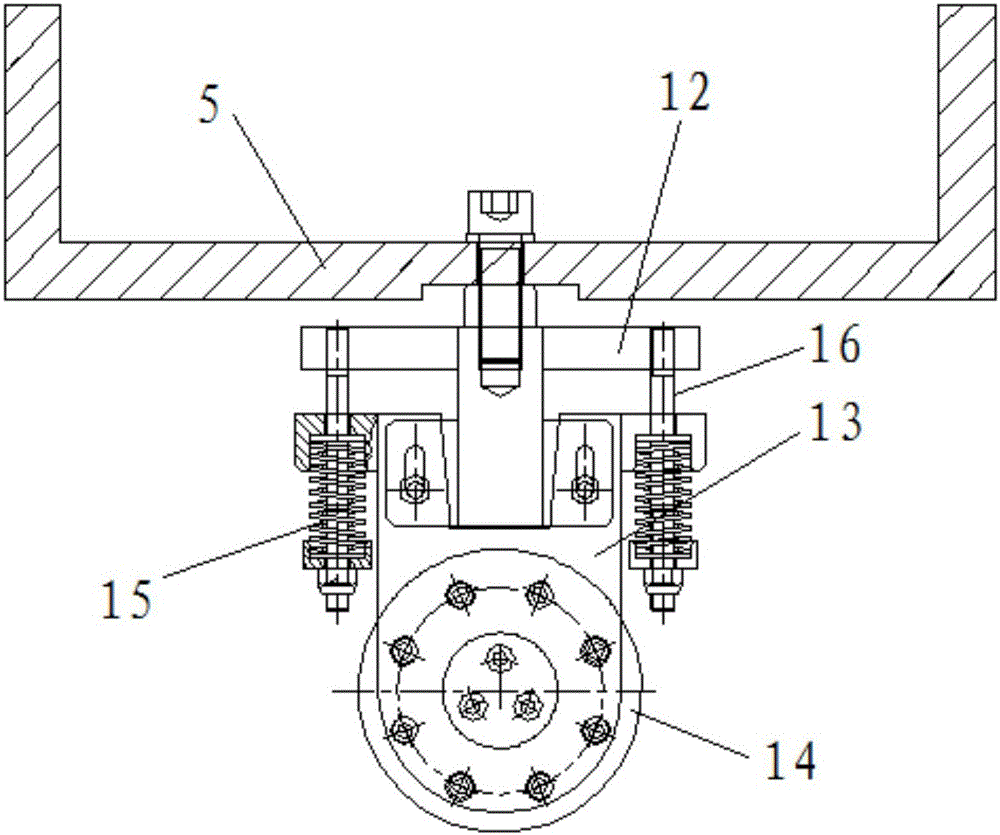

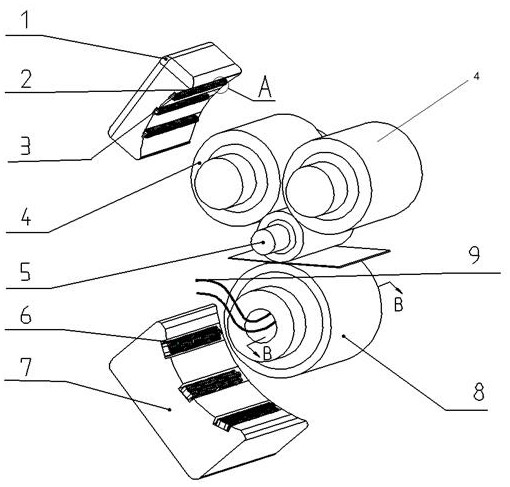

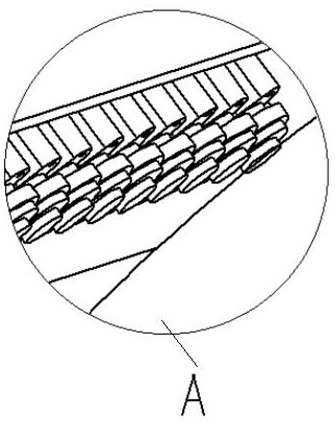

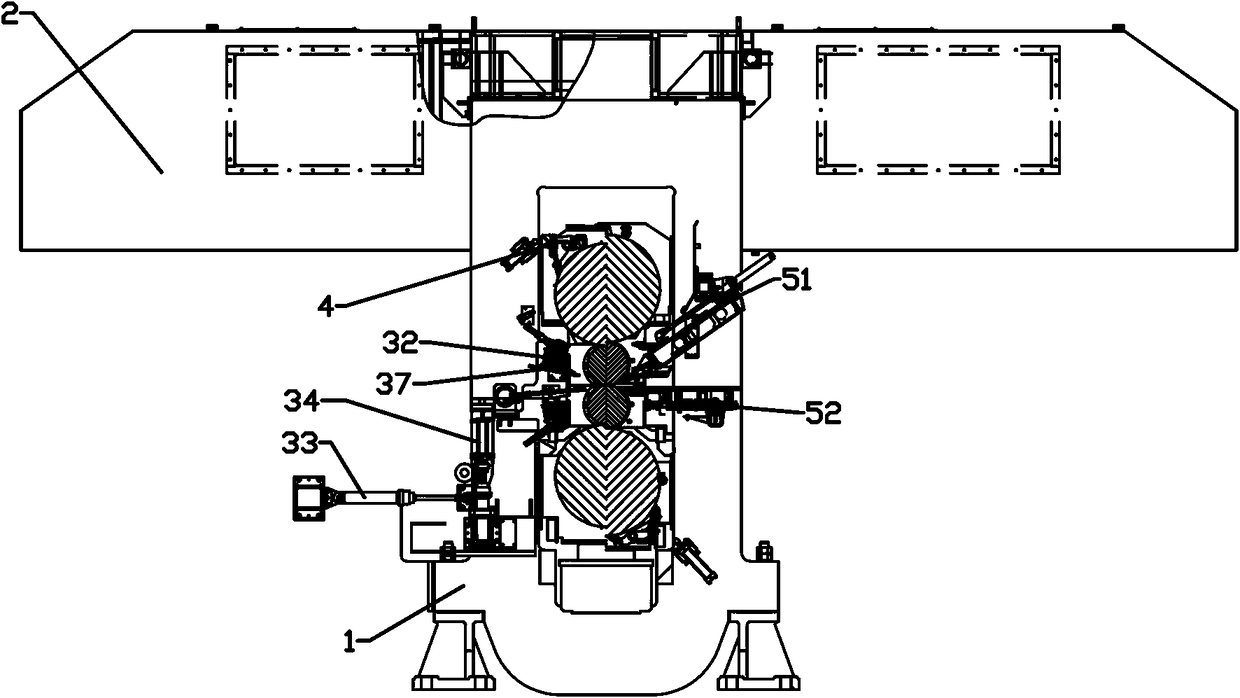

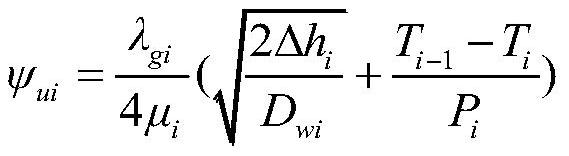

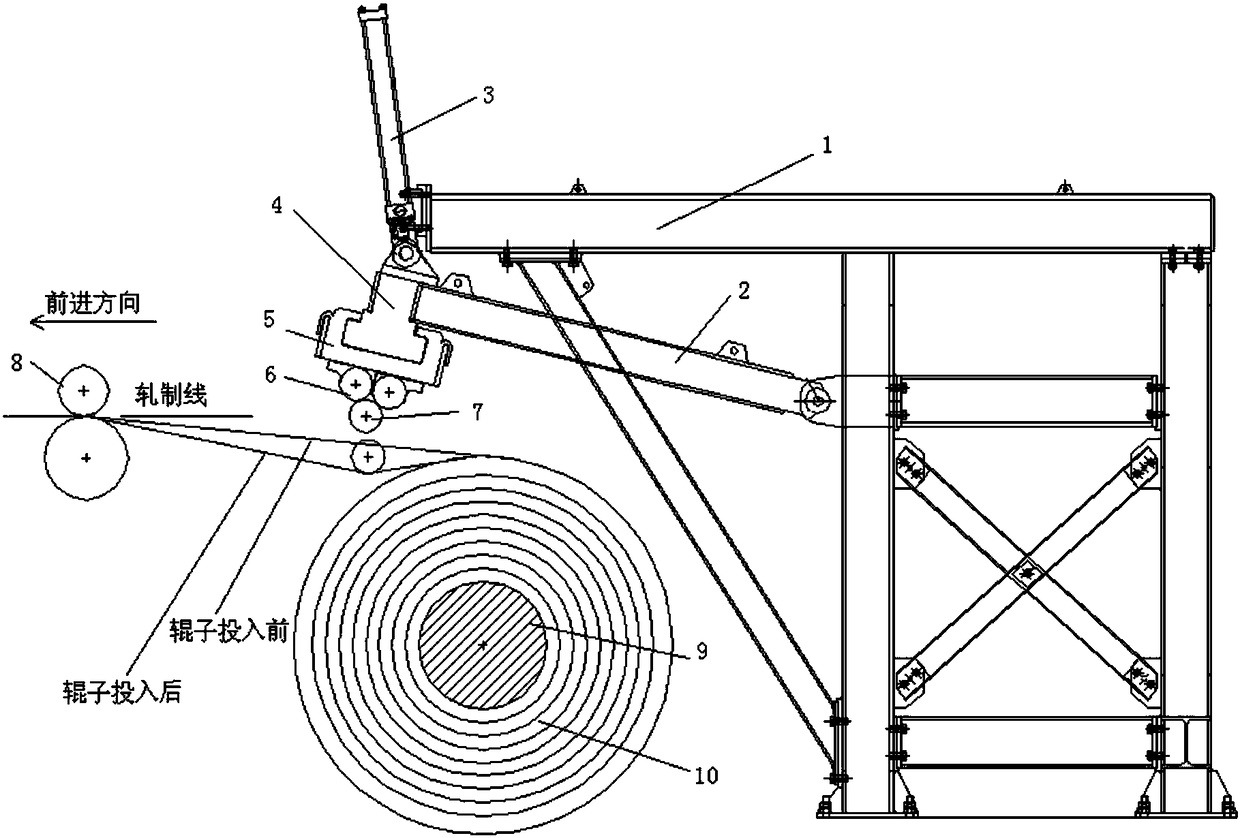

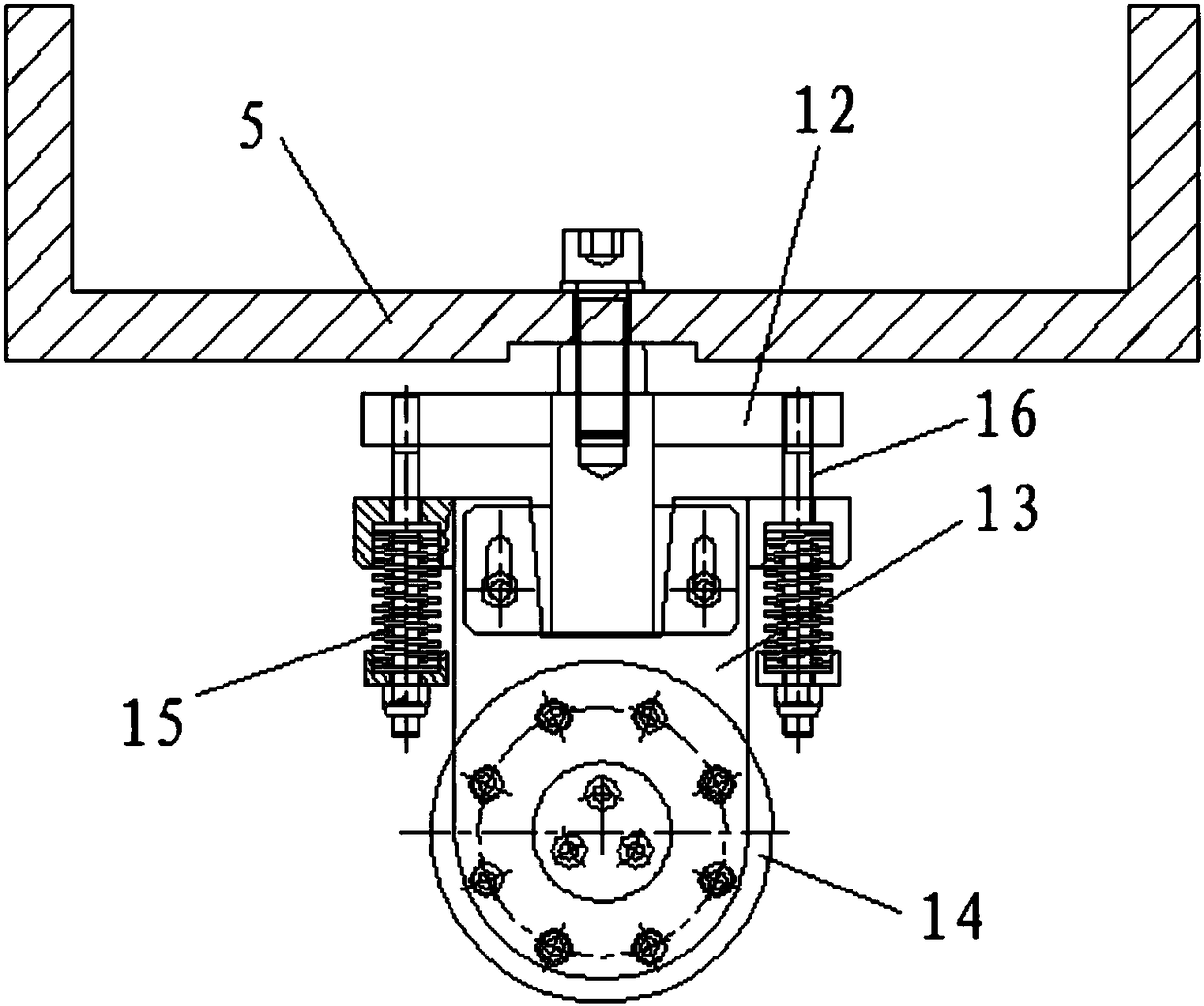

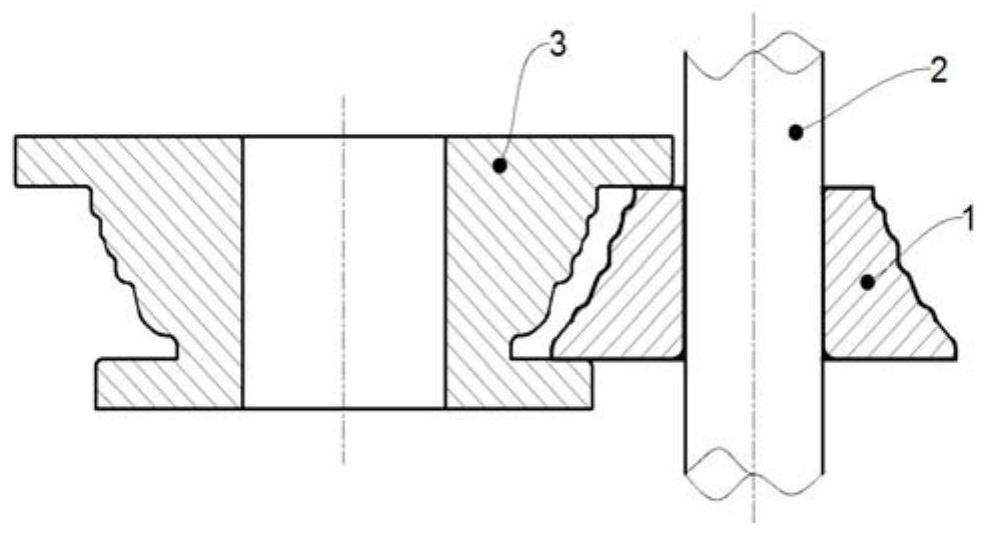

Anti-rolling-fracture roller of hot rolling temper mill and application method of anti-rolling-fracture roller

ActiveCN106001177AQuality improvementImprove performanceMetal rolling arrangementsWork rollWave shape

The invention relates to an anti-rolling-fracture roll of a hot rolling temper mill. The anti-rolling-fracture roll comprises at least two supporting rolls and work rolls. The at least two supporting rolls are arranged in two rows side by side and rotationally arranged on a movable base through a first bearing assembly. The work rolls are closely attached to the lower portions of the two rows of supporting rolls and rotationally arranged on the movable base through a second bearing assembly. A bearing block of the second bearing assembly is an elastic bearing block. The invention further relates to an application method of the anti-rolling-fracture roll of the hot rolling temper mill. The method comprises the following steps that a steel roll is coiled on a coiling block of an uncoiling machine, the steel roll is opened, and strip steel forwards penetrates a pinch roll; when the strip steel is pressed by the pinch roll, a drive device downwards presses the work rolls to the part, between the uncoiling machine and the pinch roll, of the strip steel; and when the tail of the innermost ring of the steel roll leaves the coiling block of the uncoiling machine, the drive device elevates the work rolls. The anti-rolling-fracture roll is reliable in structure and capable of absorbing vibration and impacts brought by wave shapes of fed materials, the rolling stability is guaranteed, and the surface quality and performance of the strip steel are improved.

Owner:BEIJING SHOUGANG CO LTD

Plate shape control method for steel for hot-rolled high-strength stirring tank body

ActiveCN112108527AReduce cooling-heating historySmall footprintTemperature control deviceRollsProduction lineTemperature control

Owner:武汉钢铁有限公司

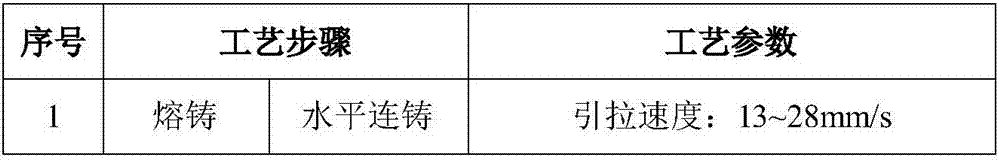

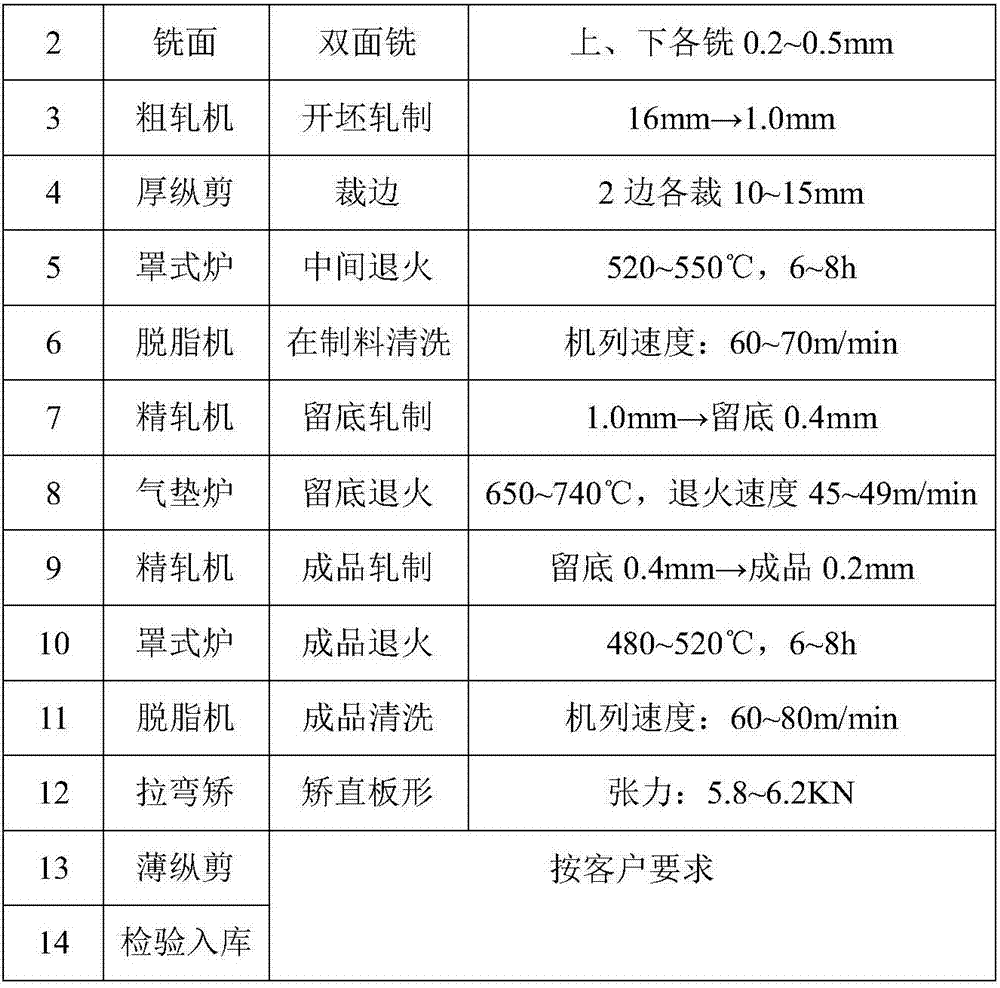

A high-performance tin phosphor bronze strip and its production method

The invention discloses a high-performance tin-phosphor bronze strip and a production method thereof. The high-performance tin-phosphor bronze strip comprises, by weight percent, 9% to 11% of Sn, 0.03% to 0.35% of P, not larger than 0.2% of Zn, not larger than 0.1% of Fe, not larger than 0.2% of Pb and the balance copper. Through the strict control over a casting technology, a rolling technology and an annealing technology of a tin-phosphor bronze alloy, a high-performance tin-phosphor bronze strip alloy product with the tin content ranging from 9% to 11% can be produced, and the application requirement of an IT industry and an electrommunication industry for a high-elasticity, high-strength and high-hardness copper alloy can be met.

Owner:安徽鑫科铜业有限公司

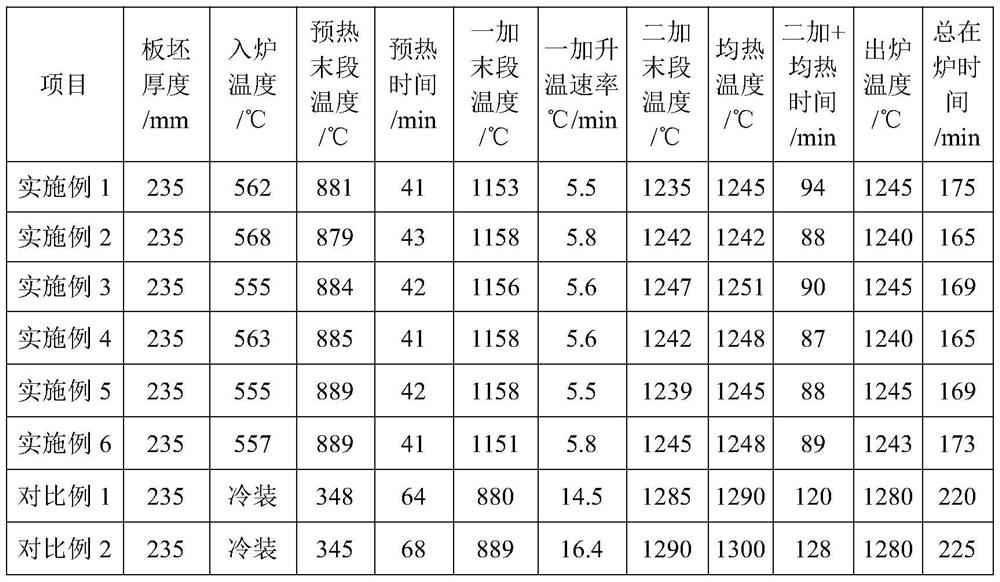

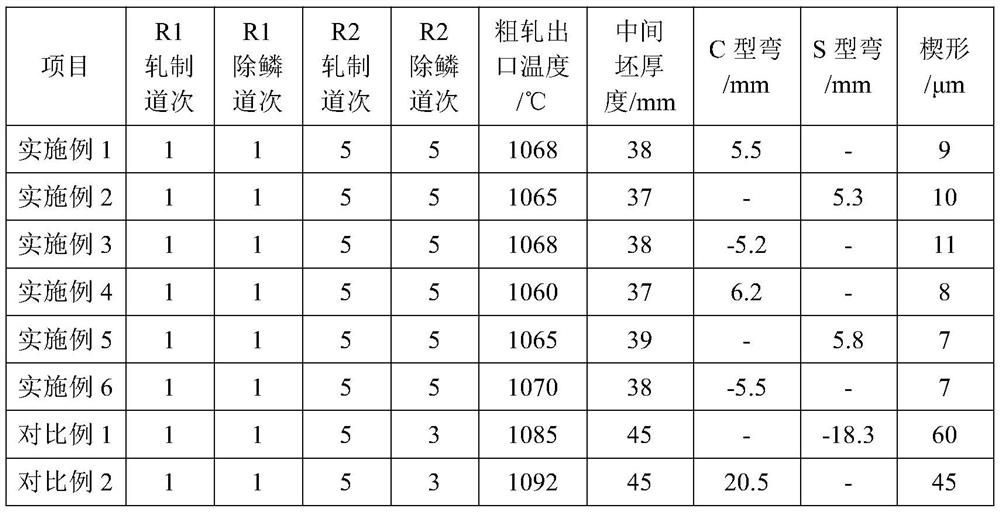

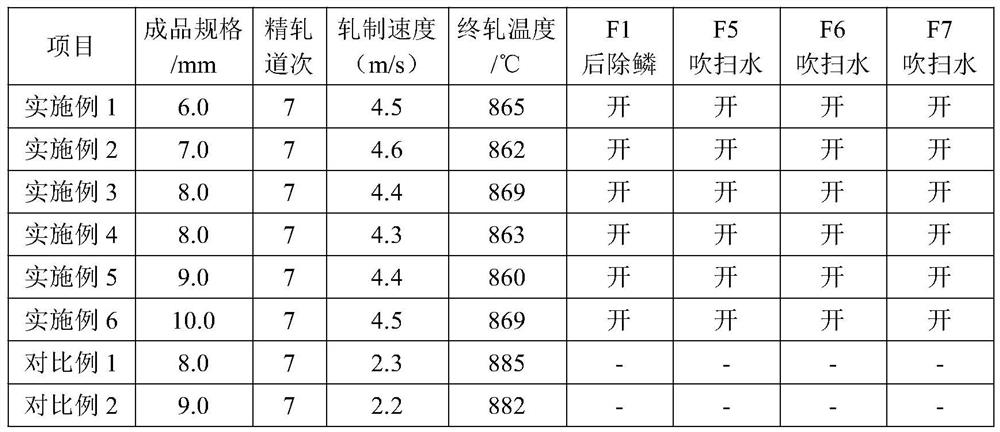

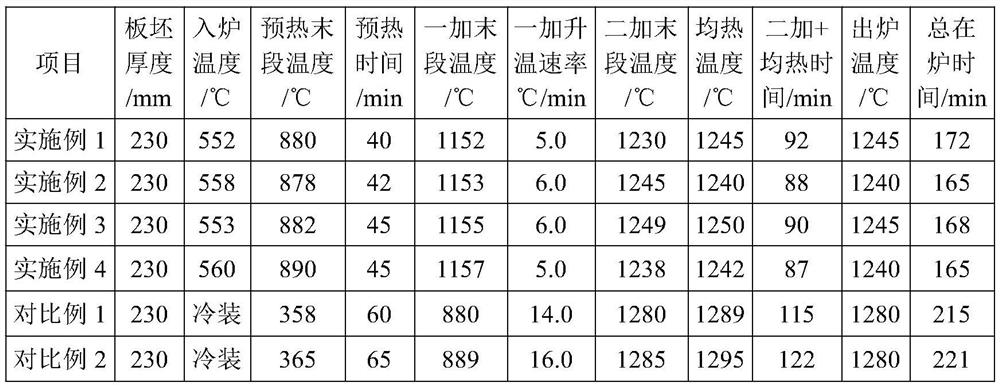

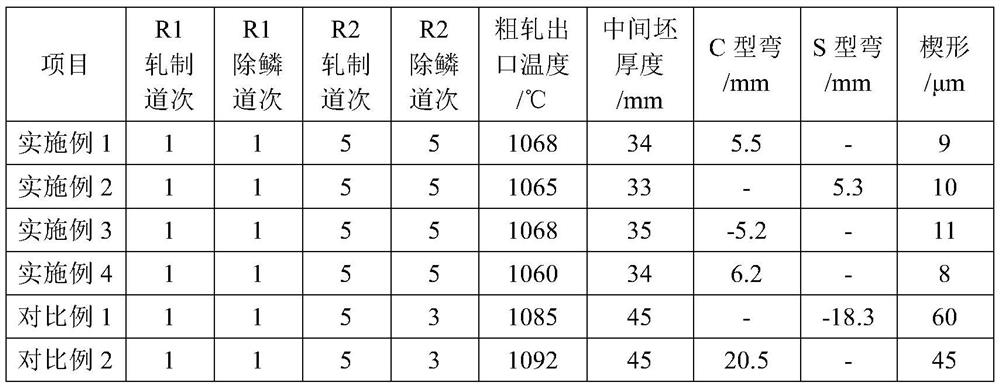

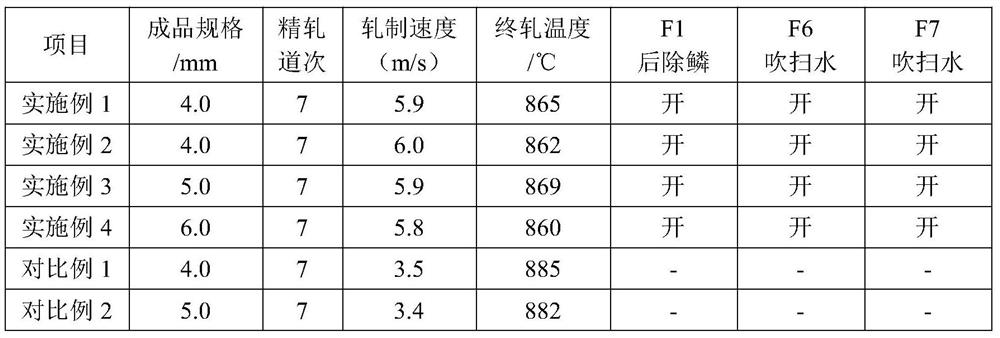

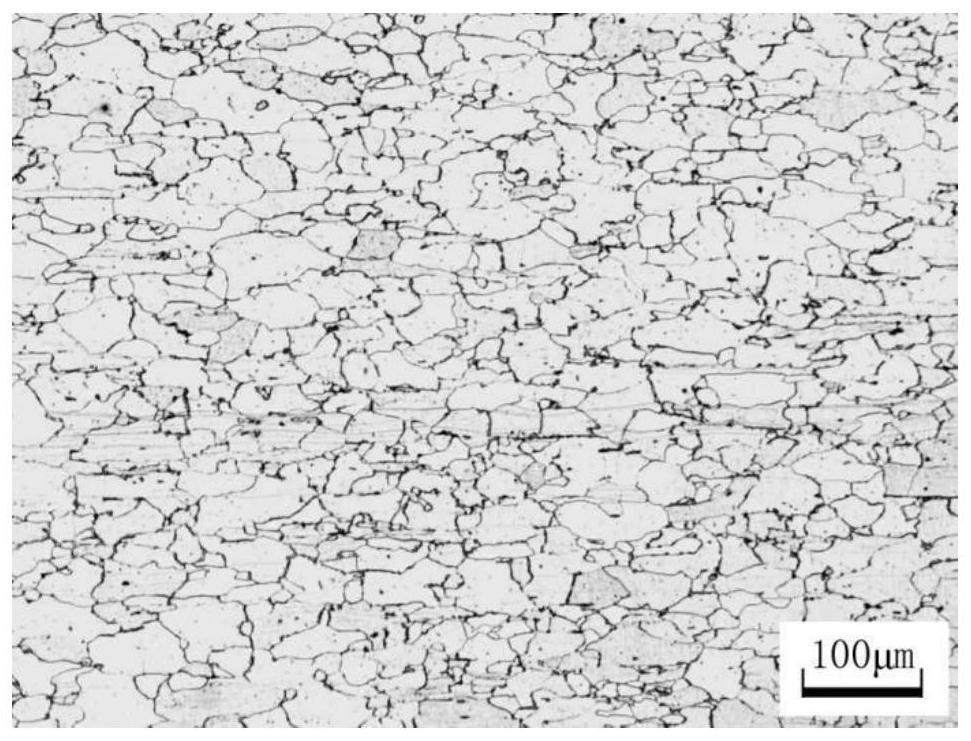

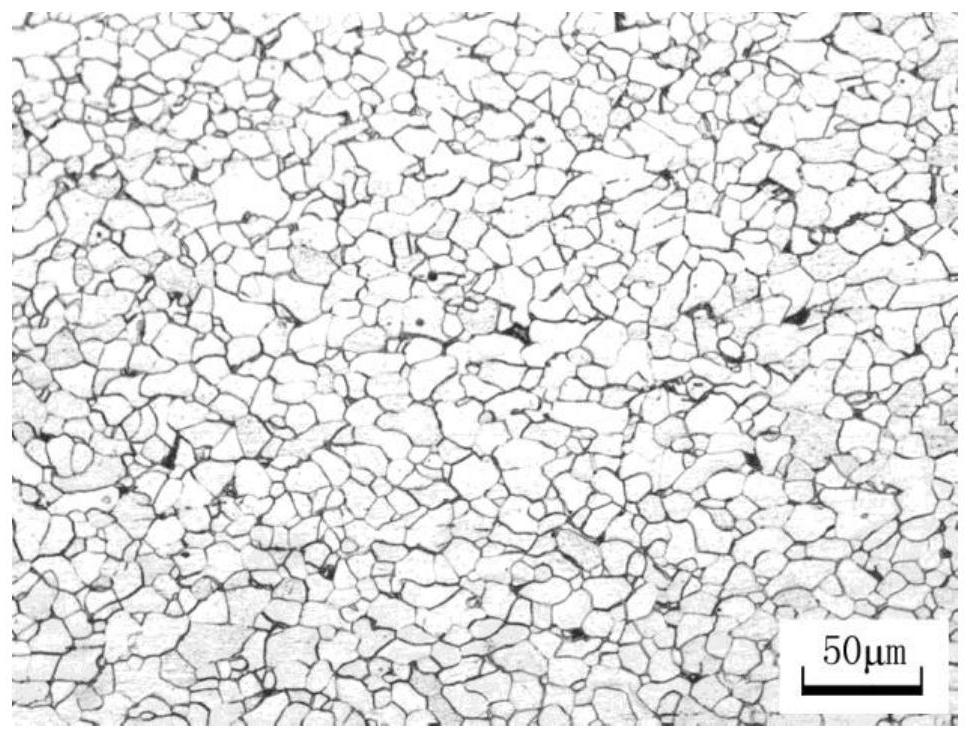

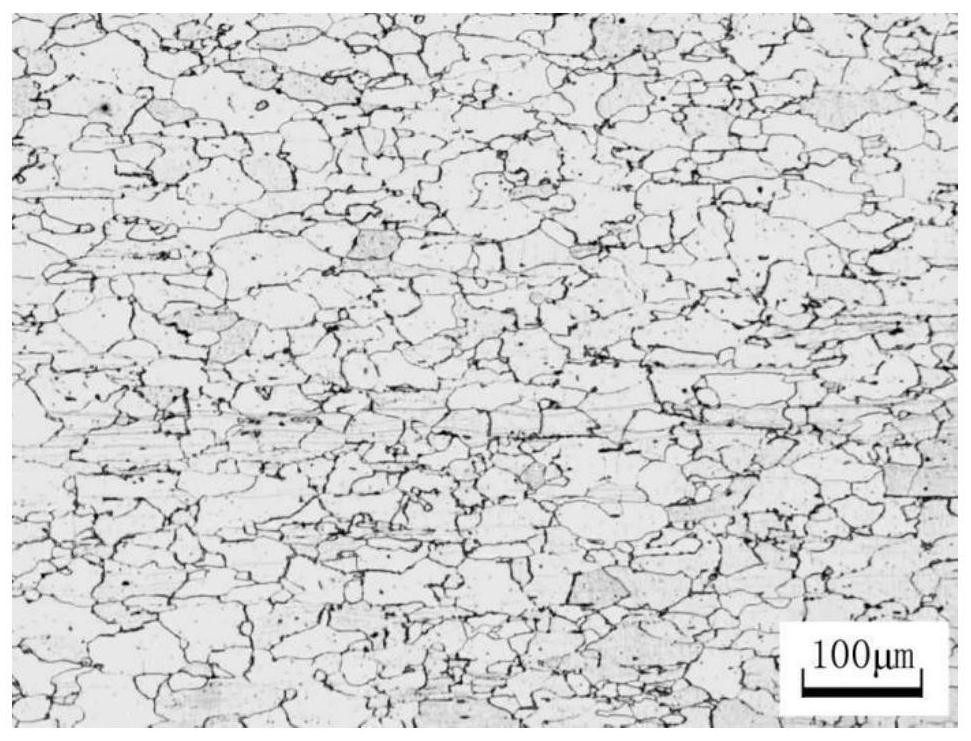

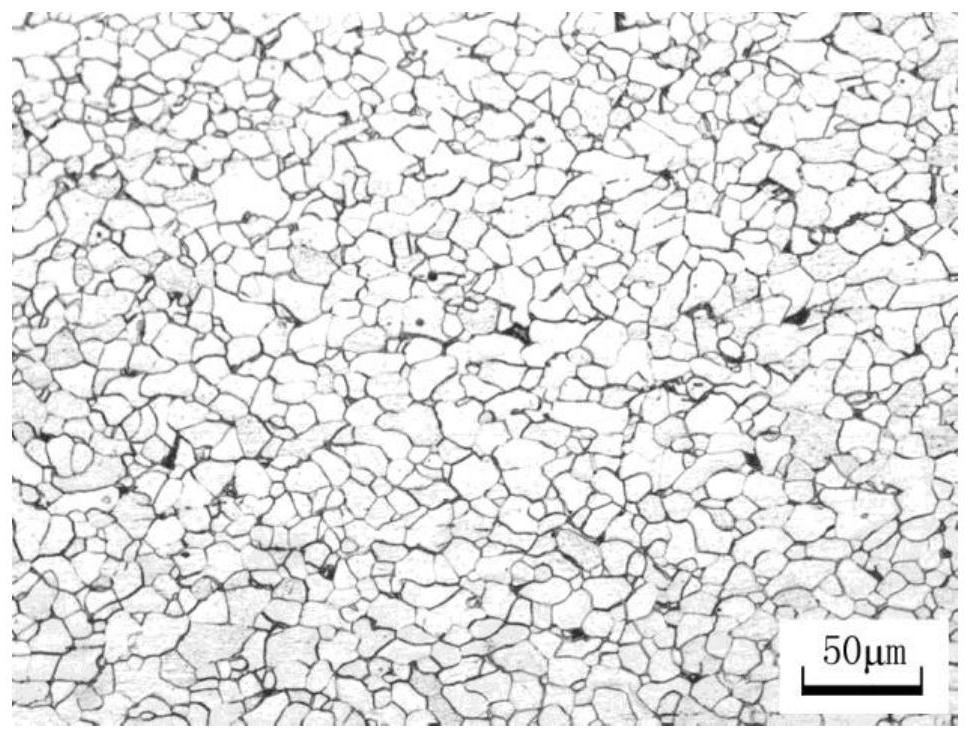

Production method for rolling production of thin-gauge low-carbon steel from ferrite on CSP production line

ActiveCN111633028ARapid rollingGuaranteed rolling stabilityRoll force/gap control deviceTemperature control deviceProduction lineUltimate tensile strength

The invention relates to a production method for rolling production of thin-gauge low-carbon steel from ferrite on a CSP production line. The production method comprises the five steps of soaking, dephosphorization, finish rolling, coiling and insulation cover slow cooling. In the absence of equipment of a rough rolling rack and an intermediate water cooling device, production of a thin-gauge high-precision hot-rolled product of 1.0-2.0 mm is achieved; product properties are that the yield strength is 180-280 MPa, the tensile strength is 300-380 MPa, the elongation is larger than or equal to 38%, the yield ratio is 0.55-0.75, and the thickness tolerance is controlled to be within the range of + / - 30 [mu]m; and the properties and the thickness precision reach the level of a cold-rolled product of the same gauge, and 'cold-rolling replaced with hot-rolling' can be achieved.

Owner:武汉钢铁有限公司

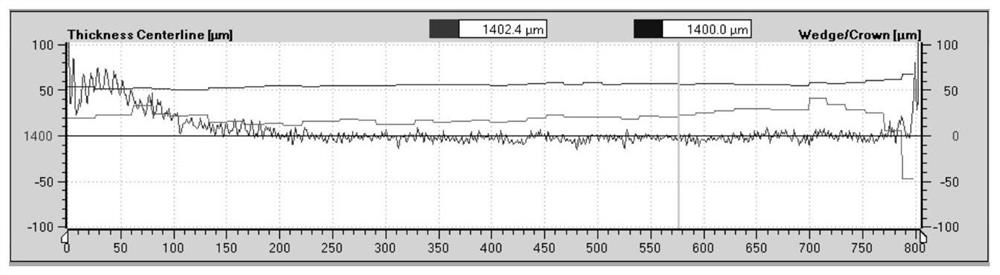

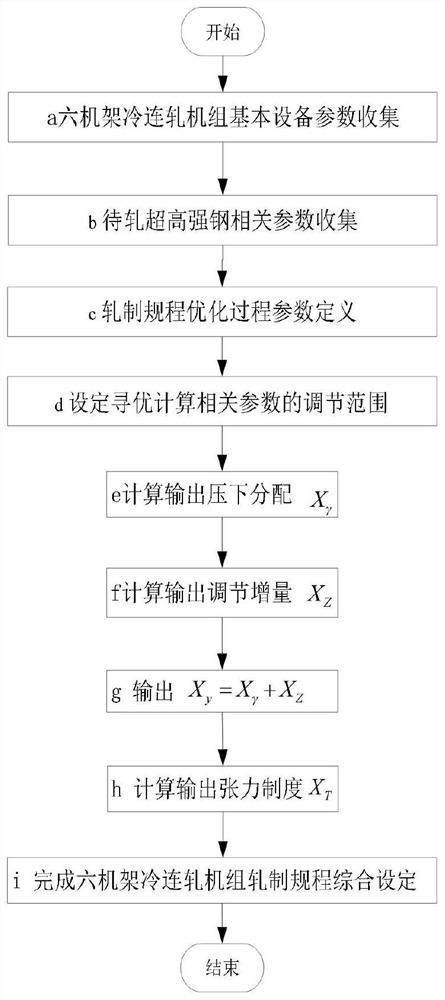

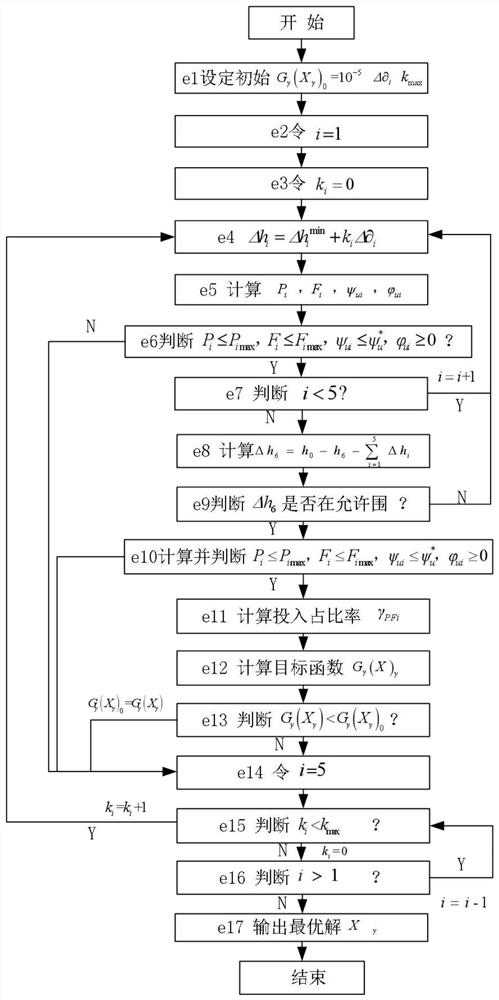

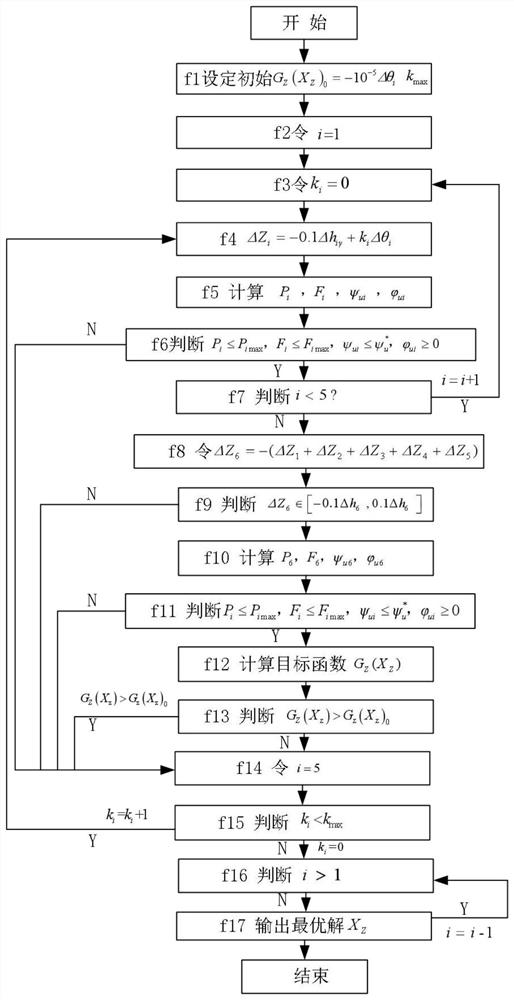

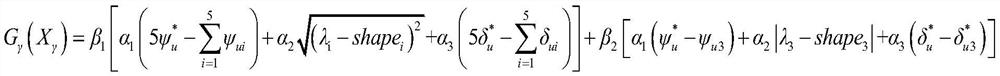

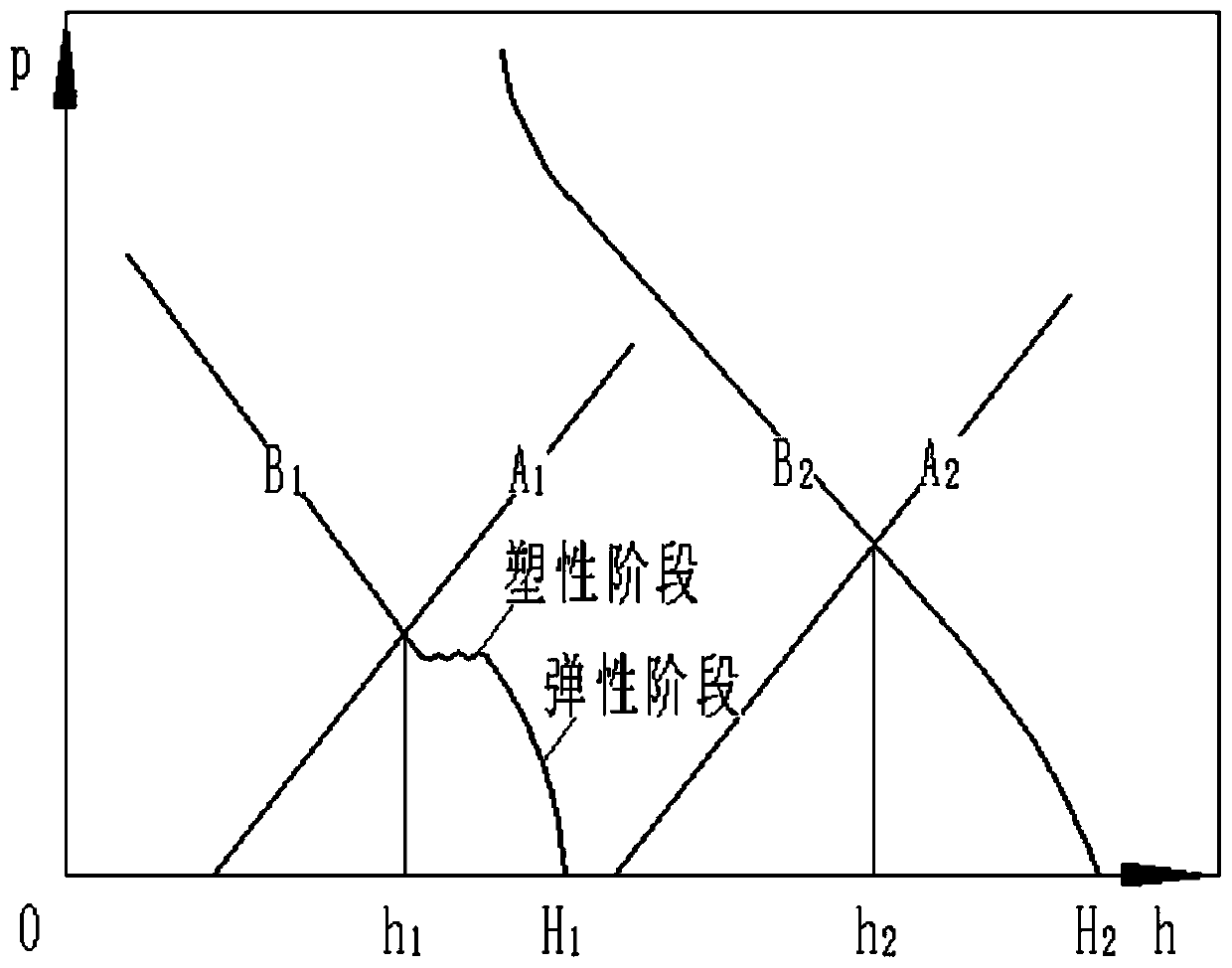

Comprehensive optimization setting method for rolling schedule of ultrahigh-strength steel of six-rack cold continuous rolling unit

PendingCN113505452AGuaranteed rolling stabilityAbility to invest evenlyGeometric CADSpecial data processing applicationsContinuous rollingIndustrial engineering

The invention discloses a comprehensive optimization setting method for a rolling schedule of ultrahigh-strength steel of a six-rack cold continuous rolling unit, and the method comprises the following steps: firstly, collecting basic equipment parameters of the six-rack cold continuous rolling unit and related parameters of ultrahigh-strength steel to be rolled; then calculating a reduction distribution result X gamma, a reduction distribution fine adjustment result XZ, a reduction distribution optimal solution Xy and a tension system optimal solution XT based on capability input ratio homogenization of each rack device; and finally, completing the comprehensive setting of the rolling schedule according to the obtained optimal data. When the method disclosed by the invention is applied, the capability of rolling mill equipment of each rack is ensured to be in a relatively uniform state, and the respective advantages and characteristics of a small-roller-diameter rolling mill and a conventional rolling mill are fully exerted, so that the pressing distribution and tension system stable complementary type rolling schedule comprehensive optimization setting method in the ultra-high-strength steel cold continuous rolling process is formed, the utilization optimization of the comprehensive rolling capacity of the unit is realized, and the rolling stability and the finished product quality in the cold continuous rolling process of the ultrahigh-strength steel are guaranteed.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD

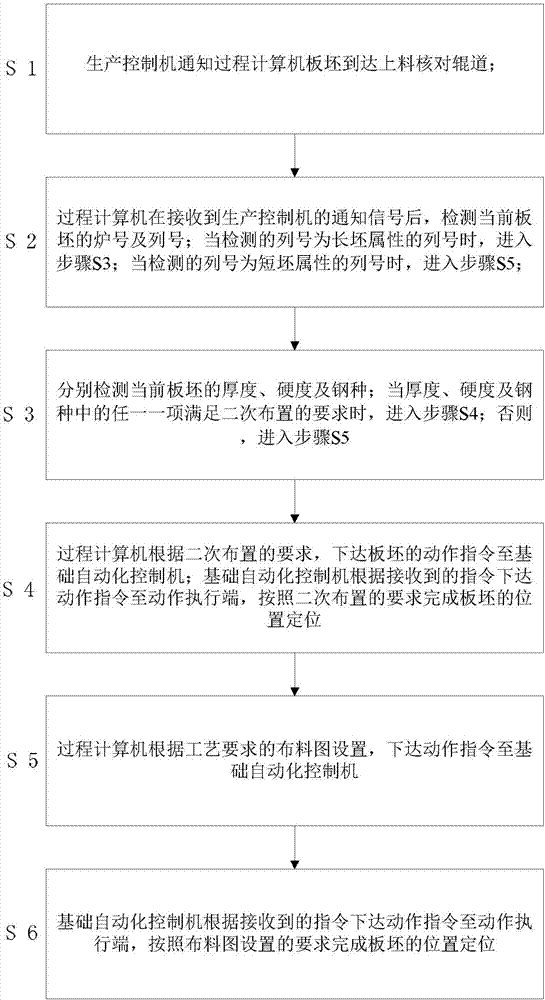

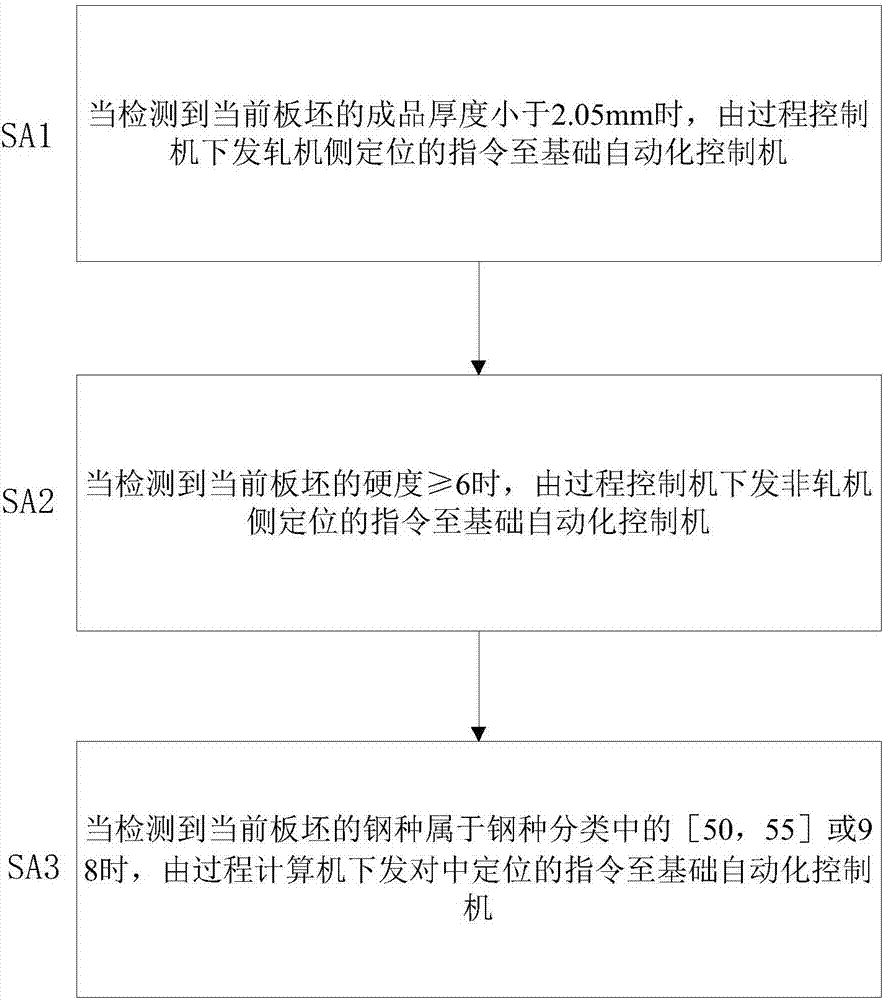

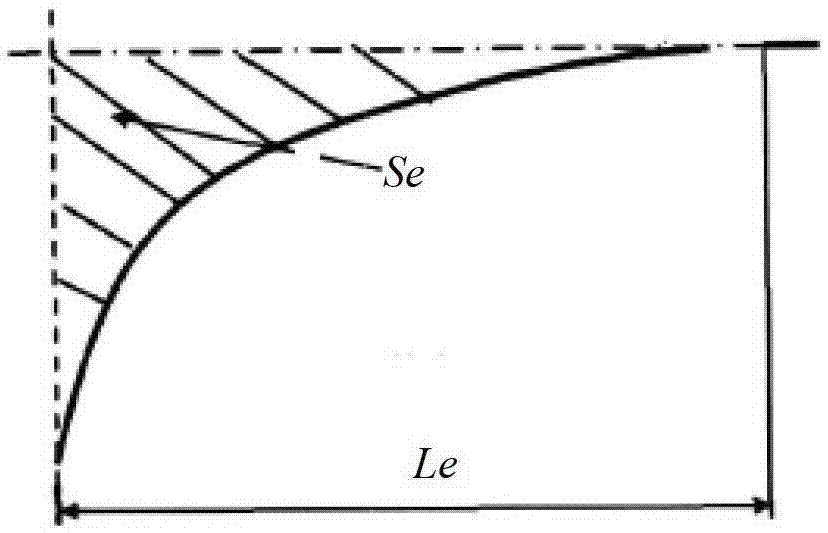

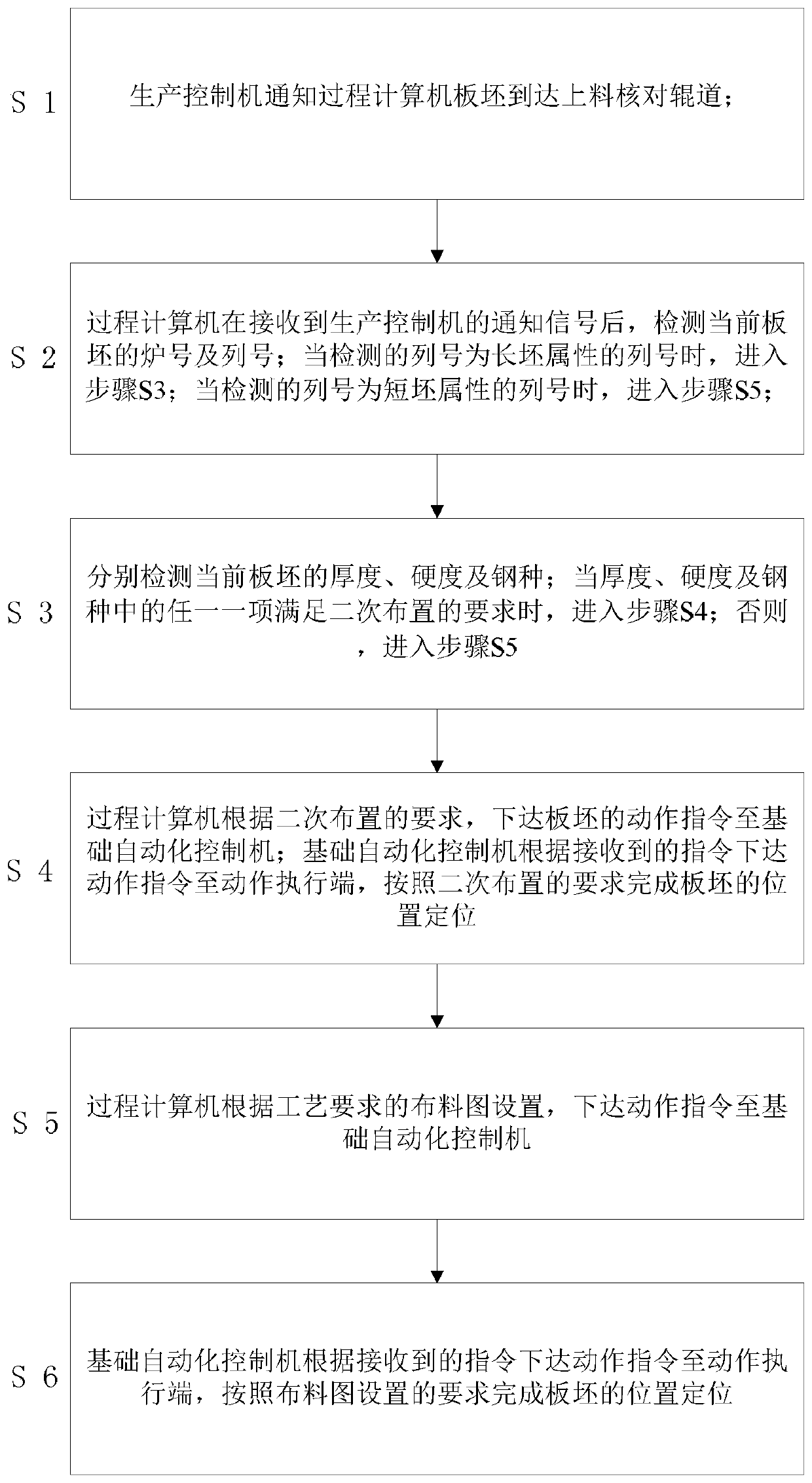

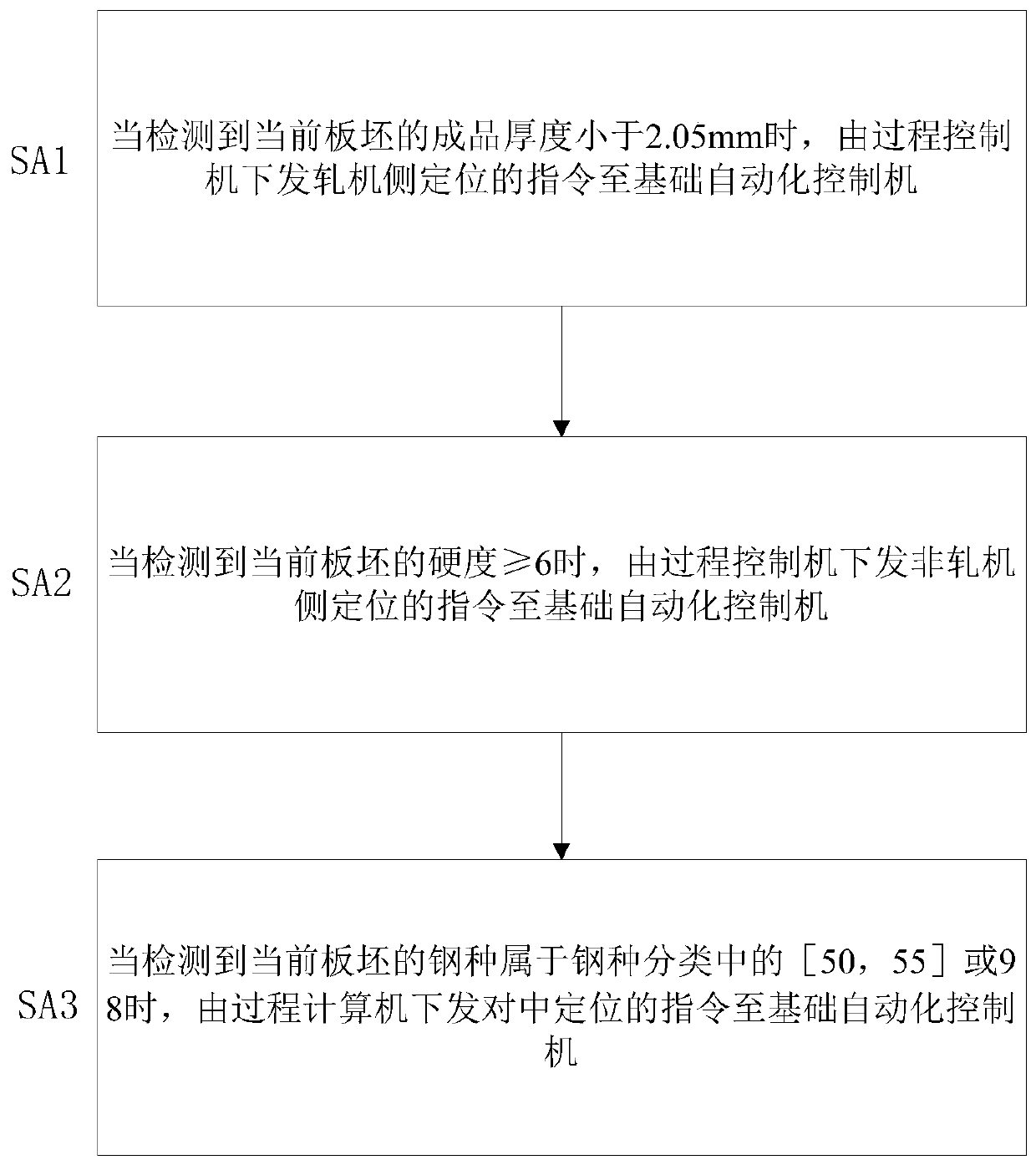

Method for positioning for plate blank distribution according to steel type and finished product specification

ActiveCN108004389ASolve the problem of rolling instabilityPrevent deviationFurnace typesHeat treatment process controlHardnessHeating furnace

The invention discloses a method for positioning for plate blank distribution according to the steel type and the finished product specification. The method is characterized in that plate blanks reaching a feeding checking roller way are subjected to secondary position positioning based on three indexes of thickness, hardness and steel type of the plate blank before entering corresponding rollingpositions according to a distribution graph meeting process requirements. According to the method, the secondary position positioning mode is adopted for three situations correspondingly, the positions of the plate blanks are further refined on the basis of previously following the distribution graph meeting the process requirements so that the parameters such as the different steel types and thefinished product specifications can be flexibly adapted to the plate blank distribution of a plate blank furnace of a heating furnace.

Owner:BAOSHAN IRON & STEEL CO LTD

A production method for controlling the warpage of strip steel in the finishing mill

ActiveCN108435803BGuaranteed rolling stabilityEliminate flying warpingMetal rolling arrangementsProfile control deviceStructural engineeringStrip steel

The invention discloses a production method controlling warping of strip steel on a finishing mill. The production method comprises the steps that for a lower guide plate at outlets of an F5 rack andan F6 rack of a finishing mill set, a transition plate and a movable overskirt plate, the height difference between the lower guide plate and the transition plate is controlled to be between 5 mm-15 mm, the height difference between the transition plate and the movable overskirt plate is controlled to be between 5 mm-15 mm, the lower guide plate is higher than the transition plate, and the transition plate is higher than the movable overskirt plate; and for the lower guide plate at the outlets of the F5 rack and the F6 rack, the height of the gnawing marks or steps of the lower guide plate iscontrolled to be lower than 5 mm, and the gnawing marks or the steps are polished. Through the production method, stable and smooth operation of thin-gauge strip steel in the finish rolling strip penetrating process can be ensured, the problem of warping of the head of the strip steel between the finish rolling racks and at the finish rolling outlet is avoided completely, meanwhile rolling stability of the strip steel is ensured, and the risk of steel piling accidents is reduced.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

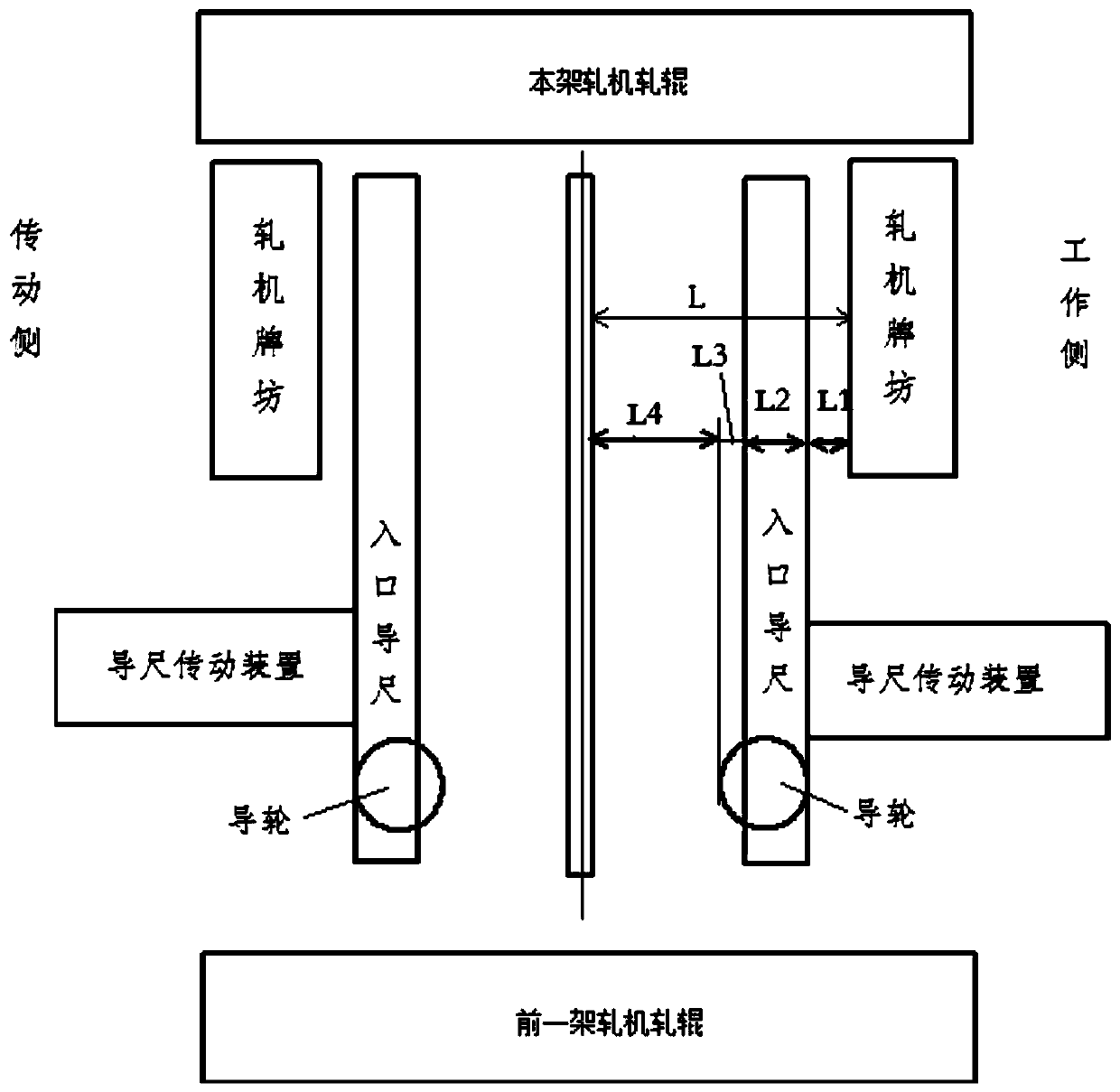

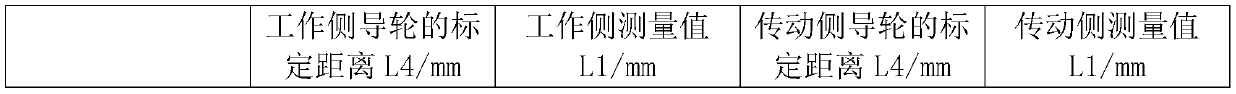

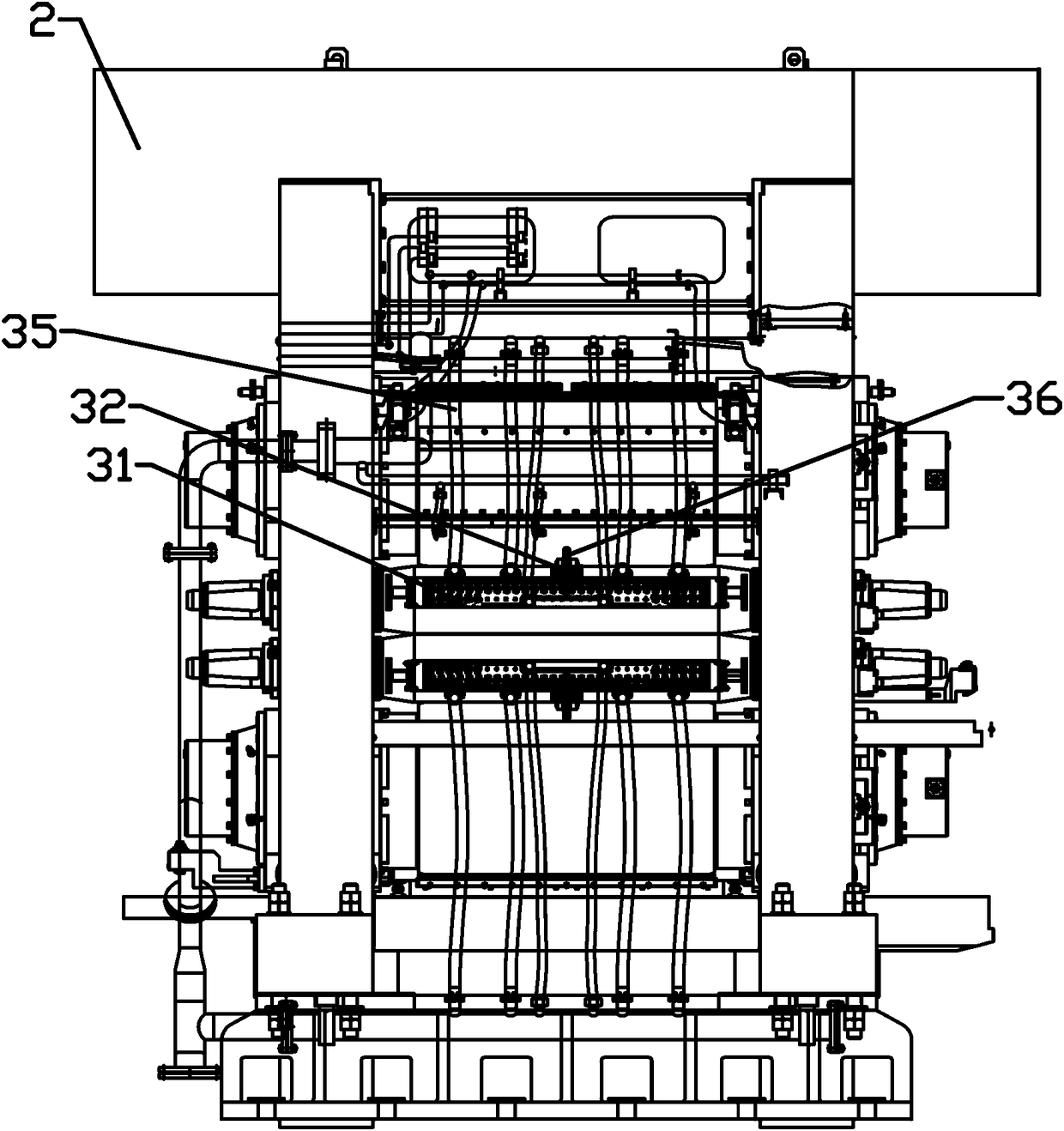

A Calibration Method of Entrance Guide Wheel in Finish Rolling

ActiveCN109365549BImprove calibration accuracyGuaranteed rolling stabilityGuiding/positioning/aligning arrangementsShortest distanceClassical mechanics

The invention relates to a calibration method for finish rolling inlet guide wheels. The method comprises the following steps of 1) selecting the outer sides of inlet guide rulers as measurement positions; 2) at the rolling mill inlet positions of the working side and the transmitting side of one rolling mill, measuring the shortest distance L1 from the inner side, close to the corresponding guide ruler transmission device, of one rolling mill housing to the outer side of the corresponding inlet guide ruler; and 3) the calibration distance of each guide wheel is calculated through adopting aformula that L4 equals L minus L1 minus L2 and minus L3. According to the calibration method, the calibration precision of the finish rolling mill inlet guide wheels is improved, the rolling stabilityof finish rolling is guaranteed, and the calibration precision is improved from the original + / -5 mm to the current + / -3 mm and is improved by 40%; the safety coefficient of the station of the calibration personnel is greatly improved; the working load of operators is reduced; and the calibration time is shortened by 30%.

Owner:ANGANG STEEL CO LTD

Production method of thin gauge low carbon steel by ferritic rolling in csp production line

ActiveCN111633028BRapid rollingGuaranteed rolling stabilityRoll force/gap control deviceTemperature control deviceProduction lineUltimate tensile strength

Owner:武汉钢铁有限公司

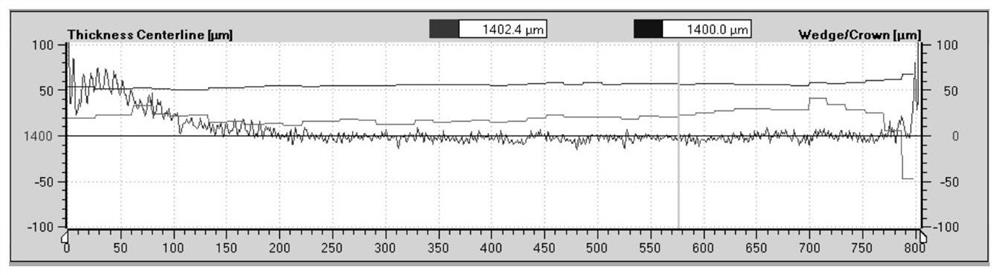

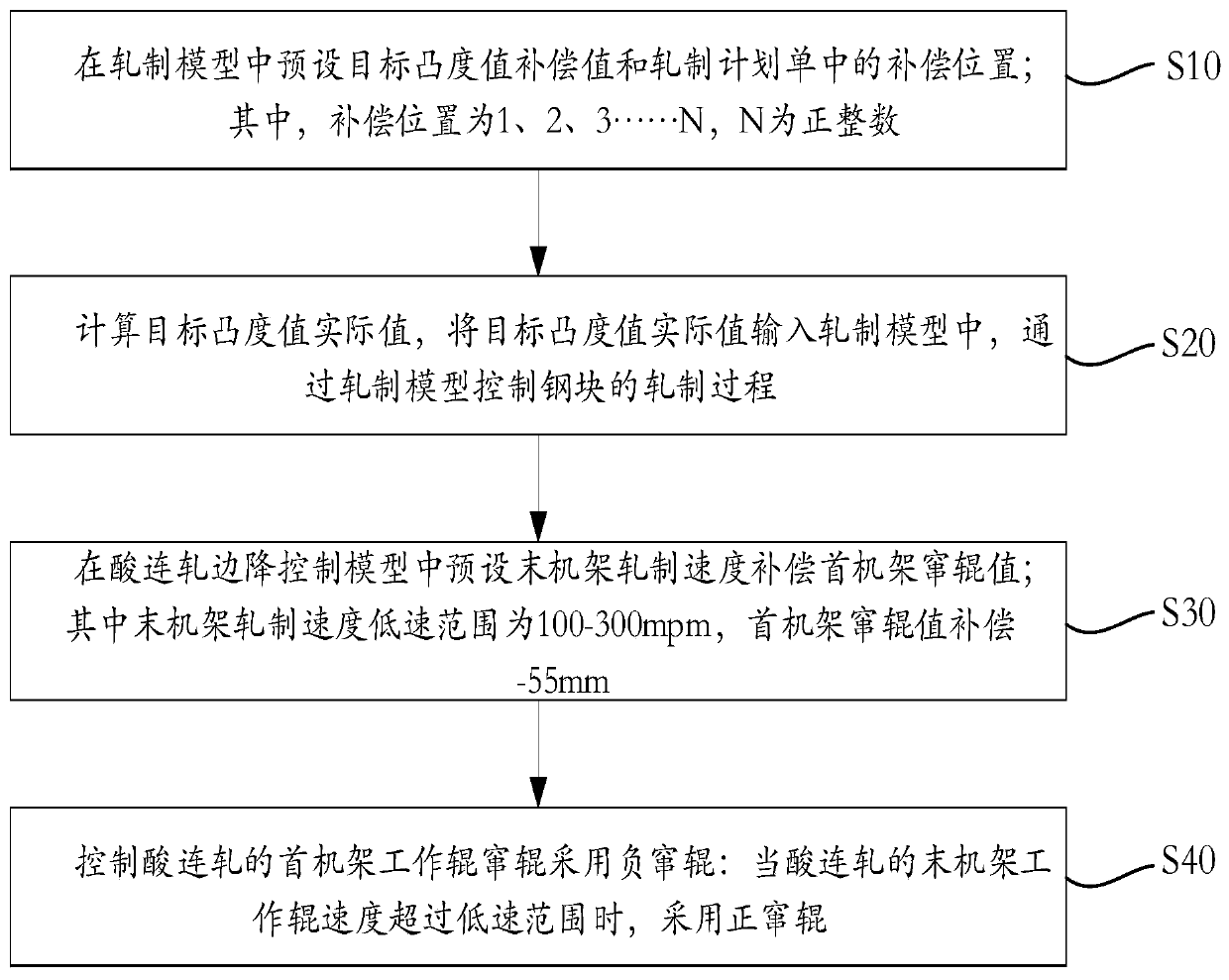

Method and device for improving the control level of lateral thickness difference of high-grade non-oriented silicon steel

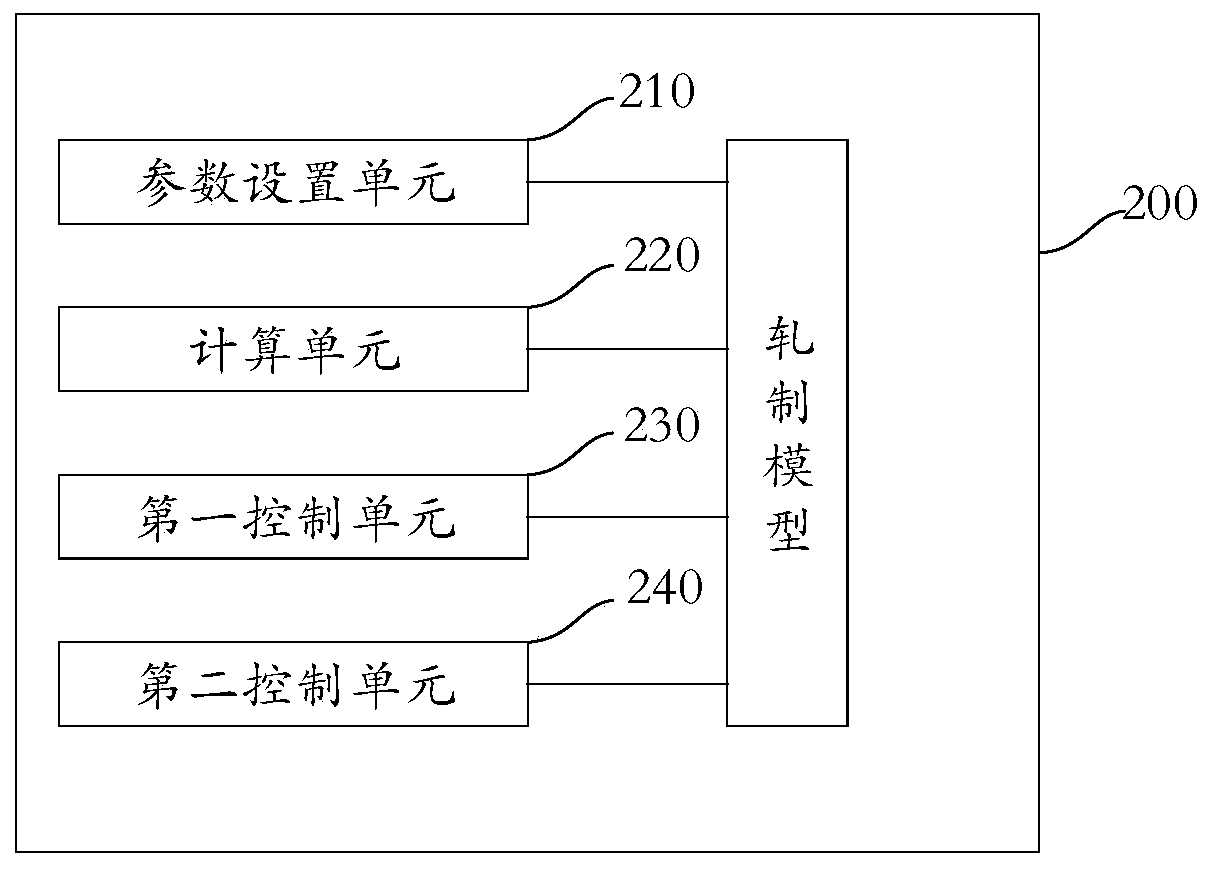

ActiveCN109465297BIncreased level of controlEnsure stabilityRoll mill control devicesDesign optimisation/simulationMetallurgyEngineering

The invention relates to the technical field of steel rolling, in particular to a method for raising the transverse thickness difference of high-grade non-oriented silicon steel, comprising: presetting a target crown value compensation value and a compensation position in a rolling plan sheet in a rolling model, wherein the compensation position is 1, 2, 3... N, and N is a positive integer. The actual value of the target crown value is calculated and input into the rolling model, and the rolling process of the steel block is controlled by the rolling model. The method for raising the transverse thickness difference of the high-grade non-oriented silicon steel provided by the embodiment of the invention improves the control level of the transverse thickness difference of the low-speed whileensuring the rolling stability.

Owner:SHOUGANG ZHIXIN QIAN AN ELECTROMAGNETIC MATERIALS CO LTD

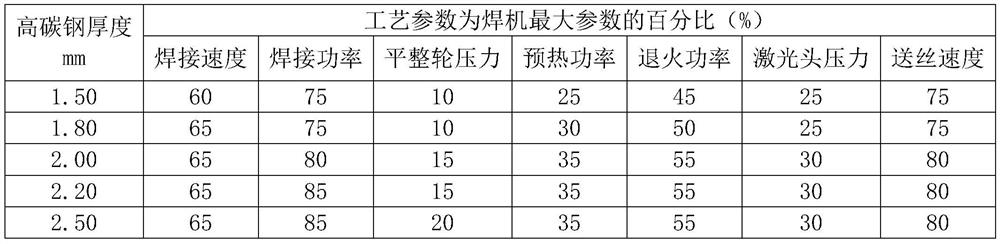

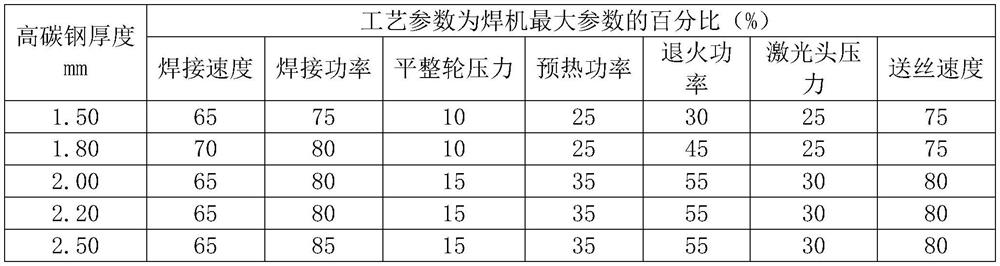

A kind of rolling method of 50mn thin-gauge high-carbon cold-rolled steel plate

ActiveCN112077165BAvoid frequent breaksGuaranteed rolling stabilityFurnace typesHeat treatment furnacesEngineeringMechanical engineering

The present invention disclosed a method of 50mn thin -specification high -carbon cold rolling steel rolling method. It belongs to the field of cold -rolled steel rolling rolling. The production process steps include: plate blank heating → rough rolling → cooling → volume to get hot rolling materials → open rolls→ Welding → Breaking Scales → Purmaking and Rinse → Five Machine Rolling → Volume → Unloading → Antuction → Flating → Cutting → Cold Rolling Products.Compared with the existing technology, 50MN high -carbon steel can be produced stably on the acid rolling line, avoiding frequent welding seams, and the quality of the 50MN cold -rolled plates is guaranteed to meet the user's use requirements.

Owner:RIZHAO BAOHUA NEW MATERIAL CO LTD

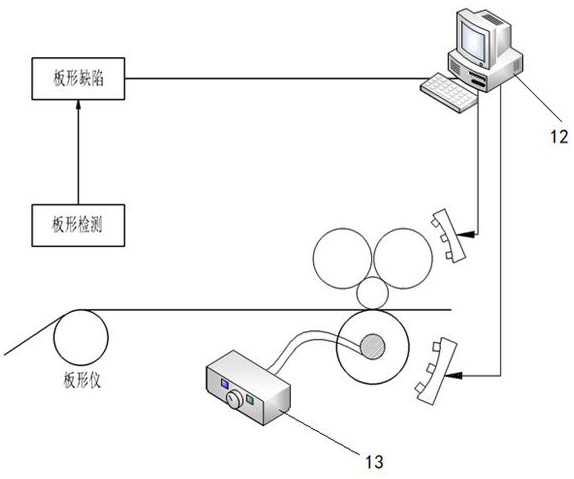

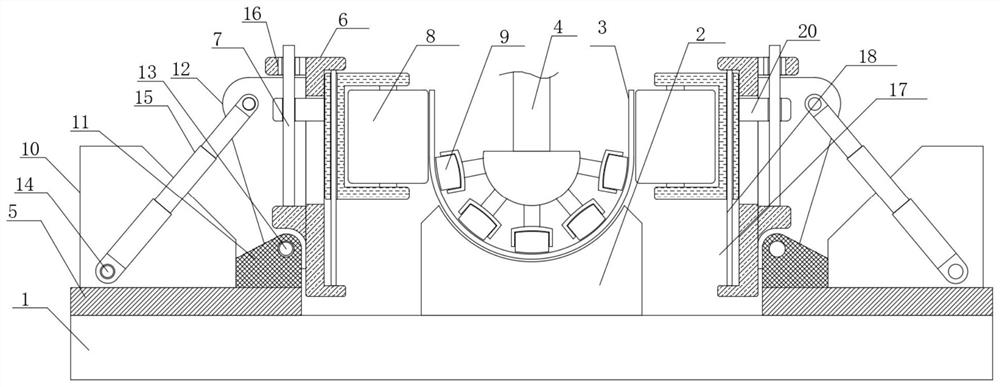

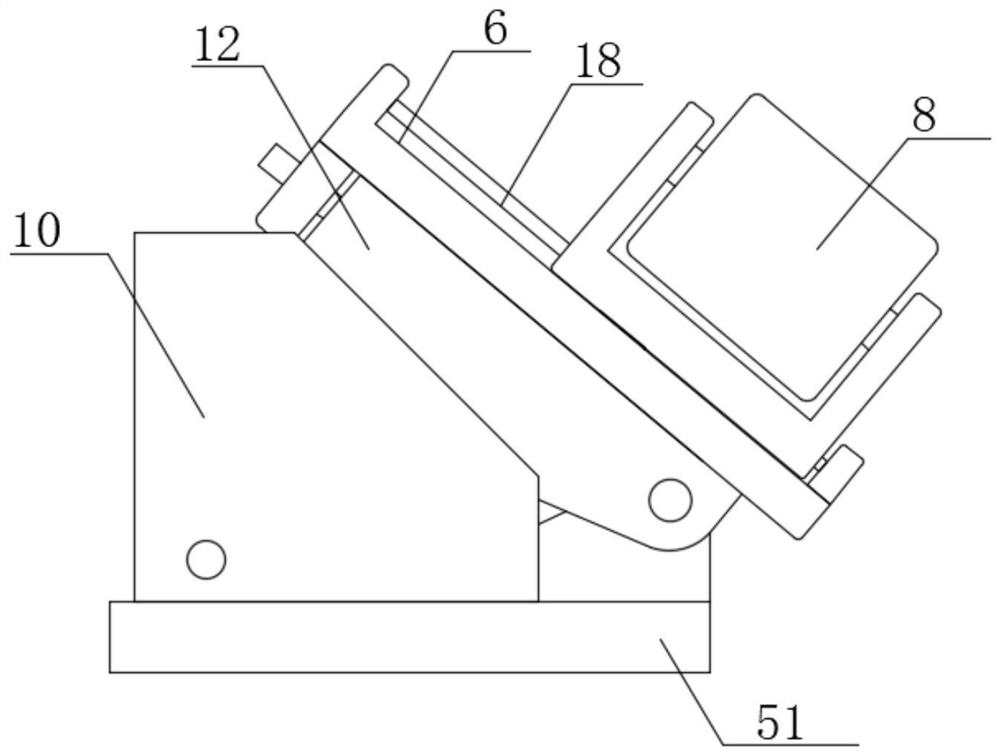

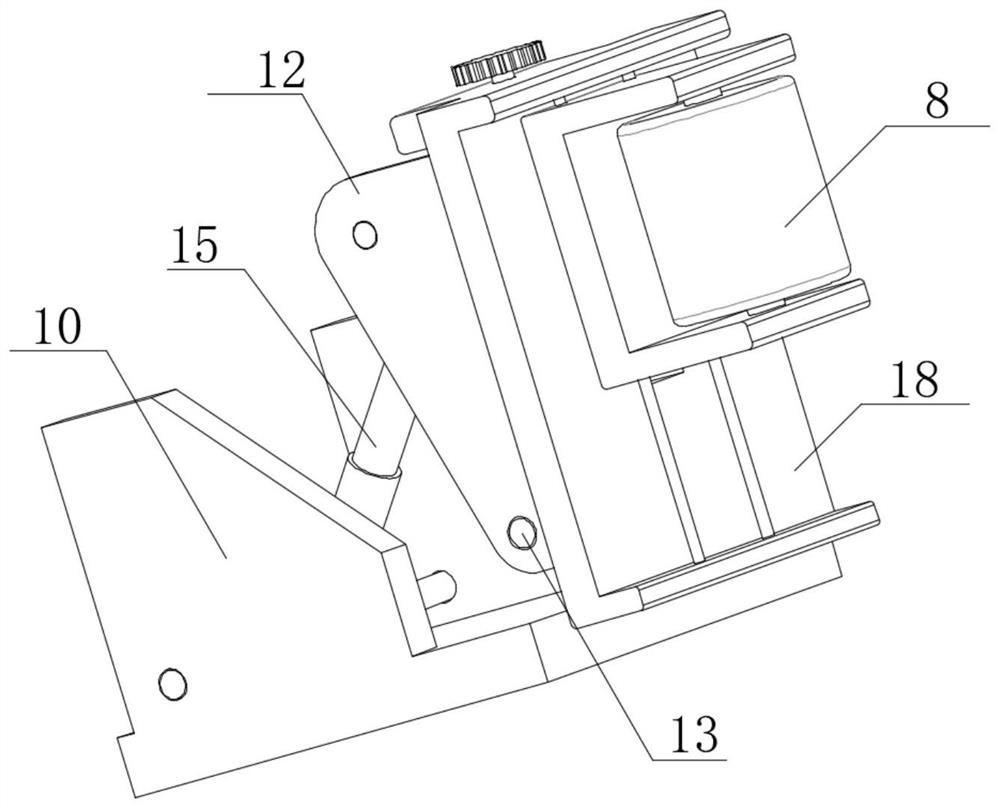

A new type of rolling mill external cooling device and its operation method for segmentally flexible adjustment of roll profile

ActiveCN112453069BImproved local heat transferSolve the phenomenon of edge thinningRollsProfile control deviceRolling millShape control

The invention relates to the technical field of shape control of metallurgical steel rolling equipment, in particular to a novel rolling mill external cooling device and an operating method for segmentally and flexibly adjusting the roll shape, which can flexibly adjust the local thermal crown of the roll to form a good roll gap shape and The parts that cannot be identified by the shape meter are compensated, and finally the flatness of the overall shape is improved, and high-quality strips are rolled.

Owner:YANSHAN UNIV

Cold rolling forming machine and U-shaped suspension arm plate production and manufacturing method

PendingCN114570800AEliminate internal stressMeet normal productionShaping toolsMolding machineThermal deformation

The invention relates to the field of forming equipment, in particular to a cold rolling forming machine and a U-shaped suspension arm plate manufacturing method.The cold rolling forming machine comprises a finishing workbench, a lower die and a plate are arranged in the center of the upper end of the finishing workbench, the plate is arranged at the upper end of the lower die, and an upper die is arranged at the position, located at the upper end of one side of the lower die, of the plate. The method shortens the elastic recovery time, prolongs the rolling time, has good effects of inhibiting stress release, improving plastic deformation and keeping rolling stability, can adapt to material performance changes in a certain range through bend angle adjustment, eliminates internal stress generated by strong rolling after normalizing treatment, and improves the rolling quality. Thermal deformation caused by heat treatment is treated in the finishing section, and the section, longitudinal bending and transverse bending of the profile are further corrected, so that the internal stress of the material of the forming section is effectively controlled, the end springback caused by placement after cutting is reduced, and the new process can meet the production of the U-shaped suspension arm.

Owner:南京图信新材料科技有限公司

A control method for the AGC system of the finishing mill of a thin plate hot rolling line

InactiveCN104907341BHigh control precisionImprove pass rateRoll mill control devicesMetal rolling arrangementsEconomic benefitsStrip steel

The invention discloses a control method of a thin plate hot rolling wire finishing mill AGC system. According to the control method, the adjusting amplitude is subdivided according to the different thickness of the finished strip steel and different racks, and the adjusting amplitude is increased when the thickness of the finished strip steel is increased, and is decreased when the sequence number of the rack is increased. Therefore, the control concept that the adjusting amplitude of all finished strip steels at each rack of the finishing mill is a certain value is changed. The linear setting is conducted based on different thickness at each rack outlet of the racks F0, F1...Fn, the control precision of the AGC system is raised; the qualified rates of the strip steels in both thick and thin specification are increased and the production stability is improved. Therefore, the strip steels in smalllot, multi steel types and multi specification can be produced at the same time based on the order, and substantial economic benefit is realized.

Owner:SHANDONG IRON & STEEL CO LTD

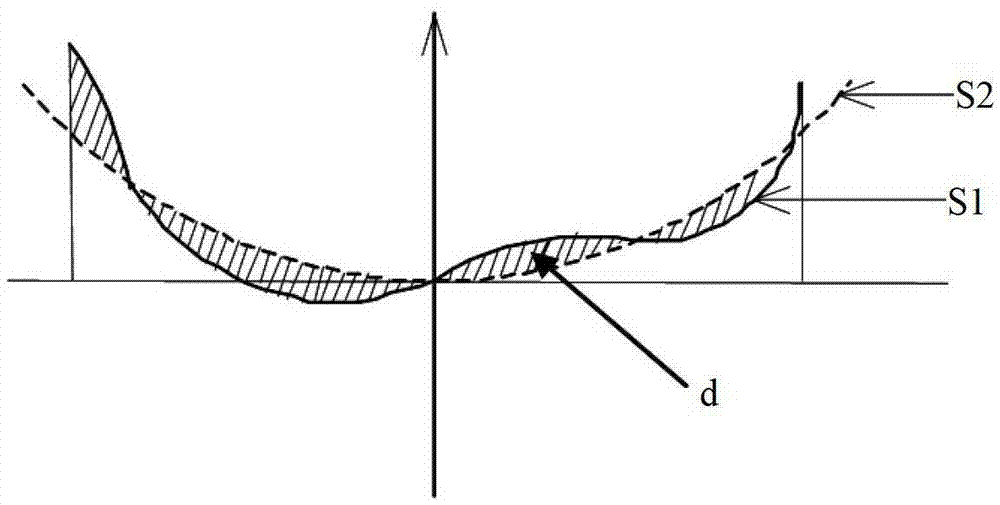

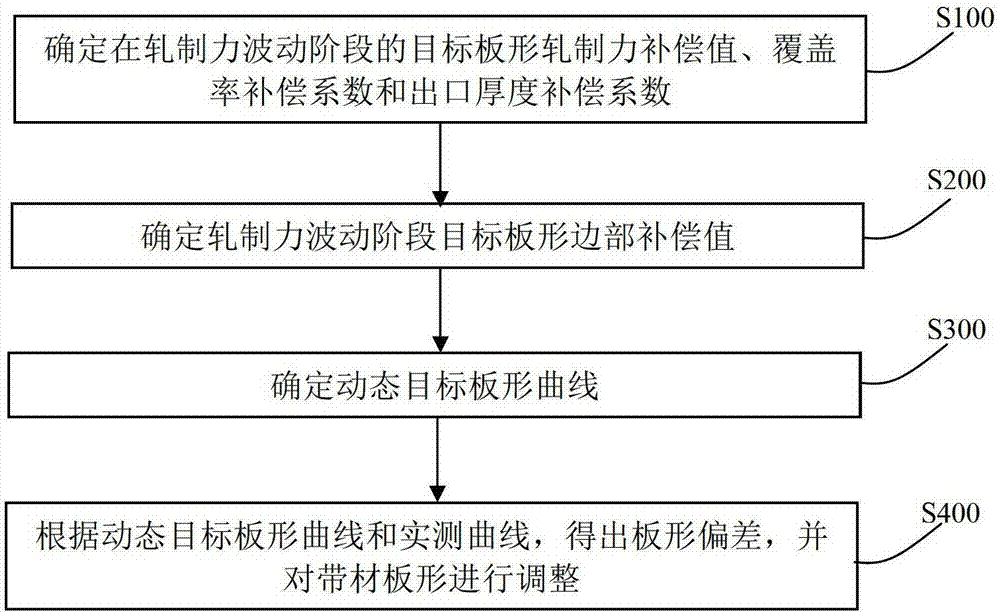

Target shape setting method

The invention discloses a target board shape setting method. The target board shape setting method comprises: step S100, confirming a target board shape rolling force compensation value, a coverage rate compensation factor and an outlet thickness compensation factor at a rolling force fluctuation stage; step S200, confirming a target board shape side portion compensation value at the rolling force fluctuation stage; step S300, confirming a dynamic target board shape curve; finally step S400, obtaining board shape deviation according to the dynamic target board shape curve and a measured curve and performing belt material board shape adjustment. The target board shape setting method can improve the board shape material object mass of belt material side portion at the rolling force fluctuation stage and ensures the rolling stability and decrease broken belt situation and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

A method for positioning slabs according to steel grades and finished product specifications

ActiveCN108004389BSolve the problem of rolling instabilityPrevent deviationFurnace typesHeat treatment process controlHardnessHeating furnace

The invention discloses a method for positioning for plate blank distribution according to the steel type and the finished product specification. The method is characterized in that plate blanks reaching a feeding checking roller way are subjected to secondary position positioning based on three indexes of thickness, hardness and steel type of the plate blank before entering corresponding rollingpositions according to a distribution graph meeting process requirements. According to the method, the secondary position positioning mode is adopted for three situations correspondingly, the positions of the plate blanks are further refined on the basis of previously following the distribution graph meeting the process requirements so that the parameters such as the different steel types and thefinished product specifications can be flexibly adapted to the plate blank distribution of a plate blank furnace of a heating furnace.

Owner:BAOSHAN IRON & STEEL CO LTD

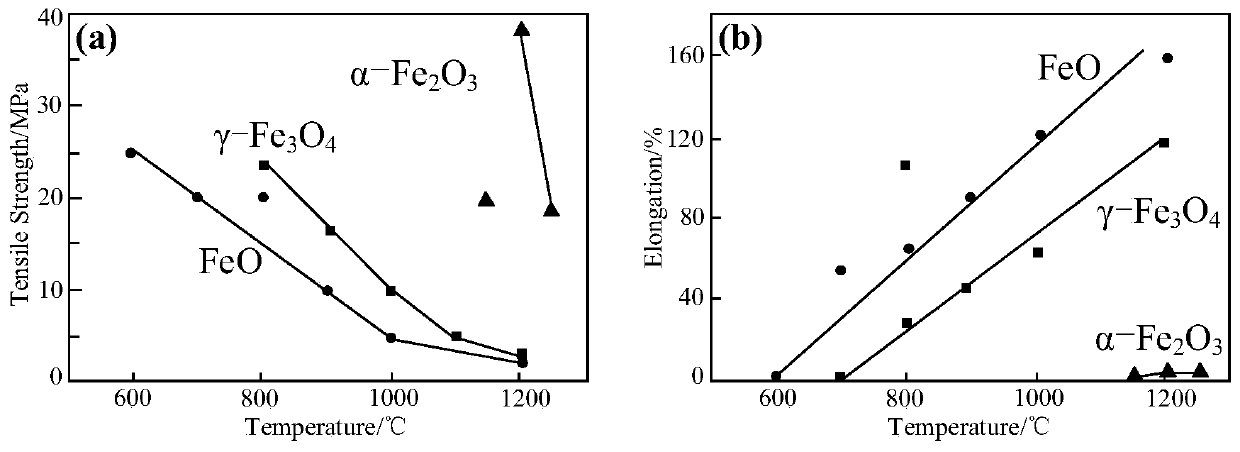

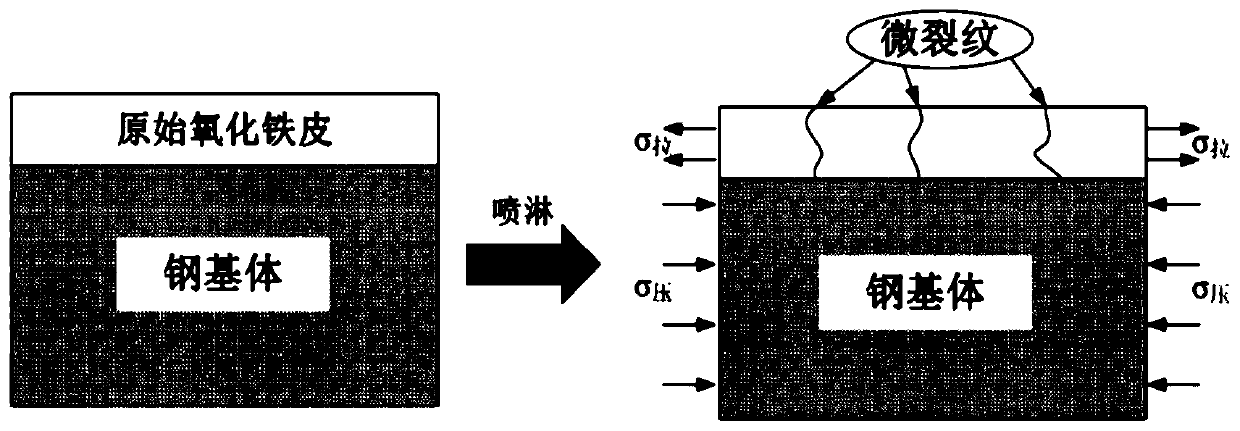

High-efficiency descaling method for iron oxide scale generated by hot-rolled short-process production line heating furnace

ActiveCN109719145APress-in defect improvementIncrease descaling water pressureWork treatment devicesMetal rolling arrangementsHigh pressure waterHigh pressure

The invention provides a high-efficiency descaling method for an iron oxide scale generated by a hot-rolled short-process production line heating furnace, the method is used for realizing the completeremoval of the iron oxide scale in the heating furnace in the short-process production process through aerosol spraying and high-pressure water descaling. The method is based on the components of thehot-rolled steel plate, the heating system, the thickness of the furnace-generated iron oxide scale and the temperature range to adjust the gas-water ratio of a gas-mist spraying device, the height between the device and the steel plate and the distance between the device and the high-pressure descaling device, on the basis of the high-temperature plastic change interval of the iron oxide scale,huge heat stress is generated in the iron oxide scale in the rapid temperature change process is utilized, the integrity of the iron oxide scale can be rapidly dissociated in the non-plastic area of the iron oxide scale, the descaling efficiency of the iron scale of the short-process tunnel type heating furnace is improved by matching with the subsequent high-pressure water descaling, so that thepressing-in defects of the iron oxide skin are reduced, and the surface quality of the rolled steel produced by the hot-rolling short process is improved.

Owner:NORTHEASTERN UNIV

Rolling oil system of four-roller cold rolling mill

PendingCN108941221AEasy to moveDosage controlRolling equipment maintainenceWork cooling devicesHigh energyControl valves

The invention discloses a rolling oil system of a four-roller cold rolling mill, and relates to the field of cold rolling mills. The rolling oil system of the four-roller cold rolling mill comprises anozzle beam device arranged on the outer side of a feed port of a frame; the nozzle beam device is connected with a control valve; an oil collecting groove is formed in the lower side of the frame; and an oil dirt filtering and purifying system is arranged between the oil collecting groove and a nozzle beam. The rolling oil system of the four-roller cold rolling mill further comprises a blowing device arranged in a discharge port of the frame and used for blowing off oil dirt on the surface of a strip; and the blowing device comprises an upper blowing assembly positioned on the upper side ofthe strip, and a lower blowing assembly positioned on the lower side of the strip. The rolling oil system of the four-roller cold rolling mill further comprises a roller cleaning device arranged on the side surface of a support roller. The rolling oil system of the four-roller cold rolling mill further comprises a smoke discharge cover arranged at the upper end of the frame. The effects of high cleaning capacity, high energy utilization rate and low environmental pollution are achieved.

Owner:LUOYANG XINYUANDA METALLURGICAL COMPLETE EQUIP CO LTD

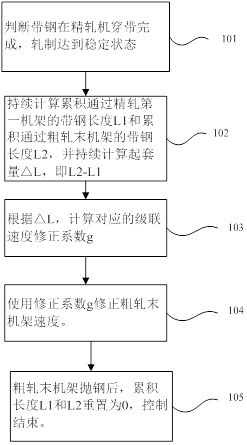

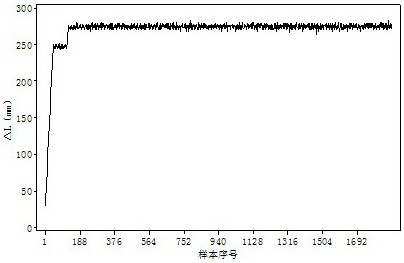

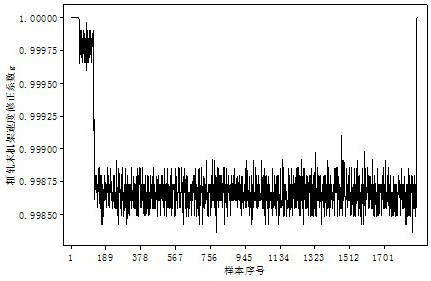

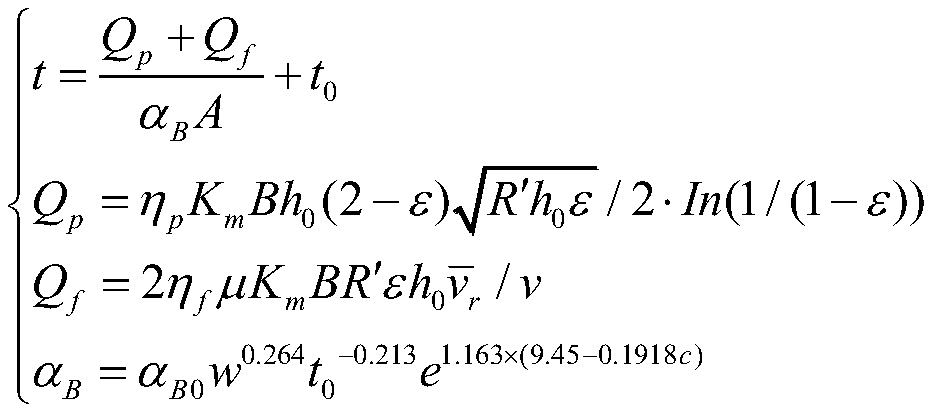

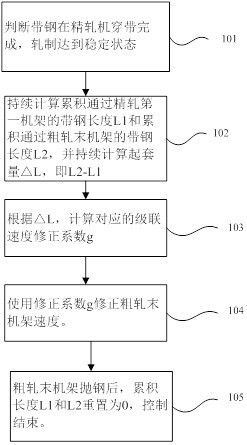

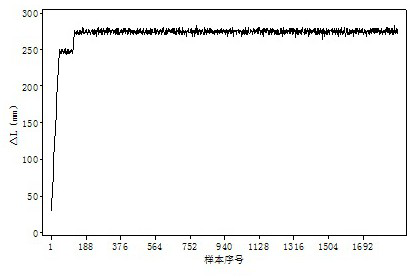

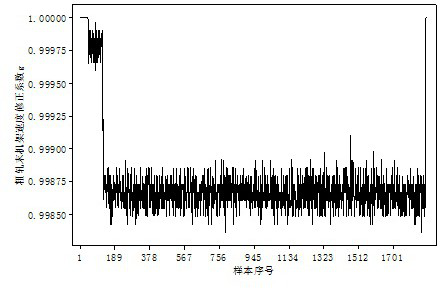

Method for preventing middle roller way strip steel from rising

ActiveCN112893483AReduce frequent adjustmentsGuaranteed rolling stabilityTension/compression control deviceStructural engineeringStrip steel

The invention relates to a method for preventing middle roller way strip steel from rising, and belongs to the technical field of steel rolling in the metallurgical industry. According to the technical scheme, the method comprises the following steps of (1) calculating the loop rising amount delta L, namely L2-L1; (2) calculating the loop rising rate e, wherein e is equal to delta L / L; (3) calculating a cascade speed correction coefficient g of a rough rolling end rack; and (4) correcting the speed of the rough rolling end rack by using the correction coefficient g, specifically, after loop rising of the middle roller way strip steel is judged and the cascade speed correction coefficient g of the rough rolling end rack is calculated, checking the upper limit and the lower limit of the correction coefficient g before the speed of the rough rolling end rack is corrected, and multiplying the correction coefficient g after the limit check by a speed set value of the rough rolling end rack to achieve a new speed setting for adjusting the rough rolling end rack so as to prevent the middle roller way strip steel from rising. The method has the beneficial effects that the loop rising condition of the middle roller way strip steel is judged through a logical algorithm, and then the speed of the rough rolling end rack is corrected, so that the purpose of preventing loop rising of the middle roller way strip steel is achieved.

Owner:TANGSHAN IRON & STEEL GROUP +1

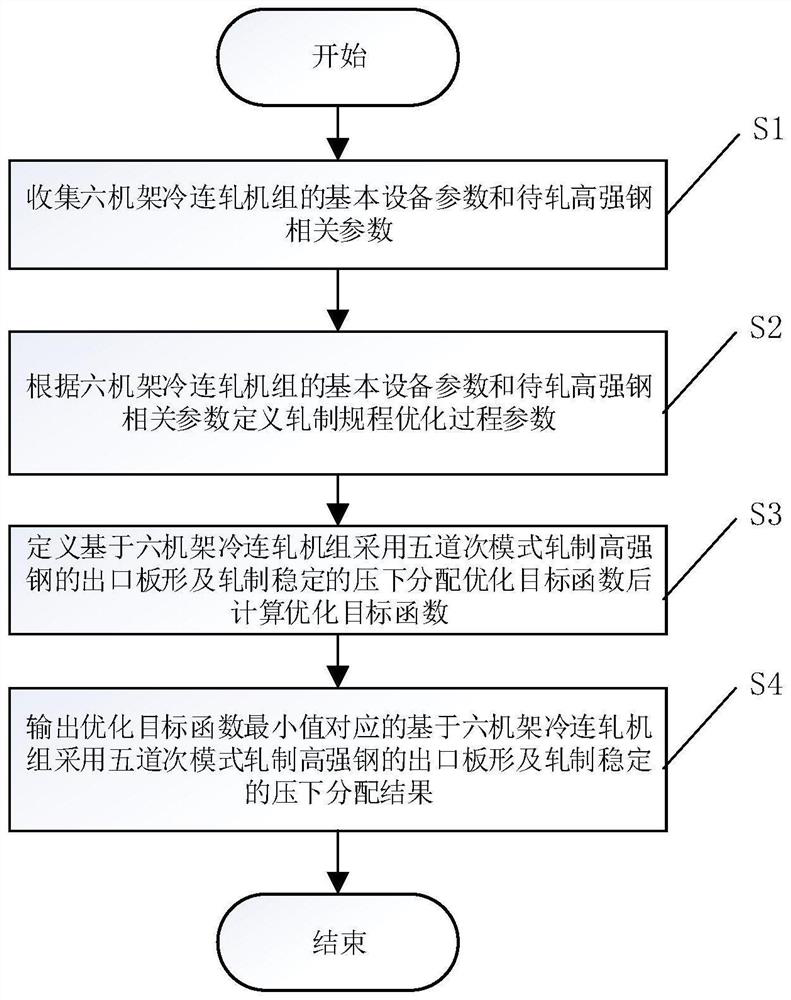

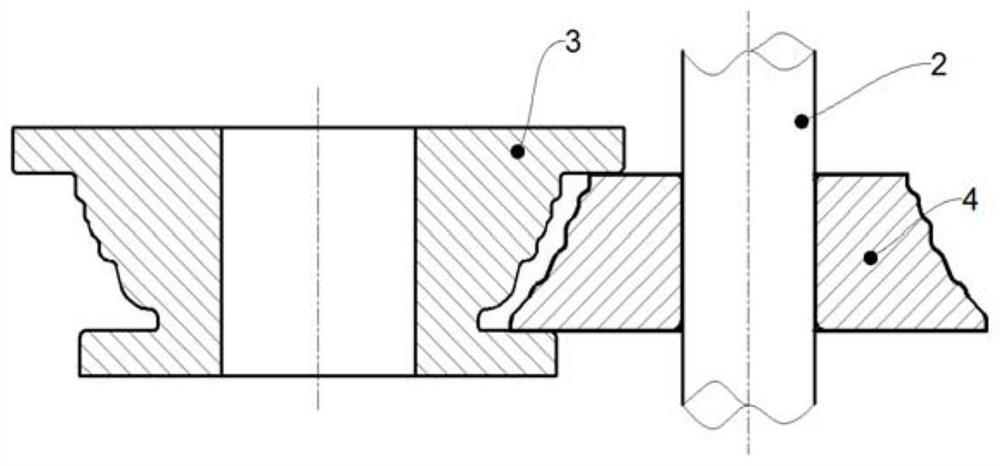

Pressing schedule optimization method for rolling steel in five-pass mode in six-rack cold continuous rolling

PendingCN114309082AGuaranteed rolling stabilityGuaranteed qualityRoll force/gap control deviceTension/compression control deviceManufacturing engineeringEnergy consumption

The invention discloses a reduction schedule optimization method for rolling steel in a five-pass mode in six-rack cold continuous rolling. The reduction schedule optimization method comprises the steps that S1, basic equipment parameters of a six-rack cold continuous rolling unit and related parameters of high-strength steel to be rolled are collected; s2, rolling schedule optimization process parameters are defined according to basic equipment parameters of the six-rack cold continuous rolling unit and related parameters of high-strength steel to be rolled; s3, defining an outlet plate shape of high-strength steel rolled in a five-pass mode based on the six-rack cold continuous rolling unit and a reduction distribution optimization objective function of stable rolling, and then calculating the optimization objective function; and S4, outputting the outlet plate shape of the high-strength steel rolled by adopting the five-pass mode based on the six-rack cold continuous rolling unit and the rolling stability reduction distribution result corresponding to the minimum value of the optimization objective function. According to the method, under the condition that one-pass rolling mode is reduced, the advantages of a small-roller-diameter rolling mill are fully played, and the purposes of reducing energy consumption and improving production efficiency are achieved on the premise that the rolling stability and the quality of finished products are guaranteed.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD

Anti-rolling and breaking roll of a hot rolling skin pass unit and its use method

ActiveCN106001177BQuality improvementImprove performanceMetal rolling arrangementsWork rollWave shape

Owner:BEIJING SHOUGANG CO LTD

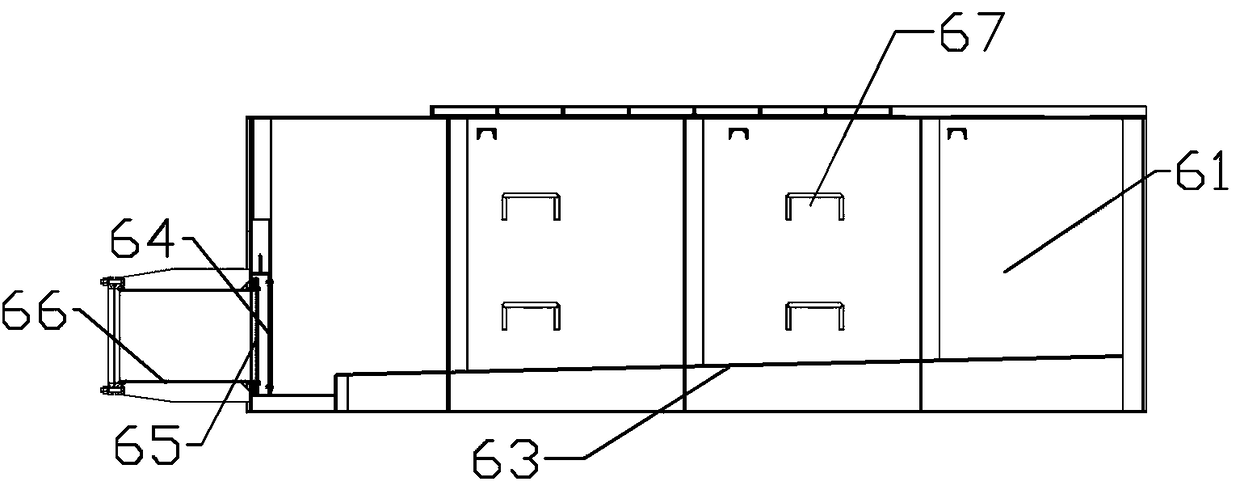

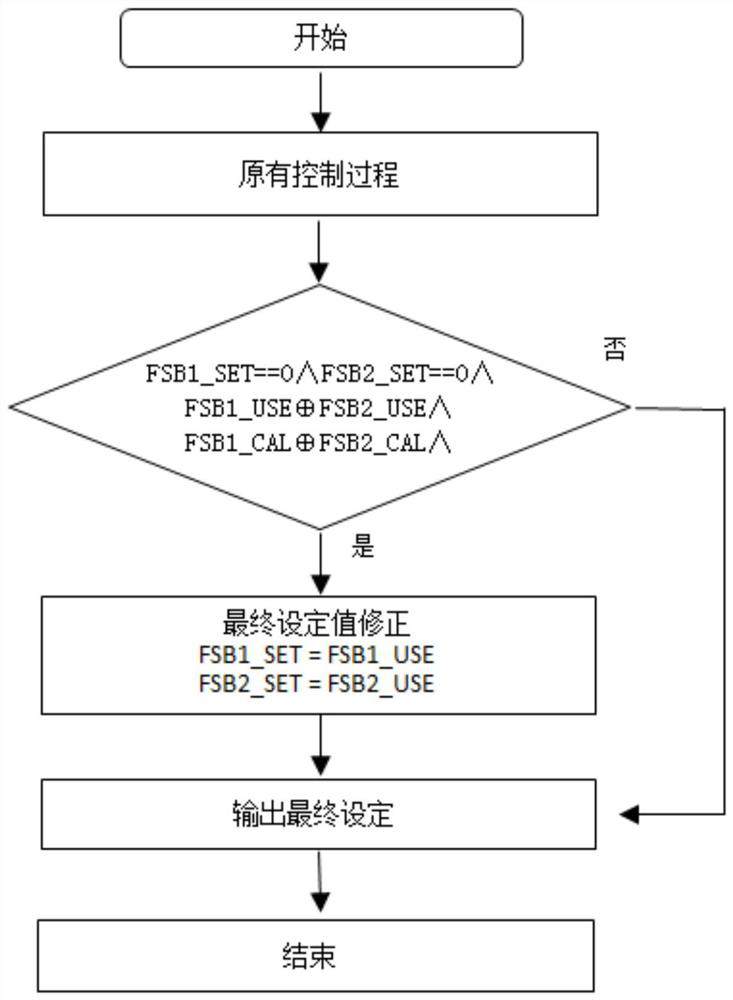

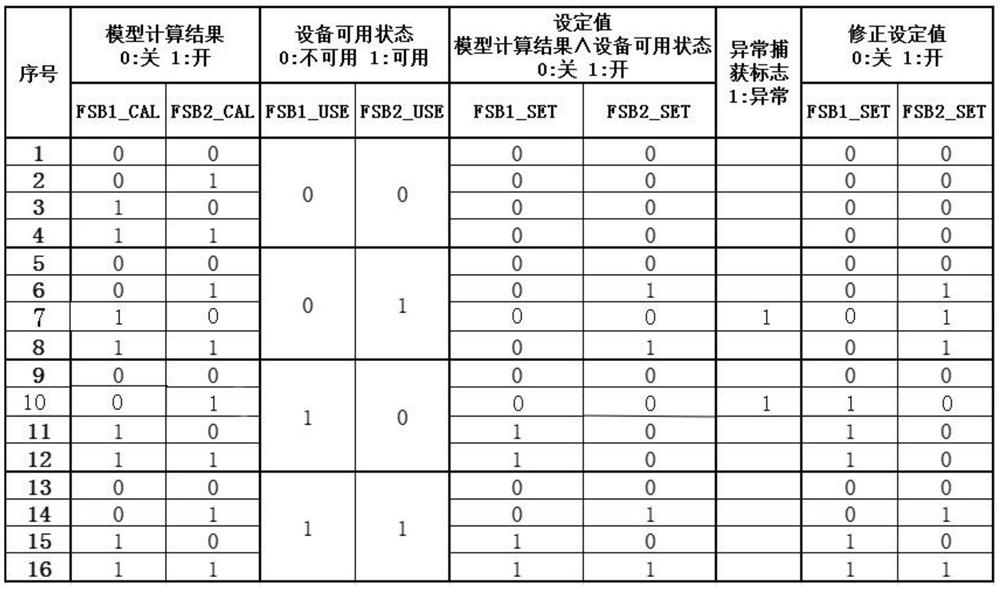

Setting method for descaling of finish rolling inlet of hot rolling strip steel production line

ActiveCN114247764AGuaranteed rolling stabilityGuarantee product surface qualityRoll mill control devicesWork treatment devicesManufacturing lineManufacturing engineering

The invention relates to the technical field of hot-rolled strip steel production control, in particular to a setting method for descaling of a finish rolling inlet of a hot-rolled strip steel production line. Comprising the following steps of 1, performing result set exhaustion analysis on original control logic, and summarizing all conditions causing an abnormal set value; 2, induction is carried out on abnormal set value occurrence conditions, and an abnormal condition capture formula is fitted; 3, the set value of the water spraying collecting pipe of the finish rolling inlet descaling equipment is corrected to be consistent with the corresponding available state: FSB1SET = FSB1USE; and FSB2SET is equal to FSB2USE. And the abnormal conditions that at least one group of FSBs is in an available state, at least one group of FSBs needs to be started according to a model calculation result, and the set values FSBs are in an all-closed state are avoided.

Owner:ANGANG STEEL CO LTD

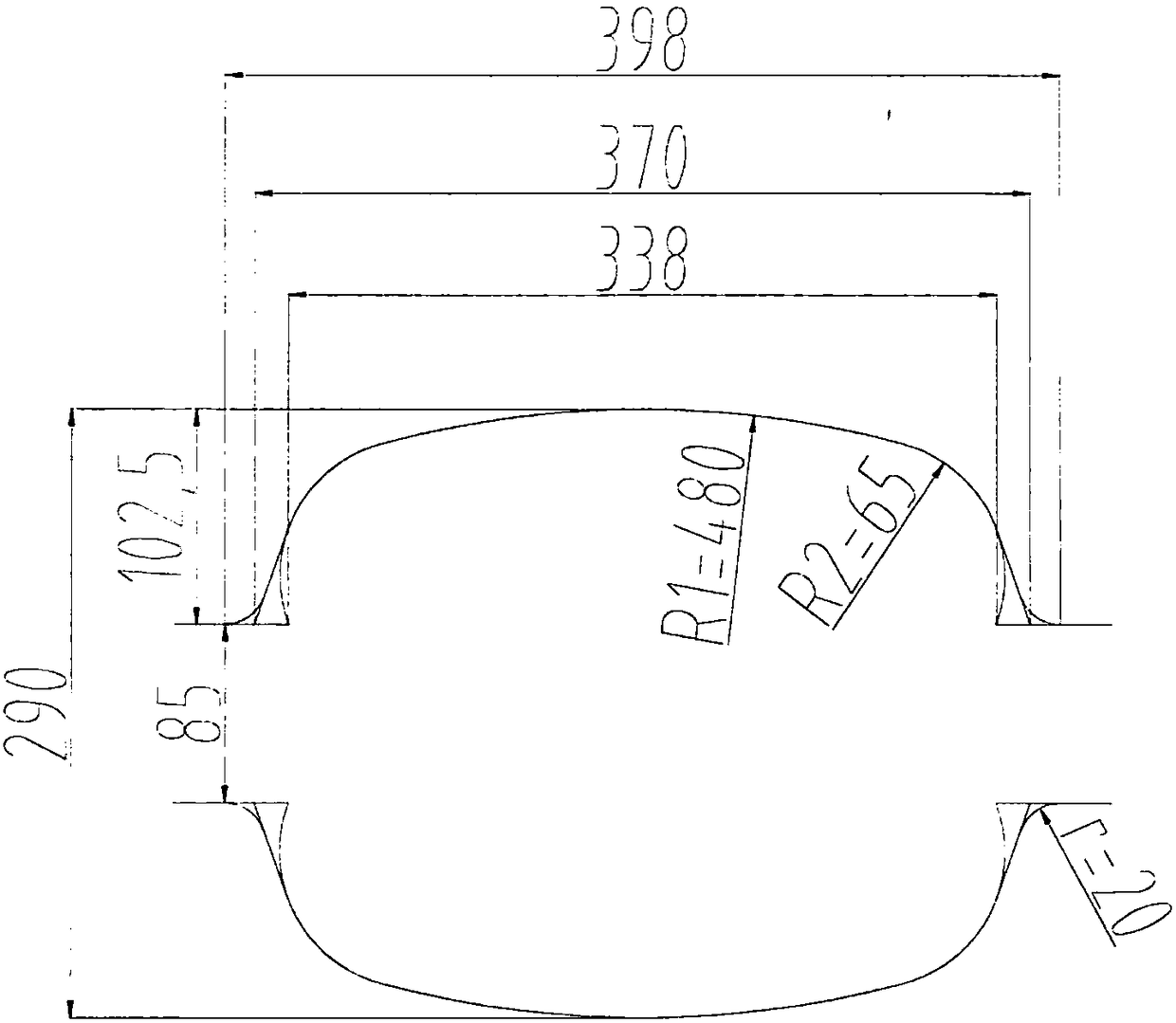

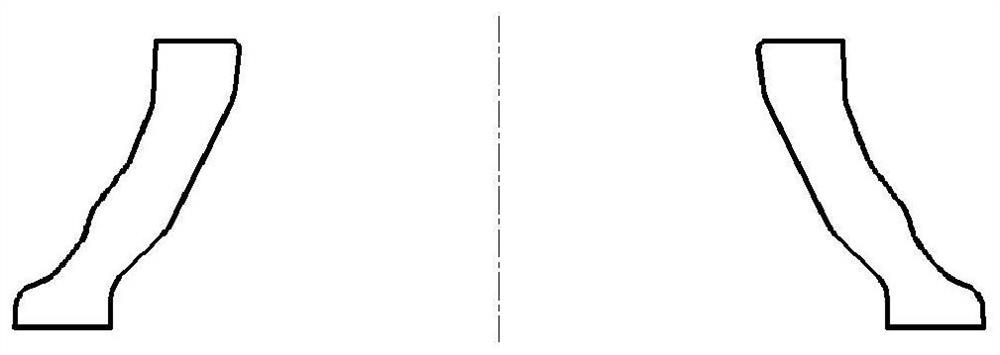

Precise rolling forming method for large Waspaloy alloy casing forge piece

The invention discloses a Waspaloy alloy large casing forge piece precision rolling forming method which is characterized in that the scheme of special-shaped pre-rolling, special-shaped finish rolling and special-shaped bulging is adopted, and the rolling deformation amount is guaranteed through the design of a pre-rolling core roller with the small size; the rolling stability of the blank in the finish rolling process is guaranteed through the finish rolling core roller with the large size; and meanwhile, the special-shaped bulging process is combined, the precision of the forged piece is improved, the material utilization rate is increased, and the manufactured Waspaloy alloy large casing forged piece meets the design requirement. The rolling forming method is mainly used for rolling forming of the large Waspaloy alloy casing forgings.

Owner:GUIZHOU ANDA AVIATION FORGING

Parameter Optimization Method for Reducing Minimum Rolling Distortion Between Secondary Cold Rolling

ActiveCN109590338BImprove ultimate deformation abilityGuaranteed rolling stabilityMetal rolling arrangementsProfile control deviceMathematical modelEngineering

Owner:BAOSHAN IRON & STEEL CO LTD

A method for preventing middle roller table strip from rising

ActiveCN112893483BReduce frequent adjustmentsGuaranteed rolling stabilityTension/compression control deviceEngineeringStrip steel

The invention relates to a method for preventing strip steel from rising up in an intermediate roller table, and belongs to the technical field of steel rolling in the metallurgical industry. The technical solution is: operate according to the following steps: (1) Calculate the starting amount △L, that is, L2‑L1; (2) Calculate the starting rate e, e=△L / L; (3) Calculate the rough rolling mill Frame cascading speed correction coefficient g, (4) Use the correction coefficient g to correct the rough rolling final frame speed: when it is judged that the intermediate roller table strip is pulled up and the rough rolling final frame cascading speed correction coefficient g is calculated, in Before correcting the rack speed of the rough rolling mill, check the upper and lower limits of the correction coefficient g. The correction coefficient g after the limit check is multiplied by the speed setting value of the rough rolling mill stand to reach the new speed setting, which is used to adjust the rough rolling mill end. frame, so as to prevent the middle roller strip from rising. The beneficial effect of the invention is that: through the logic algorithm, the strip-up condition of the intermediate roller table is judged, and then the speed of the rack at the end of rough rolling is corrected, so as to achieve the purpose of preventing the strip-up of the intermediate roller table.

Owner:TANGSHAN IRON & STEEL GROUP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com