Method for preventing middle roller way strip steel from rising

An intermediate roll and strip technology, applied in the field of steel rolling in the metallurgical industry, can solve the problems of insufficient intervention, excessive intervention, strip narrowing, etc., and achieve the effect of reducing frequent adjustments, preventing slippage, and ensuring rolling stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with the accompanying drawings, the present invention will be further described by examples.

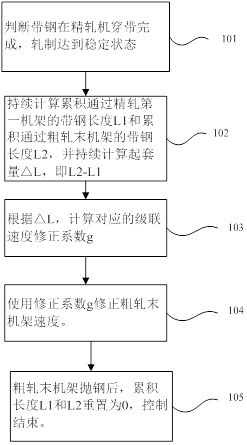

[0027] Refer to the attached Figure 1-4 , a method to prevent the middle roller strip from rising up, follow the steps below:

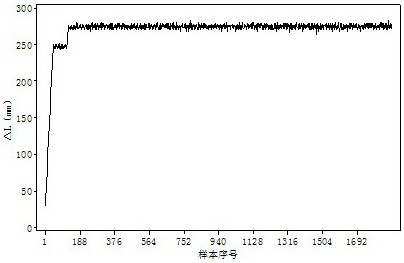

[0028] (1) After the finishing stand is bitten and delayed for a period of time, the cumulative strip length L1 passing through the first finishing stand and the cumulative strip length L2 passing through the rough rolling stand are continuously calculated, and the calculation is continued. The starting amount △L, namely L2-L1;

[0029] (2) According to △L, calculate the lifting rate e. The lifting rate e is the ratio of the lifting amount △L to the length L of the final rack of rough rolling and the first rack of finishing rolling, namely:

[0030] e=△L / L

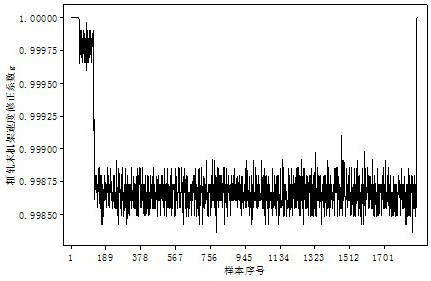

[0031] (3) Set the control dead zone value Ɛ, the value range of Ɛ is 0~0.015, when the lifting rate e is less than or equal to the control dead zone value Ɛ, the correcti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com