A kind of rolling method of 50mn thin-gauge high-carbon cold-rolled steel plate

A cold-rolled steel plate and thin-gauge technology, which is applied in the field of 50Mn high-carbon steel production technology, can solve the problems of low yield strength, reduced fatigue life, and product quality that cannot meet the requirements, and achieve high yield strength, simple composition, and increased The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific embodiments. Unless otherwise defined, technical or scientific terms used in this disclosure should have the ordinary meaning as understood by one of ordinary skill in the art to which this invention belongs.

[0030] The invention is a rolling method suitable for thin gauge 50Mn high carbon cold-rolled steel sheet with thickness ≤2.5mm.

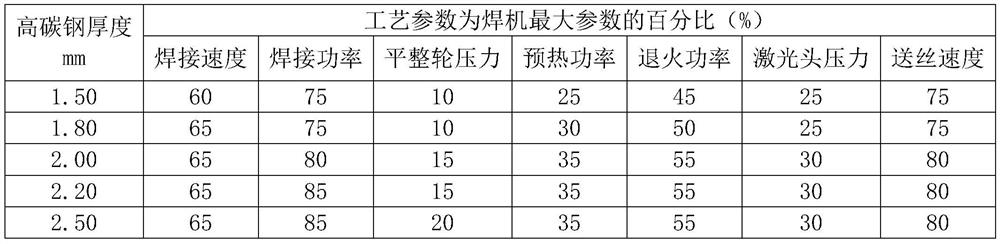

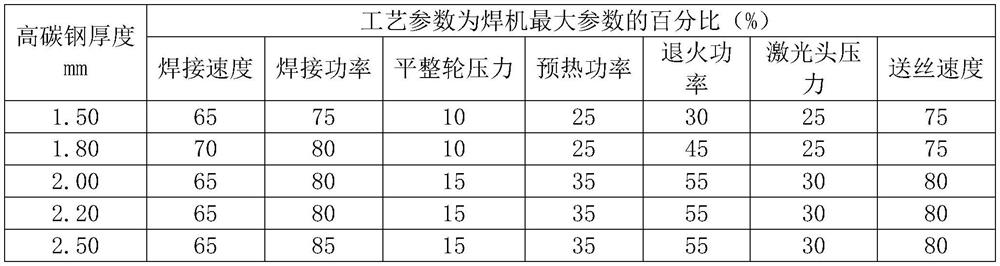

[0031] The production process steps of the invention include: slab heating → rough rolling → finishing rolling → cooling → coil to obtain hot-rolled material → uncoiling → welding → scale breaking → pickling and rinsing → five-stand rolling → coiling → unloading → annealing → Flattening→cutting→cold rolled finished product.

[0032] S1, slab heating

[0033] The composition design of the 50Mn high carbon steel hot-rolled material is: C: 0.5%-0.56%; Si: 0.2%-0.3%; Mn: 0.6%-0.7%, P: ≤ 0.025%; S: ≤ 0.005%; Als: ≤ 0.02%; Cr: ≤ 0.02%; Ni ≤ 0.02%; Cu ≤ 0.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com