Processing method for preventing porous mould of laboratory gene memory board from cracking

A technology of porous molds and processing methods, applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of unsynchronized steel, stress accumulation, cracking, etc., and achieve the effect of preventing frequent fractures, good rigidity, and good surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with embodiment the present invention is described in further detail:

[0017] The processing method for preventing the cracking of the porous mold of the laboratory gene storage plate includes:

[0018] (1) The core of the mold is made of steel, and the groove at the bottom of the mold insert after grinding is formed into a rounded corner;

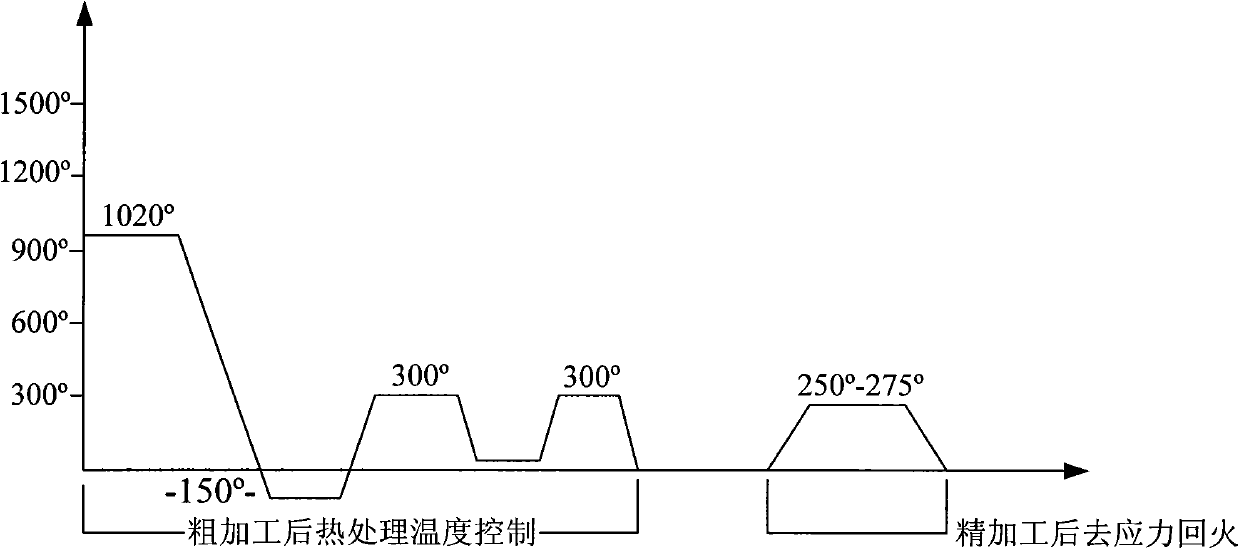

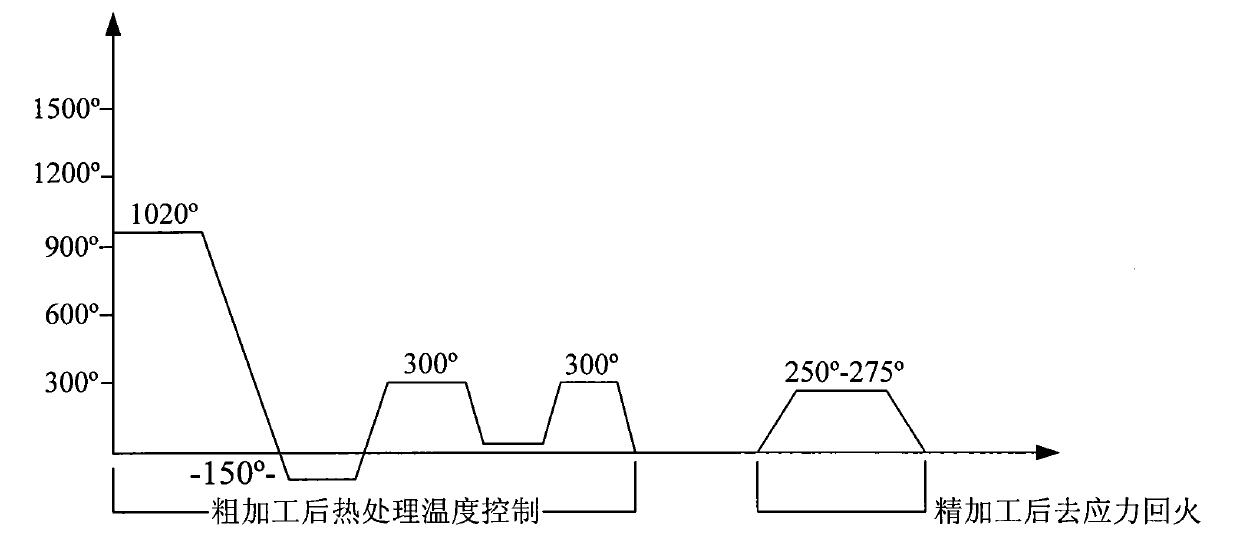

[0019] (2) Carry out high temperature quenching at 1020 degrees;

[0020] (3) Carry out subzero 150 ° cryogenic tempering;

[0021] (4) After 2 times of 300 ° low temperature tempering;

[0022] (5) Carry out precision machining to the steel, and carry out mold assembly after finish machining;

[0023] (6) After the mold trial is qualified, the mold is again subjected to low-temperature stress-relief tempering within the range of 250° to 275°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com