Pressing schedule optimization method for rolling steel in five-pass mode in six-rack cold continuous rolling

A technology of reduction schedule and optimization method, applied in the field of high-strength steel cold rolling, can solve the problems of low production efficiency, excessive rolling force, and unstable rolling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order for those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that, in the absence of conflict, the embodiments of the present application And the features in the embodiments can be combined with each other.

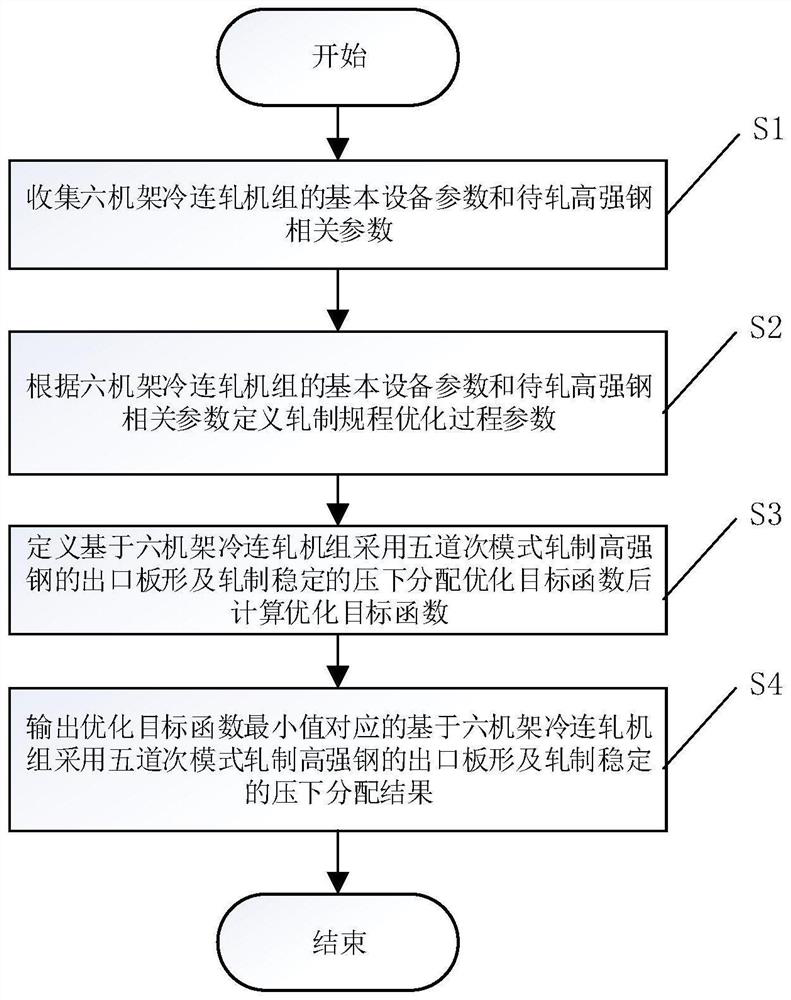

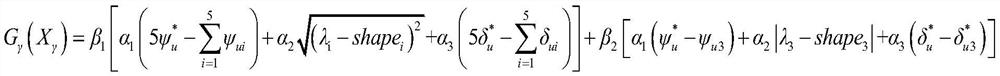

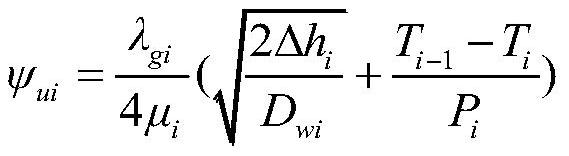

[0043] combine figure 1 As shown, the embodiment of the present invention provides a method for optimizing the reduction schedule of rolling steel in five-pass mode in six-stand continuous cold rolling, comprising the following steps:

[0044] S1. Collect the basic equipment parameters of the six-stand cold tandem rolling unit and the relevant parameters of the high-strength steel to be rolled, wherein the basic equipment parameters of the six-stand cold tandem rolling unit include the entry tension, The allowable value of the maximum rolling pressure, the diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com