Setting method for descaling of finish rolling inlet of hot rolling strip steel production line

A hot-rolled strip and production line technology, applied in metal rolling, metal rolling, rolling mill control devices, etc., can solve defects, reduce rolling stability of finishing mills, production accidents and other problems, and ensure rolling stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

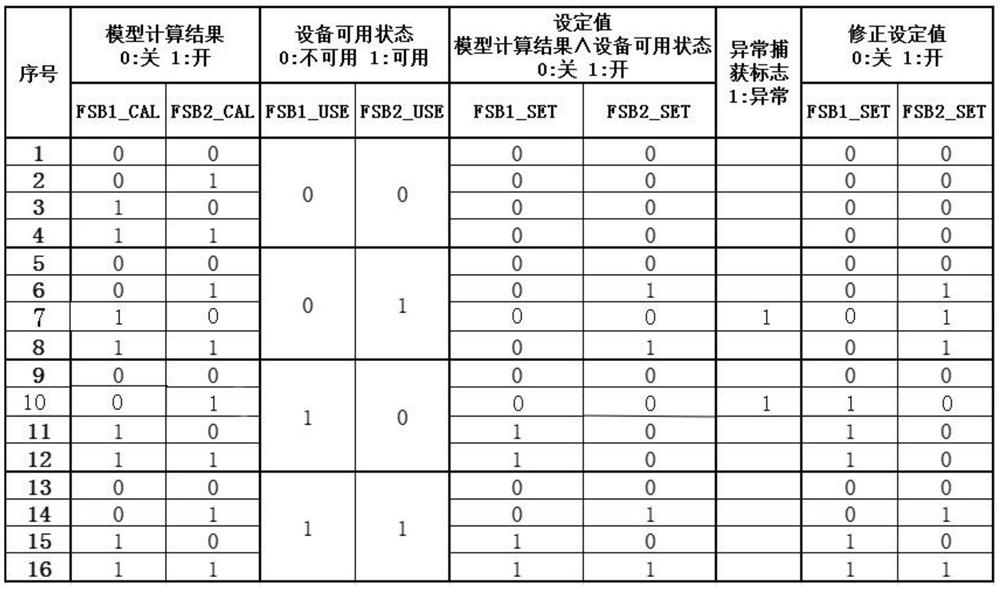

[0047] The parameters of a certain steel grade and a certain specification of hot-rolled products are as follows:

[0048] Model calculation results FSB1_CAL=1, FSB2_CAL=0

[0049] Device availability status FSB1_USE=0, FSB2_USE=1

[0050] set value

[0051] FSB1_SET=FSB1_CAL∧FSB1_USE=0

[0052] FSB2_SET=FSB2_CAL∧FSB2_USE=0

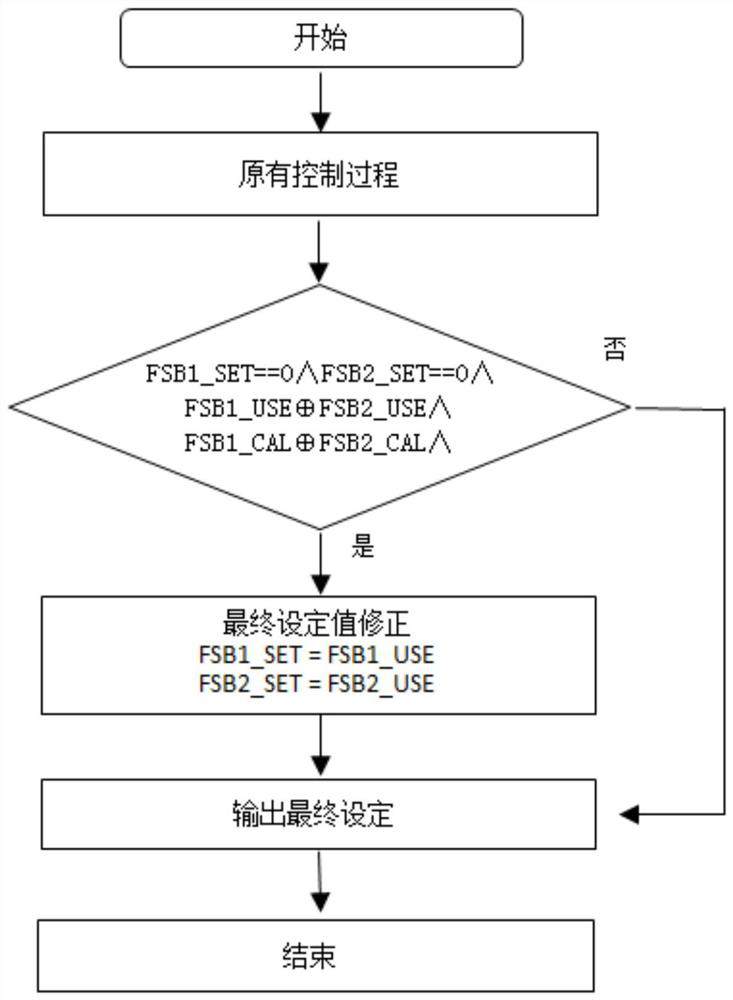

[0053] Error capture (Condition 1∧Condition 2∧Condition 3 should be met)

[0054] Satisfy condition 1: FSB1, FSB2 setting value is 0 at the same time.

[0055] Formula: FSB1_SET==0∧FSB2_SET==0

[0056] Condition 2 is met: FSB1 and FSB2 devices are available in different states. (0,1 or 1,0)

[0057] Formula: FSB1_USE⊕FSB2_USE

[0058] Condition 3 is satisfied: the calculation results of FSB1 and FSB2 models are different. (0,1 or 1,0)

[0059] Formula: FSB1_CAL⊕FSB2_CAL

[0060] The three conditions are met at the same time, so the setting value is corrected as follows:

[0061] FSB1_SET=FSB1_USE=0

[0062] FSB2_SET=FSB2_USE=1

[0063] In th...

Embodiment 2

[0065] The parameters of a certain steel grade and a certain specification of hot-rolled products are as follows:

[0066] Model calculation results FSB1_CAL=0, FSB2_CAL=1

[0067] Device availability status FSB1_USE=1, FSB2_USE=0

[0068] set value

[0069] FSB1_SET=FSB1_CAL∧FSB1_USE=0

[0070] FSB2_SET=FSB2_CAL∧FSB2_USE=0

[0071] Error capture (Condition 1∧Condition 2∧Condition 3 should be met)

[0072] Satisfy condition 1: FSB1, FSB2 setting value is 0 at the same time.

[0073] Formula: FSB1_SET==0∧FSB2_SET==0

[0074] Condition 2 is met: FSB1 and FSB2 devices are available in different states. (0,1 or 1,0)

[0075] Formula: FSB1_USE⊕FSB2_USE

[0076]Condition 3 is satisfied: the calculation results of FSB1 and FSB2 models are different. (0,1 or 1,0)

[0077] Formula: FSB1_CAL⊕FSB2_CAL

[0078] The three conditions are met at the same time, so the setting value is corrected as follows:

[0079] FSB1_SET=FSB1_USE=1

[0080] FSB2_SET=FSB2_USE=0

[0081] In thi...

Embodiment 3

[0083] The parameters of a certain steel grade and a certain specification of hot-rolled products are as follows:

[0084] Model calculation results FSB1_CAL=0, FSB2_CAL=1

[0085] Device availability status FSB1_USE=0, FSB2_USE=0

[0086] set value

[0087] FSB1_SET=FSB1_CAL∧FSB1_USE=0

[0088] FSB2_SET=FSB2_CAL∧FSB2_USE=0

[0089] Error capture (Condition 1∧Condition 2∧Condition 3 should be met)

[0090] Satisfy condition 1: FSB1, FSB2 setting value is 0 at the same time.

[0091] Formula: FSB1_SET==0∧FSB2_SET==0

[0092] Condition 2 is not met: FSB1 and FSB2 devices are available in different states. (0,1 or 1,0)

[0093] Formula: FSB1_USE⊕FSB2_USE

[0094] Condition 3 is satisfied: the calculation results of FSB1 and FSB2 models are different. (0,1 or 1,0)

[0095] Formula: FSB1_CAL⊕FSB2_CAL

[0096] The three conditions are not met simultaneously, so no correction processing is performed:

[0097] FSB1_SET=0

[0098] FSB2_SET=0

[0099] In this example, ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com